Optical cable sheath metal belt and preparation method and application thereof

A technology of metal tape and metal base tape, which is applied in the field of optical cable manufacturing, can solve the problem of unbalanced amount of ointment for water blocking effect, etc., and achieve the effects of excellent water blocking effect, reduced production cost, and simplified coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

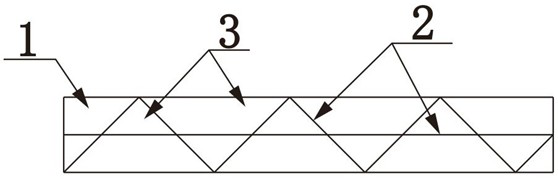

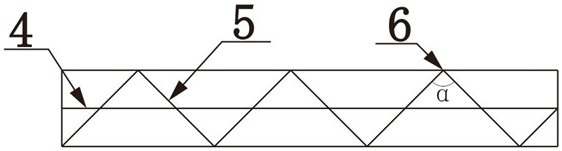

[0043] A metal tape for optical cable sheath, such as figure 2 As shown, the metal base strip 1 is included, and the inside of the metal base strip 1 is coated with two water-blocking grease lines 2 with a line width of 5mm. These two water-blocking grease lines 2 are respectively the horizontal water-blocking grease line 4 and the wave resistance Water grease line 5. Among them, the horizontal water-blocking grease line 4 is parallel to the edge of the metal base strip 1 and coincides with the central axis of the metal base strip 1; the wavy water-blocking grease line 5 is bent back and forth around the horizontal water-blocking grease line 4 to form a continuous broken line, wave The bending point 6 of the water-blocking grease line 5 is flush with the edge of the metal base strip 1, and the angle α between the bending point 6 is 60°; the horizontal water-blocking grease line 4 and the wave water-blocking grease line 5 are on the metal Several water-blocking chambers 3 are...

Embodiment 2

[0048] A metal tape for optical cable sheath, such as figure 2 As shown, the metal base strip 1 is included, and the inside of the metal base strip 1 is coated with two water-blocking grease lines 2 with a line width of 5mm. These two water-blocking grease lines 2 are respectively the horizontal water-blocking grease line 4 and the wave resistance Water grease line 5. Among them, the horizontal water-blocking grease line 4 is parallel to the edge of the metal base strip 1 and coincides with the central axis of the metal base strip 1; the wavy water-blocking grease line 5 is bent back and forth around the horizontal water-blocking grease line 4 to form a continuous broken line, wave The bending point 6 of the water-blocking grease line 5 is flush with the edge of the metal base strip 1, and the angle α between the bending point 6 is 90°; the horizontal water-blocking grease line 4 and the wave water-blocking grease line 5 are on the Several water-blocking chambers 3 are stagg...

Embodiment 3

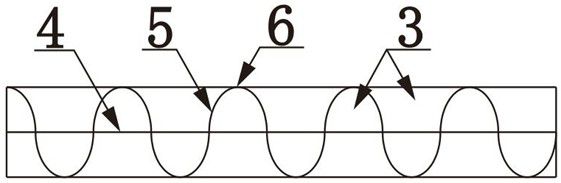

[0053] A metal tape for optical cable sheath, such as image 3 As shown, the metal base strip 1 is included, and the inside of the metal base strip 1 is coated with two water-blocking grease lines 2 with a line width of 5mm. These two water-blocking grease lines 2 are respectively the horizontal water-blocking grease line 4 and the wave resistance Water grease line 5. Among them, the horizontal water-blocking grease line 4 is parallel to the edge of the metal base strip 1 and coincides with the central axis of the metal base strip 1; the wave water-blocking grease line 5 is bent back and forth around the horizontal water-blocking grease line 4 at a frequency of 1 / 2π, A continuous cosine curve is formed, and the bending point 6 of the wavy water-blocking grease line 5 is flush with the edge of the metal base strip 1; Water blocking chamber 3.

[0054] The linear water-blocking ointment on the metal tape of the optical cable sheath in this embodiment is obtained by applying a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com