Manufacturing method of parallel water cooling disc assembly of lithium battery

A manufacturing method, lithium battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of small (generally only about 80%), reduced heat exchange efficiency, high manufacturing cost, etc., to achieve the benefit of heat transfer , Improve heat exchange efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

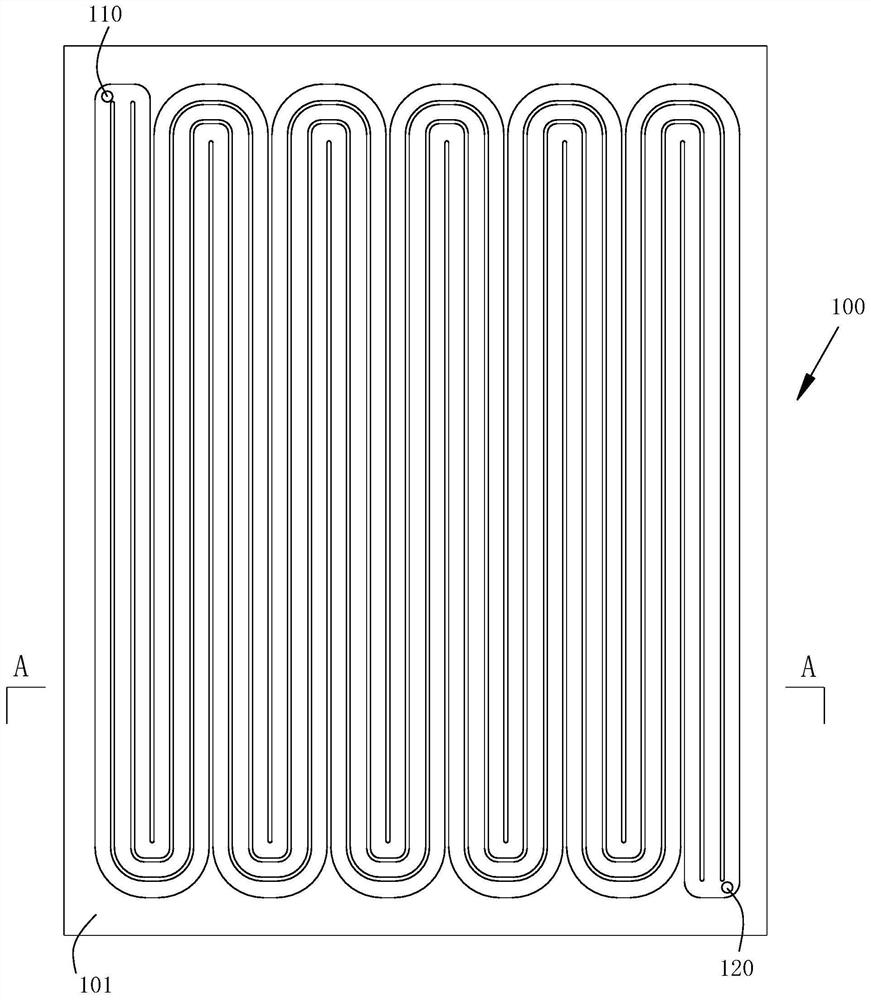

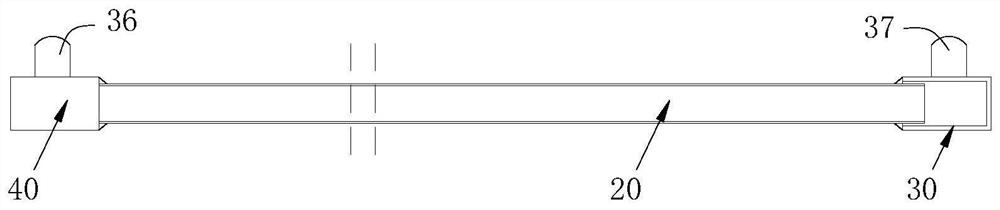

[0032] The structure of the parallel flow water cooling plate assembly of the lithium battery is firstly described below, please refer to Figure 3-Figure 7 , the parallel flow water cooling plate assembly includes four aluminum flat tubes 20 arranged along the same plane and parallel to each other. One collecting pipe 30 is sealed and installed respectively, and a pipe joint is respectively installed on the two collecting pipes, one pipe joint is used as the refrigerant inlet pipe 36 , and the other pipe joint is used as the refrigerant outlet pipe 37 .

[0033] The manufacturing method of the parallel flow water cooling plate assembly is described below. The size of the parallel flow water cooling plate assembly manufactured in this embodiment is 1000mm*800mm. The manufacturing method includes the following steps:

[0034] (1) Four aluminum flat tubes 20 are prepared, that is, N=4.

[0035] see Figure 8 , each aluminum flat tube 20 includes a top plate 21, a bottom plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com