Material cutting machine for machining production

A technology of mechanical processing and material cutting machine, which is applied in the direction of metal processing equipment, manufacturing tools, metal sawing equipment, etc., can solve the problems of manpower consumption, non-compliance with processing specifications, and inability to ensure the smoothness of aluminum cuts, etc., to achieve improvement The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

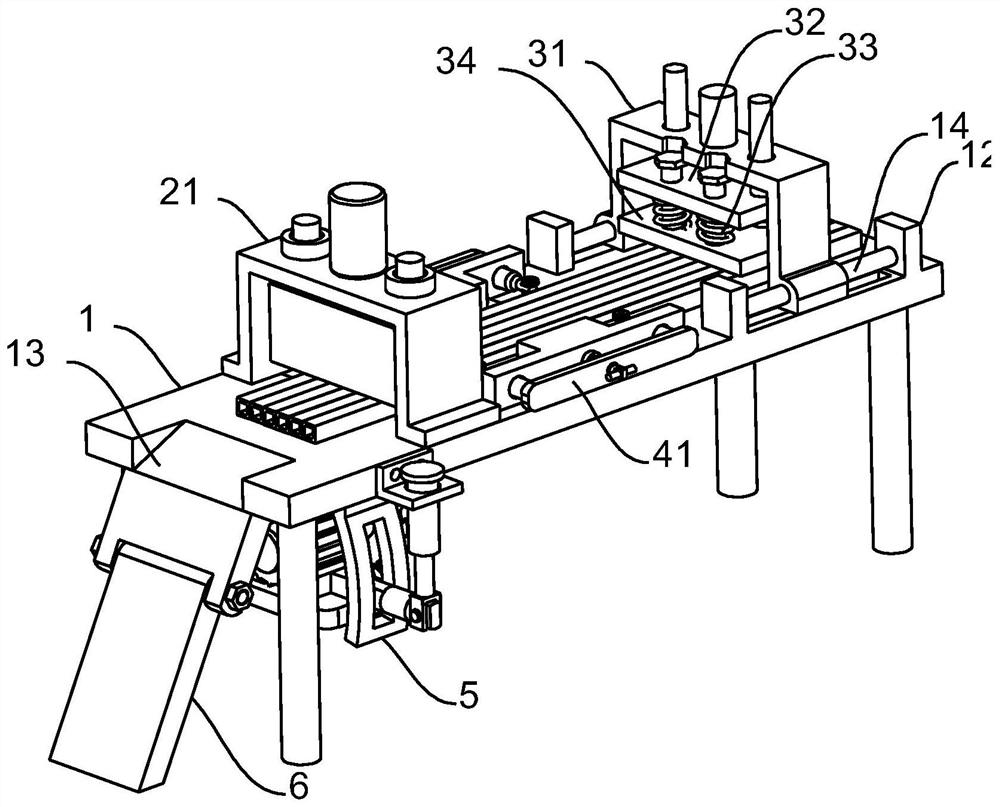

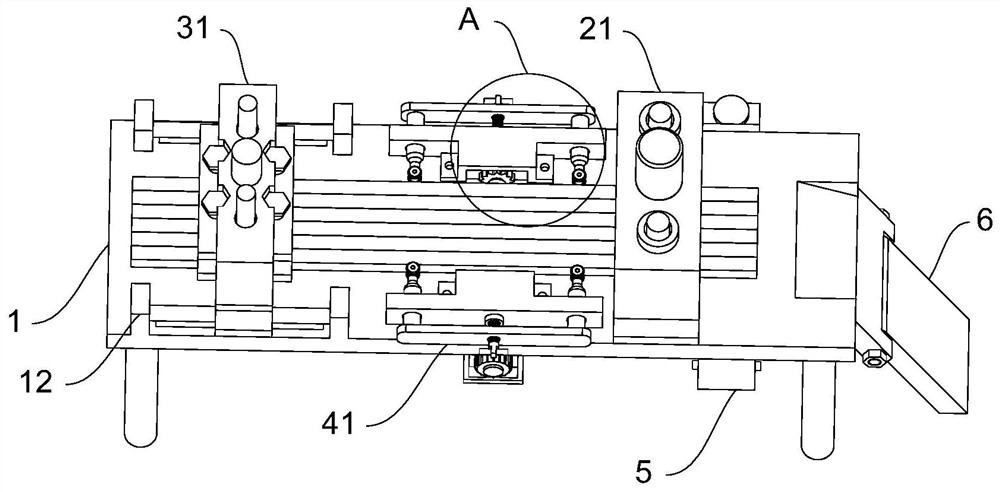

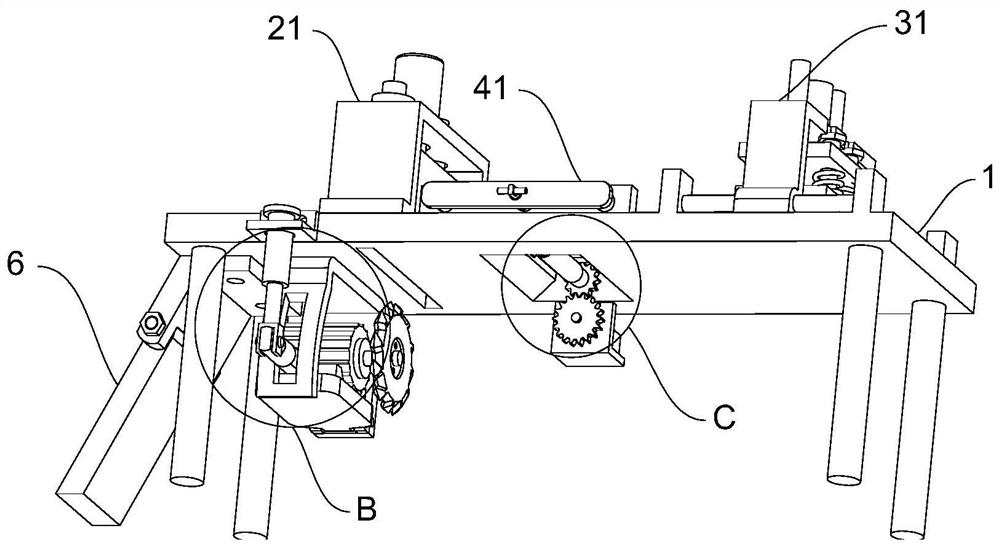

[0031] As an embodiment of the present invention, a groove 11 is provided in the middle of the bottom surface of the workbench 1, and a rotating roller 17 is rotatably connected to the inner wall of the groove 11; both ends of the rotating roller 17 are fixedly connected There is a driven gear 18, and the lower end of the driven gear 18 engages with a drive assembly 15; the drive assembly 15 is fixedly connected to one side of the workbench 1; the workbench 1 corresponds to the cutting assembly 5 One end is provided with a chute 12; the workbench 1 is provided with a through slot 16 corresponding to the No. 1 pressurizing mechanism.

[0032] During work, during the processing of aluminum materials, the driven gear 18 is driven by the No. 1 drive assembly 15 to rotate, so that the rotating roller 17 rotates, and the rotation of the rotating roller 17 will drive the aluminum material at the top of the through groove 16 to move to the cutting assembly 5 At this time, the No. 1 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com