Leveler with residual coal collection mechanism

A collection mechanism and coal leveling device technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of difficult coal collection in the collection tank, inevitable coal waste, fixed volume of the collection tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

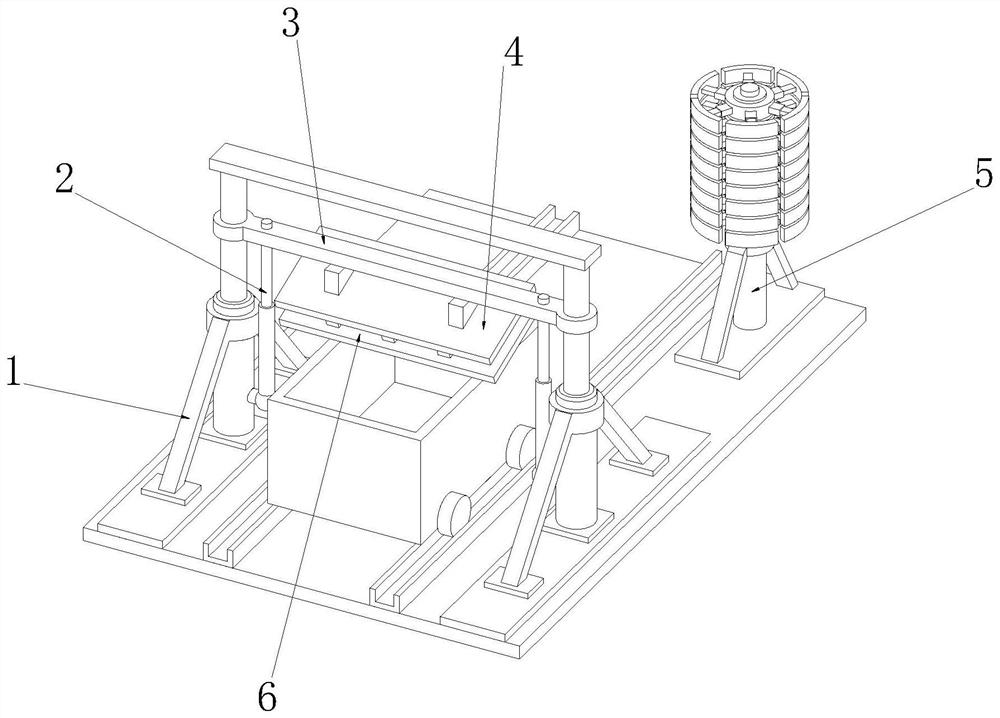

[0041] see Figure 1-4 As shown, the coal flatter with residual coal collection mechanism includes a bracket 1, a lifting rod 2, a support plate 3 and a flat coal plate 4, the inner wall of the bracket 1 is connected with the lifting rod 2, and the upper side wall of the lifting rod 2 is connected with the supporting plate 3 , a flat coal plate 4 is connected to the middle position of the lower surface of the support plate 3;

[0042] The lifting rod 2 connected to the support 1 can adjust the height of the support plate 3 under the control of the control equipment after the infrared detection equipment of the leveler detects the height of the train carriage, so that the leveling coal connected to the lower surface of the support plate 3 Plate 4 can carry out level coal operation to the passing train carriage;

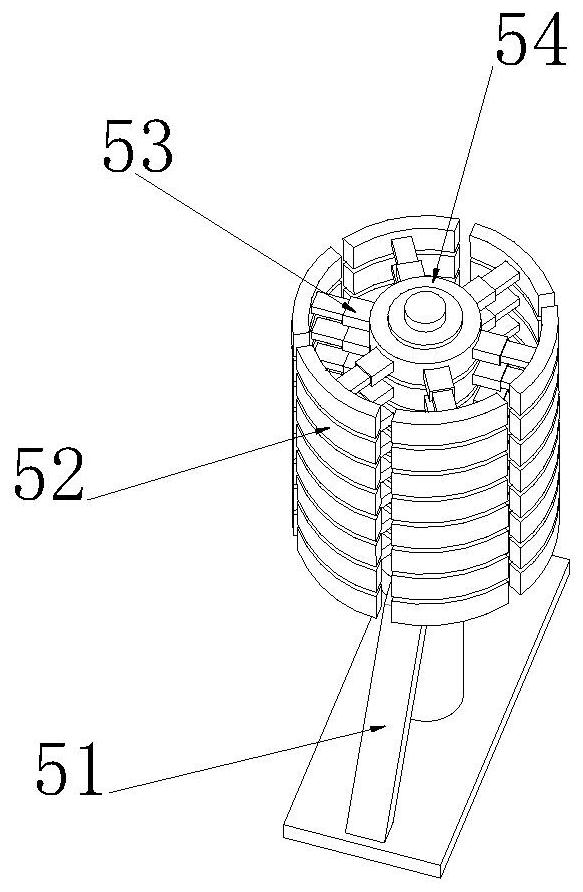

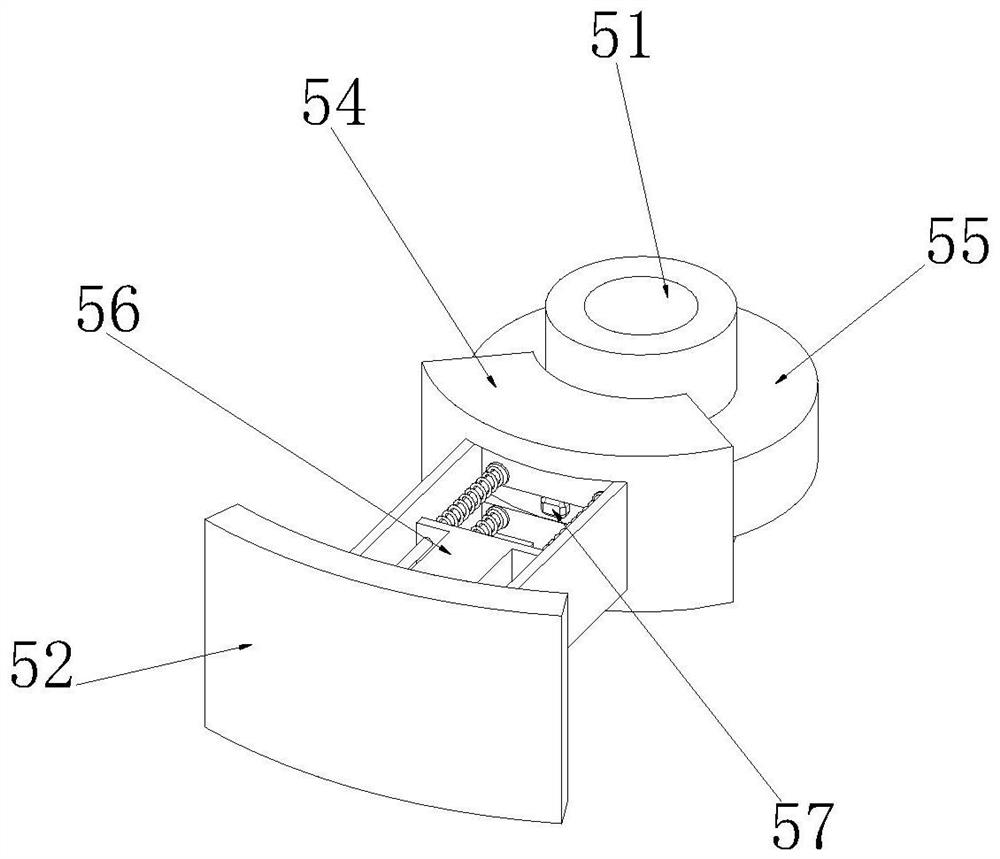

[0043] One side behind the support 1 is provided with a height-measuring mechanism 5, the height-measuring mechanism 5 includes a support frame 51, and several evenly...

Embodiment 2

[0046] When the leveling coal plate 4 is performing the operation of leveling the coal in the train carriage, the coal that is positioned on both sides of the train carriage and is higher than the train carriage is easy to slide down from the side of the train carriage under the flat push of the leveling coal plate 4, and is located in the middle of the train carriage. The coal that is higher than the train compartment at the position is easy to slide down from the opposite direction position of the train compartment under the flat push of the flat coal plate 4, causing the loss of coal resources;

[0047] see Figure 5-7 As shown, the lower surface of the flat coal plate 4 is provided with a collection mechanism 6, the collection mechanism 6 includes an adjustment plate 62, and one end of the adjustment plate 62 is integrally formed with an extrusion plate 61, and the inclined extrusion plate 61 can squeeze each other after contacting the train carriage. pressure, so that the...

Embodiment 3

[0050] The coal loaded in the train car is unevenly distributed, so that after the flat coal plate 4 performs the coal leveling operation on the train car, part of the coal falls from both sides of the train car, and the middle concave position cannot be supplemented with coal. The coal loaded in the train car amount reduced;

[0051] see Figure 8-9 As shown, a coal return mechanism 7 is provided on both sides of the lower surface of the coal collection box 63, and the coal return mechanism 7 includes a blanking box 72, and a drive motor 73 is connected to one side of the outer wall of the blanking box 72, and a drive motor 73 is connected to the lower surface of the blanking box 72. Return pipe 74, the inner side wall of return pipe 74 is rotatably connected with shaftless auger 75, the outer side wall of blanking box 72 is connected with transmission box at the position corresponding to driving motor 73, and the rotating shaft on the output end of driving motor 73 inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com