Universal tool holder for vertical numerical control lathe and method

A technology of CNC lathes and tool holders, applied in the direction of tool holders, etc., to achieve the effect of reducing adjustment time, shortening processing cycle, and reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

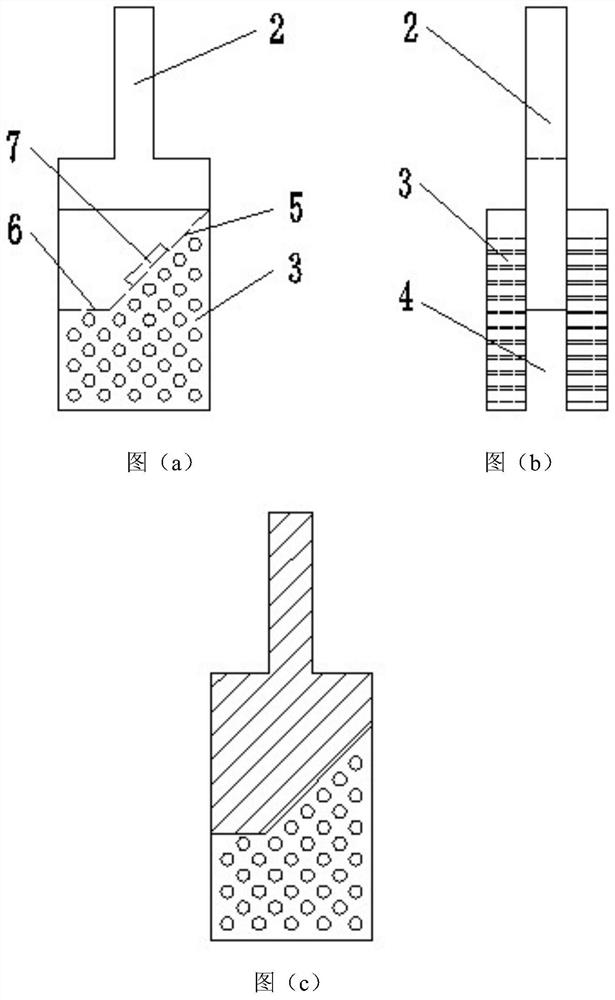

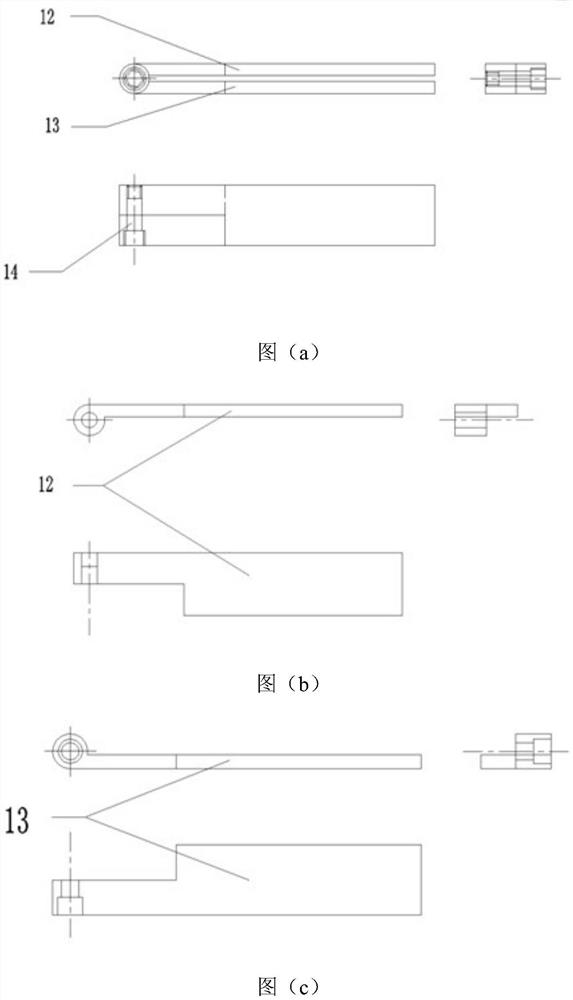

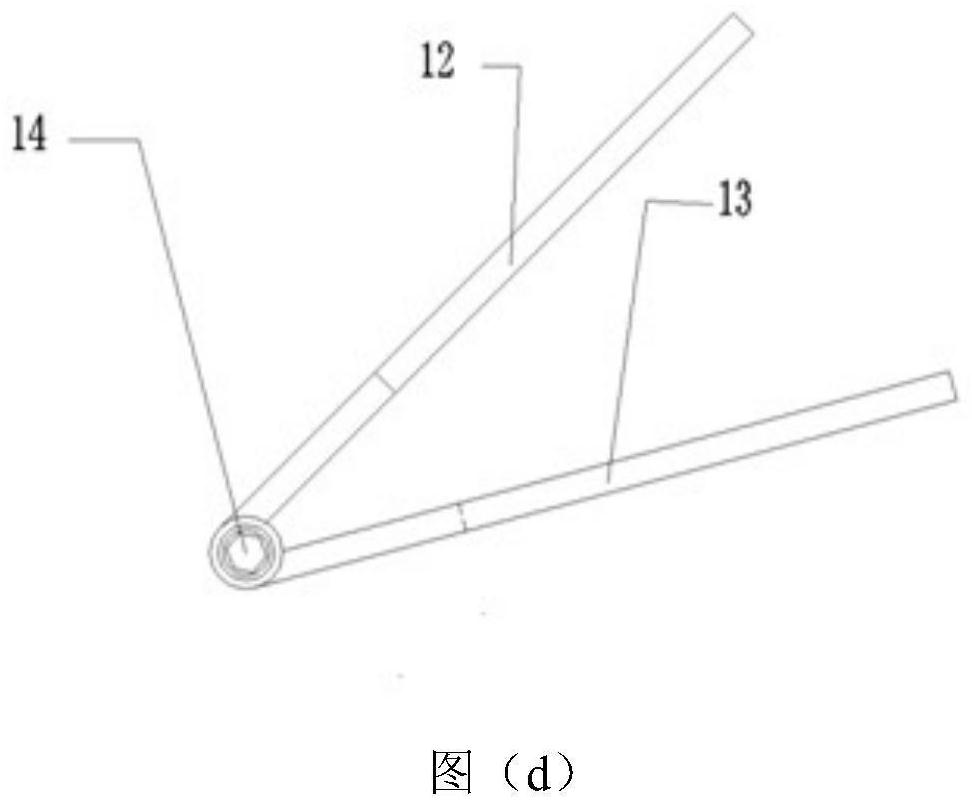

[0026] like Figure 1-3 As shown, a universal tool holder 1 for a vertical numerical control lathe includes the tool holder clamping part 2 and the tool holder part 3, and the tool holder clamping part 2 is "T" shaped, increasing While the length of the tool holder is clamped, it greatly increases the rigidity and stability of the tool holder. The tool clamping part 3 is fixed on the bottom of the horizontal section of the "T" shaped tool rest clamping part 2 . The bottom of the tool holding part 3 is provided with a groove 4, the symmetry plane of the groove 4 coincides with the symmetry plane of the tool holder holding part 2, and the tool holder can be turned horizontally by 180° for use. The groove 4 has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com