Flow equalizing adjusting plate for heat pump dryer

A drying machine, flow adjustment technology, applied in the direction of drying machine, drying, drying gas arrangement, etc., can solve the problems of uneven air flow and reduce air flow unevenness, so as to reduce unevenness and improve treatment efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

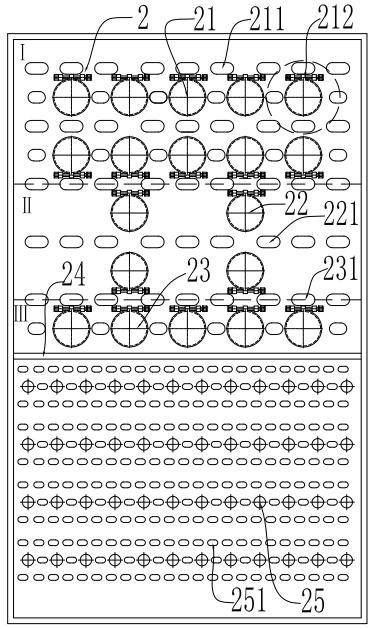

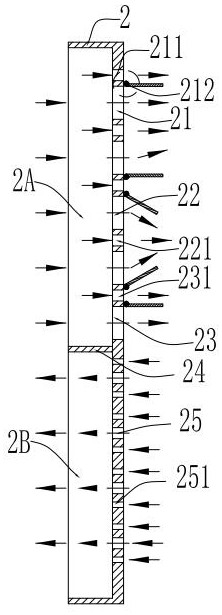

[0034] Such as figure 1 , figure 2 As shown, a flow equalizing plate for a heat pump dryer includes a plate body 2, a first air outlet through hole 21, a second air outlet through hole 22, a third air outlet through hole 23, a partition 24, and a return air The through hole 25 and the dividing plate 24 divide the plate body 2 into two parts, the air outlet and the return air, according to the air flow direction. The air outlet part is arranged on the upper part of the plate body 2; The lower part is separated by a partition 24;

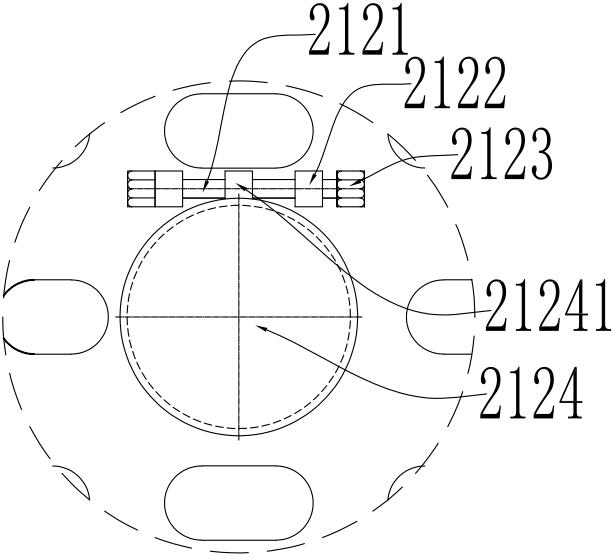

[0035] In the air outlet part of the sheet body 2, from top to bottom, the first air outlet through hole 21, the second air outlet through hole 22, and the third air outlet through hole 23 are arranged in sequence, along the center of the first air outlet thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com