Slurry slicking device for bean curd production

A technology for Qianye tofu and slurry, which is applied in the field of slurry leveling devices for Qianye tofu production, can solve the problems of low efficiency, large consumption of time and manpower, and poor leveling effect, saving labor and time , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

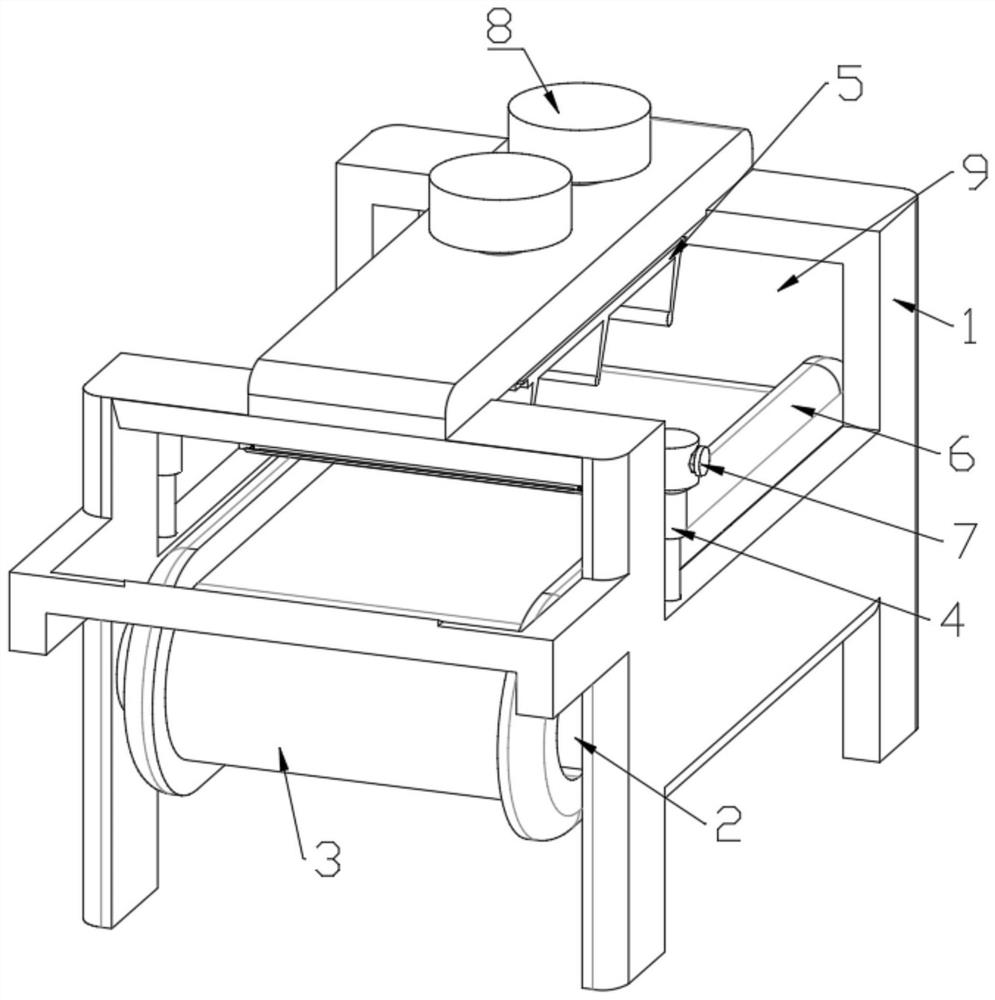

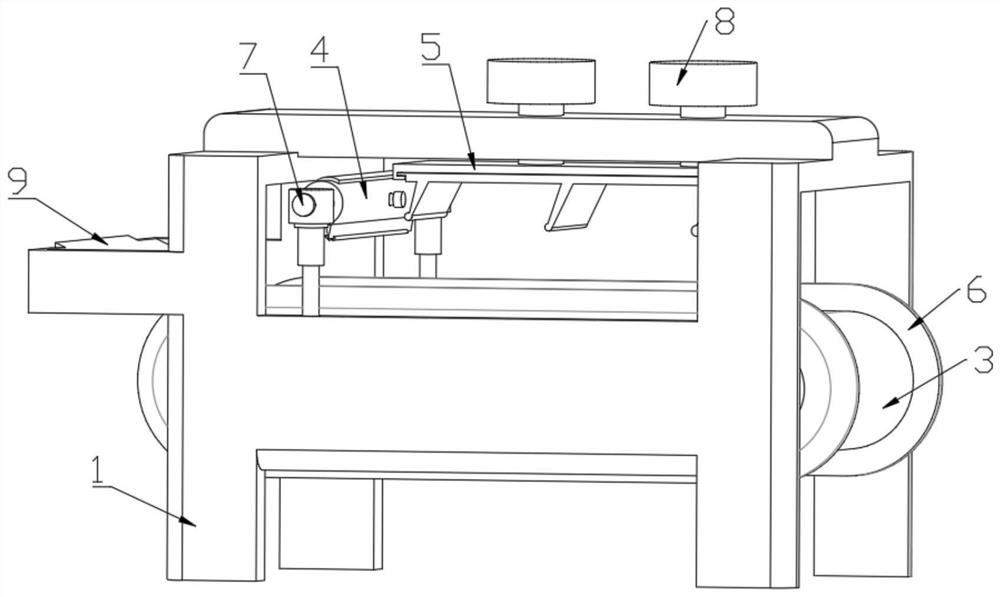

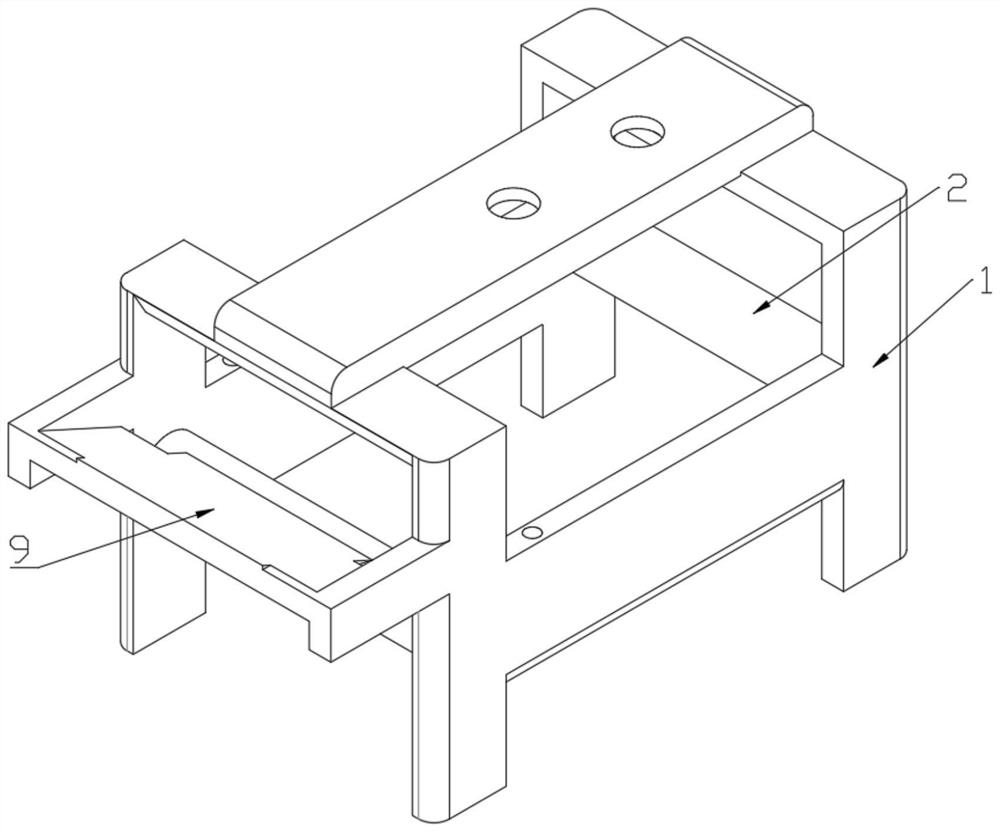

[0030] Refer Figure 1-6 , A slashing device for producing a millenar bean curd production, including:

[0031] The frame body 1, the frame body 1 is hollow, and there is a top wall, and the middle portion of the frame body 1 is mounted with a conveying assembly for conveying the slurry, and the transfer assembly includes a roller 2 and a conveyor belt 3, and the two rollers 2 rotate mounted between the frame body 1. The conveyor belt is set on two rollers 2;

[0032] The scratch assembly 4, the scratch assembly 4 includes a threaded rod 41, a transfer hand 42, a rotating shaft 43, a mounting tube 44, and a scraper 45. The upper surface of the outer portion of the rack body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com