Filter pressing system in manganese sulfate production process

A production process and technology of manganese sulfate, applied in manganese sulfate, filtration separation, separation methods, etc., can solve the problems of inability to adjust the parameters of the filter press conditions, fix the filter press effect, etc., to facilitate maintenance and technology upgrades, avoid production waste, The effect of expanding the usable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

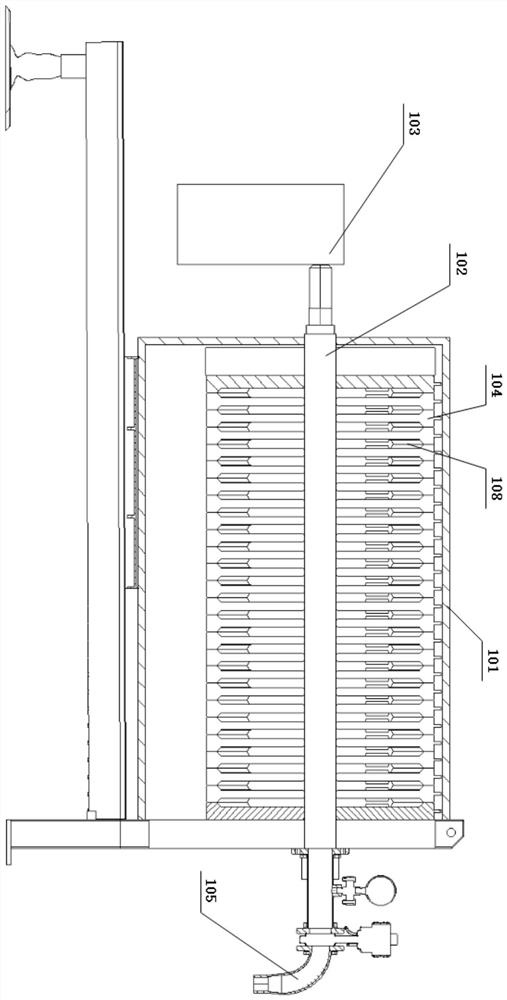

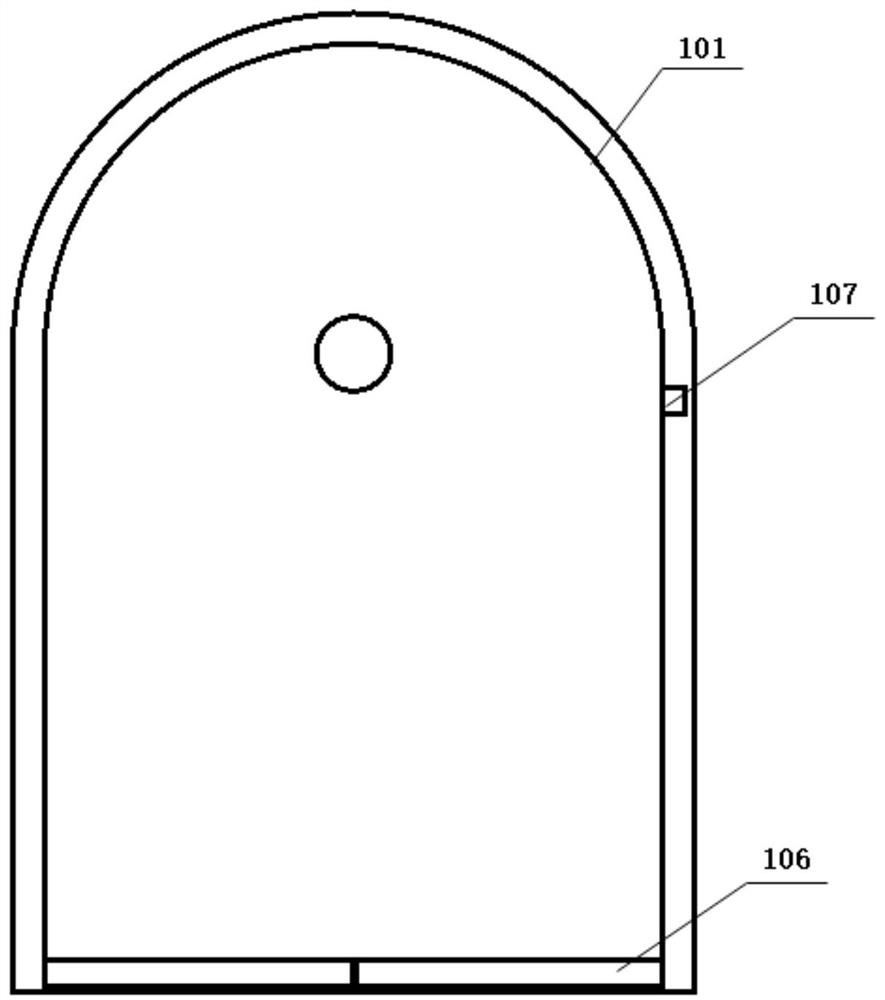

[0033] as attached figure 1 , a filter press system in the production process of manganese sulfate, the filter press system includes a pressure tank 101, a pressurization device, a moisture measurement module and a control system; the pressure tank forms a sealed working space and is formed by an air compressor High-pressure space; the pressurization device includes a screw compression rod 102, a plurality of filter press plates 104 and a driving device 103; the screw compression rod 102 rotates under the power of the driving device 103, thereby opening the compression stroke and compressing A plurality of filter press plates 104; the filter press plates 104 are used to filter the moisture in the pulp and guide the moisture to the collection container; the moisture measurement module enters the filter press chamber 108 with the pressure increase in the latter part of the filter press , and measure the water content in the filter residue; the control system is connected to the ...

Embodiment 2

[0048] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements on the basis thereof;

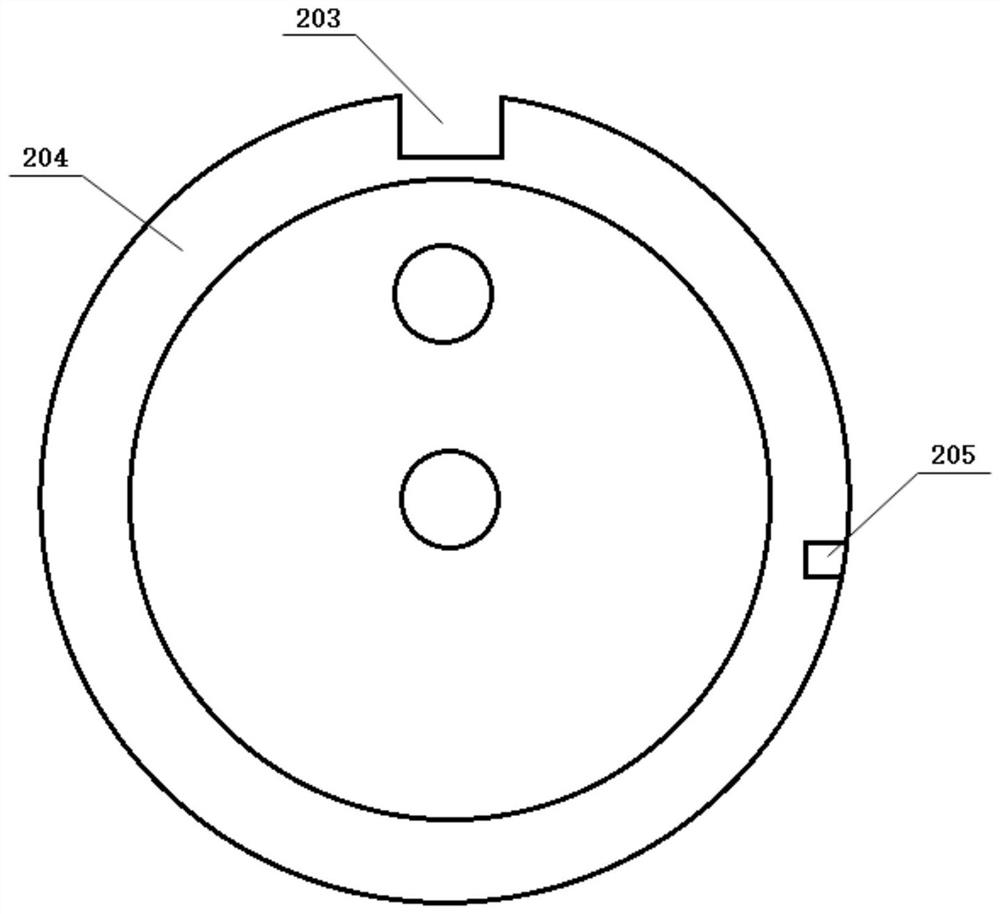

[0049] In the compression stroke of the filter press system, due to the need to compress the plate shoulder 204 with a strong pressure, the pressure reaches 4 to 5Mpa and maintains it for a period of time, which will easily cause excessive loss of the plate shoulder 204; The pressing time directly affects the total duration of the pressing process, so the moisture measurement module is used to measure the water content of the filter residue to further optimize the overall pressing process;

[0050] The moisture measurement module can measure the water content in the filter residue without contact by using the principle of high-frequency microwave; microwave is a kind of high-frequency electromagnetic wave, and the attenuation and phase change generated when microwave penetrates the medium are mainly determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com