Gluing device and method for viscose cotton yarn

A glue coating device and viscose cotton technology, applied in the field of cotton yarn processing, can solve the problems of glue coagulation and deterioration, and achieve the effect of maintaining continuous operation, reducing contact time and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

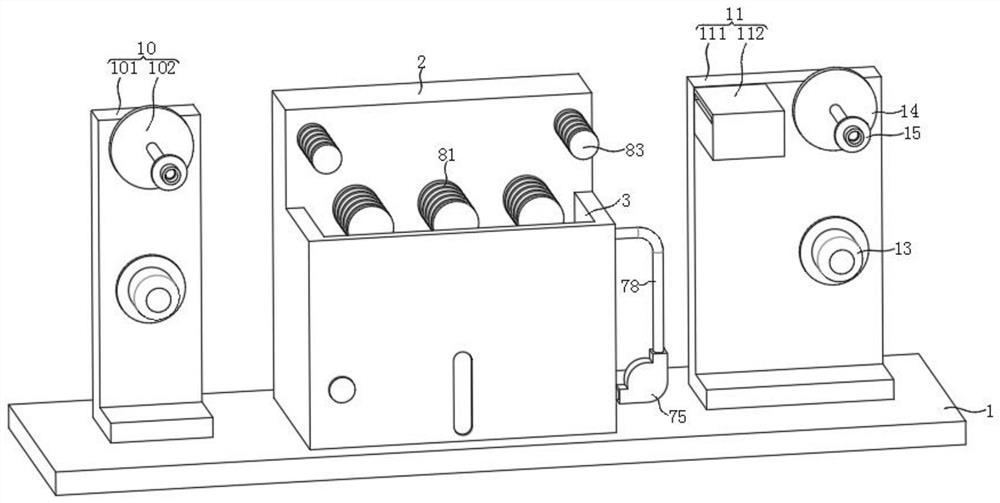

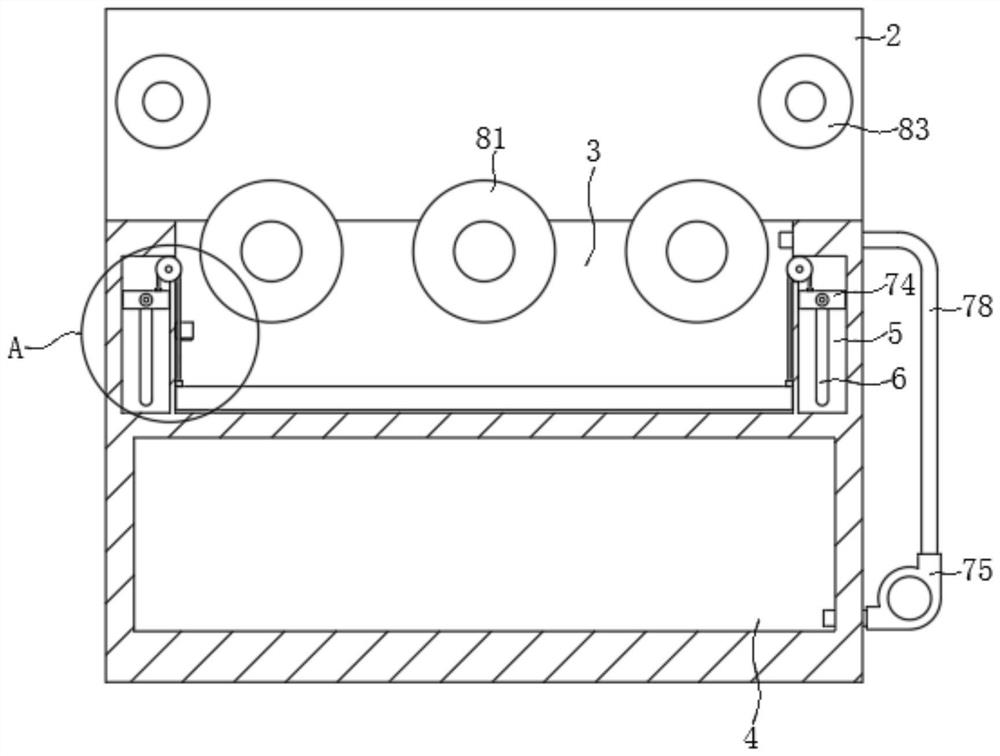

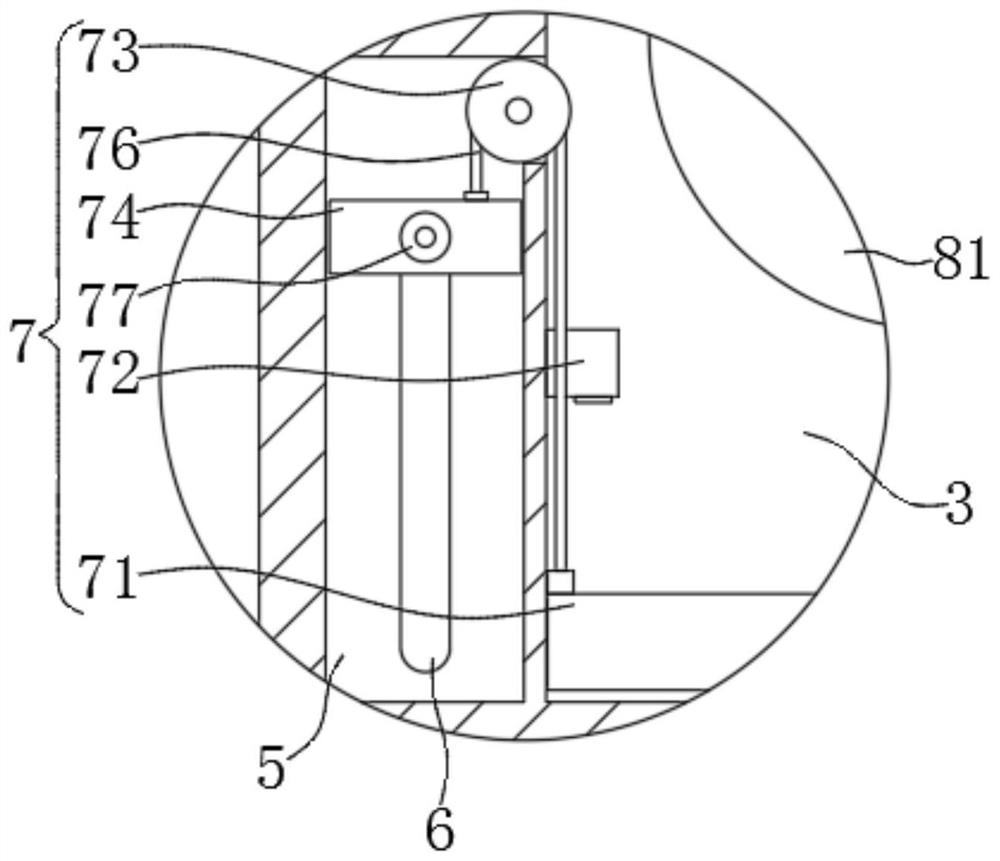

[0053] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 ,in, figure 1 The structural representation of the gluing device of the viscose cotton yarn provided by the present invention; figure 2 forfigure 1 The schematic diagram of the structure inside the gluing box shown; image 3 for figure 2 The enlarged schematic diagram of part A shown; Figure 4 for figure 1 The structure schematic diagram of the back of the gluing box shown; Figure 5 for figure 1 The schematic diagram of the side structure of the gluing box shown; Figure 6 It is a schematic diagram of the state of the viscose cotton yarn gluing device provided by the present invention in use. Gluing device for viscose cotton yarn, including:

[0054] base1;

[0055] A gluing box 2, the gluing box 2 is fixedly installed on the top of the base 1, a gluing groove 3 is opened on the top of the gluing box 2, and a storage room 4 is opened inside the gluing box 2, Both sid...

no. 2 example

[0081] Please refer to Figure 7 and Figure 8 , based on the first embodiment of the present invention, a viscose cotton yarn gluing device and method, the second embodiment of the present invention provides another viscose cotton gluing device and method, wherein, the second embodiment does not It will hinder the independent implementation of the technical solution of the first embodiment.

[0082] Specifically, the present invention provides another gluing device for viscose cotton yarn and the difference in the method is:

[0083] The gluing box 2 is provided with a stirring structure 12, the stirring structure 12 includes three stirring members 121, the stirring members 121 rotate inside the storage chamber 4, the outside of the stirring member 121 is located in the A third transmission wheel 122 is fixedly installed inside the device slot 9, and the third transmission wheel 122 is connected to the outside of the first transmission wheel 84 through a transmission belt. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap