Joint structure for conveying yellow water in cellar

A joint structure and water conveying technology, applied in the field of liquor brewing equipment, can solve the problems of high labor intensity, time-consuming operation process, low production efficiency, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

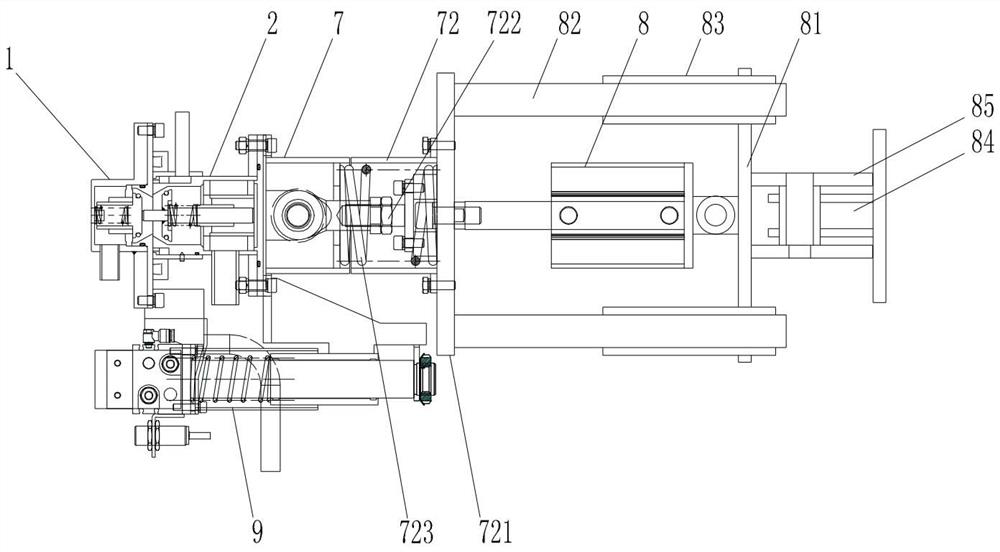

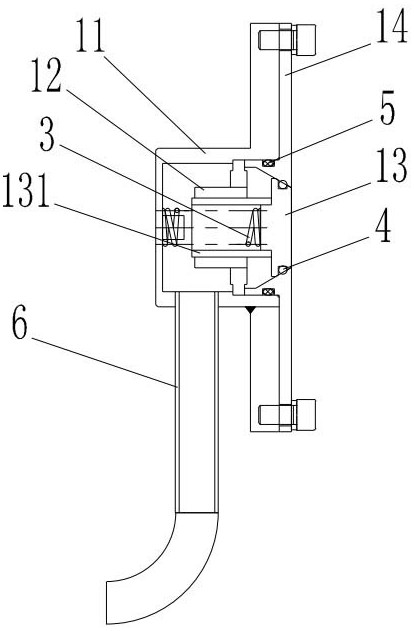

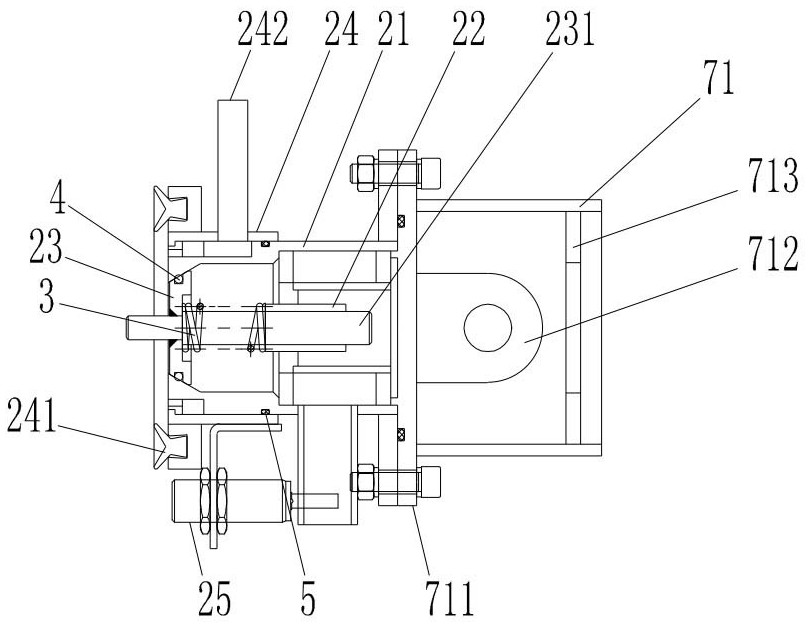

[0048] The specific embodiment of the present invention is as Figure 1-5 As shown, a joint structure for transporting yellow water in cellar ponds includes a passive end joint 1 , an active end joint 2 , an active end joint swing assembly 7 and a telescopic cylinder 8 arranged coaxially in sequence. The passive end joint 1 is arranged on the outer wall of the cellar and communicates with the interior of the cellar through the yellow water delivery pipe 6 . The active end joint 2 and the passive end joint 1 are connected in a quick-release type, and the active sealing block 23 and the passive sealing block 13 which are opened when the two are connected are respectively provided inside the two. The active end joint 2, the active end joint swing assembly 7 and the telescopic cylinder 8 are fixedly connected in sequence. The outer side of the active end joint 2 is provided with a yellow water delivery pipe 6 and a clamping and fixing assembly 9 connected thereto. A yellow water...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap