Temperature measuring device and temperature measuring method in friction process of friction pair material

A temperature measuring device and friction pair technology, applied in measuring devices, thermometers, measuring heat, etc., can solve the problems of accurate measurement of friction coefficient and wear rate, cumbersome and difficult operation, and non-contact temperature measurement, etc., and achieve reliable data. effect of source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

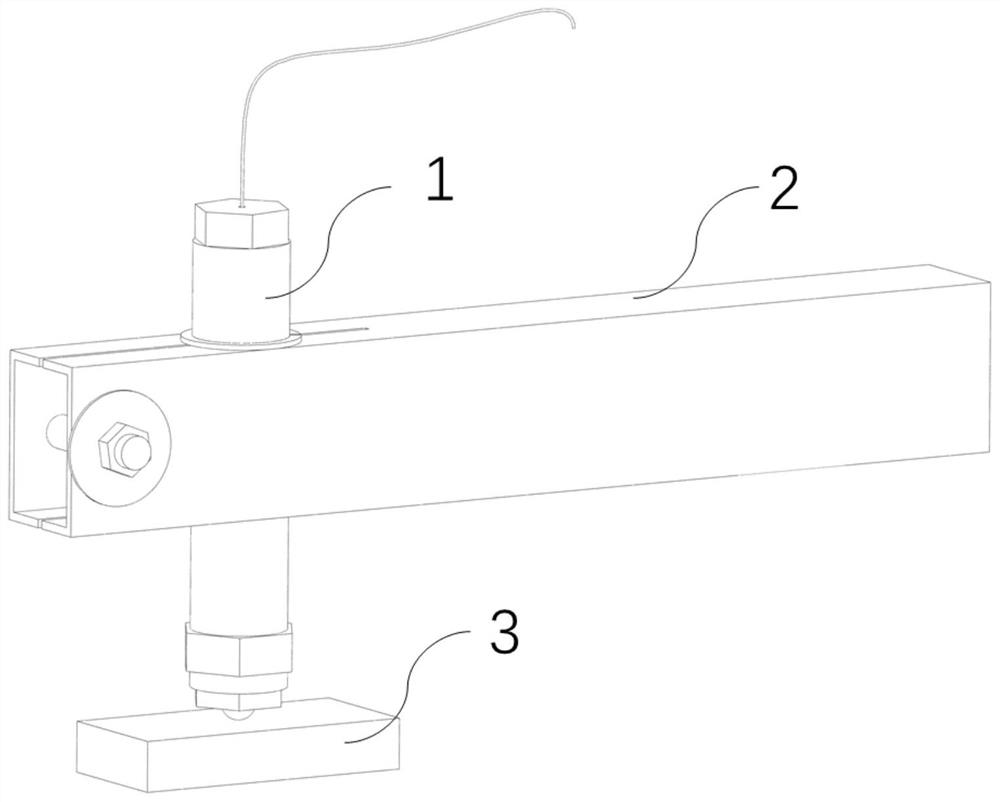

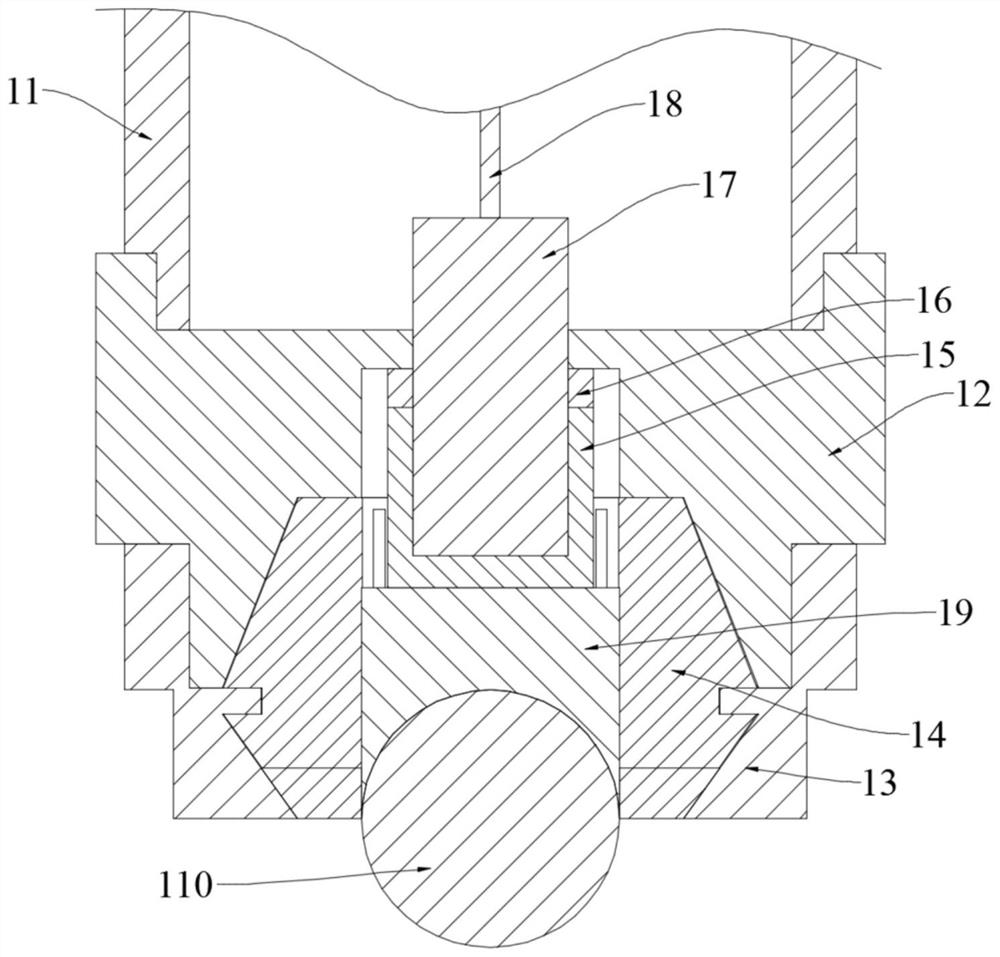

[0032] Example 1: The following spherical sample is used as the friction pair material, and the friction and wear test is carried out with the pair of the German Evonik P84NT1 polyimide molded product pair, and the temperature of the friction pair material of the spherical sample is measured by the temperature measuring component 17 The change.

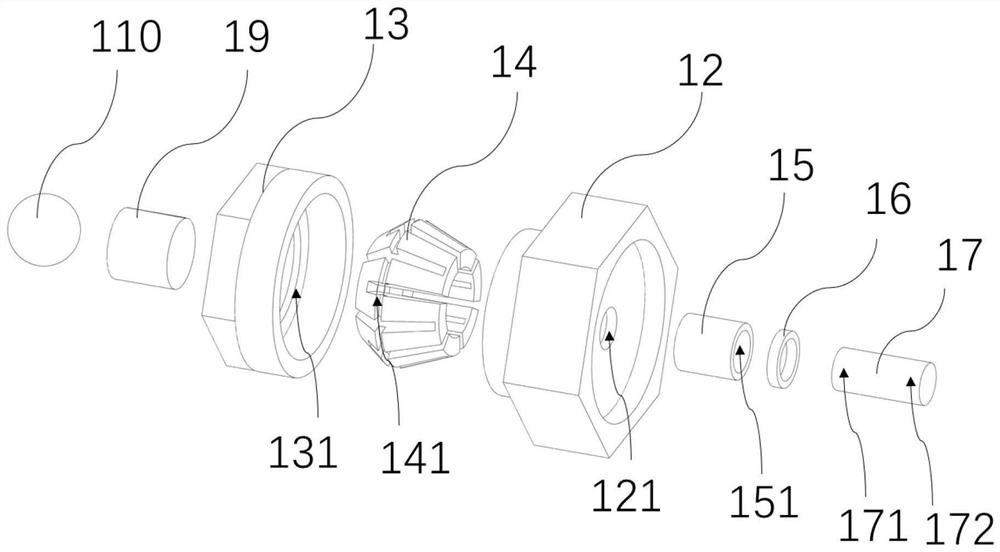

[0033] Such as Figure 1 to Figure 5 As shown, the present invention discloses a temperature measuring device, which includes a hollow base 12 , an extension rod 11 , a locking cap 13 , a snap spring 14 , a top post 15 , and a temperature measuring component 17 . The connection relationship is as follows: the locking cap 13 and the snap spring 14 are buckled and connected through the convex ring 131 and the annular slot 141, and the upper and lower ends of the hollow base 12 are respectively connected with the locking cap 13 and the extension rod 11 by bolts. The cap 13 locks the circlip 14 to clamp the material of the friction pair ...

Embodiment 2

[0044] Embodiment 2: Others are the same as in Embodiment 1, the difference is that the test object of this embodiment is a cylindrical friction pair 20, so this embodiment omits the concave hemispherical support column 19, and the cylindrical friction pair 20 is directly in contact with the top column 15 .

[0045] The temperature measuring device 1 of the present invention is not only capable of testing spherical geometric samples and cylinders, but also can test the temperature changes during the friction and wear process of cones, cubic friction pair materials and the like. According to different shapes of the friction pair, select the corresponding support column to contact the top column 15, and improve the thermal conductivity through the support column, so as to solve the problem of insufficient thermal conductivity of the material of the friction pair and the top column 15 in direct contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com