Maotai-flavor flavoring liquor and preparation method thereof

A sauce-flavored liquor and a sauce-flavored technology, applied in the field of liquor, can solve the problems of limited beneficial microorganisms, lack of sauce-flavored flavor, and unfavorable synthesis of special flavor substances, so as to promote aroma production, increase flavor, and benefit the development of sauce-flavored The effect of body material transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of sauce-flavored seasoning wine of the present invention is as follows:

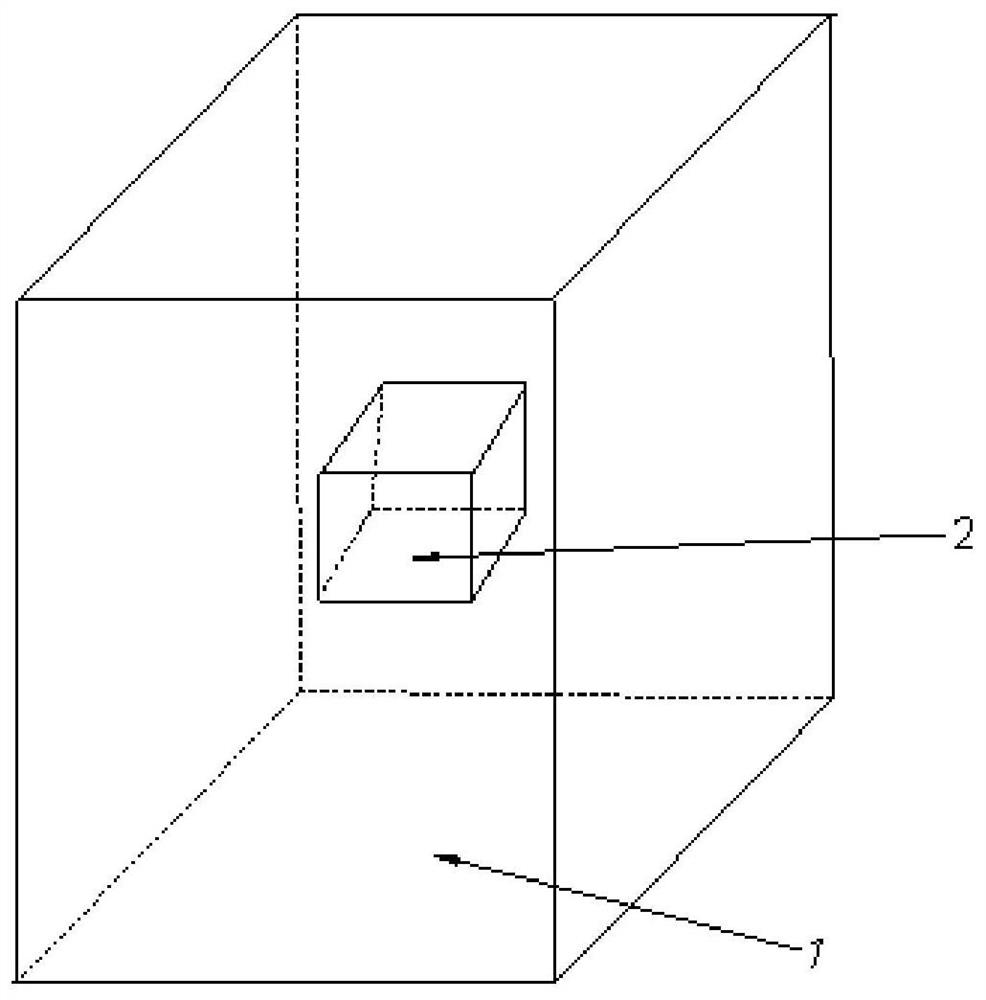

[0042]Select high-quality high-temperature Daqu with outstanding sauce aroma, and heat it at a constant temperature of 50-70°C for 2-8 hours to make rejuvenating koji medicine for use; choose old straw curtains with a thickness of 3-8cm and regular shapes that have not been damaged from the koji storage room. Spray 2-10kg tail wine water first, then sprinkle 5-15kg rejuvenating koji medicine and 5-15kg 37℃ water for microbial inoculation; then select between the third and fifth rounds of fermentation in the production process of ordinary sauce-flavored liquor To pile up the saccharified saccharification heap, take 50-60 ℃ fermented grains (500-700kg) and add 36-90kg rejuvenating koji medicine and 36-72kg 37 ℃ water, after mixing evenly, make Maotai-flavored seasoning distiller's grains; Dig the surface of ordinary Maotai-flavored distiller's grains from the middle of the ce...

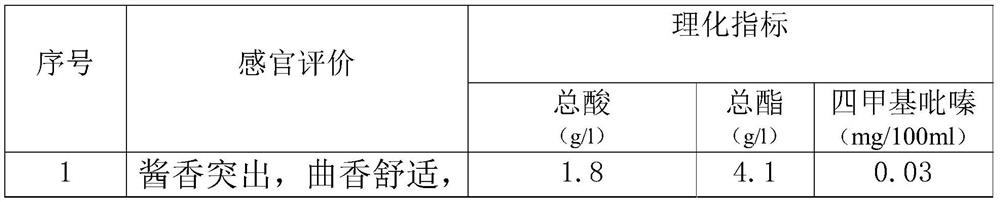

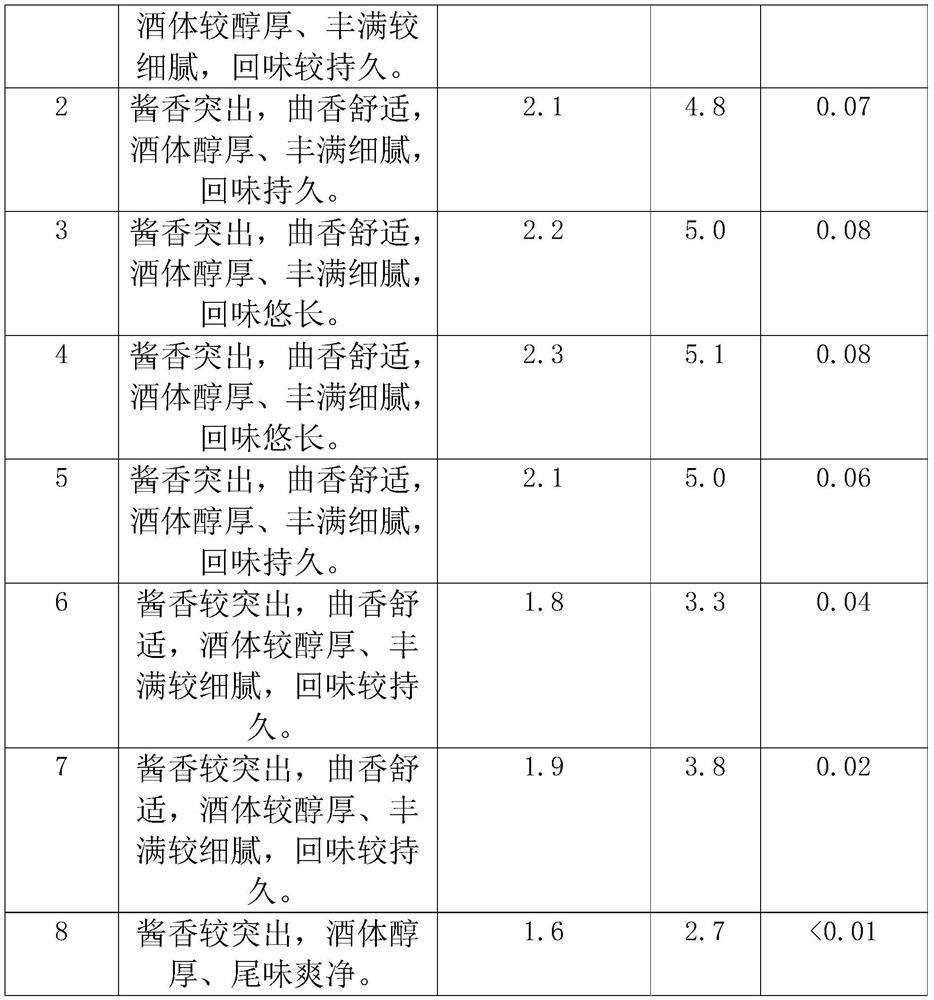

Embodiment 1

[0044] Select high-quality high-temperature Daqu with outstanding sauce aroma, and select old straw curtains with a thickness of about 5cm and regular shape that have not been damaged from the storage room. Each straw curtain is first sprayed with 8kg of tail wine, and then sprinkled with 10kg of high-quality high-temperature Daqu and 10kg of 37℃ water for microorganisms Inoculate; then select the saccharification heap accumulated in the third round of saccharification in the production process of ordinary Maotai-flavored liquor, take 600 kg of 55 ℃ fermented grains under the 45 cm bacterial layer on the surface of the saccharification heap with a height of 80 cm, and add 48 kg of high-quality high-temperature Daqu and 48kg of water at 37°C are mixed evenly to make a sauce-flavored distiller's grains; the surface of the ordinary sauce-flavored distiller's grains that enters the cellar to the middle of the cellar is cut into grooves, and the volume of the groove is 1% of the volu...

Embodiment 2

[0046] Select high-quality high-temperature Daqu with outstanding sauce aroma, and heat it at a constant temperature of 50°C for 2 hours to make a rejuvenating koji medicine for use; select old straw curtains with a thickness of about 5cm and regular shapes that have not been damaged from the koji storage room, and spray 2kg tailings on each straw curtain first. Sprinkle 5kg of rejuvenating koji medicine and 5kg of water at about 37°C for microbial inoculation; then select the saccharification heap that has been saccharified in the third round during the production process of ordinary Maotai-flavored liquor, and place the saccharification heap on the surface of the saccharification heap with a height of 140cm. Take 600kg of 55°C distiller's grains under the 45cm bacterial layer, add 36kg of rejuvenating koji medicine and 36kg of 37°C water, and mix well to make a sauce-flavored seasoning distiller's grains; put the ordinary sauce-flavored distiller's grains in the middle of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com