Pick-up device for garlic harvesting machinery

A technology for harvesting machinery and garlic, applied in the direction of excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of high harvesting costs, difficult harvesting, and insufficient labor supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] To make the objectives, technical solutions and advantages of the present invention will become more apparent hereinafter in conjunction with the accompanying drawings, the present invention will be further described in detail. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

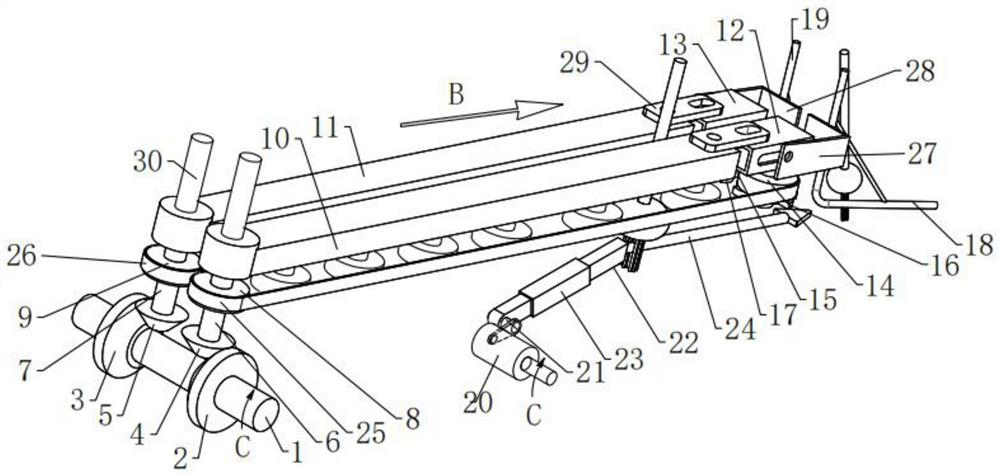

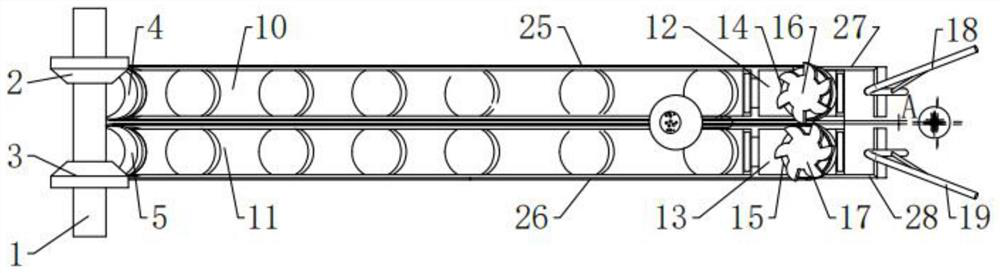

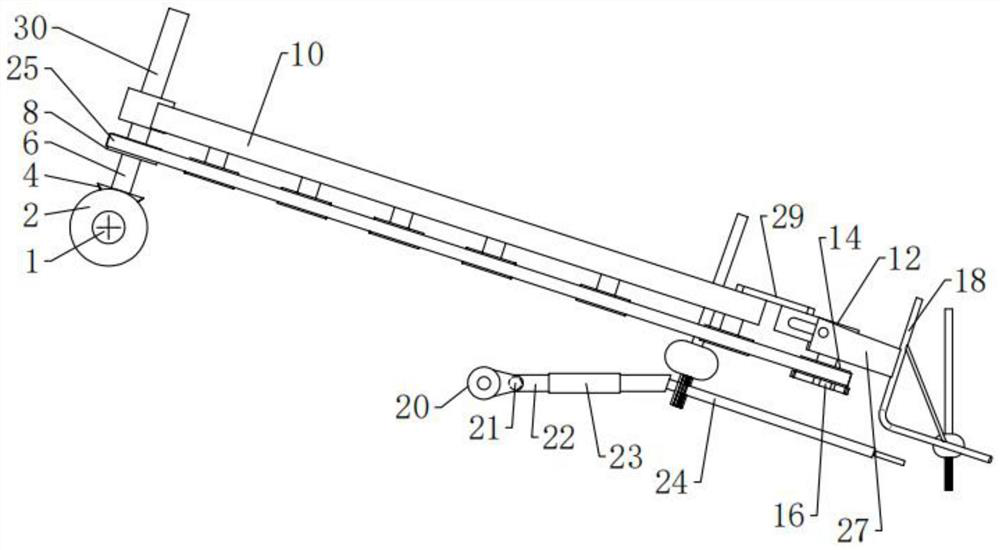

[0018] See figure 1 The present invention provides a harvesting machine with a pick-up apparatus of garlic, comprising means ripper, pickup means and conveying means.

[0019] See figure 1 , Ripper mechanism comprises a third driven shaft is connected to the output of the drive power Harvester 20, the third driven shaft 20 driven fourth hinge shaft 21, the fourth driven shaft 21 and driven shaft 20 disposed parallel to the third fourth driven shaft 21 is fixedly connected to an end of the slide rod 22, slide rod 22 slidably fitted over the inner sliding sleeve 23, the sleeve 23 can slide fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com