Method for rapidly detecting residual quantity of flocculating agent in sand for concrete

A detection method, flocculant technology, applied in the direction of transmittance measurement, etc., can solve the problems of high flocculant dosage, impact on concrete performance, and inability to achieve rapid and effective detection, and achieve the effect of reducing impact and scientific use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

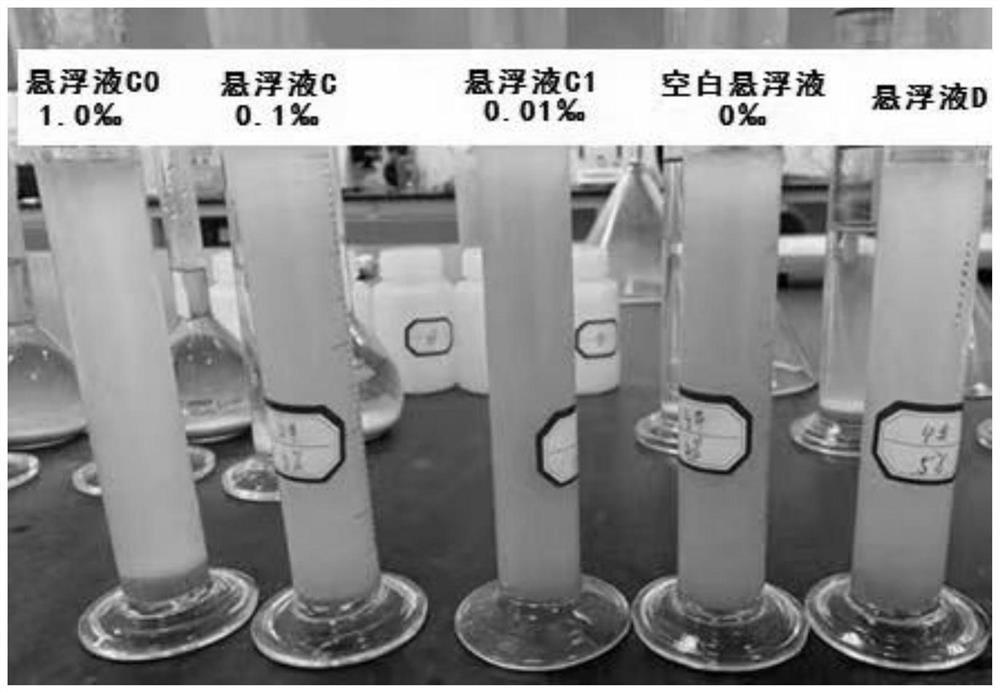

[0023] According to the following method to detect the residual amount of flocculant in concrete sand:

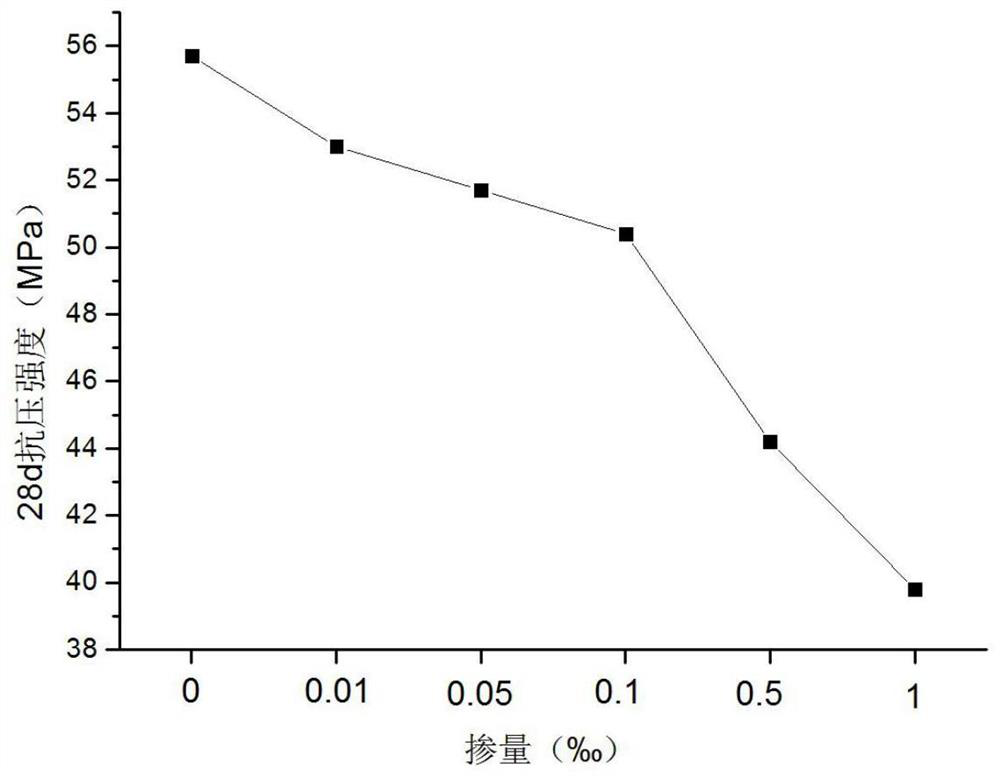

[0024] (1) By weight, the concrete raw materials: 270kg of cement, 58kg of mineral powder, 40kg of fly ash, 172kg of water, 890kg of sand to be tested without flocculant, 1003kg of gravel, and 7.73kg of admixture are prepared into concrete samples; The concrete samples are mixed with polyacrylamide in different mass proportions, wherein the polyacrylamide dosage (by weight of the sand to be tested) is 0, 0.01‰, 0.05‰, 0.1‰, 0.5‰, 1‰; into six groups of standard concrete to be tested;

[0025] (2) Test the working performance of the above six groups of standard concrete to be tested respectively. In this embodiment, slump, expansion, collapse emptying time and time loss are used to test the working performance of the concrete. The results are shown in Table 1.

[0026] Table 1 Six groups of test results of standard concrete work performance

[0027] sample 1 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com