Production scheduling method and system based on hybrid parallel inheritance and variable neighborhood algorithm

A Production Scheduling, Algorithm Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

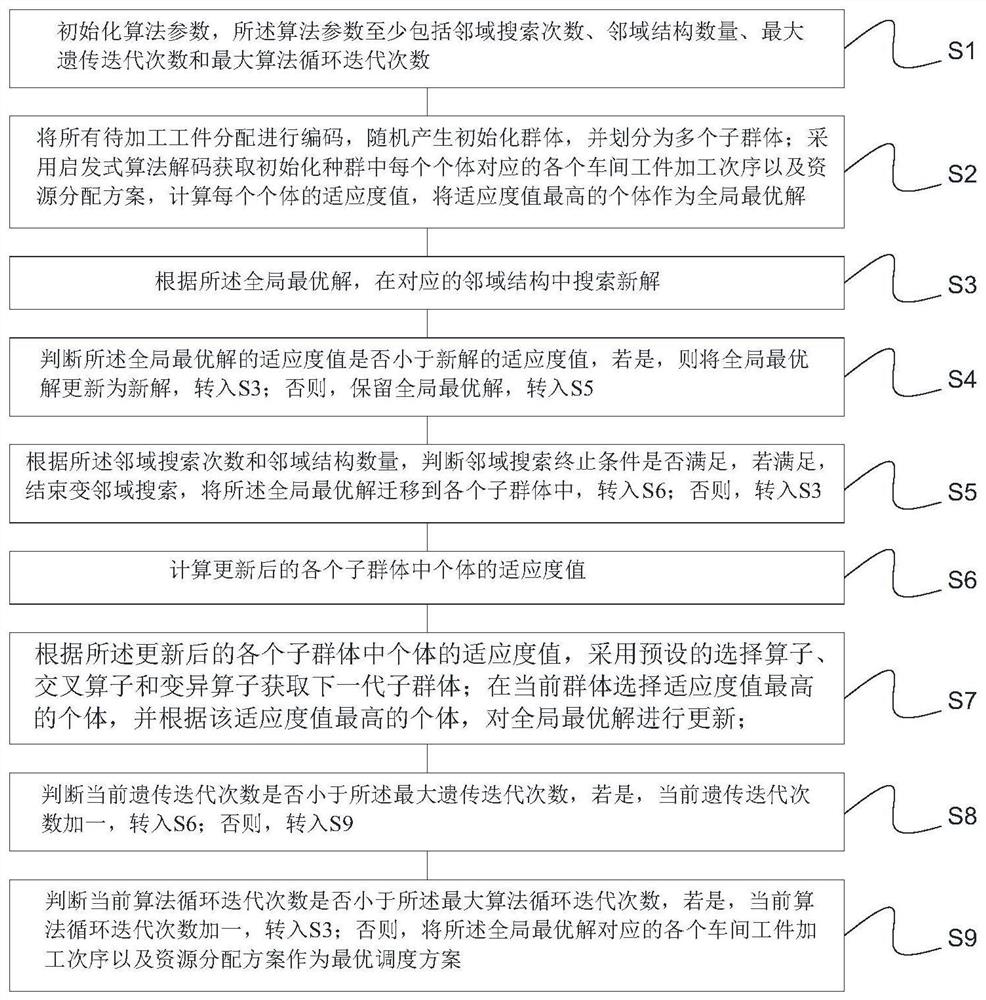

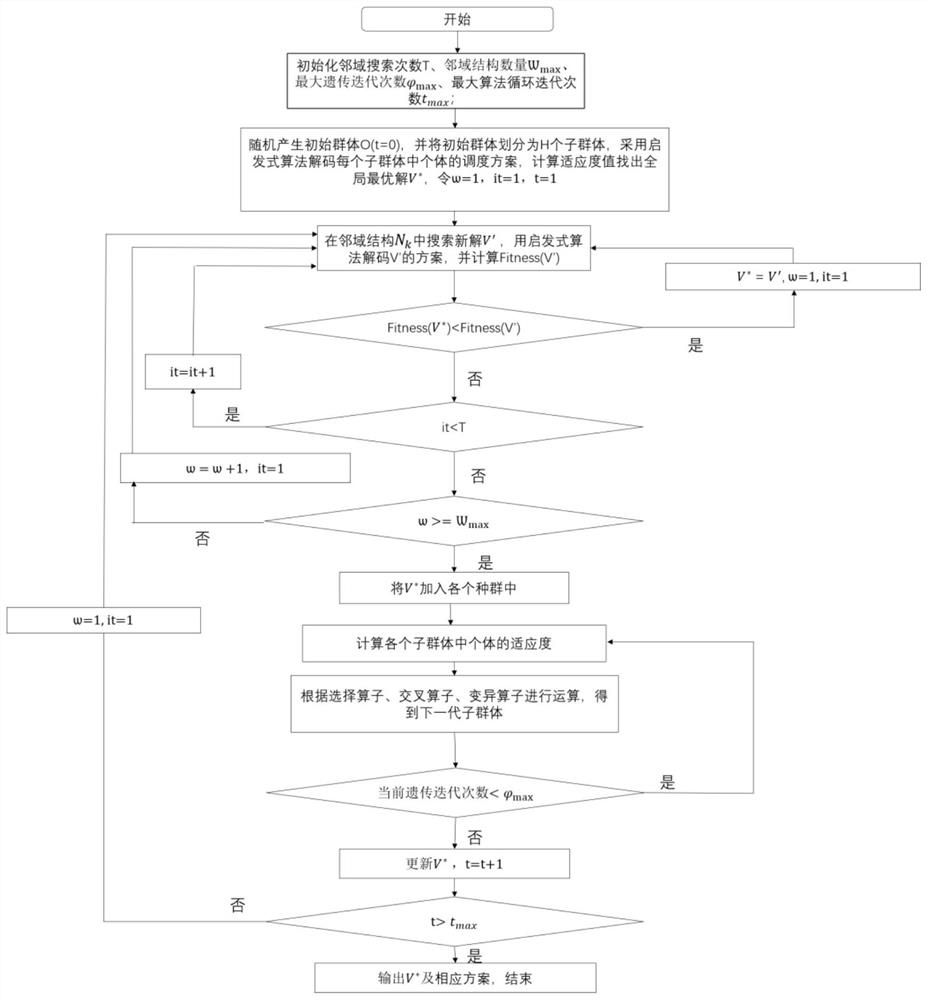

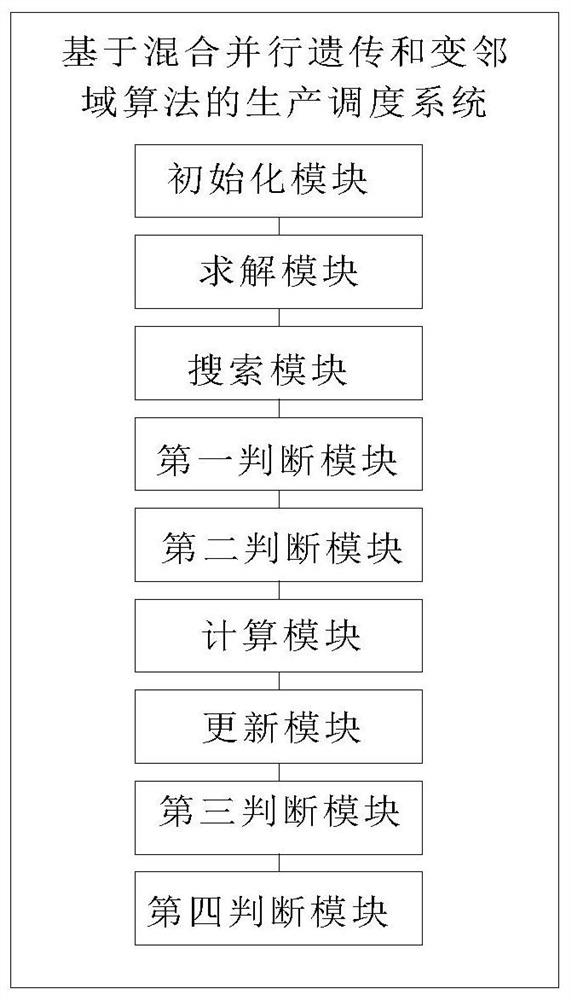

[0105] First aspect, such as figure 1 As shown, the embodiment of the present invention provides a production scheduling method based on hybrid parallel genetic and variable neighborhood algorithms, including:

[0106] S1. Initialize algorithm parameters, the algorithm parameters at least include the number of neighborhood searches, the number of neighborhood structures, the maximum number of genetic iterations, and the maximum number of algorithm loop iterations;

[0107] S2. Encode the allocation of all the workpieces to be processed, randomly generate the initialization group, and divide it into multiple subgroups; use the heuristic algorithm to decode and obtain the processing sequence and resource allocation plan of each workshop workpiece corresponding to each individual in the initialization group, and calculate each The fitness value of the individual, the individual with the highest fitness value is taken as the global optimal solution;

[0108] S3. According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com