Side slope protection connecting plate, ecological protection slope and construction method of ecological protection slope

A technology of ecological slope protection and connecting boards, which is applied in the fields of slope protection connecting boards, ecological slope protection and its construction, and environmental protection building structures. It can solve the problems of waste tires not being firmly fixed, tires prone to sliding and dislocation, and slope coverage incomplete. , to achieve high stability, high work efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

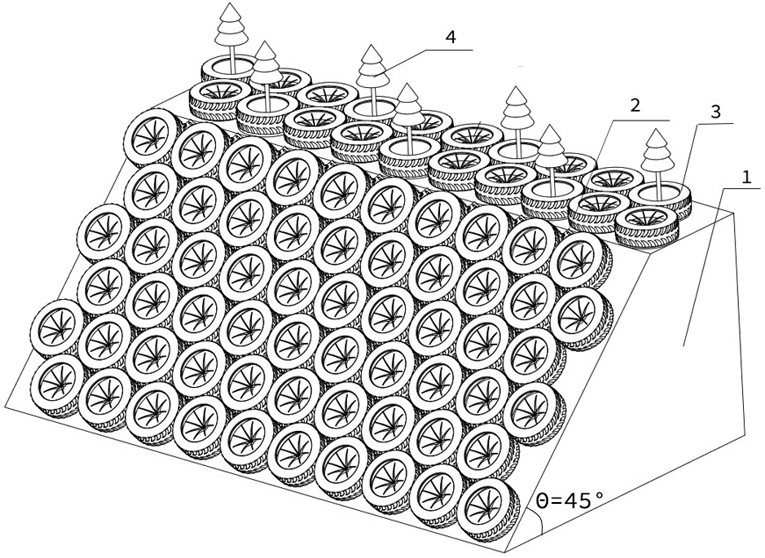

[0076] A stable landscaping project on a soil slope, the slope is about 20 meters long and 4 meters high, and the slope is about 45 degrees. figure 1 For the effect diagram of this embodiment, after the first step is carried out to make the slope surface relatively flat, a certain amount of water is poured on the surface of the soil slope to make the surface moist and soft, which is helpful for the direct insertion of the traction nail.

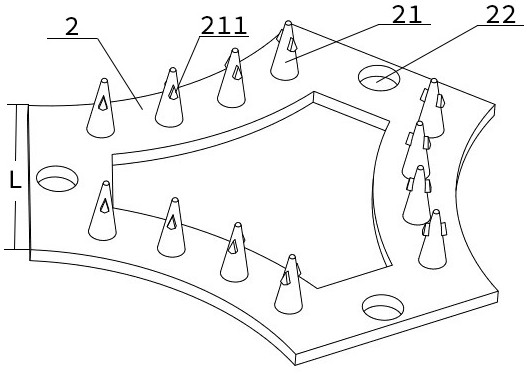

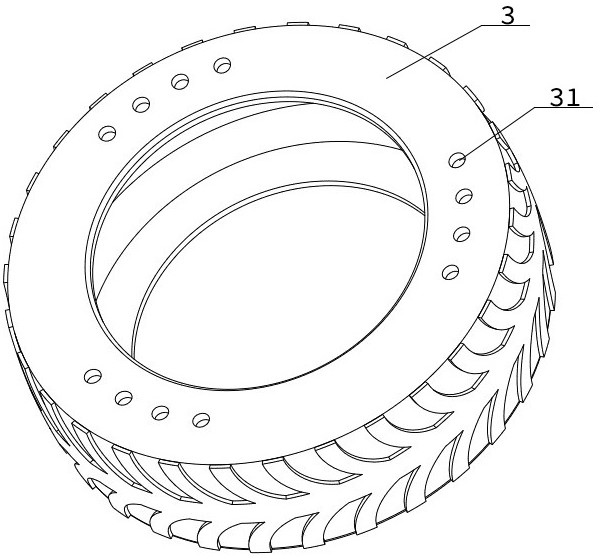

[0077] Use the tangential dense arrangement of tires, select the traction nails with barb shape to pass through the fixing holes on the side slope protection connection plate, and install the side slope protection connection plate sequentially from bottom to top on the slope surface, where the side slope protection connection The plate specification is made according to the size of the waste tires to be processed.

[0078] The discarded tires with preset fixing holes are interferingly fitted with the nail-shaped protrusions on the slope prote...

specific Embodiment 2

[0082] A greening project on a cement slope with a slope of approximately 50 degrees on both sides of a section of road and a height of 3 meters. Such as Figure 8 It is the engineering design rendering of this specific embodiment. In this project, there is a drainage channel on one side of the slope of the road, so the environmental protection slope protection module is suspended and installed on this side. Figure 8 As shown on the left, the other side adopts the installation in contact with the road, such as Figure 8 shown on the right. In the implementation, it is first determined to use the expansion-type traction nails and the dense arrangement of tires tangentially. After planning the waste tires to be used, design and manufacture the corresponding specifications of the slope protection connecting plate.

[0083]After the processing of the fixed hole position on the slope protection connecting plate is completed, measure the cement slope, and calculate the nailing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com