Liquid formula for preventing metal housing of pressure sensor from being oxidized and treatment process

A pressure sensor, metal shell technology, applied in the direction of painting room, electrolysis process, electrolysis components, etc., can solve the problems affecting the corrosion resistance and sealing of the shell, and the nickel plating layer cannot form a good adhesion, etc., to increase the effect of rough treatment, The effect of improving the adhesion of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

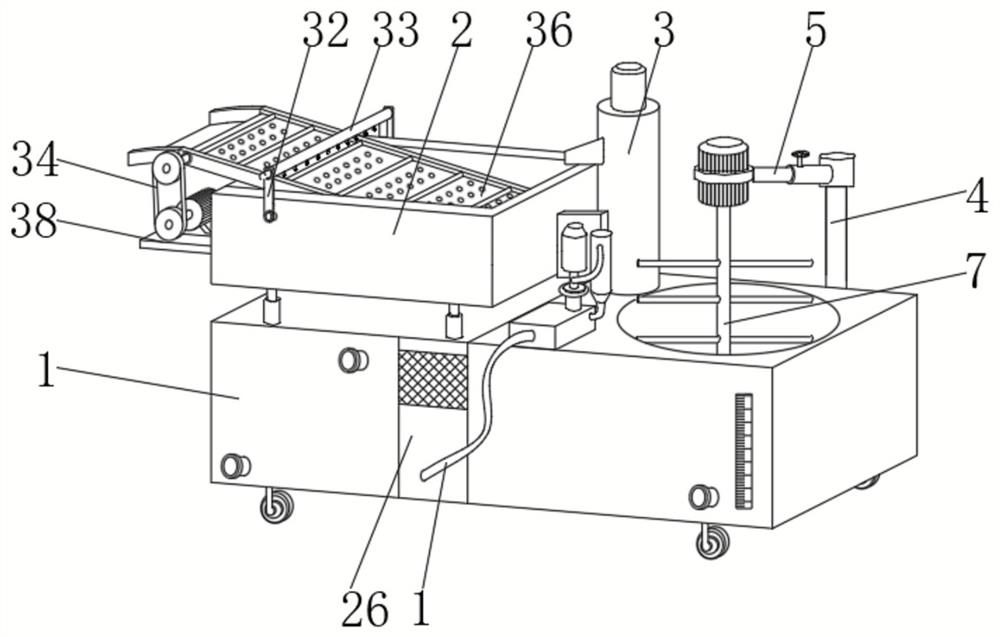

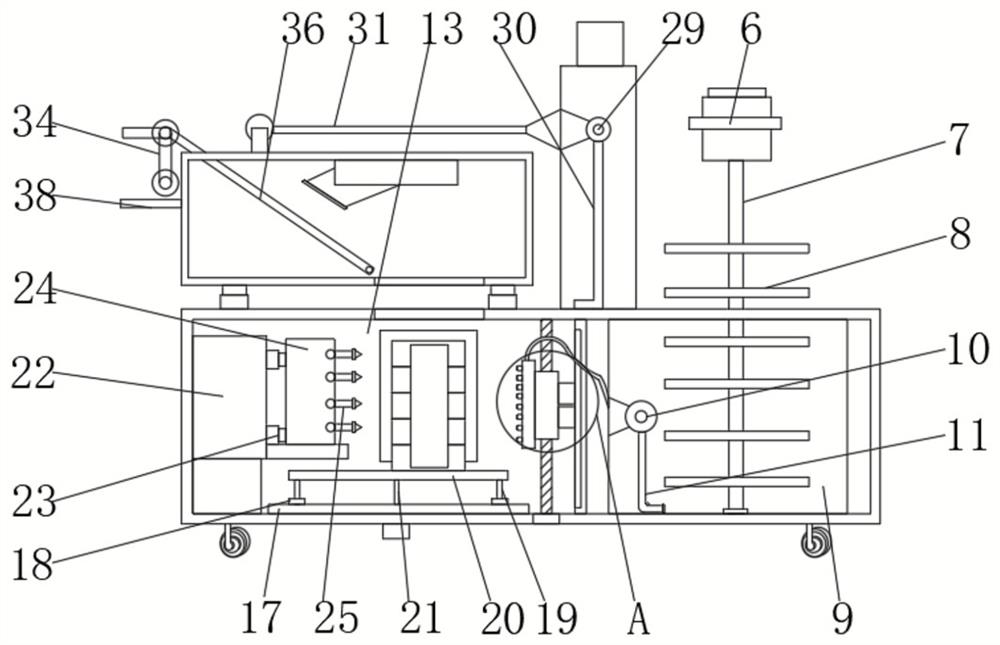

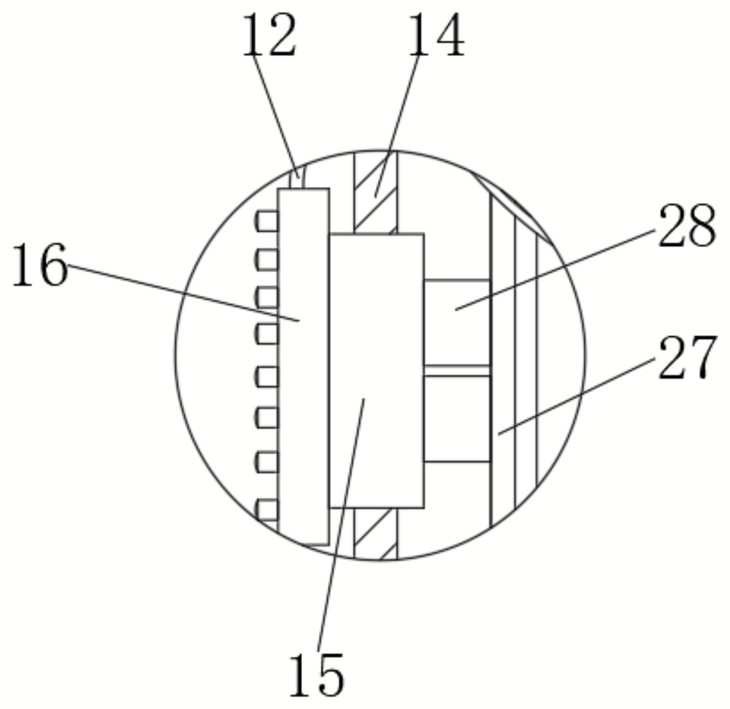

[0035] see Figure 1-5, a liquid formula and treatment process for preventing the oxidation of the metal shell of the pressure sensor. The oxide treatment equipment 2 is arranged on one side of the upper surface of the shell treatment equipment 1, and the two sides of the inside of the shell treatment equipment 1 are respectively provided with an oxidation liquid preparation box 9, The shell reduction box 13, the inner side of the oxidizing liquid preparation box 9 is provided with a delivery pump 10, and the lower end of the delivery pump 10 is connected with a suction pipe 11, and the suction pipe 11 is arranged at the inner bottom of the oxidizing liquid preparation box 9, and the delivery pump The outer side of machine one 10 is connected with delivery pipe one 12, and the other end of delivery pipe one 12 is arranged on the upper surface of oxidizing liquid shower 16, one side of oxidizing liquid shower 16 is fixedly connected to the side of moving ring 15, and moving ring...

Embodiment 2

[0038] see Figure 1-5 , the present invention provides the following technical solutions: a liquid formula for preventing oxidation after surface treatment of steel shells, made of the following raw materials in grams by weight: 30g of 5% citric acid and 30g of 5% boric acid.

[0039] A liquid formula and treatment process for preventing oxidation of a metal shell of a pressure sensor, comprising the following steps:

[0040] Step 1: Prepare an oxidized liquid in the oxidized liquid preparation box 9, take a certain amount of citric acid and 5% boric acid at a concentration, and stir the citric acid and boric acid by mixing and stirring to obtain the oxidized liquid;

[0041] Step 2: After the oxidation liquid is prepared, the oxide treatment equipment 2 is roughened by wet sandblasting to break the oxide film on the surface, increase the surface area at the same time, and improve the bonding force of the coating, and then at a certain higher temperature , using complexing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com