Water segregator device capable of accurately controlling water inlet proportion, and adjusting method

A technology of water inlet ratio and water separator, which is applied in chemical instruments and methods, water/sewage treatment, water treatment parameter control, etc. The effect of low consumption and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

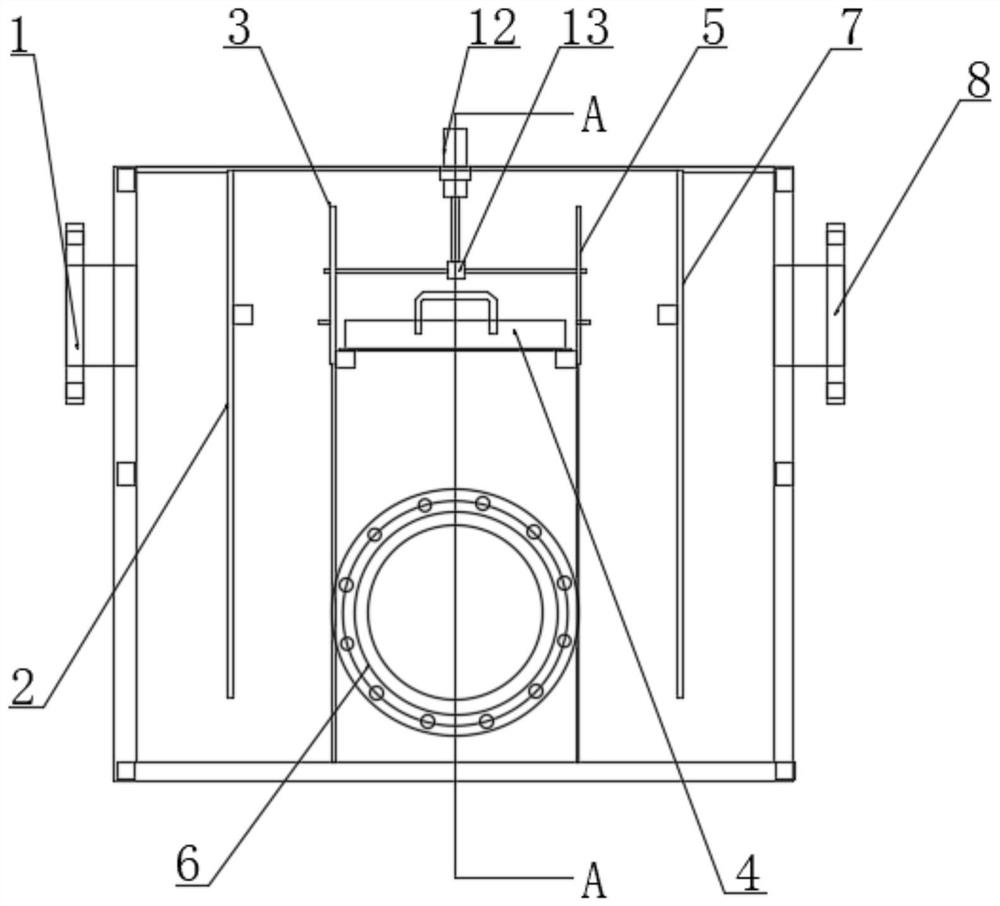

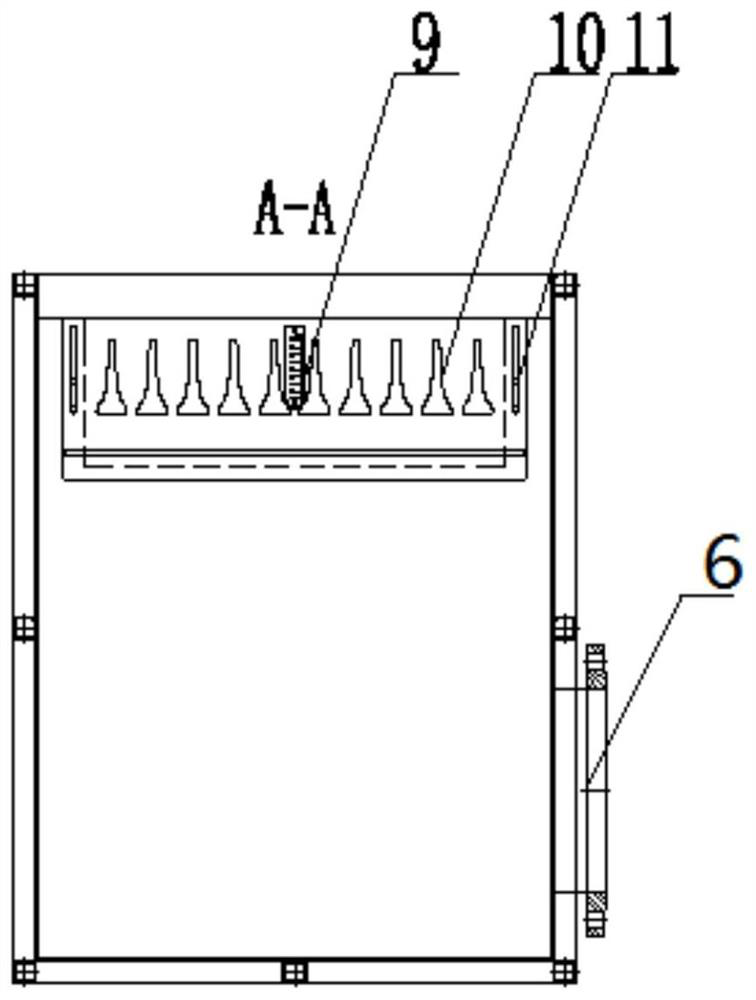

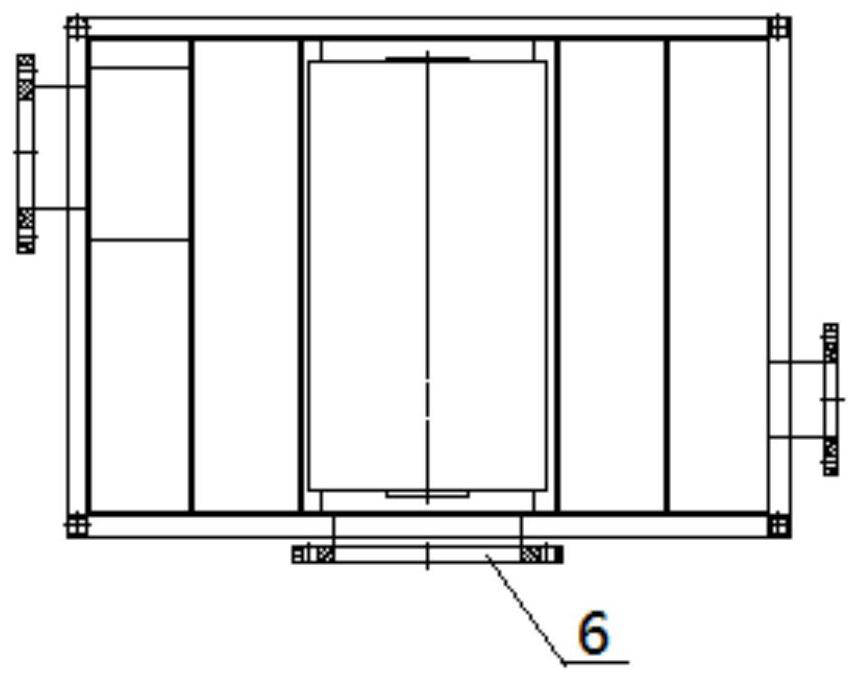

[0029] see Figure 1-4 , the present invention provides a technical solution: a water separator device that can accurately control the water inlet ratio, including a water separator box, and the two sides of the water distributor box are respectively connected with a No. 1 water inlet and a No. 2 water inlet. 8. The front of the water distributor box is connected to the water outlet 6 for outputting sewage, and the two sides of the top of the water distributor box are respectively fixedly connected with the No. 1 water retaining plate 2 and the No. 2 water retaining plate for releasing the sewage pressure. Plate 7, the water separator box is located in the cavity between the No. 1 water retaining plate 2 and the No. 2 water retaining plate 7. A water diversion structure for controlling the water intake is provided. The top of the water diversion structure is fixedly connected with a filter screen 4 and Anti-blocking mechanism.

[0030] The water diversion structure includes l...

Embodiment 2

[0038] see Figure 5 , on the basis of Example 1, a project is designed to treat 400m of sewage per day 3 / d, the sewage treatment process is the AO process. In order to meet the requirement that there is enough nitrate nitrogen to participate in the denitrification reaction in the anoxic section, nitrate reflux is required to return the effluent from the aerobic end to the front end of the anoxic section. After the water is fully mixed, it enters the anoxic section to participate in the subsequent reaction. The ratio of water inflow to nitrate return flow is 1:1.5, that is, the water inflow is 400m 3 / d, the nitrate return flow is 600m 3 / d, let the height of the overflow weir 10 be 10cm, set 10 overflow weirs 10 on each weir plate, and the maximum flow rate of each weir plate of the overflow weir is 1000m 3 / d, the weir plate can realize equidistant water depth on the weir corresponding to equal flow.

[0039] Under the initial conditions, the height of the overflow weir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com