Combined sand box unloading device

An unloading device and combined technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of unbalanced force on the device, injury to construction personnel, overload damage of the unloading device, etc., to achieve high synchronization control accuracy and improve work efficiency. Efficiency and security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

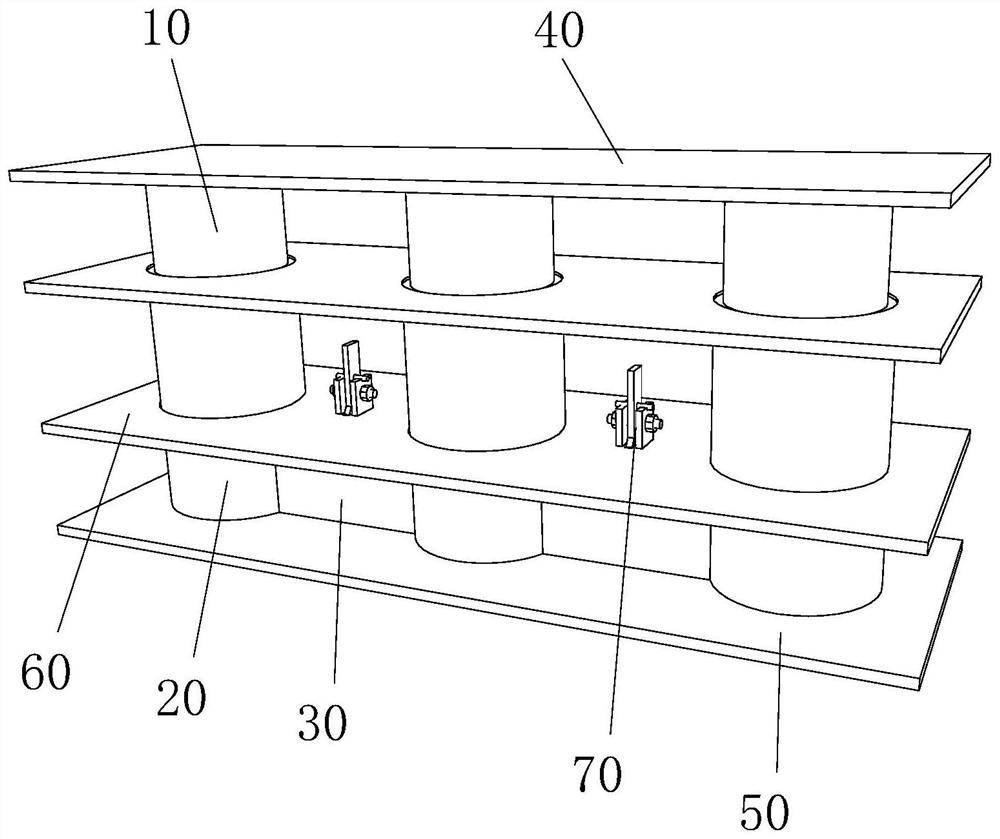

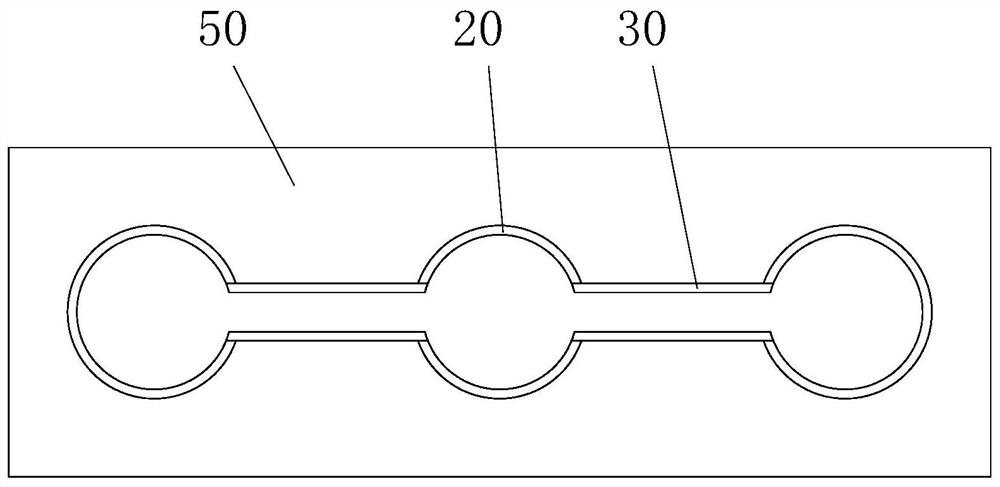

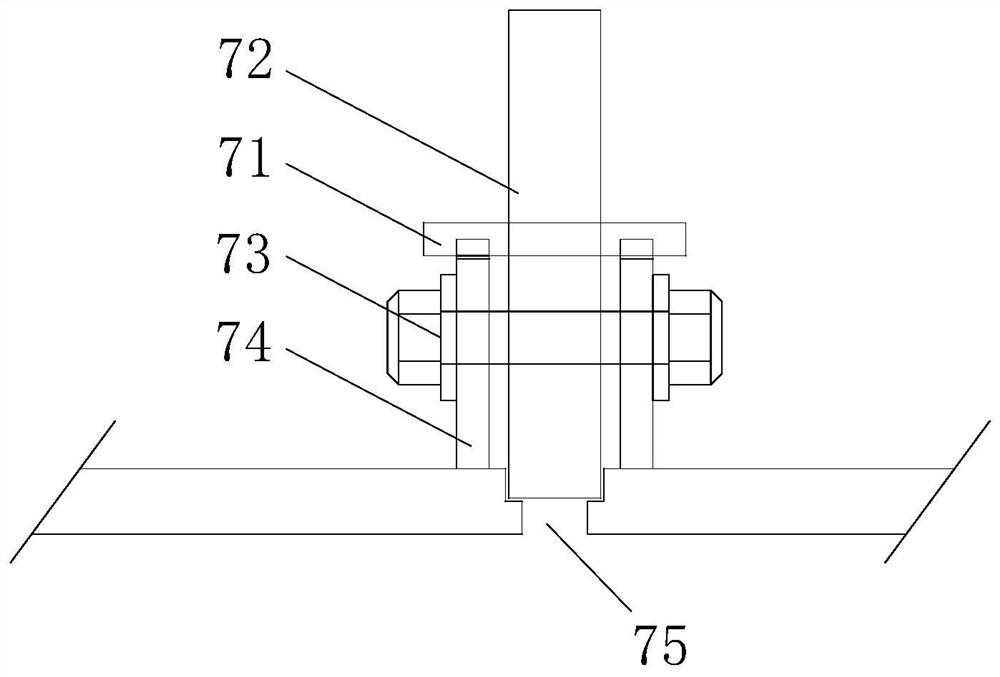

[0034] like Figure 1-3 As shown, the bottom of the sleeve 20 is fixedly connected to the second support plate 50, preferably by welding, for higher reliability. The inside of the sleeve 20 forms a cavity, and an opening for inserting the piston 10 is provided at the top of the sleeve 20 . The sleeves 20 are connected through the connecting channel 30 to form an internal space for containing sand particles. Specifically, the sleeves 20 are arranged side by side on the second support plate 50, and the adjacent sleeves 20 are connected through the connecting channel 30. And the bottom of the connecting channel 30 is also fixedly connected with the second support plate 50, the connecting channel 30 can also play a stabilizing effect on the sleeve 20, and at the same time, the bottom surface of the connecting channel 30 can be flush with the bottom surface of the sleeve 20 or tend to In this way, it can be ensured that when unloading, the sand particles in the inner space always ...

Embodiment 2

[0041] like Figure 4-5 As shown, as another preferred embodiment, the difference between this embodiment and Embodiment 1 is that the sleeves 20 are arranged in the shape of an equilateral triangle, and this arrangement is suitable for a single larger support point or relatively concentrated multiple support points situation.

[0042] When the number of sleeves 20 is more than three, except for the case where the sleeves 20 are arranged side by side, connecting passages 30 can be provided between any two sleeves 20 to utilize synchronous control. In a word, the number and arrangement of the sleeves 20 of the present invention are designed according to the stress and cross-sectional shape of the support structure of the foundation pit, but the basic principles are interoperable.

[0043] When the present invention is in use, it is directly installed on the support of the foundation pit, and the support bears huge pressure. Of course, this pressure also acts on the sand box un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap