Calcium carbide discharging process

A calcium carbide and process technology, which is applied in the field of calcium carbide production technology, can solve problems such as inability to achieve precise positioning, uneven force on the trolley for the furnace, and the trolley falls out of the furnace, so as to solve the difficulty of furnace production, improve stability and safety, and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

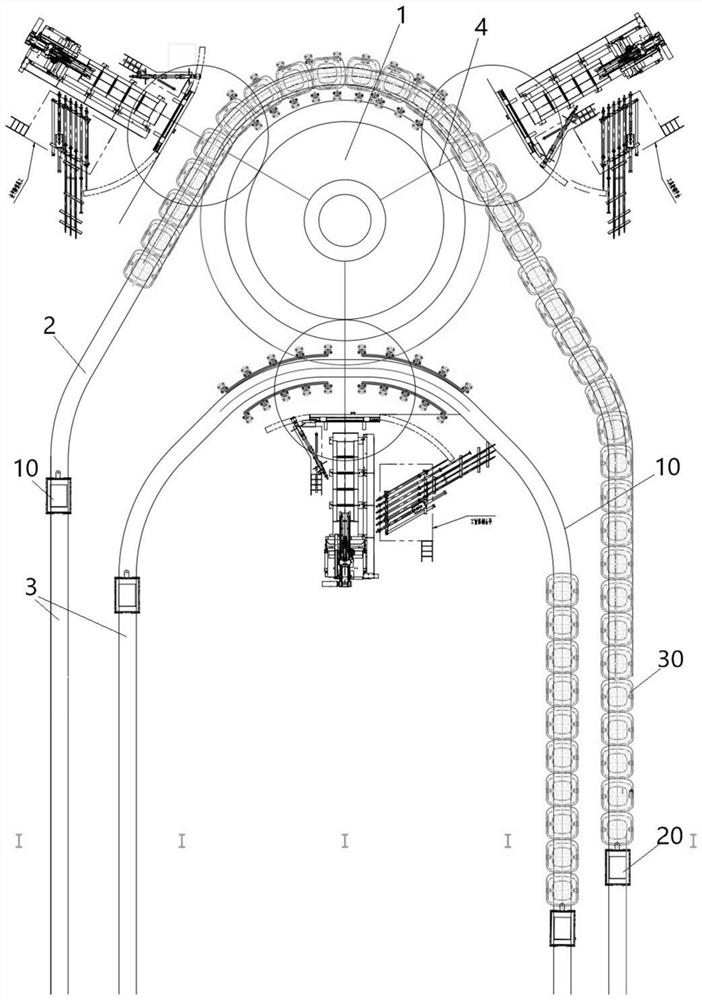

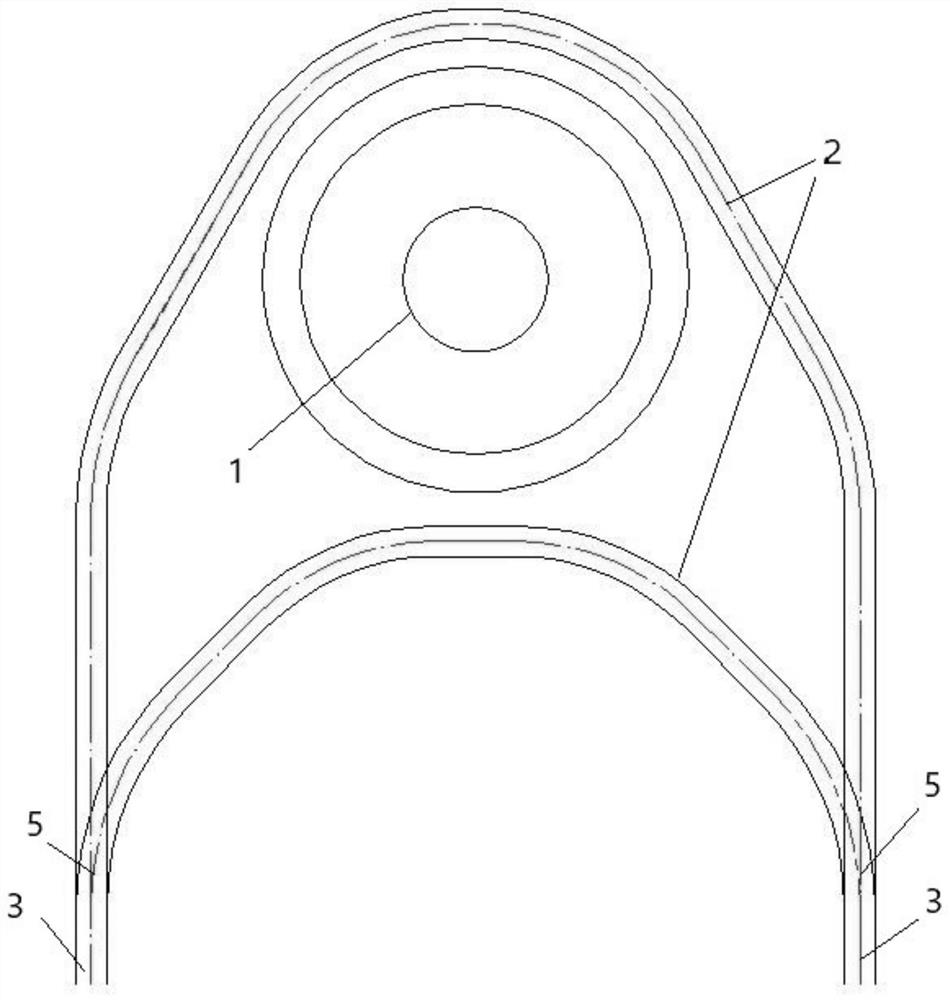

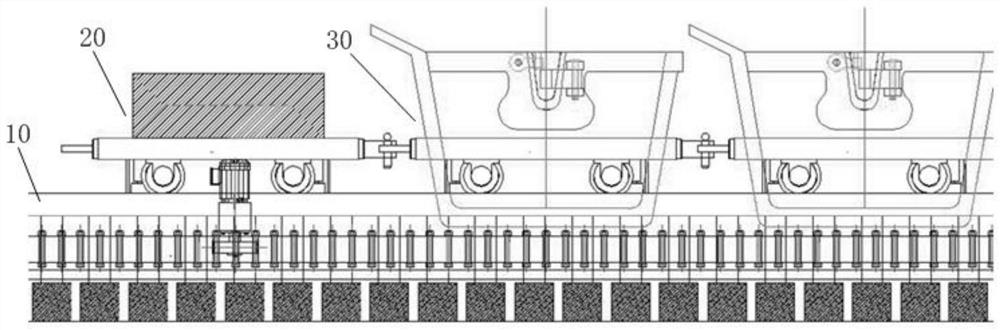

[0054] Such as Figure 1 to Figure 8 As shown, the calcium carbide furnace process first plans the calcium carbide furnace path according to the design. This embodiment takes a medium-sized circular calcium carbide heating furnace 1 as an example for illustration. It is generally equipped with three furnace ports 4, which are 120 degrees along the outer edge of the circle. ° angle interval arrangement, also can be adapted for other models and shapes of calcium carbide heating furnace. Concrete process and relevant structure of technique of the present invention are as follows:

[0055] S1. Along the periphery of the calcium carbide heating furnace, a discharge path 2 corresponding to the furnace mouth for high-temperature calcium carbide discharge is arranged, and a continuous discharge carrying path 3 is arranged at both ends of the discharge path. and the furnace carrying path constitute the calcium carbide furnace path. For different types and sizes of calcium carbide hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com