Cable bridge closed based on gravity extrusion

A cable bridge and gravity technology, applied in the direction of electrical components, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of low efficiency, difficult maintenance and repair, and many laying steps, so as to prevent damage, prevent the concentration of internal forces, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

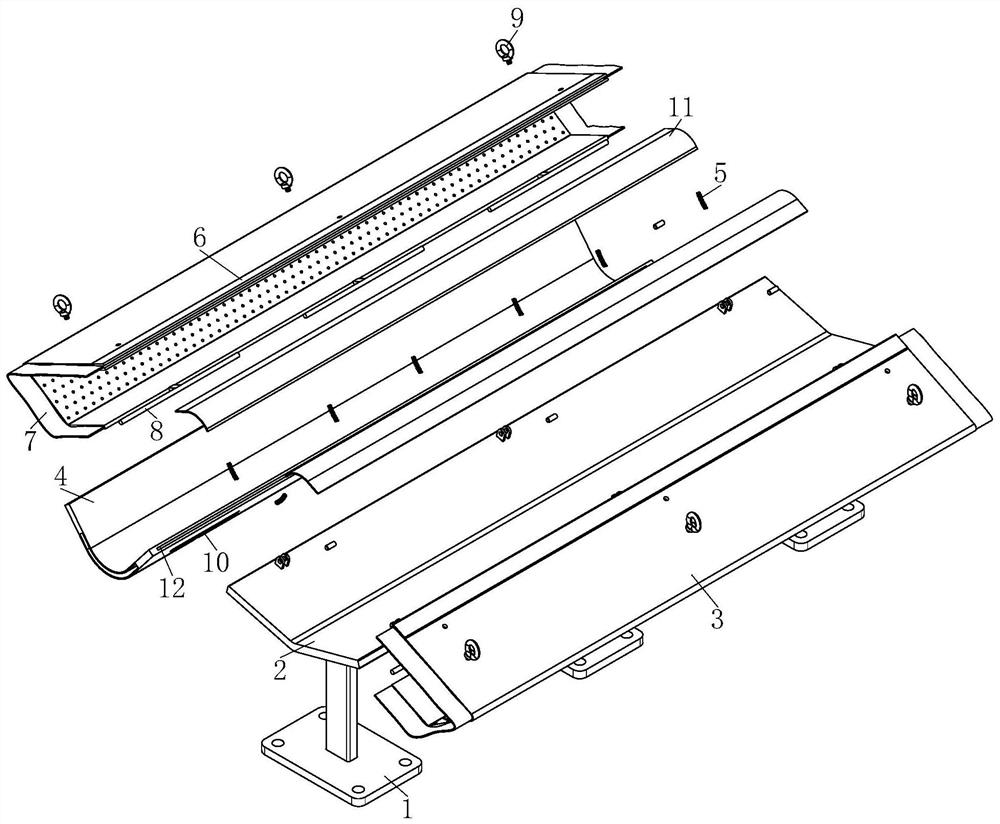

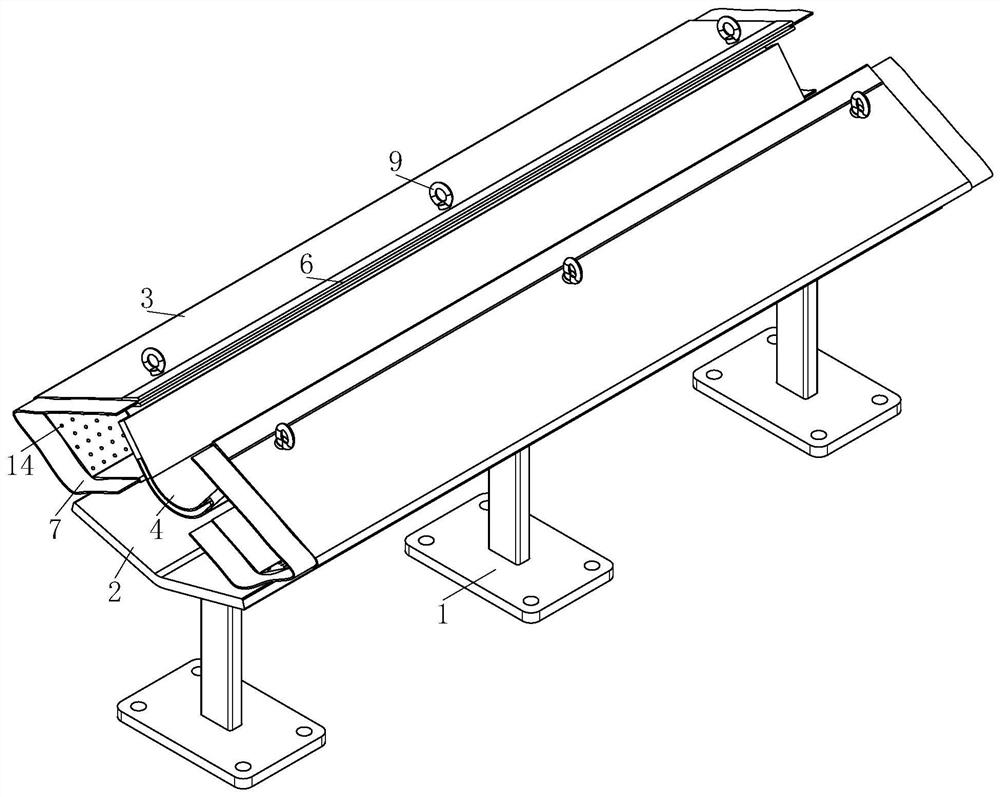

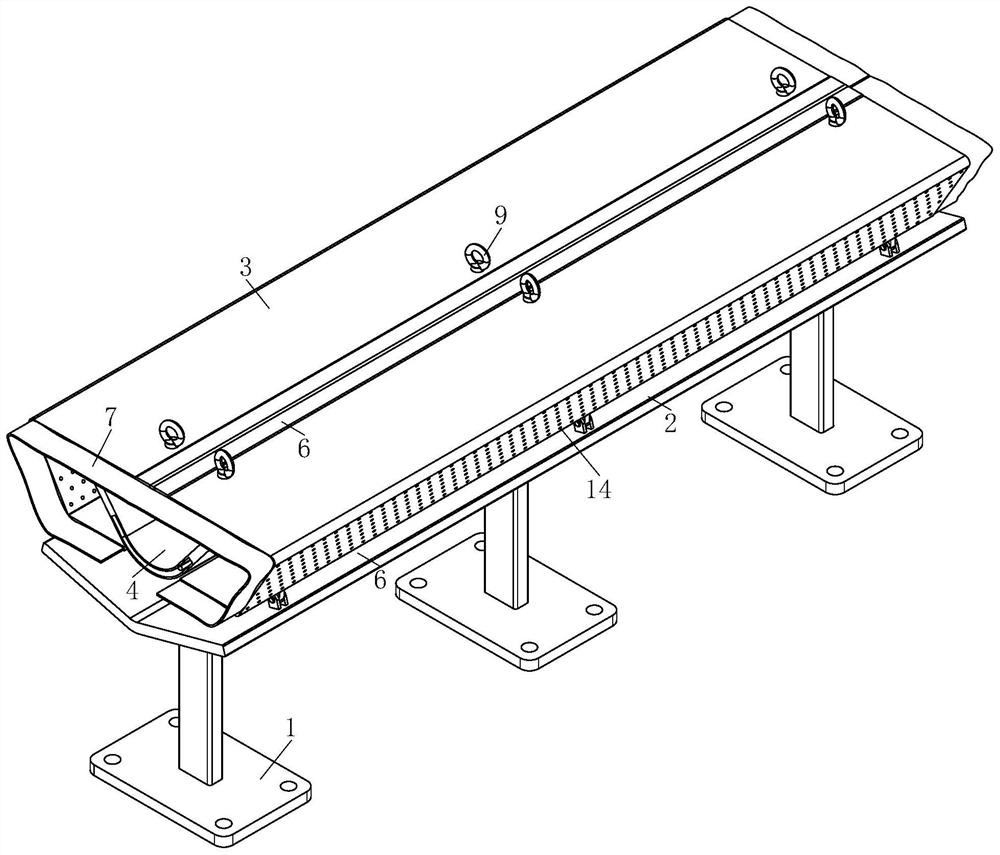

[0034] like Figure 1 to Figure 8 As shown, a cable tray based on gravity extrusion closure, including a bottom frame 1, a fixed plate 2, a trunking frame 3, a movable frame 4, a tension spring 5, a sealing member 6, a sealing sheet 7, a sliding rod 8 and a pull ring 9; the upper part of the bottom frame 1 is provided with the fixed plate 2; the fixed plate 2 is fixedly connected with the bottom frame 1; the section of the fixed plate 2 is V-shaped; the upper part of the fixed plate 2 is symmetrically arranged Said trunking frame 3; the bottom of said trunking frame 3 is rotationally connected with said fixed plate 2 by pin; The trunking frame 3 is fixedly connected; the movable frame 4 is arranged between the trunking frames 3; the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com