Three-dimensional distributed production line

A distributed and three-dimensional technology, applied in the direction of lifting devices, lifting frames, conveyor objects, etc., can solve the problems of large area occupied by the assembly line and increase the cost of enterprises, so as to save the floor space of the workshop and reduce the cost of enterprises. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

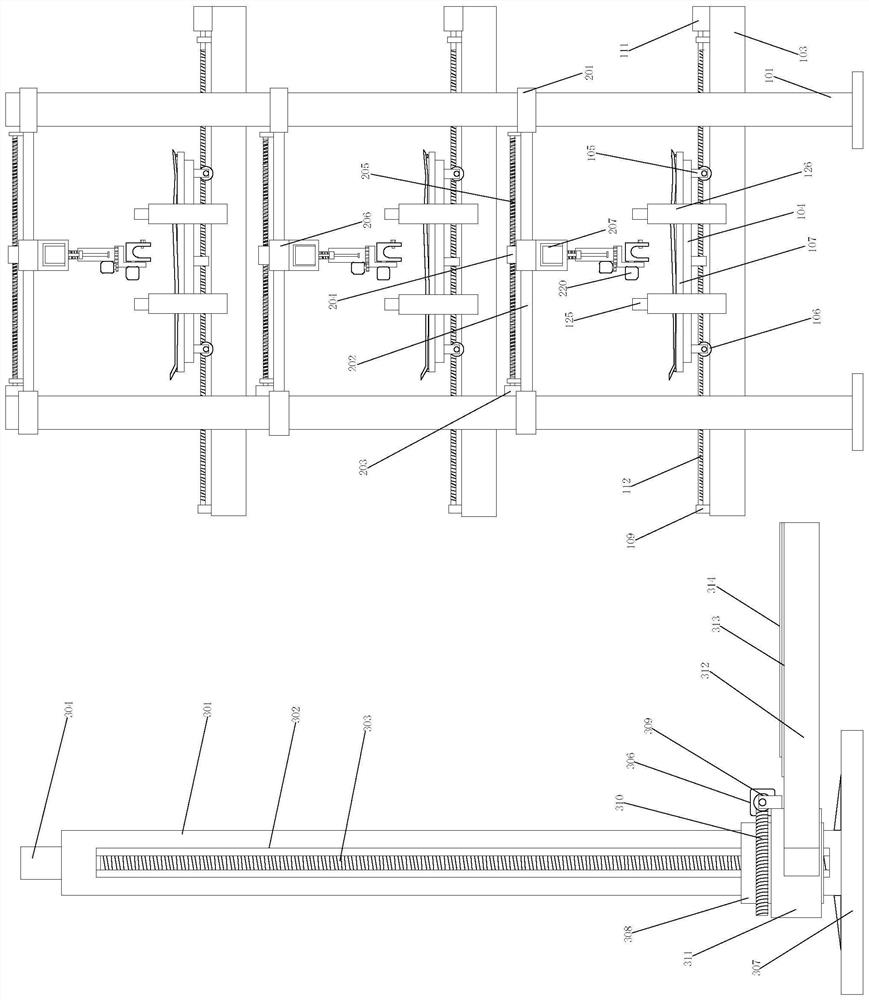

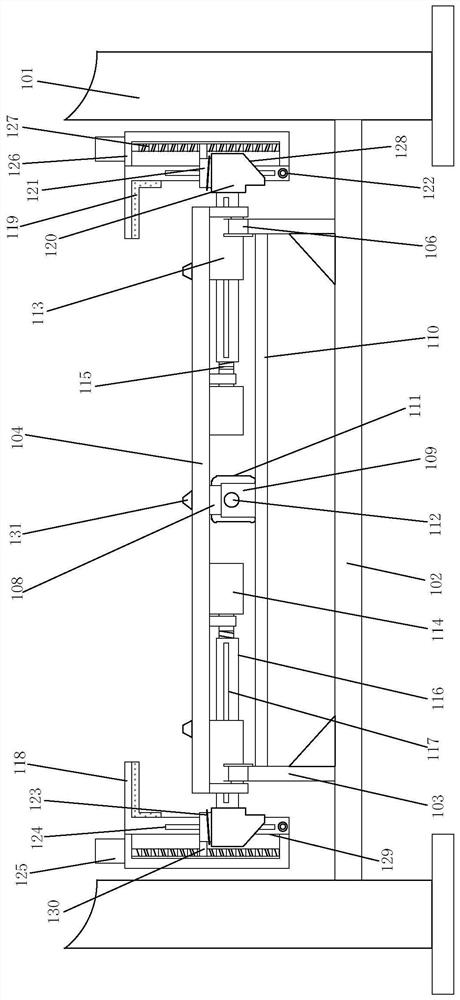

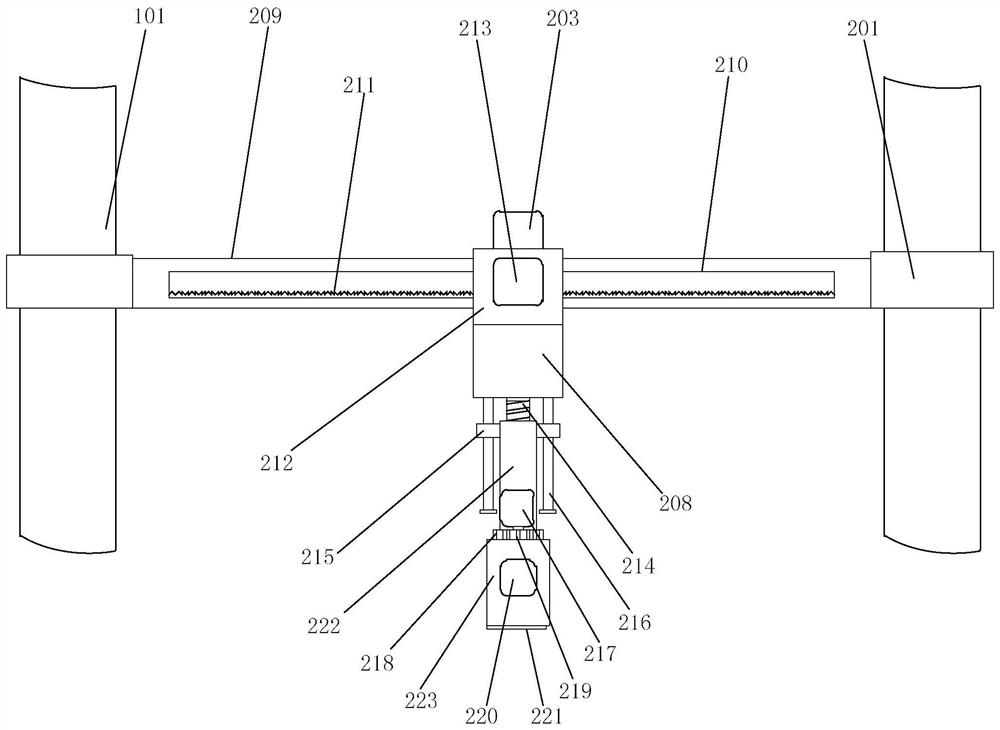

[0029] Such as Figure 1-4 As shown, the three-dimensional distributed production line disclosed in the present invention includes: at least one lifting transfer device and at least one three-dimensional processing device; the lifting transfer device includes a lifting drive mechanism, a rotating transfer mechanism and a translation transfer mechanism; the three-dimensional processing equipment includes Three-dimensional support frame, each translation support mechanism and each suspension processing mechanism;

[0030] Each translation support mechanism and each suspension processing mechanism are vertically spaced and installed on the three-dimensional support frame, and each suspension processing mechanism is respectively located above the corresponding translation support mechanism; the translation support mechanism is used to place the workpiece to be processed, and Drive the workpiece to be processed to move horizontally and laterally; the suspended processing unit is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com