Processing and stirring equipment for preparing banana fertilizer

A mixing equipment and fertilizer technology, which is applied in the field of processing and mixing equipment for banana fertilizer preparation, can solve the problems of no fertilizer screening, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

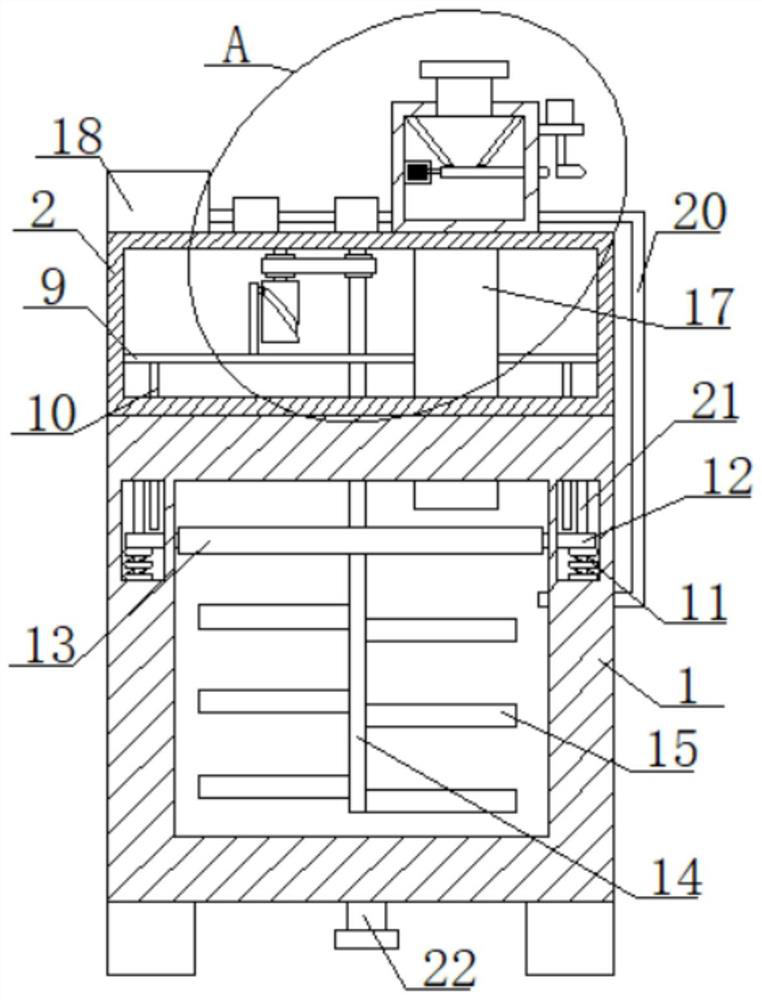

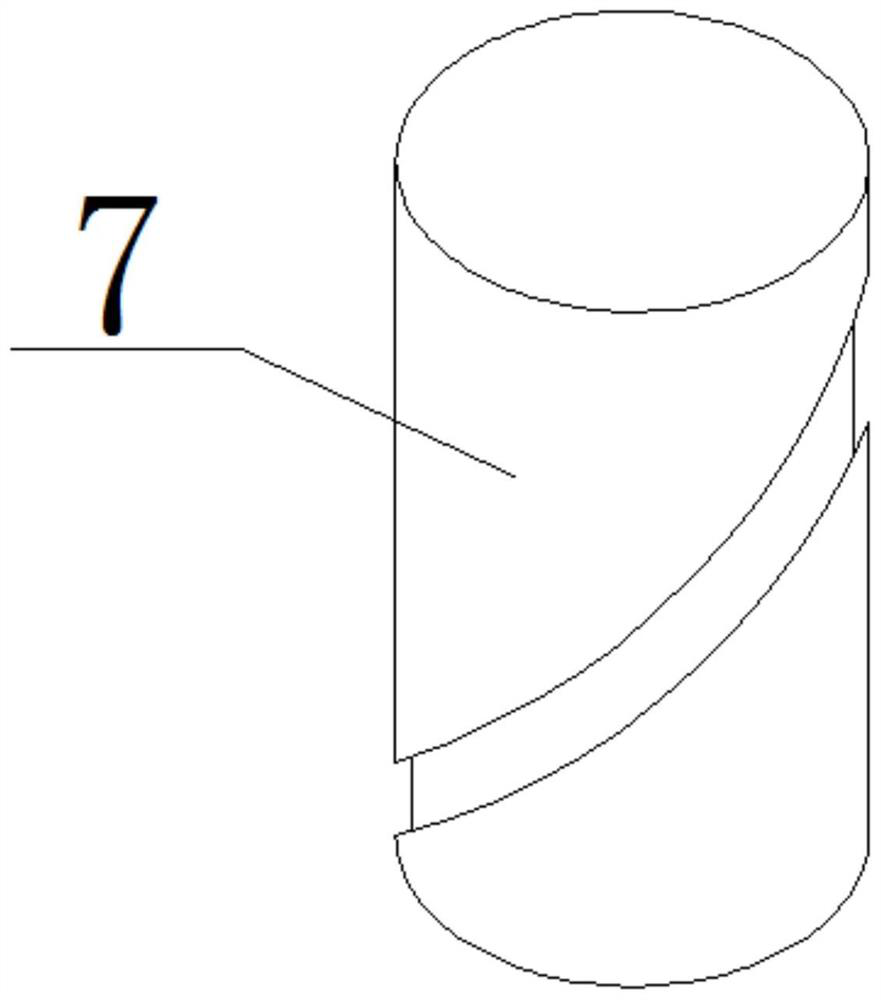

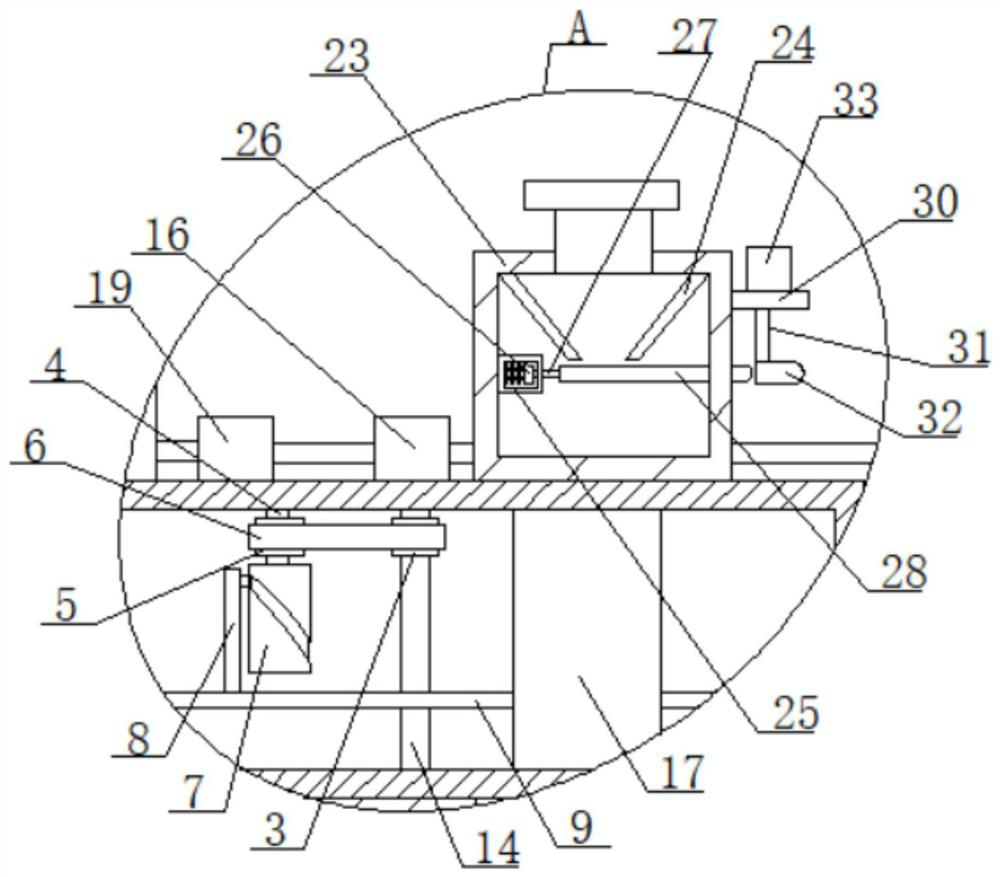

Embodiment 1

[0023] refer to Figure 1-5 , a kind of processing and mixing equipment for preparing banana fertilizers, comprising a processing box 1, a stirring mechanism is arranged in the processing box 1, a screening mechanism is arranged on the processing box 1, and the screening mechanism includes a screening assembly box 2, a first synchronous wheel 3, and a synchronous rotating shaft 4. The second synchronous wheel 5, synchronous belt 6, circular column 7, lower pressure plate 8, auxiliary slide 9, two push rods 10, two return springs 11, two connecting plates 12, screen 13 and two longitudinal The slide bar 21, the screening component box 2 is located on the top of the processing box 1, the screening component box 2 is fixedly connected with the processing box 1, the first synchronous wheel 3, the synchronous rotating shaft 4, the second synchronous wheel 5, the synchronous belt 6, and the round column 7 , lower pressing plate 8, auxiliary slide plate 9 and two push rods 10 are all...

Embodiment 2

[0030] refer to Figure 1-5 , a kind of processing and mixing equipment for preparing banana fertilizers, comprising a processing box 1, a stirring mechanism is arranged in the processing box 1, a screening mechanism is arranged on the processing box 1, and the screening mechanism includes a screening assembly box 2, a first synchronous wheel 3, and a synchronous rotating shaft 4. The second synchronous wheel 5, synchronous belt 6, circular column 7, lower pressure plate 8, auxiliary slide 9, two push rods 10, two return springs 11, two connecting plates 12, screen 13 and two longitudinal The slide bar 21, the screening component box 2 is located on the top of the processing box 1, the screening component box 2 is welded to the processing box 1, the first synchronous wheel 3, the synchronous shaft 4, the second synchronous wheel 5, the synchronous belt 6, and the round column 7 , lower platen 8, auxiliary slide plate 9 and two push rods 10 are all located in the screening asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com