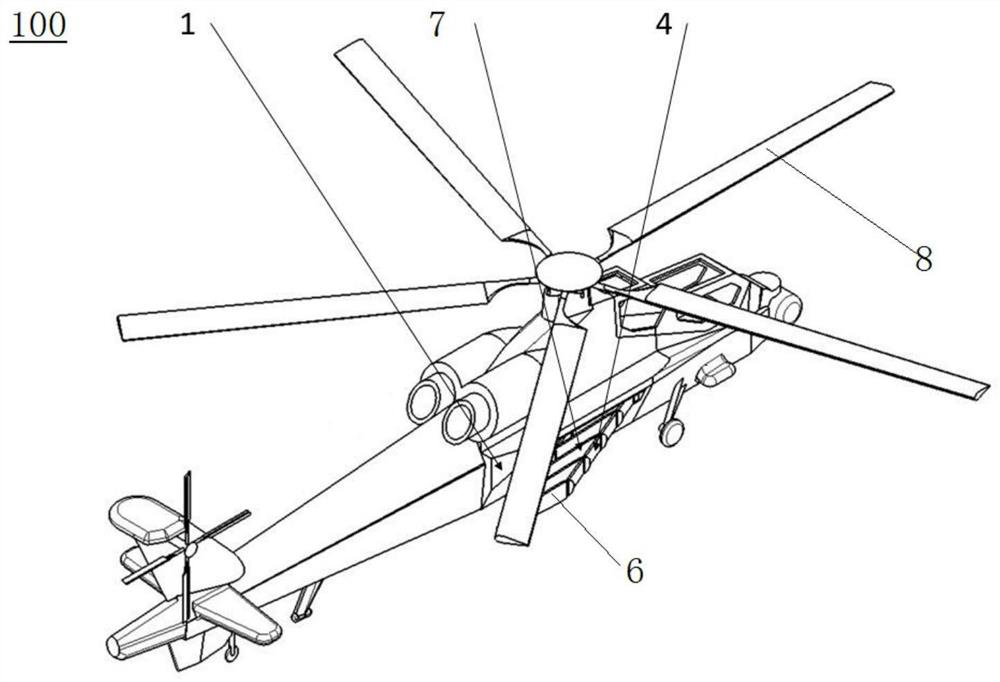

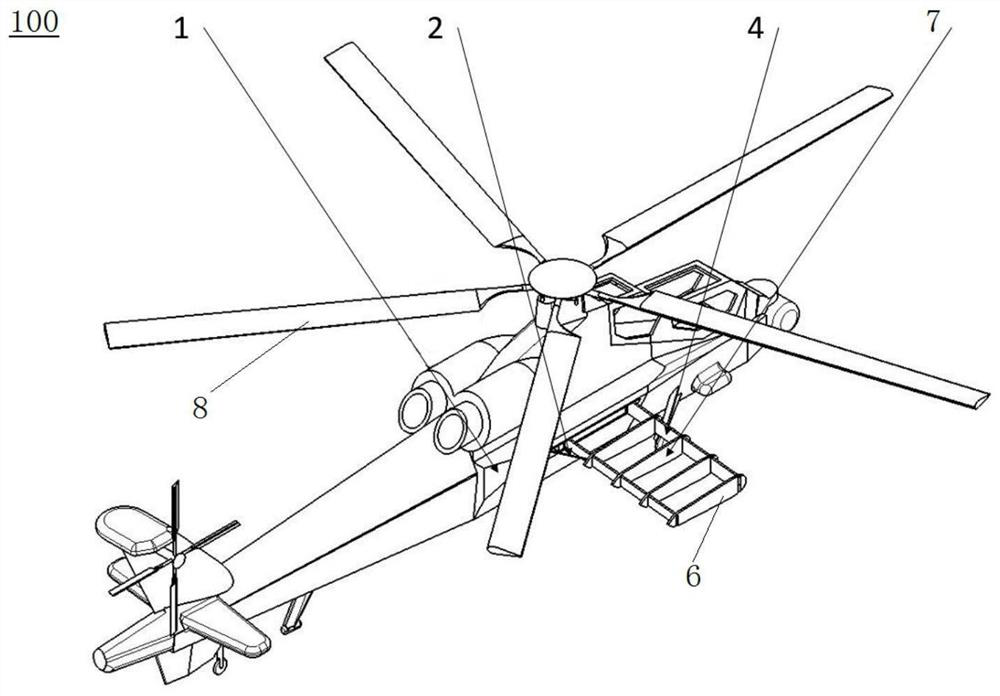

Conventional layout helicopter and flight control method

A helicopter and layout technology, applied in the aviation field, can solve problems such as reducing aerodynamic efficiency, achieve high forward flight speed, and increase forward flight speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

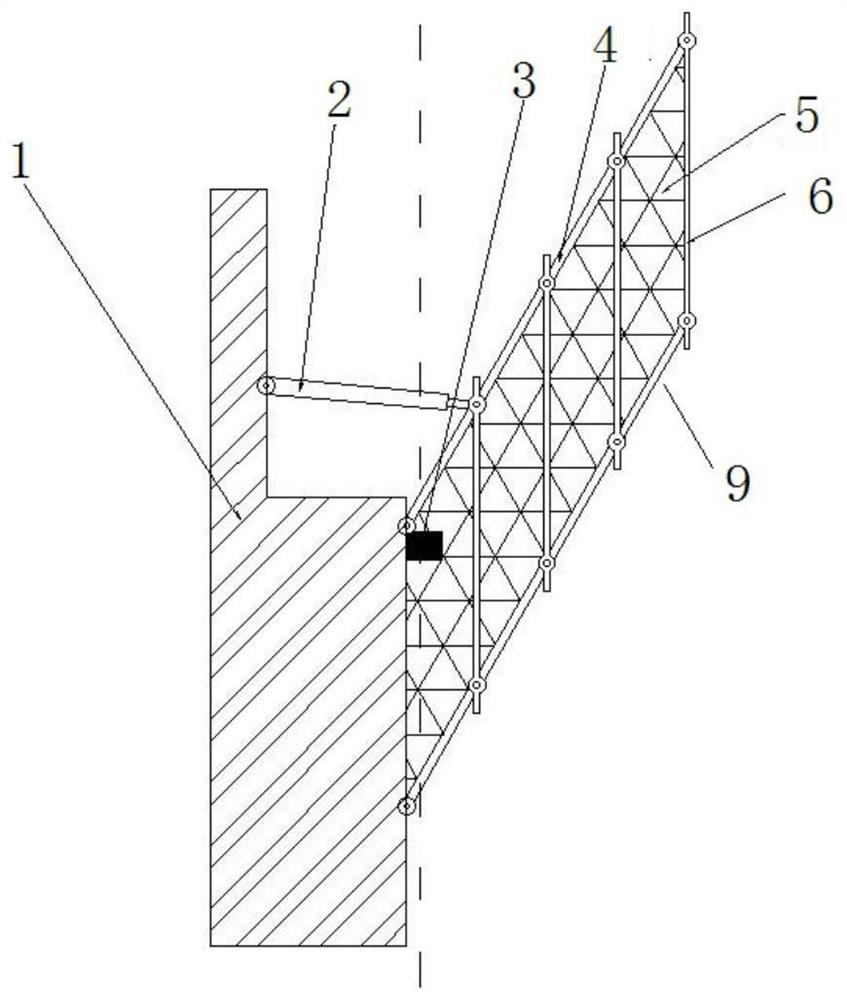

[0045] The present embodiment provides a flight control method of a conventional layout helicopter 100, comprising the following steps:

[0046] S1. Obtain the current rolling moment Mb and the maximum rolling moment M of the short wings of the conventional layout helicopter 100 bmax , Minimum rolling moment M bmin and the current roll moment M of the ABC single rotor 8 r ;

[0047] S2. Judging the current rolling moment M of the ABC single rotor 8 r The current roll moment M with the short wing b , the maximum rolling moment M bmax , Minimum rolling moment M bmin size relationship;

[0048] S31. When the current rolling moment M of the ABC single rotor 8 r Greater than the maximum rolling moment M of the short wing bmax , obtain the rolling moment that needs to be reduced by the ABC single-rotor 8, expand the frame assembly 9 to the maximum and reduce the rolling moment of the ABC single-rotor 8 to the target value, specifically, the target value is the maximum rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com