Cooking utensil, control method of cooking utensil and computer readable storage medium

A technology of cooking utensils and control methods, which is applied in the direction of temperature control, induction heating control, control/regulation system, etc., and can solve the problems of poor thermal conductivity of glass panels, insufficient temperature detection sensitivity, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

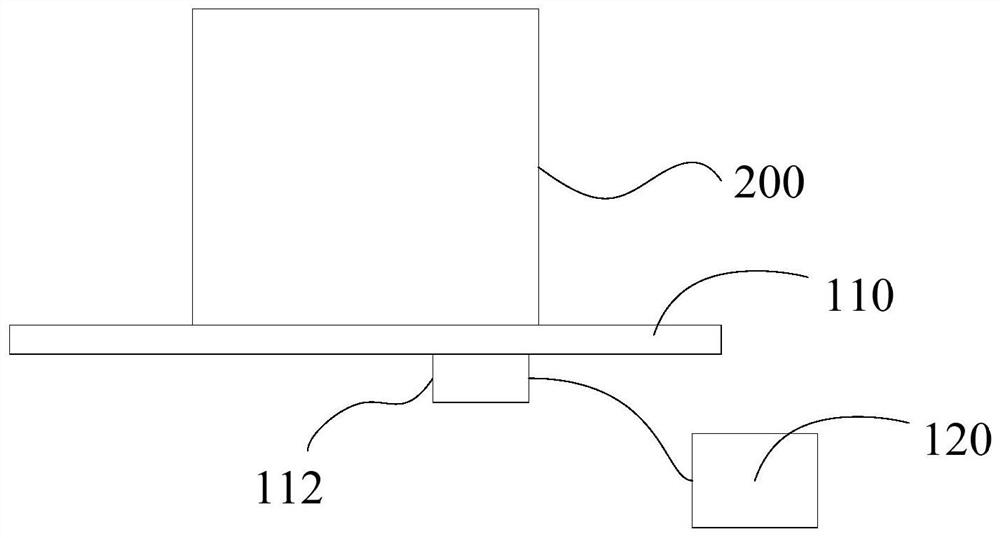

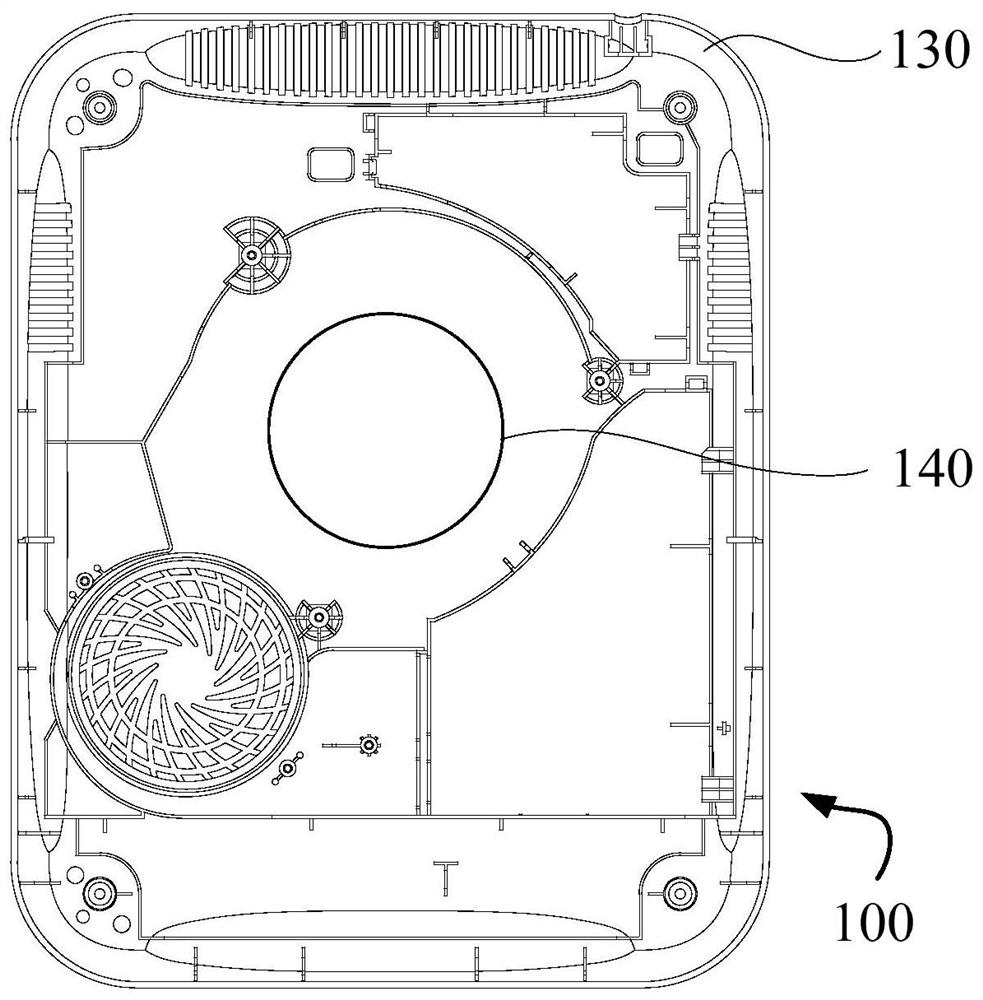

[0045] like figure 1 and figure 2 As shown, according to the embodiment of the first aspect of the present invention, a cooking appliance 100 is proposed, including: an object loading portion 110 , a heating element 140 , a capacitive sensor 112 and a controller 120 .

[0046] Specifically, the loading part 110 is provided with a radiation area, the heating element 140 is configured to be suitable for heating the radiation area, the capacitive sensor 112 is arranged on the side of the loading part 110 facing the heating element 140, the controller 120 communicates with the capacitive sensor 112 and The heating element 140 is electrically connected, and the controller 120 is configured to control the working state of the heating element 140 according to the capacitance value of the capacitive sensor 112 .

[0047] In this embodiment, the cooking utensil 100 includes a loading part 110, a heating element 140, a capacitive sensor 112, and a controller 120. The loading part 110 ...

Embodiment 2

[0052] like figure 1 and figure 2 As shown, according to one embodiment of the present invention, a cooking utensil 100 is proposed, including: an object loading portion 110, a heating element 140, a capacitive sensor 112, a controller 120, a seat body 130 and a detection assembly (not shown in the figure out).

[0053] Specifically, the seat body 130 is connected to the loading part 110, and an accommodation cavity is formed between the base body 130 and the loading part 110, and the heating element 140 is located inside the accommodation cavity, and placed on the side of the loading section 110 facing away from the heating element 140. There is a pot 200 , and the detection component is configured to be suitable for identifying the type information of the pot 200 .

[0054] In this embodiment, the cooking utensil 100 further includes a seat body 130 and a detection assembly. An accommodating cavity is formed between the seat body 130 and the loading part 110, and the heat...

Embodiment 3

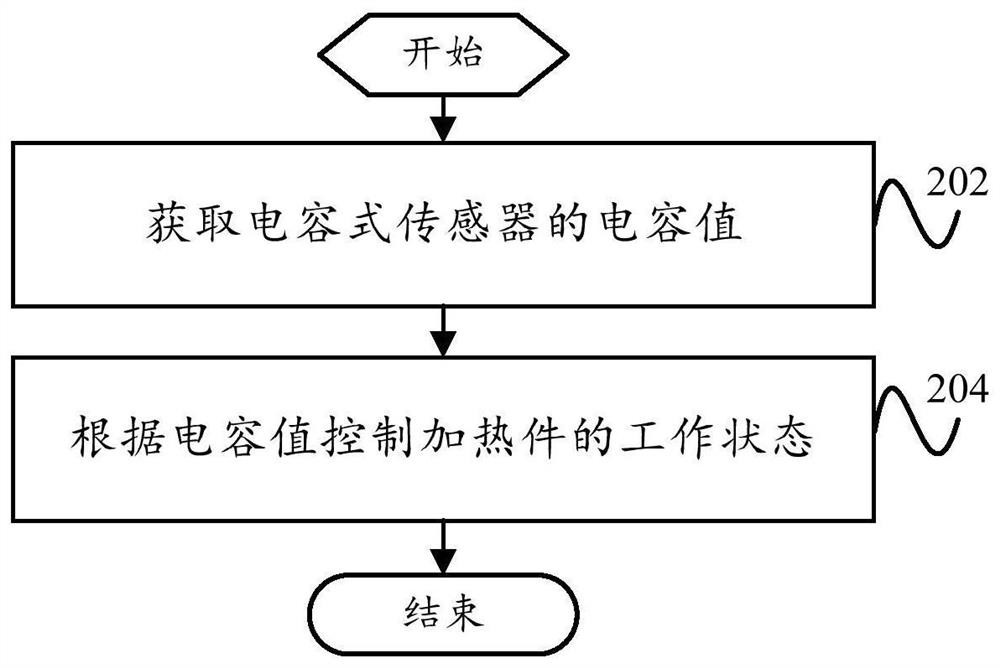

[0056] like image 3 As shown, according to the embodiment of the second aspect of the present invention, a method for controlling a cooking appliance is proposed, which is suitable for controlling the cooking appliance provided in the embodiment of the first aspect, the method comprising:

[0057] Step 202, obtaining the capacitance value of the capacitive sensor;

[0058] Step 204, controlling the working state of the heating element according to the capacitance value.

[0059] In this embodiment, since the capacitance value of the capacitive sensor changes significantly after the pot is placed, it is judged according to the capacitance value of the capacitive sensor whether a pot is placed, and based on this, the heating element is controlled to start and stop, so as to realize Intelligent control of cooking appliances. At the same time, since the capacitance value of the capacitive sensor is easily affected by temperature changes, the temperature drift phenomenon of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com