Method for improving desalination stability of porous ceramic membrane by constructing hydrophobic protective layer

A technology of porous ceramic membrane and hydrophobic protective layer, which is applied in the field of membrane distillation desalination, can solve the problems that steam cannot pass through the membrane material and cannot be desalted by membrane distillation, and achieves strong operability, obvious hydrophobic protection effect, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

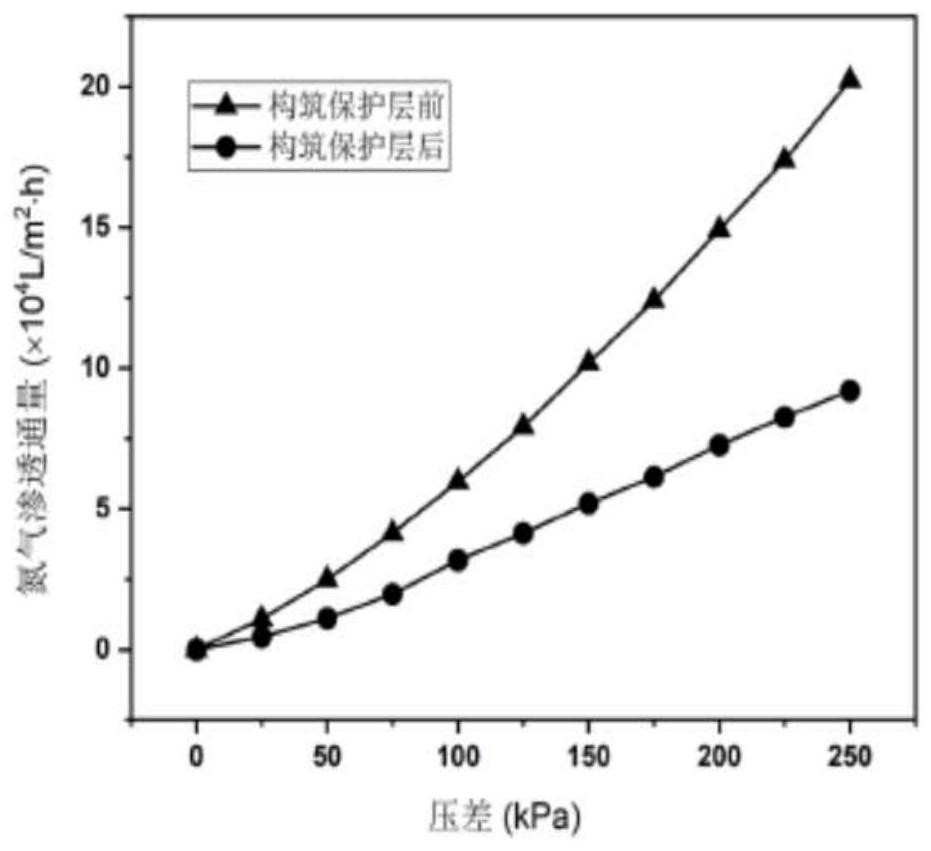

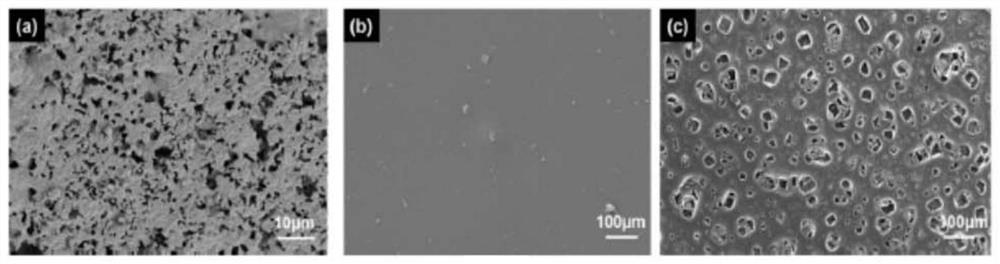

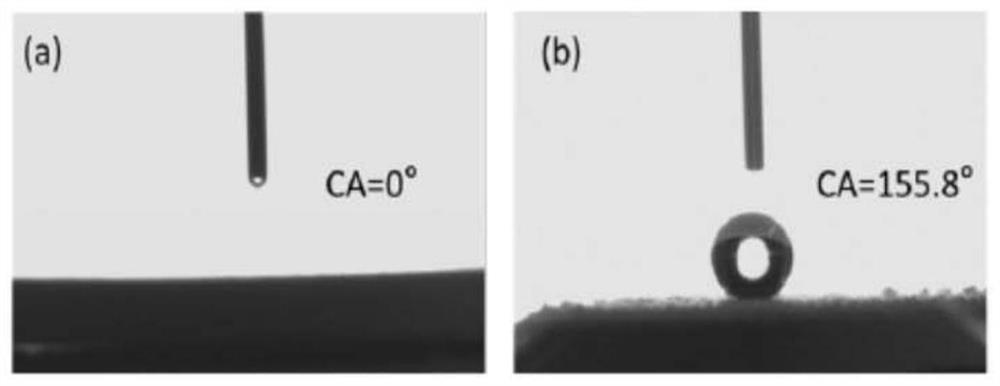

[0033] Cordierite porous ceramic membrane with a pore size of 0.1-0.5 μm was post-grafted in 15% tridecafluorooctyltriethoxysilane-ethanol solution for 24 hours, and then placed in an oven at 100°C for condensation reaction , Take it out after 24 hours. Prepare a NaCl solution with a mass fraction of 20%, put it into an air pressure spray gun with a nozzle diameter of 0.3mm, and spray it at a distance of 20cm from the ceramic membrane substrate for 15s, and then place it in an oven at 50°C to crystallize NaCl. Weigh Sylgard184-PDMS in proportion, add n-hexane to dilute to a diluent with a mass fraction of 10%; add SiO with a mass ratio of 0.30 to PDMS 2 , and mix evenly; put the mixed solution into an air pressure spray gun with a nozzle diameter of 0.3mm, and spray it 10cm away from the ceramic membrane substrate for 15s. Then put the ceramic membrane in an oven at 80°C to cure for 2 hours, and then soak it in deionized water, changing the water three times during this perio...

Embodiment 2

[0035] Cordierite porous ceramic membrane with a pore size of 0.1-0.5 μm was post-grafted in 15% tridecafluorooctyltriethoxysilane-ethanol solution for 24 hours, and then placed in an oven at 100°C for condensation reaction , Take it out after 24 hours. Prepare a NaCl solution with a mass fraction of 20%, put it into an air pressure spray gun with a nozzle diameter of 0.3mm, and spray it at a distance of 20cm from the ceramic membrane substrate for 15s, and then place it in an oven at 50°C to crystallize NaCl. Weigh Sylgard184-PDMS in proportion, add n-hexane to dilute into a diluent with a mass fraction of 10%; add SiO2 with a mass ratio of 0.30 to PDMS, and mix evenly; put the mixed solution into an air pressure spray gun with a nozzle diameter of 0.3mm, Spray at a distance of 10cm from the base of the ceramic membrane for 15s. Then put the ceramic membrane in an oven at 80°C to cure for 2 hours, and then soak it in deionized water, changing the water three times during thi...

Embodiment 3

[0037]Cordierite porous ceramic membrane with a pore size of 0.1-0.5 μm was post-grafted in 15% tridecafluorooctyltriethoxysilane-ethanol solution for 24 hours, and then placed in an oven at 100°C for condensation reaction , Take it out after 24 hours. Prepare a NaCl solution with a mass fraction of 20%, put it into an air pressure spray gun with a nozzle diameter of 0.3mm, and spray it at a distance of 20cm from the ceramic membrane substrate for 15s, and then place it in an oven at 50°C to crystallize NaCl. Weigh Sylgard184-PDMS in proportion, add n-hexane to dilute into a diluent with a mass fraction of 10%; add SiO2 with a mass ratio of 0.30 to PDMS, and mix evenly; put the mixed solution into an air pressure spray gun with a nozzle diameter of 0.3mm, Spray at a distance of 10cm from the base of the ceramic membrane for 15s. Then put the ceramic membrane in an oven at 80°C to cure for 2 hours, and then soak it in deionized water, changing the water three times during this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com