Metallographic sample preparation method of aluminum alloy

A technology for metallographic sample preparation and aluminum alloy, which is applied in the preparation, sampling, and measuring devices of samples for testing, and can solve problems such as the lack of a guiding sample preparation theory and the inapplicability of aluminum alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

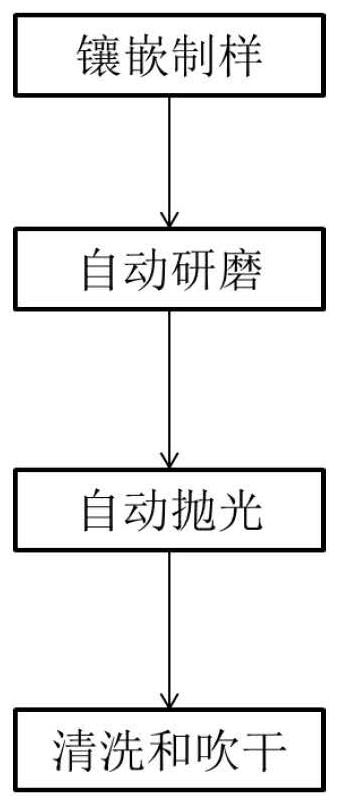

Method used

Image

Examples

Embodiment 1

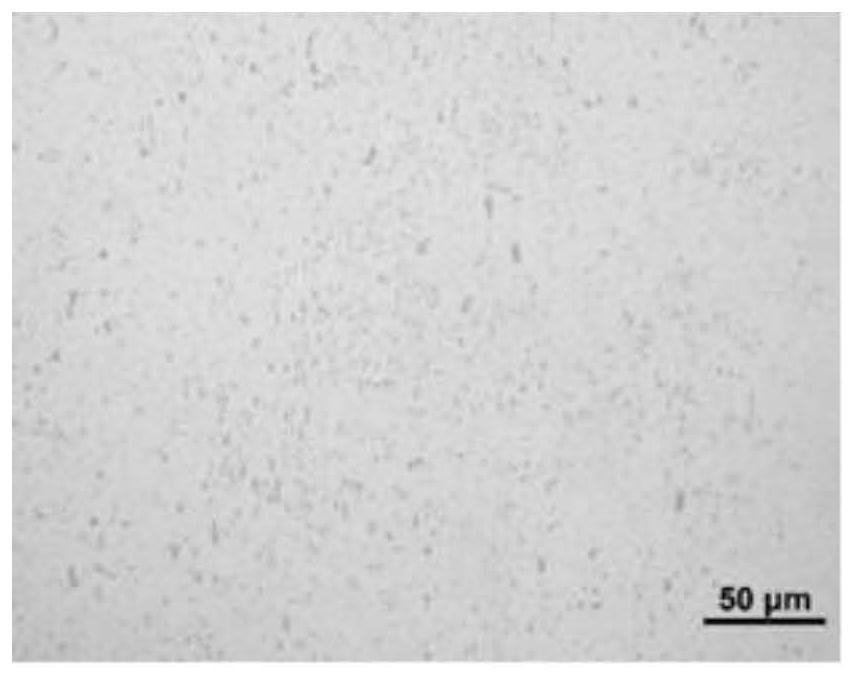

[0035] The 8021-H112 state (Hv=32), 1050-O state (Hv=22) aluminum alloys were subjected to cold mounting sample preparation, and the specifications were obtained as Samples with a height of 20 mm, and then the samples after cold mounting were subjected to grinding and polishing experiments using an automatic grinding and polishing machine.

[0036] First, use an automatic grinding and polishing machine for three-stage automatic grinding, that is, use 400 mesh, 800 mesh and 2000 mesh water-grinding sandpaper for automatic grinding step by step. Then, use an automatic polishing machine for three-stage automatic polishing, that is, use a polishing liquid and a polishing cloth with a 9 μm abrasive grain, a polishing liquid and a polishing cloth with a 3 μm abrasive grain, and a polishing liquid and a polishing cloth with a 0.02 μm abrasive grain. Perform automatic polishing. Finally, the polished aluminum alloy samples were rinsed with water and absolute ethanol in turn and drie...

Embodiment 2

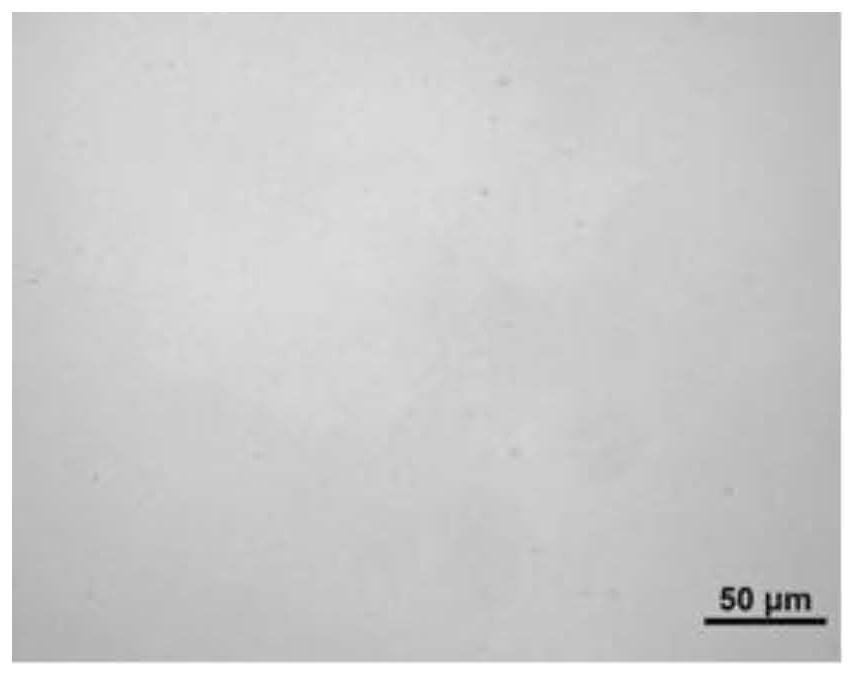

[0040] The 6061-T6 state (Hv=75), 6013-homogeneous state (Hv=71), 6082-cast state (Hv=80), 6110-cast state (Hv=60), 5754-O state (Hv=60 ), 3004-O state (Hv=54), 7075-cast state (Hv=72), ZL101A-cast state (Hv=93) aluminum alloys for cold mounting sample preparation, and the specifications are Samples with a height of 20 mm, and then the samples after cold mounting were subjected to grinding and polishing experiments using an automatic grinding and polishing machine.

[0041] First, use an automatic grinding and polishing machine for three-stage automatic grinding, that is, use 400 mesh, 800 mesh and 2000 mesh water-grinding sandpaper for automatic grinding step by step. Then, use an automatic polishing machine for three-stage automatic polishing, that is, use a polishing liquid and a polishing cloth with a 9 μm abrasive grain, a polishing liquid and a polishing cloth with a 3 μm abrasive grain, and a polishing liquid and a polishing cloth with a 0.02 μm abrasive grain. Perfor...

Embodiment 3

[0045] The 7075-H112 state (Hv=169), 2524-T3 state (Hv=149), 6110-T6 state (Hv=120) aluminum alloys were subjected to cold mounting sample preparation, and the specifications were obtained as Samples with a height of 20 mm, and then the samples after cold mounting were subjected to grinding and polishing experiments using an automatic grinding and polishing machine.

[0046] First, use an automatic grinding and polishing machine for three-stage automatic grinding, that is, use 400 mesh, 800 mesh and 2000 mesh water-grinding sandpaper for automatic grinding step by step. Then, use an automatic polishing machine for three-stage automatic polishing, that is, use a polishing liquid and a polishing cloth with a 9 μm abrasive grain, a polishing liquid and a polishing cloth with a 3 μm abrasive grain, and a polishing liquid and a polishing cloth with a 0.02 μm abrasive grain. Perform automatic polishing. Finally, the polished aluminum alloy samples were rinsed with water and absolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com