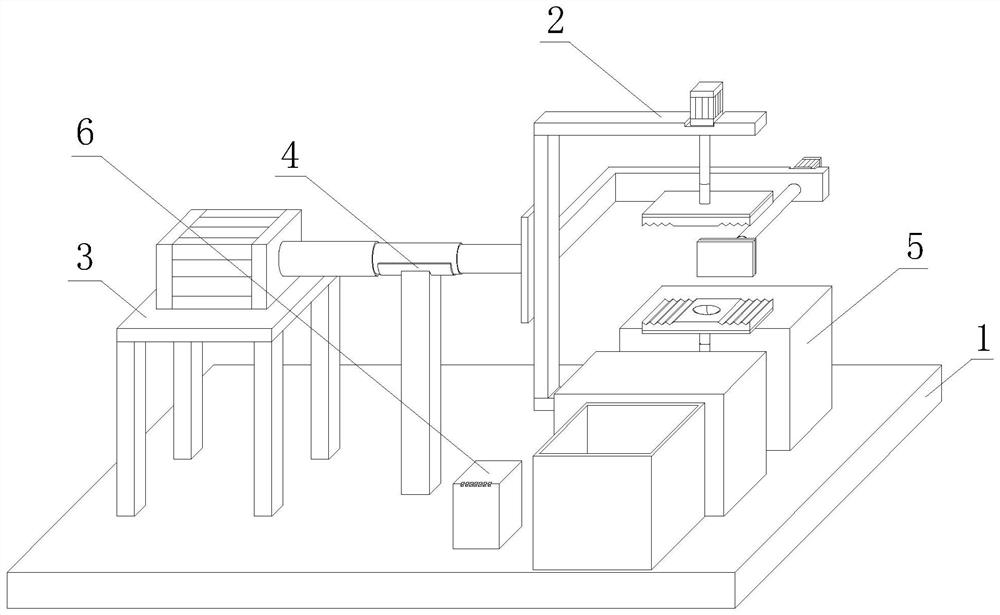

Manipulator for precise injection molding and operation method thereof

An injection molding and manipulator technology, applied in the field of manipulators, can solve the problems of no auxiliary structure, affecting workpiece processing, workpiece shaking, etc., and achieves the effects of high stability, improved applicability, and prevention of workpiece falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] In order to better demonstrate the implementation process of the manipulator for precision injection molding, this embodiment now proposes an implementation method of the manipulator for precision injection molding, including the following steps:

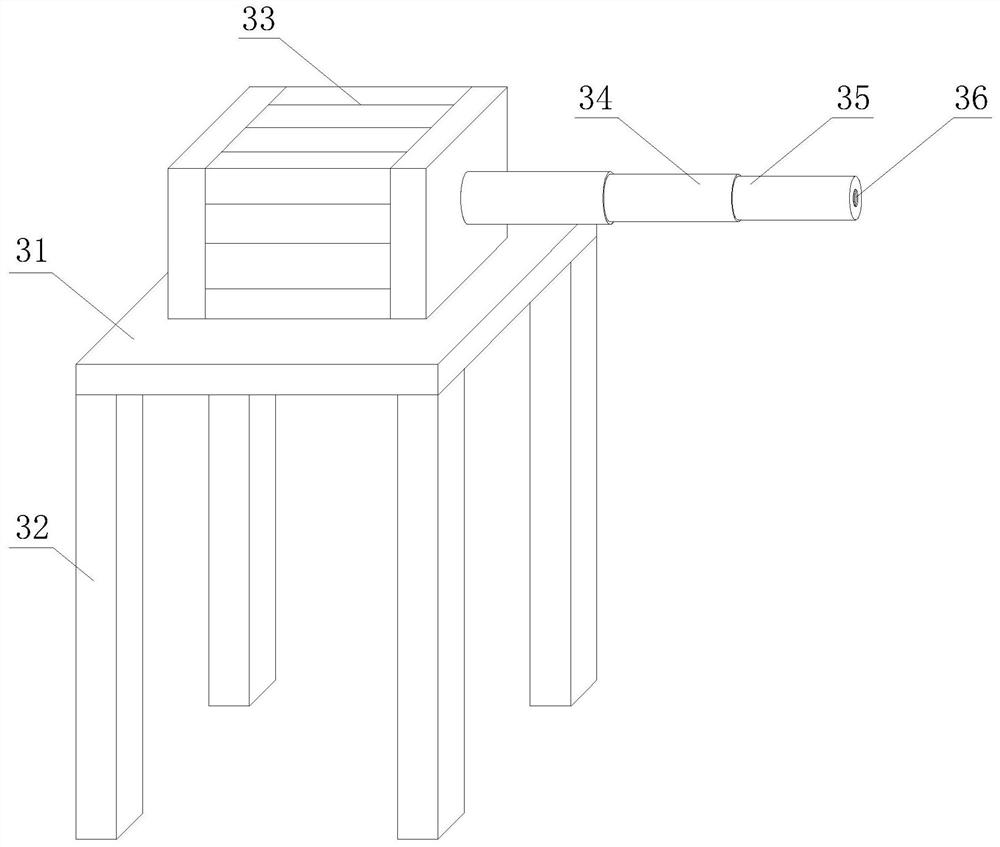

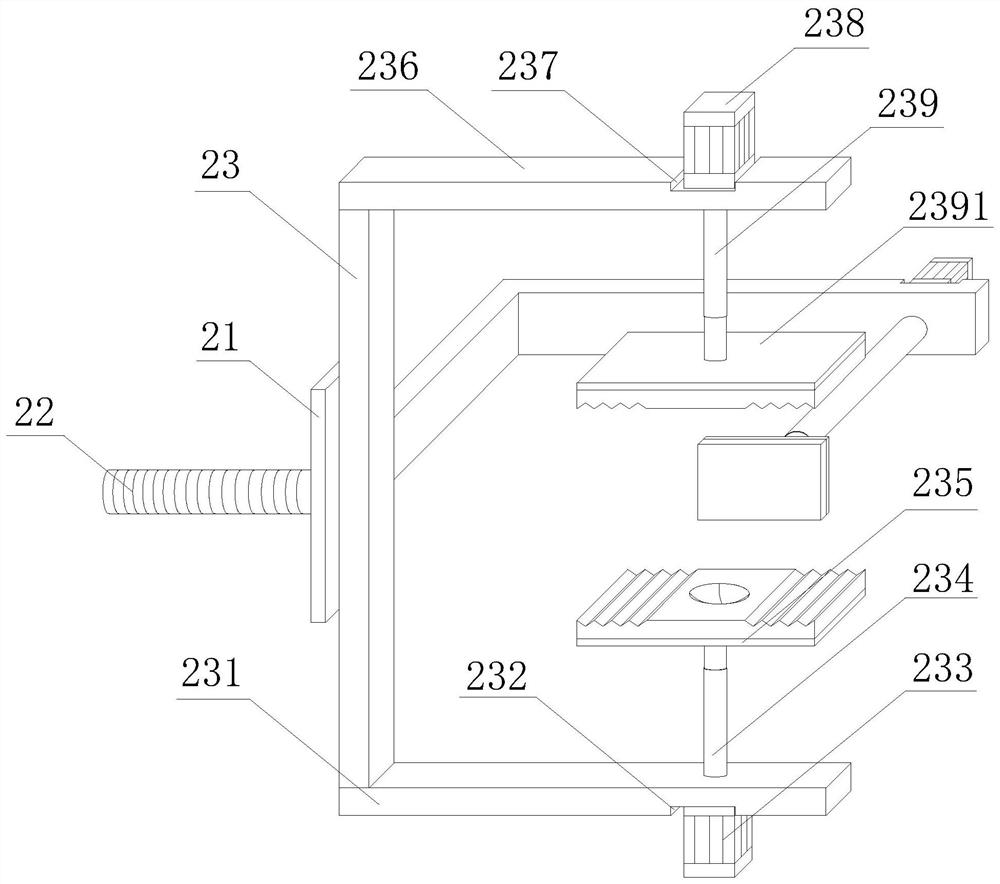

[0038] Step 1: The PLC controller 6 controls the start of the fourth hydraulic pump 33, the fourth hydraulic pump 33 drives the fourth hydraulic telescopic column 34 to expand and contract to the right, and the fourth hydraulic telescopic column 34 drives the grasping assembly 2 to move to the right until the lower The grabbing plate 235 enters the inside of the limit channel 52, so that the lower grabbing plate 235 is flush with the precision injection molded workpiece placed on the upper grabbing plate 2391 and the storage table 51. When the PLC controller 6 controls the fourth hydraulic pump 33 to stop operating ;

[0039] Step 2: Then the PLC controller 6 controls the first hydraulic pump 233 to start, the first hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com