Industrial wastewater treatment equipment convenient to install and maintain

A technology for treating equipment and industrial wastewater, which is applied in the process of wastewater treatment, water/sewage treatment equipment, water/sewage treatment, etc. Cleaning is not clean and other problems, to achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiment of the present invention is as follows:

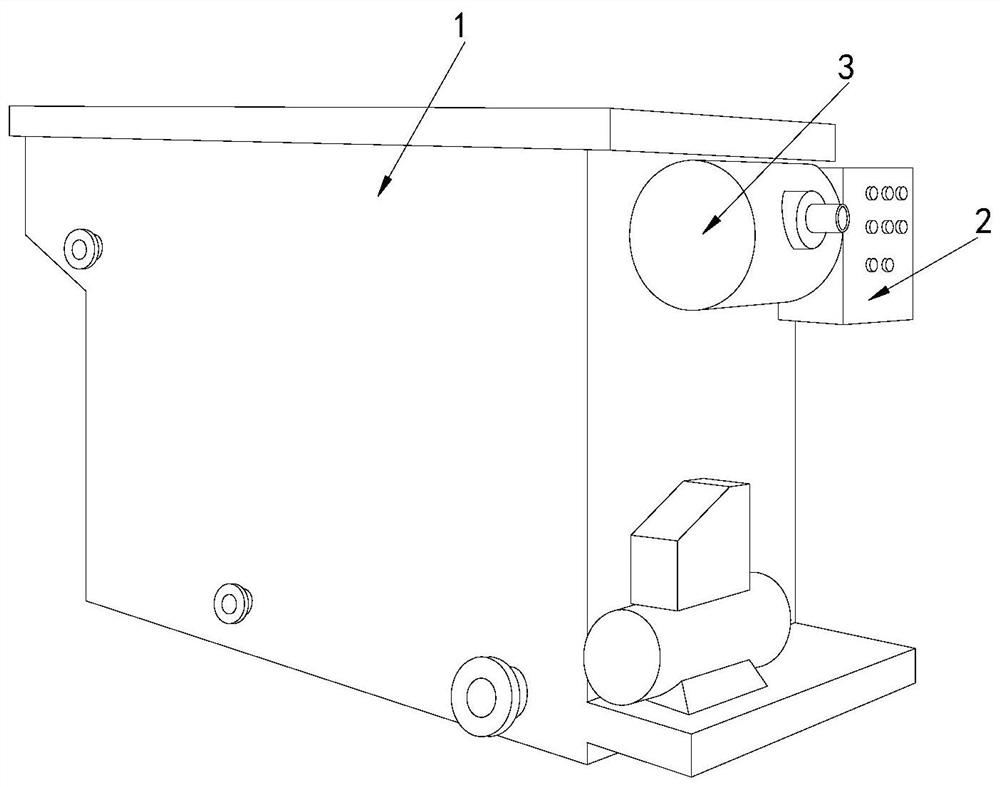

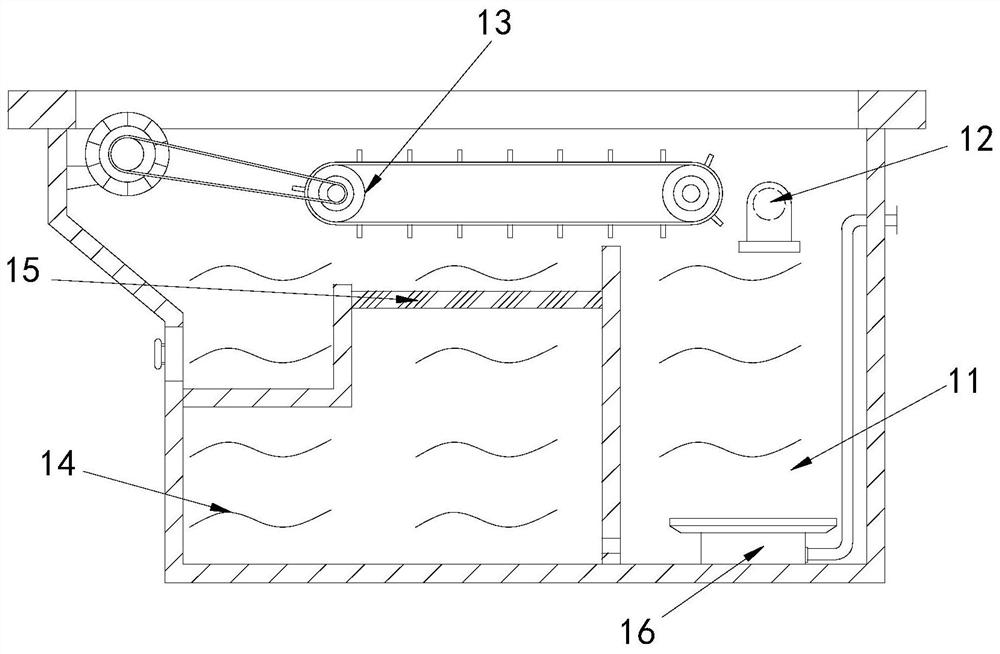

[0029] Its structure includes a main body 1, a control panel 2, and an air pump 3. The side end of the main body 1 is provided with a control panel 2, and the air pump 3 is installed at the front end of the control panel 2. The main body 1 includes an adjustment pool 11 and a water inlet 12. , the material guide belt 13, the reservoir 14, the filter device 15, the foaming machine 16, the adjustment tank 11 is arranged on the inner right side of the main body 1, the water inlet 12 is located at the rear end of the adjustment tank 11, the said The material guide belt 13 is laterally installed on the inner top of the main body 1 , the reservoir 14 is located on the left inner side of the main body 1 , the filter device 15 is laterally installed on the top of the reservoir 14 , and the foam generator 16 is arranged on the The inner bottom end of the tank 11 is ...

Embodiment 2

[0035] Example 2: Please refer to Figure 7-Figure 9 , the specific embodiment of the present invention is as follows:

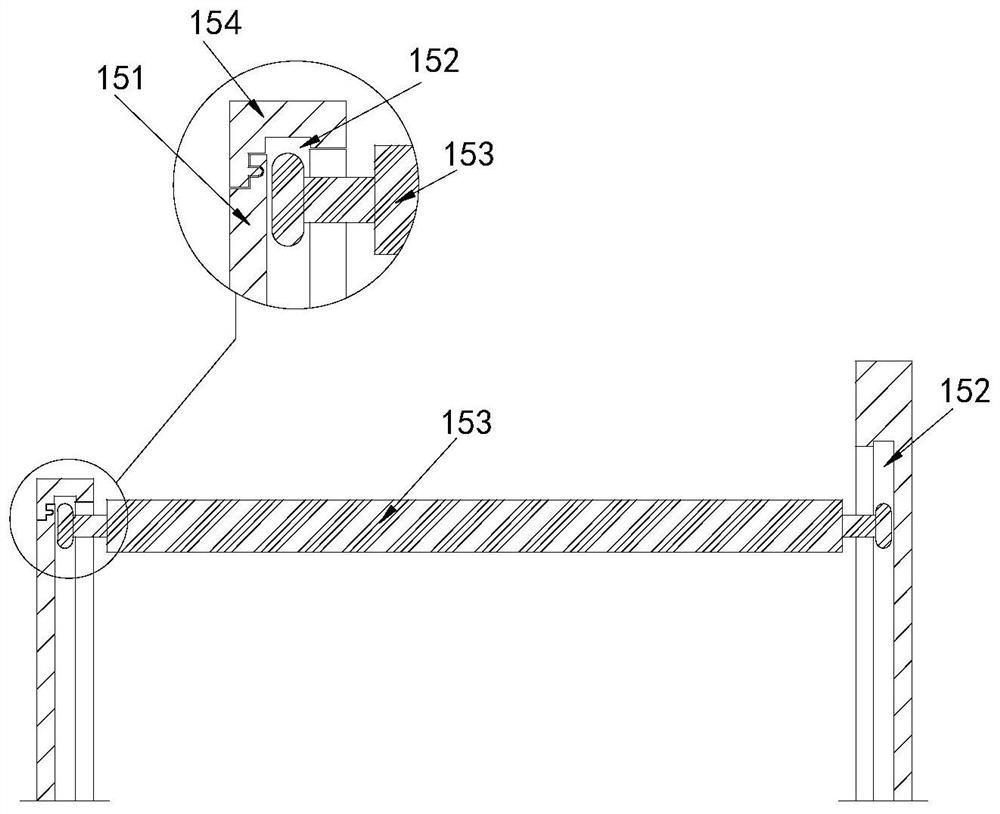

[0036] The filter material plate a3 includes a filter material body c1, a clamping slot c2, and a clamping hook c3. The filter material body c1 is provided with four, and is laterally arranged on the end face of the frame a1, and the clamping groove c2 is provided with eight. And in a group of four, horizontally arranged at the front and rear ends of the frame a1, the hooks c3 are provided with two, and they are respectively arranged on the front and rear ends of the filter body c1. The hooks c3 and the slots c2 are movable. The snapping is beneficial to fix the filter material body c1 in the snap groove c2 through the snap hook c3, which is convenient for installation and dismounting.

[0037] The filter material body c1 includes a filter board c11, a water filter tank c12, a filter screen a13, and a paper storage tank a14. The upper end of the filter boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com