Production line for producing and processing composite geomembrane

A composite geomembrane and production line technology, which is applied to metal processing equipment, manufacturing tools, and parts of grinding machine tools, etc., can solve the problems of affecting the shape of the geomembrane, inconvenient storage and transportation, and polluting the working environment, so as to facilitate storage and transportation, easy to clean, and avoid polluting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

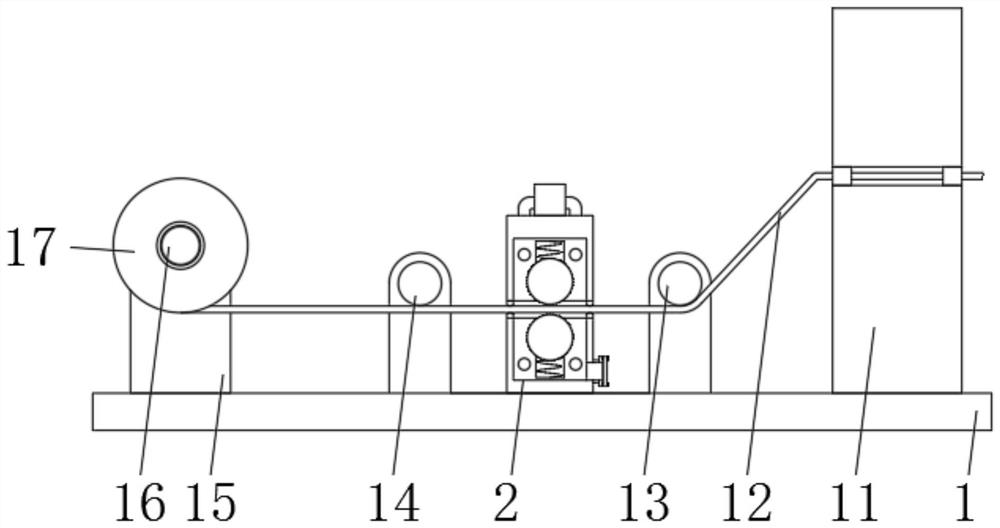

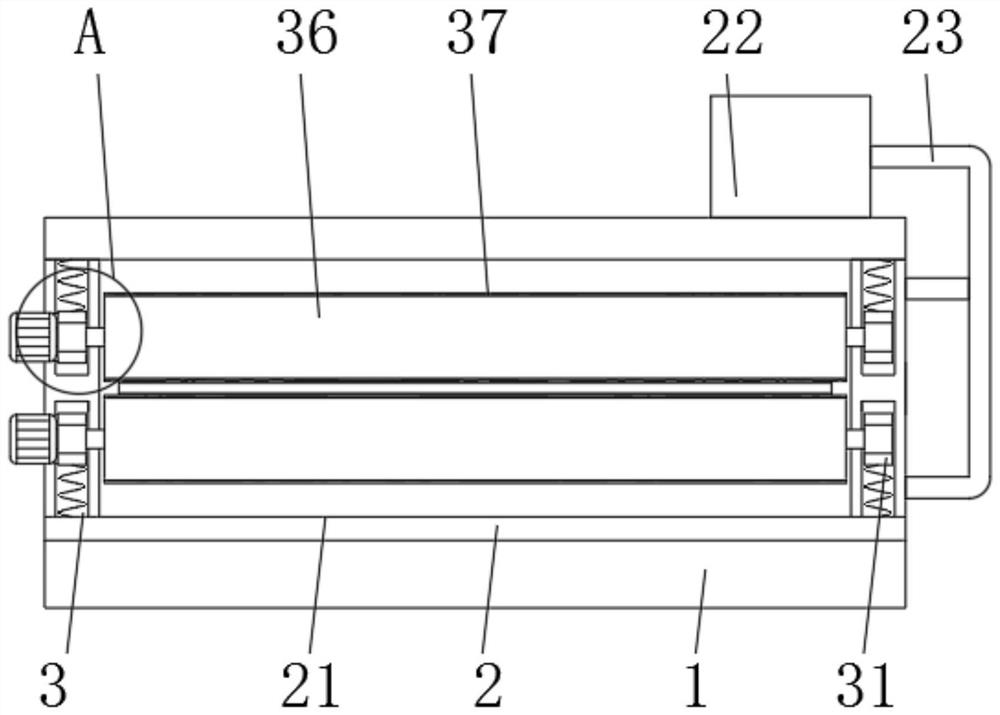

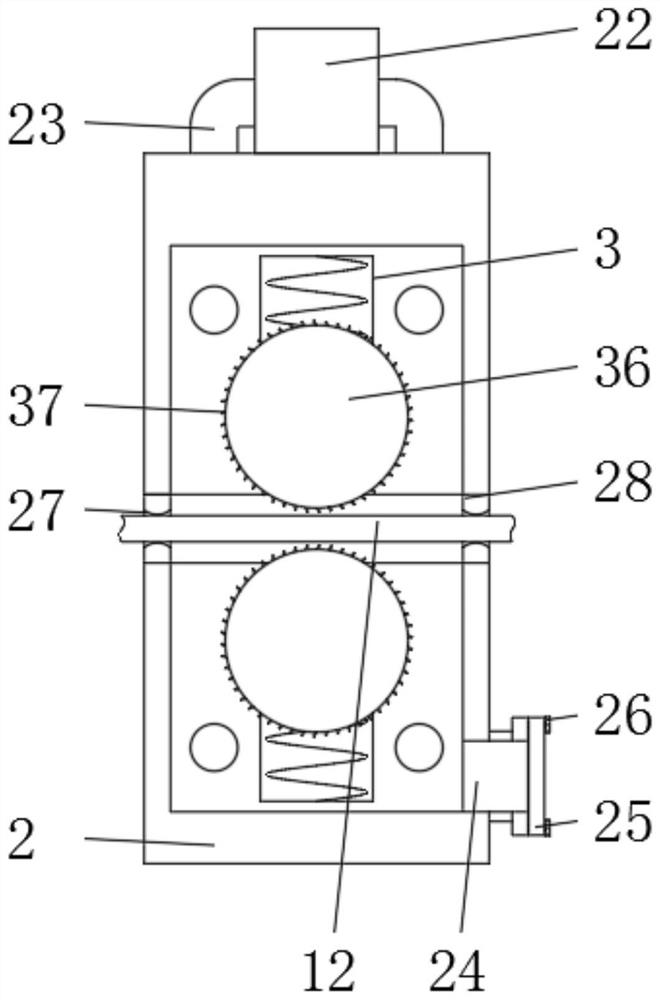

[0027] Embodiment 1: A production line for the production and processing of composite geomembranes, including a bottom plate 1, a fixed block 2, a movable groove 3, a processing groove 21 and a slider 32, a processing device body 11 is installed on the outer wall side of the upper end of the bottom plate 1, and the bottom plate 1 is provided with a material body 12 inside, and the outer wall of the bottom plate 1 facing away from the processing device body 11 is sequentially installed with a first guide roller 13, a fixed block 2, a second guide roller 14 and a support frame 15, and a processing groove 21 is opened inside the fixed block 2 , Both sides of the inner wall of the processing tank 21 are provided with feed ports 27 .

[0028] The inside of the support frame 15 is rotatably equipped with a collection roller 16, and the outer wall of the collection roller 16 is rotatably installed with a material roll 17, and the material roll 17 collects the material body 12 through ...

Embodiment 2

[0031] Embodiment 2: A production line for the production and processing of composite geomembranes, including a bottom plate 1, a fixed block 2, a movable groove 3, a processing groove 21 and a slider 32, a processing device body 11 is installed on the outer wall side of the upper end of the bottom plate 1, and the bottom plate 1 is provided with a material body 12 inside, and the outer wall of the bottom plate 1 facing away from the processing device body 11 is sequentially installed with a first guide roller 13, a fixed block 2, a second guide roller 14 and a support frame 15, and a processing groove 21 is opened inside the fixed block 2 , Both sides of the inner wall of the processing tank 21 are provided with a feed inlet 27, and the inner wall of the feed inlet 27 is bonded and fixed with a rubber pad 28. The rubber pad 28 is in contact with the material body 12, and the rubber pad 28 has reached the purpose of protecting the material body 12. Avoid contact between the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com