A sheet metal laser cutting fixture for ship electrical box shell for high-end equipment manufacturing

A laser cutting and equipment technology, applied in manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problem of inability to fix the electric box shell, and achieve the effect of avoiding normal processing, improving quality, and reducing sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

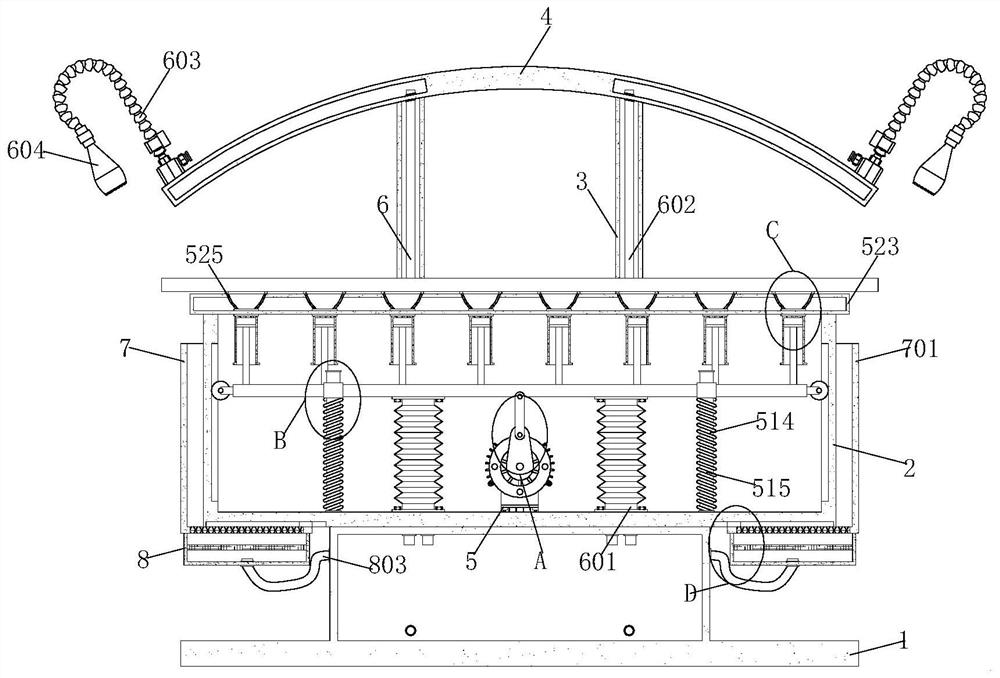

[0036] see Figure 1-8 , the present invention provides a technical solution: a sheet metal laser cutting jig for a marine electrical box shell for high-end equipment manufacturing, including a water tank 1, a fixing mechanism 5, a cooling mechanism 6, a collection mechanism 7 and a filtering mechanism 8, the top of the water tank 1 A placement slot 2 is fixedly installed, the front side of the placement slot 2 is fixedly connected with a water inlet pipe, and one end of the water inlet pipe extends to the inside of the placement slot 2. The rear side of the water tank 1 is fixedly installed with two sets of return plates 3, and two sets of return plates. The top of 3 is fixedly installed with a hollow curved plate 4, and the fixing mechanism 5 is located inside the placing slot 2. The fixing mechanism 5 includes a driving component 51 and an adsorption component 52. The mechanism 6 is arranged on the placement tank 2 and the hollow curved plate 4. The cooling mechanism 6 incl...

Embodiment 2

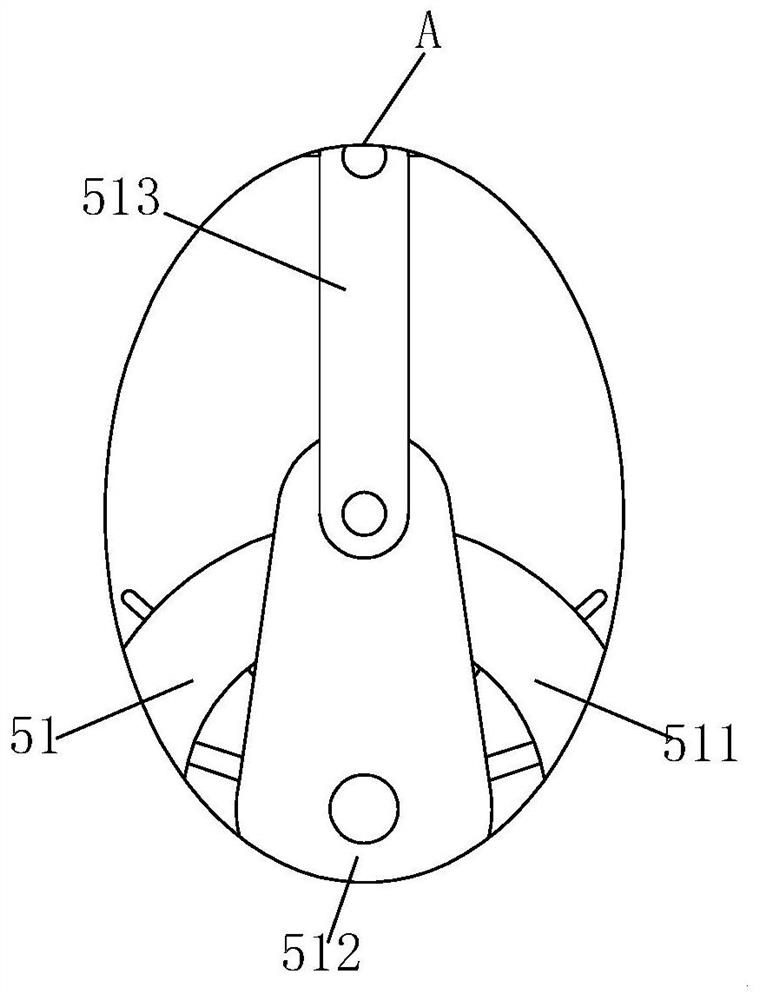

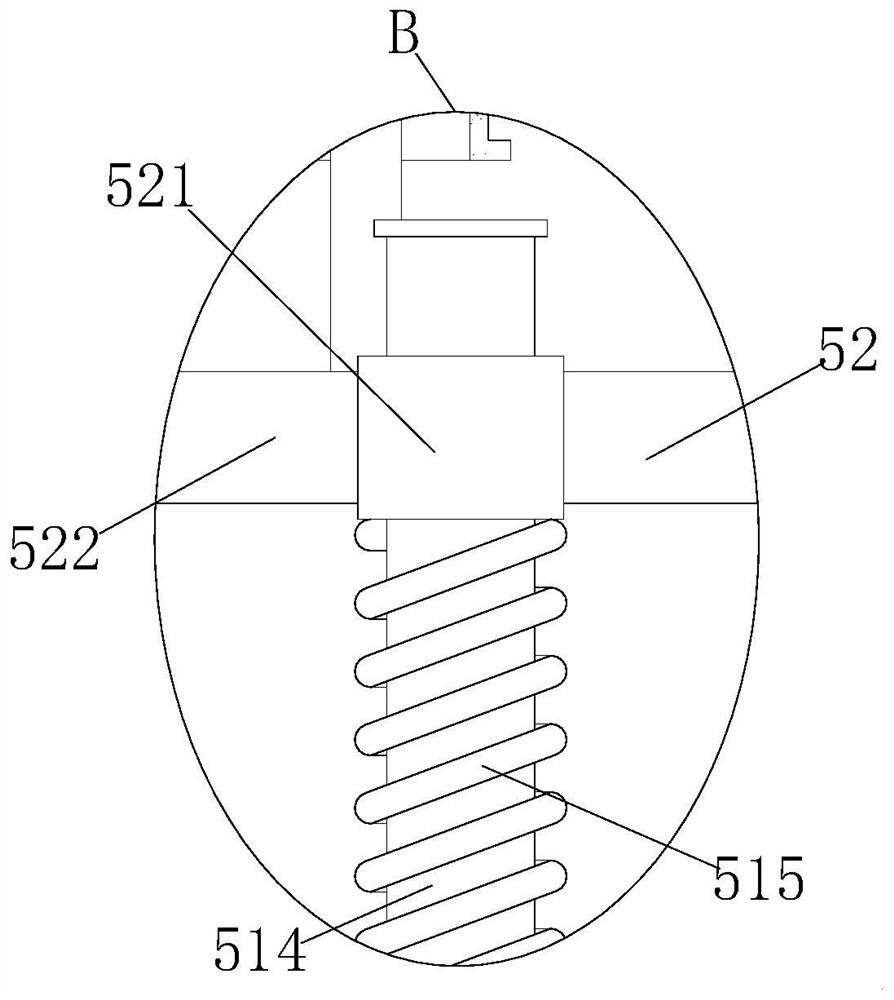

[0038] see Figure 1-8 On the basis of the first embodiment, the drive assembly 51 includes a motor 511, an eccentric wheel 512, a hinge plate 513, a sliding rod 514 and a telescopic spring 515. The number of the sliding rod 514 and the telescopic spring 515 has four groups. The rear side of the eccentric wheel 512 is fixedly connected to the output shaft of the motor 511, the rear side of the hinge plate 513 is hingedly installed with the front side of the eccentric wheel 512, and one end of the four sets of sliding rods 514 They are all fixedly connected to the inner bottom of the placement slot 2. The four groups of telescopic springs 515 are respectively sleeved on the outer walls of the four groups of sliding rods 514. The adsorption assembly 52 includes a sliding rod sleeve 521, a horizontal plate 522, a horizontal hollow plate 523, and a sleeve 524. , suction cup 525, piston 526 and connecting rod 527, the number of sliding rod sleeves 521 has four groups and the four g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com