Corrugated carton and processing technology thereof

A corrugated box and processing technology, which is applied to cardboard items and other directions, can solve the problems of reduced use effect and great influence on compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

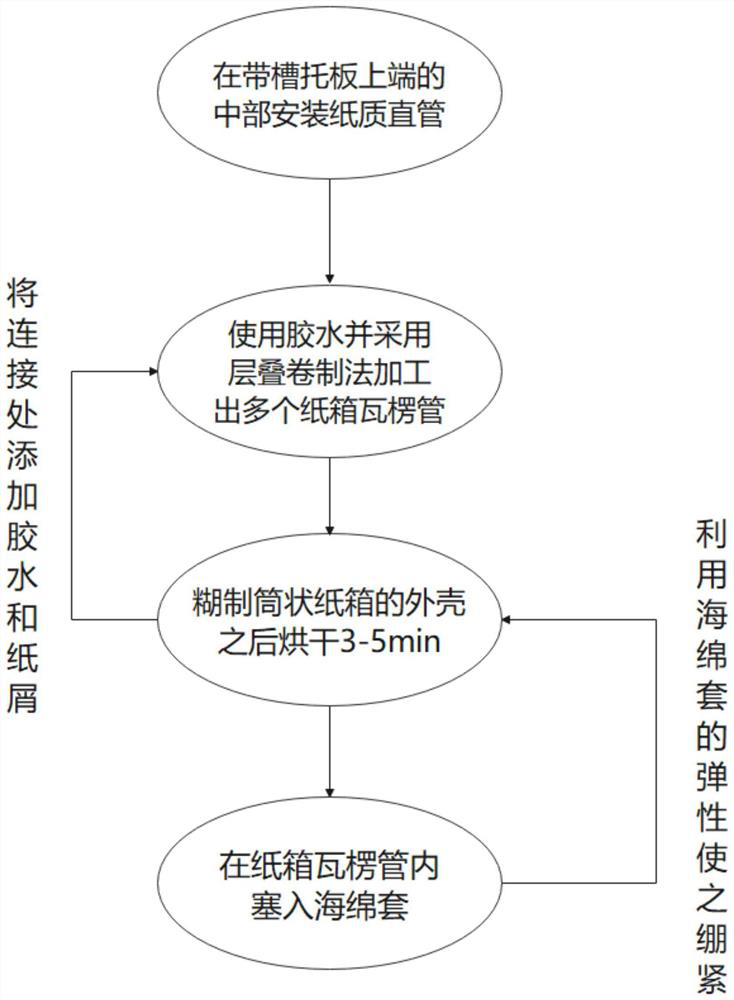

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described below.

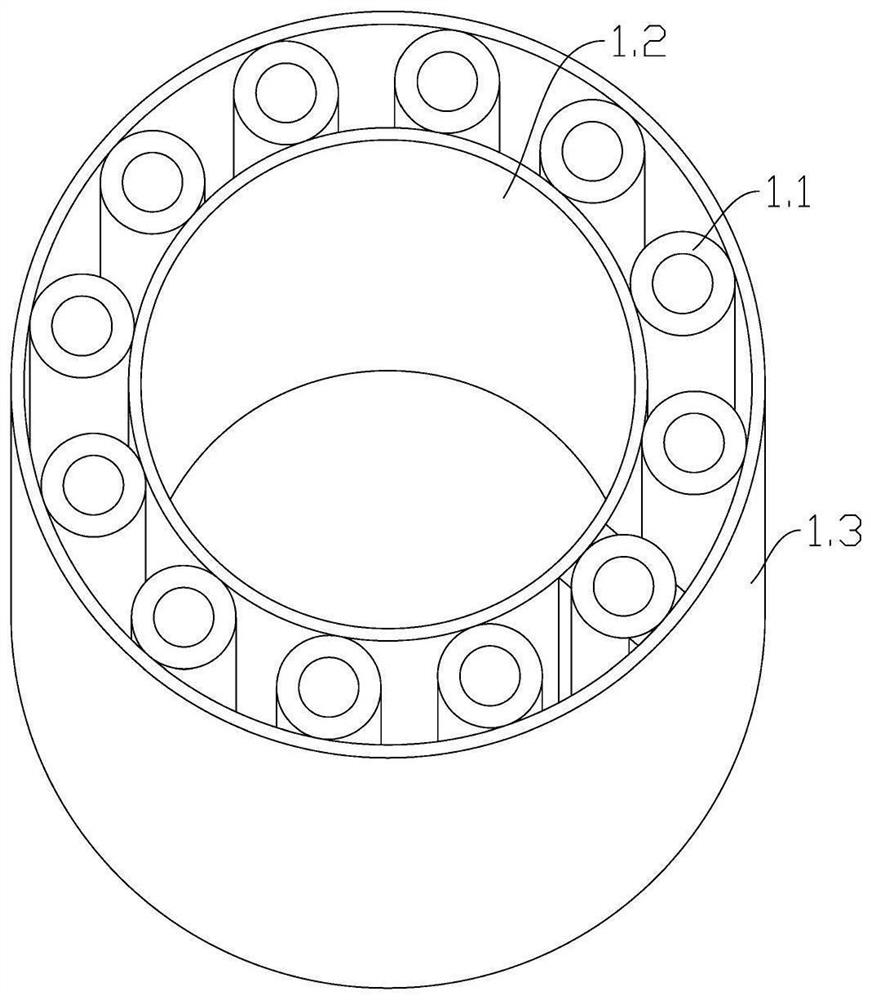

[0030] See figure 2 shown:

[0031] A corrugated box, comprising a corrugated carton tube 1.1, a straight paper tube 1.2 and a carton shell 1.3, a plurality of corrugated tubes 1.1 are provided, and the inner and outer sides of the plurality of corrugated tubes 1.1 are respectively installed with a straight paper tube 1.2 and a carton Shell 1.3.

[0032] The paper straight tube 1.2 and the carton shell 1.3 are the inner and outer layers of the carton respectively. The paper straight tube 1.2 and the carton shell 1.3 are both arranged in a tube. This design can improve the accommodating and handling effect of the shape close to the column. , reduce the distance between the outer side of the columnar item and the inner side of the carton, thereby reducing the damage to the item caused by shaking;

[0033] The paper straight tube 1.2 and the carton shell 1.3 constitute a tubular carton. The design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com