Embedded material of austenitic stainless steel in medical use

An austenitic stainless steel and austenitic technology, applied in prosthesis, medical science and other directions, can solve problems such as restenosis affecting coronary stents, and achieve low cost, excellent combination of strength and toughness, good wear resistance and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] According to the chemical composition range set by the present invention, 4 heats of steel were smelted in a vacuum induction furnace with a capacity of 25 kg, and the specific chemical composition is as shown in Table 1. These 4 furnaces of steel were poured into φ120×450 steel ingots respectively, and processed according to the above processing and heat treatment specifications.

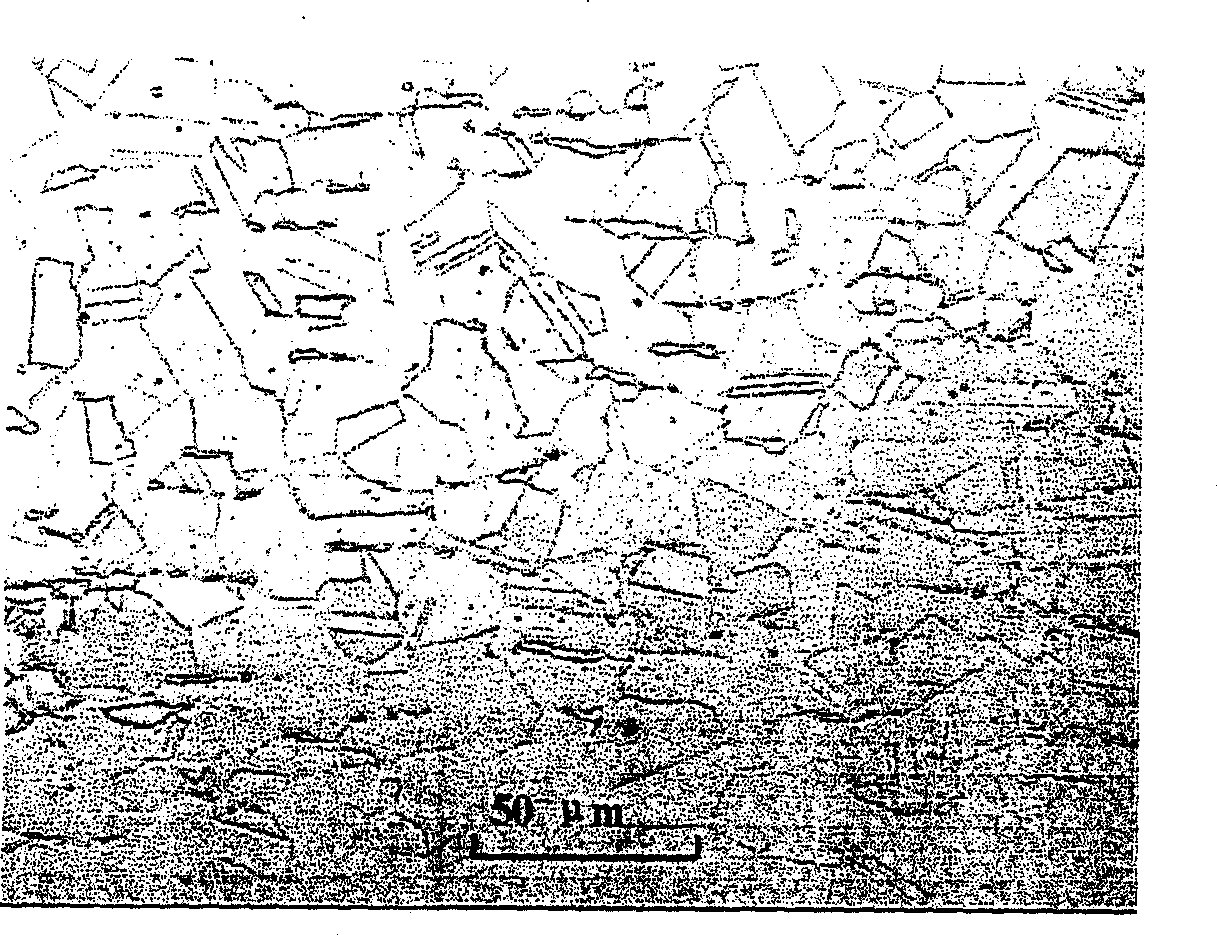

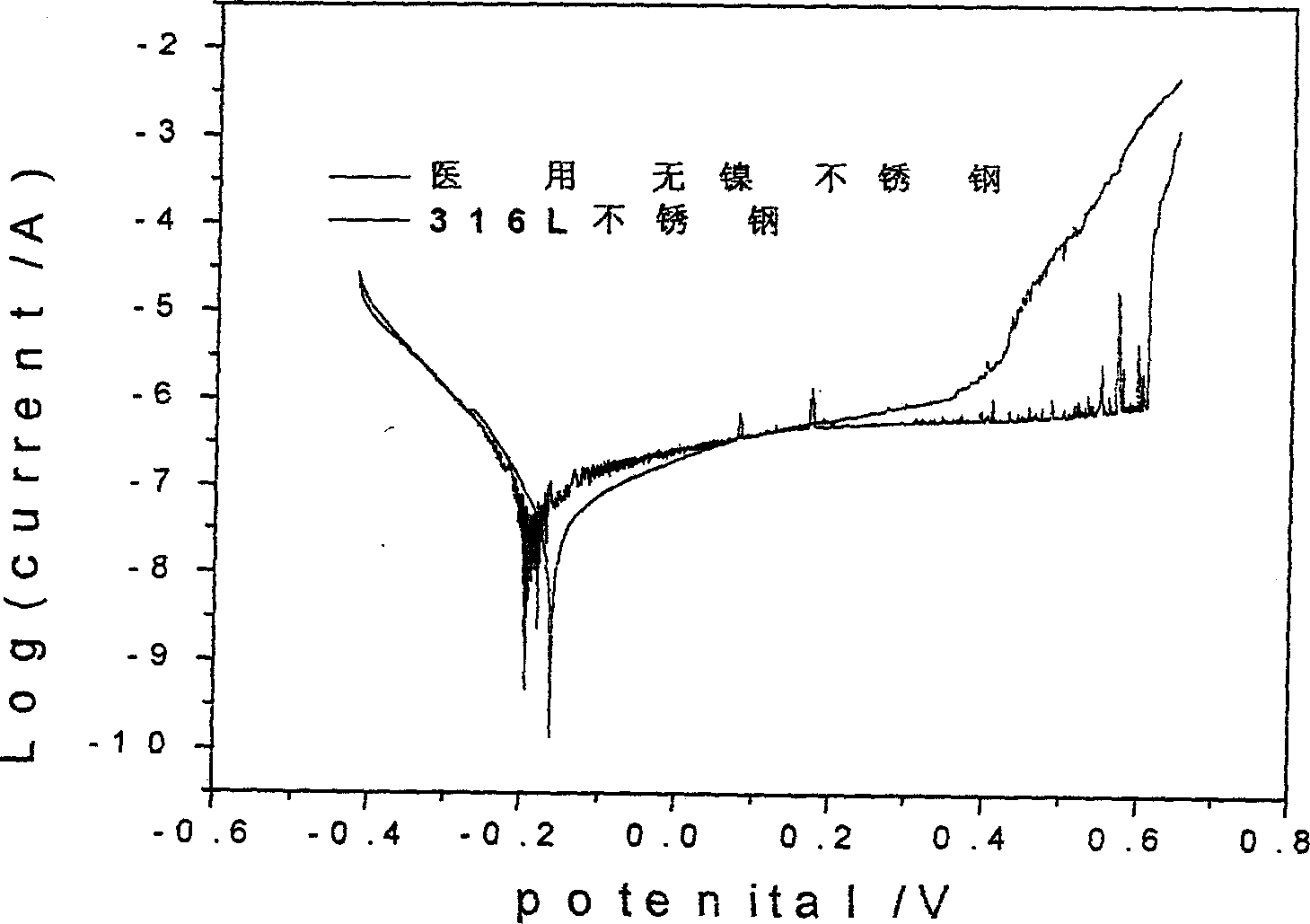

[0025] All test specimens are sampled vertically along the rolling direction, and after the above heat treatment, the steel of the present invention is a single austenitic structure (such as figure 1 Shown), the measured mechanical properties are shown in Table 2. Electrochemical method was used to study the anodic polarization curve of medical nickel-free austenitic stainless steel in equivalent physiological solution at 37°C. The results showed that the corrosion resistance of the new nickel-free stainless steel was better than that of medical 316L stainless steel, especially pitting prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com