Manipulator for continuously grabbing test pieces

A technology for grasping manipulators and test pieces, applied in the field of test pieces, it can solve the problems of inability to control the initial position and end position, and inability to transfer test pieces, and achieve the effect of increasing efficiency, quick connection and rich functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

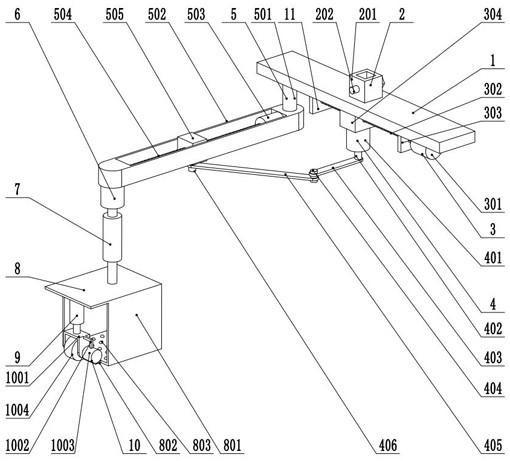

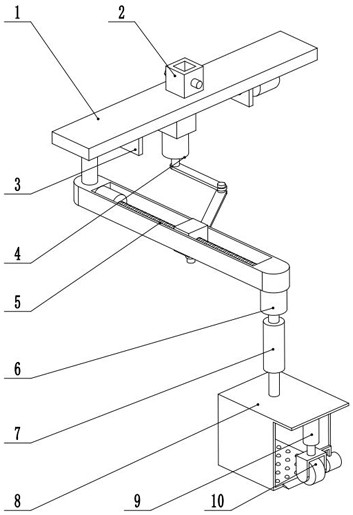

[0028] see Figure 1-3 , a manipulator for continuous grabbing of test pieces, including a mount 1,

[0029] The mounting seat 1 is fixedly connected to the connecting mechanism 2;

[0030] The mounting seat 1 is fixedly connected to the transposition assembly 11, and the transposition assembly 11 includes a displacement mechanism 3, a link mechanism 4 and a transposition lever mechanism 5, and the displacement mechanism 3 and the transposition lever mechanism 5 are all located on the mounting seat 1, and are connected to each other. The rod mechanism 4 is arranged between the displacement mechanism 3 and the shift rod mechanism 5, the displacement mechanism 3 is used to adjust the position of the link mechanism 4, and the link mechanism 4 is used to drive the shift rod mechanism 5 to swing;

[0031] The transposition lever mechanism 5 is fixedly connected to the first motor 6;

[0032] The output shaft of the first motor 6 is fixedly connected to the electric push rod 7;

...

Embodiment 2

[0047] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, except that the pressing mechanism 9 includes a pressing sleeve 901 fixed on the box body 801, and a spring 902 is fixedly connected in the pressing sleeve 901, and the spring The end of 902 away from the compression sleeve 901 is fixedly connected to the compression block 903, the compression block 903 and the compression sleeve 901 are slidingly connected, and the side of the compression block 903 away from the spring 902 is fixedly connected to the compression rod 904, and the compression rod 904 Pass through the compression sleeve 901 and be slidably connected with the compression sleeve 901 .

[0048] In the implementation process of the present invention, the integral manipulator is first connected with other parts through the connecting mechanism 2, and then when the grasping stroke needs to be adjusted, the displacement mechanism 3 is opened at this time, thereby realizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com