A semiconductor packaging device

A technology for packaging devices and semiconductors, which can be applied to devices that apply liquid to surfaces, semiconductor/solid-state device manufacturing, and coating. Avoid the effect of height reduction, increase dispensing range, and increase the rate of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

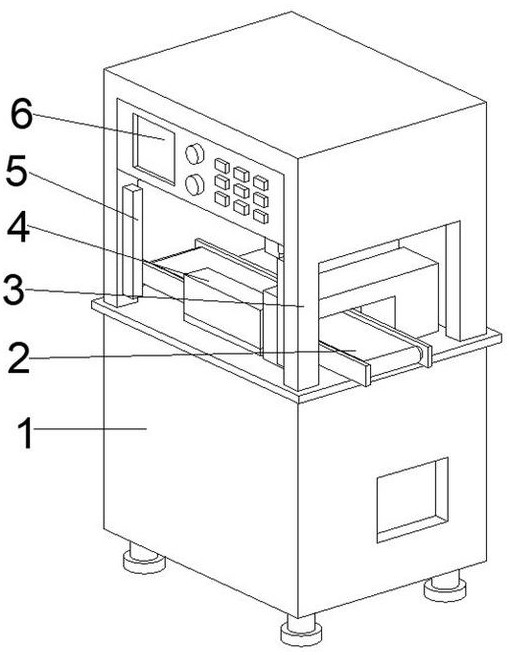

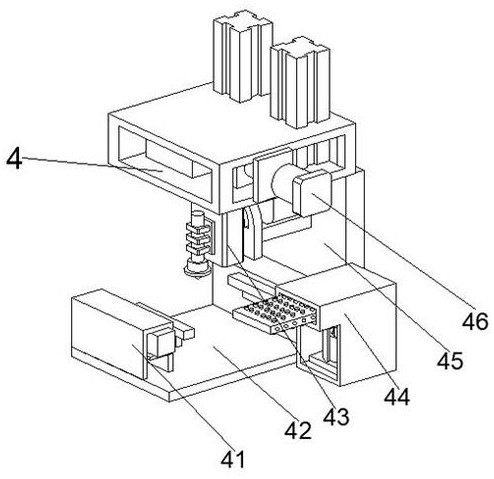

[0043] see Figure 1-6 , the present invention provides a technical solution: a semiconductor packaging device, including a device body 1, a processing frame 3 is fixedly connected to the top of the device body 1, and a feeding frame 2 is fixedly connected to the middle position of the bottom of the inner cavity of the processing frame 3. Driven by the power parts, the frame 2 transports the semiconductor to the encapsulation dispensing position for encapsulation, which effectively improves the rate of encapsulation and avoids the deviation of the dispensing position caused by the offset of placement, and the bottom of the inner cavity of the processing frame 3 is fixed The packaging device 4 is connected, the front bottom of the packaging device 4 penetrates the feeding rack 2 and extends to the outside of the feeding rack 2, the front top of the processing frame 3 is fixedly connected to the control panel 6, and the front and bottom sides of the processing frame 3 are fixedly...

Embodiment 2

[0050] see Figure 1-6, on the basis of Embodiment 1, the present invention provides a technical solution: a method for using a semiconductor packaging device, step 1: install and fix the equipment, and fix the equipment main body 1 with the processing frame 3, and feed the The frame 2 is fixedly connected to the packaging device 4, and the equipment main body 1 is connected to the energy source, and the detection light curtain 5 is fixedly connected to the processing frame 3;

[0051] Step 2: Use the dispensing cavity produced by the glue dispenser 43 and the packaging fixture 41 to apply glue at fixed points, and when the semiconductor is fixed, it is in the center position, and the guide device 44 is fixedly connected to the carrier plate 42, and the carrier plate 42 is fixed. It is fixedly connected with the packaging fixture 41, so that the semiconductor is fixed to the dispenser 43;

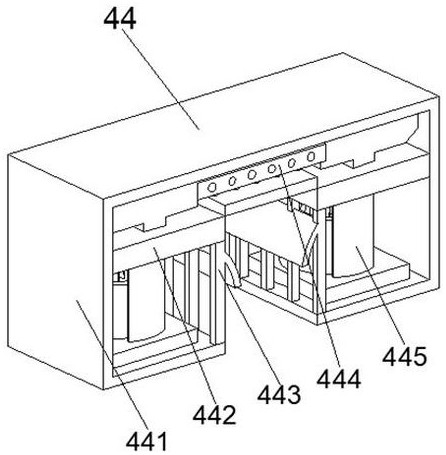

[0052] Step 3: Use the cold air blown by the cooling plate 444 to contact the dispensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com