Rotator cuff prosthesis, preparation method thereof and rotator cuff prosthesis device

A prosthesis and rotator cuff technology, applied in the field of medical devices, can solve problems such as filler leakage, rotator cuff balloon failure, and limited service life of rotator cuff prosthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

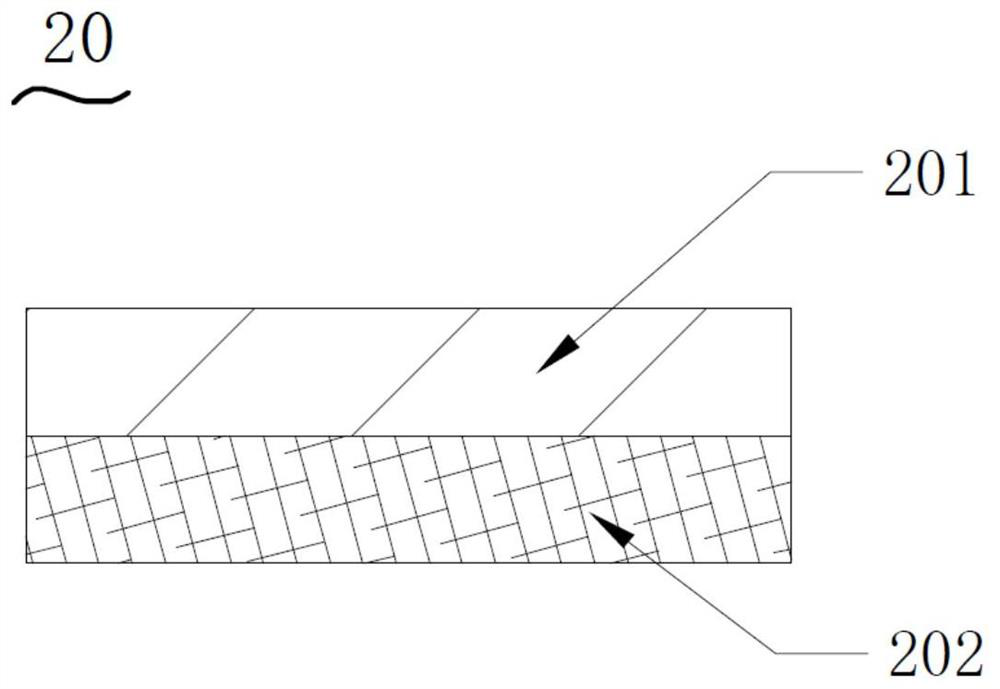

[0101] Examples of materials for the preparation of the above-mentioned unprotected prosthetic body include ultra-high molecular weight polyethylene, high-density polyethylene, polypropylene, polyethylene terephthalate, and nylon. It can be braided and formed by composite yarn, which is composed of several monofilaments, and one monofilament is composed of multiple threads.

[0102] The prosthetic sleeve obtained by adding a protective structure (preferably a coating structure) to the main body of the prosthetic sleeve is required to have good wear resistance, for example, it needs to withstand at least 5 million times of friction.

[0103] When the rotator cuff prosthesis does not include a prosthesis cover, the outer surface of the prosthesis needs to be provided with the protective structure of the present invention. At this time, the protective structure can be used as a surface layer of the prosthesis (for example, as a protective coating), and the surface layer includes ...

Embodiment 1

[0187] Example 1. Preparation of Braided Silk with PTFE Coating (for the Preparation of Balloons)

[0188] Using two winding devices, one end will convey the 20D ultra-high molecular weight polyethylene fiber, and pass through the solution tank (1 meter long) filled with aqueous polytetrafluoroethylene dispersion emulsion (solid content 30%) at a speed of 5m / min, after that Through the 120°C high-temperature blast channel (channel length 10 meters), after the water is evaporated and dried, the coating thickness is about 80 microns, and the fiber filaments enter the other end for winding, which is worth braided filaments with PTFE coating.

[0189] The braided yarn obtained in this embodiment forms a coating structure on its outer surface layer, and is braided to obtain a braided fabric. At this time, the surface of the braided fabric also has a PFTE protective layer correspondingly, which can be used as a protective structure.

Embodiment 2

[0190] Embodiment 2. Preparation of braided silk with PTFE coating (for preparing balloon cover)

[0191] Use the winder to rewind the 20D ultra-high molecular weight polyethylene fiber, place the solution tank filled with water-based polytetrafluoroethylene dispersion emulsion (solid content 30%) on the wire passage of the winder, and rewind the braided silk The solution is passed through the drum, and the rewinding speed is 30m / min, so that the surface of the braided yarn is evenly coated with polytetrafluoroethylene emulsion, and the coating thickness is about 100 microns. After the coating is completed, put a drum of yarn into an oven and heat it at 80°C Dry for 60 minutes to completely volatilize the moisture, and the coating is formed to obtain a PTFE-coated braided wire.

[0192] The braided yarn obtained in this embodiment forms a coating structure on its outer surface layer, and is braided to obtain a braided fabric. At this time, a PTFE protective layer is correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com