Electric automobile secondary loop heat pump air conditioning system capable of preventing frosting

A secondary circuit, electric vehicle technology, applied to vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problem of frosting of outdoor heat exchangers, poor operating conditions, and unfavorable system reliability, etc. problems, to achieve the effects of reducing the temperature difference between the main road and the environment, low production costs, high heating capacity and heating energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

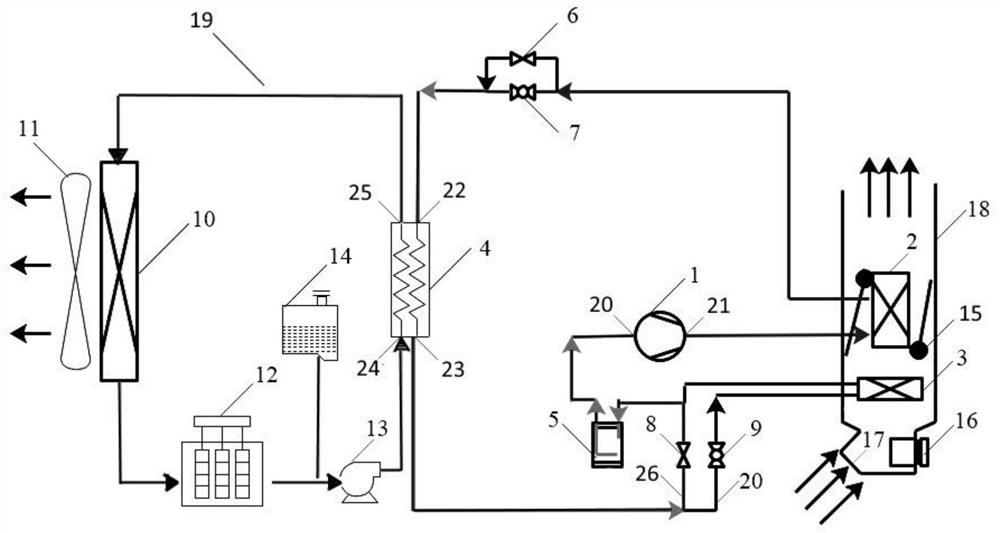

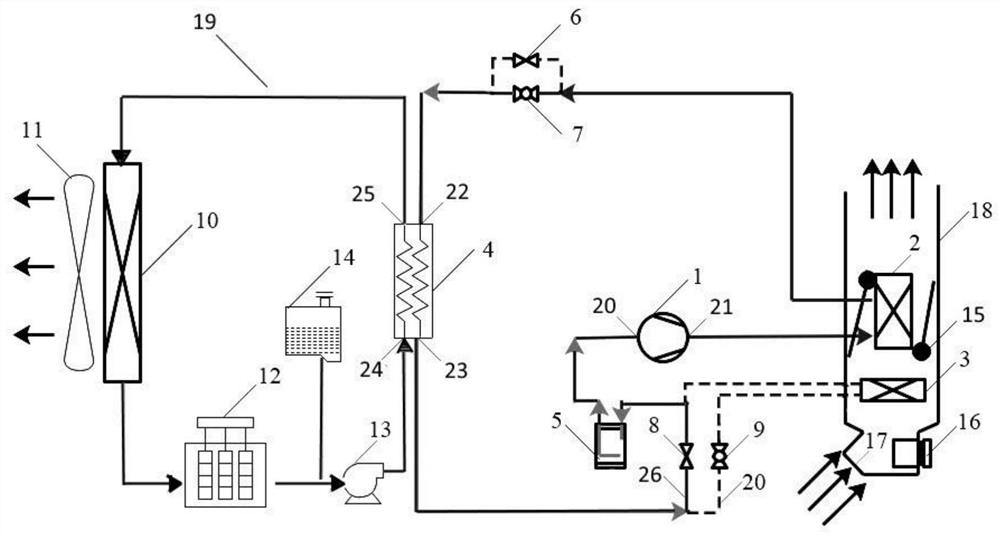

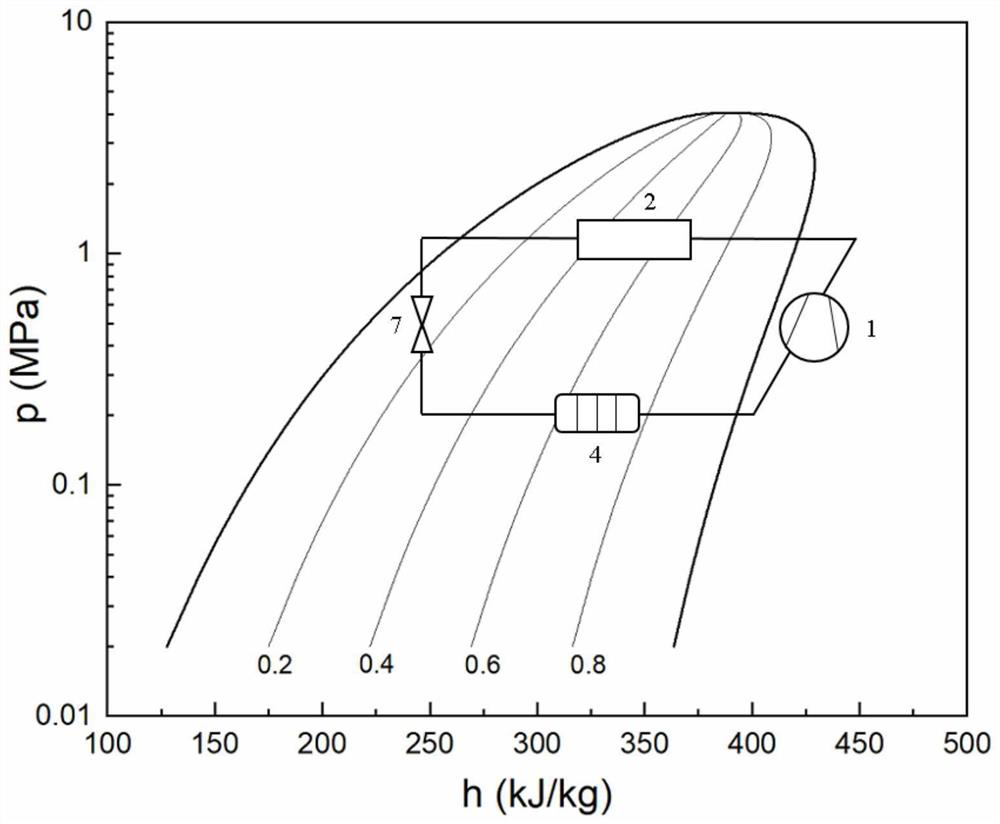

[0025] Such as figure 1 As shown, it is a secondary circuit heat pump air-conditioning system for electric vehicles that prevents frosting in this embodiment. Switching between dehumidification heating mode and defrosting mode, which includes: compressor 1 connected in sequence, first heat exchanger 2, first throttle valve 3 for throttling expansion, secondary loop water circulation system 19, The second throttle valve 9 for throttling expansion, the second heat exchanger 3 and the gas-liquid separator 5, as well as the first solenoid valve 6 and the second solenoid valve 8 for switching the refrigerant flow path, and are used for regulating the compartment The temperature and humidity inside the air conditioning box 18, wherein: the first solenoid valve 6 is connected in parallel to both ends of the first throttle valve 7 for controlling the on-off of the first throttle valve 7, and the second solenoid valve 8 is connected in parallel to The two ends of the second throttle v...

Embodiment 2

[0036] Such as Figure 4 As shown, the refrigeration mode is: the first solenoid valve 6 is set to be in the open state, the first throttle valve 7 is set to be in the fully closed state, the second solenoid valve 8 is set to be in the closed state, and the second throttle valve is set to be in the closed state. 9 is set to be in a throttling state, the heating and cooling air door 15 is set to be in an open state, and the air to be blown into the passenger compartment directly flows through the side channel without passing through the first heat exchanger 2 .

[0037] In the cooling mode, the refrigerant main circuit circulation path is: the high-temperature and high-pressure refrigerant compressed by the compressor 1 enters the first heat exchanger 2 without heat exchange, and then flows through the outlet of the first heat exchanger 2 After the first solenoid valve 6 enters the interior of the battery cooler 4, it exchanges heat with the low-temperature water on the water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com