Intelligent freeze-thaw cycle test device

A freeze-thaw cycle and test device technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems that affect the accuracy of test results, increase the error probability, and consume a lot of manpower, so as to avoid human interference factors and improve Quality and efficiency, to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

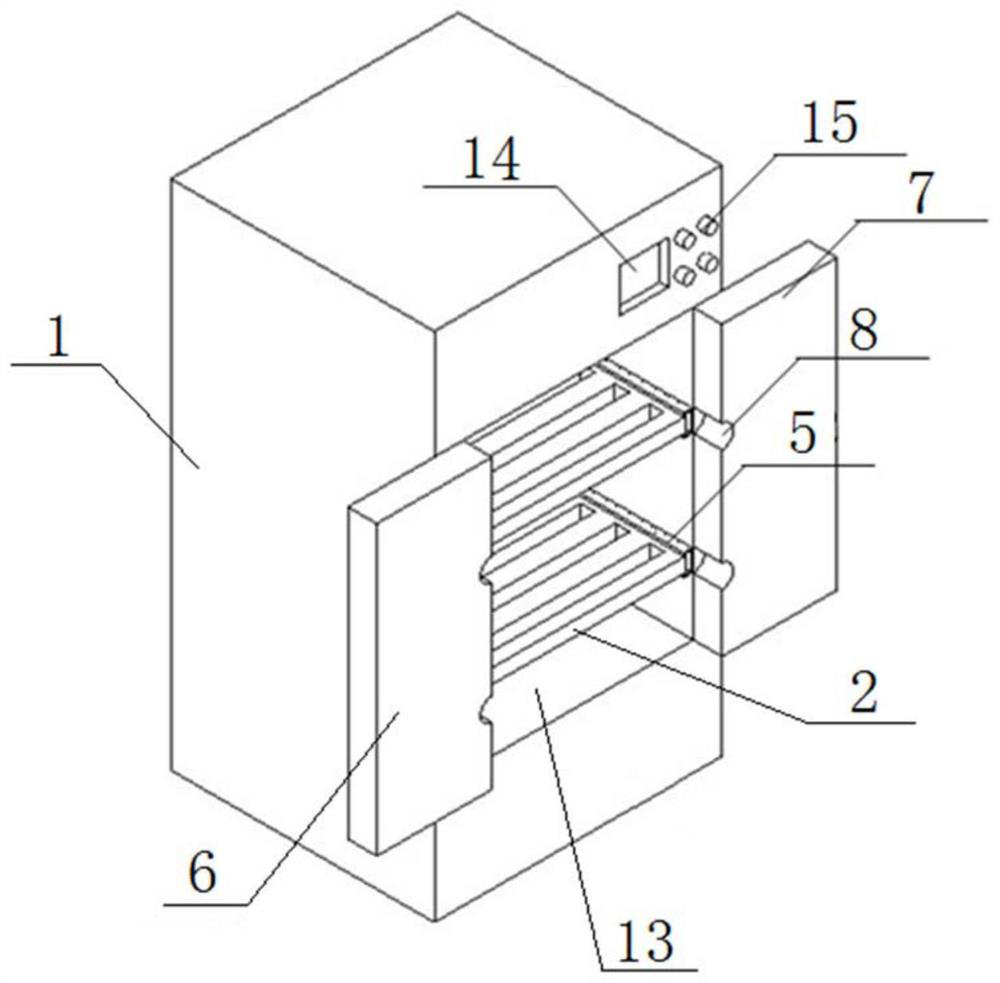

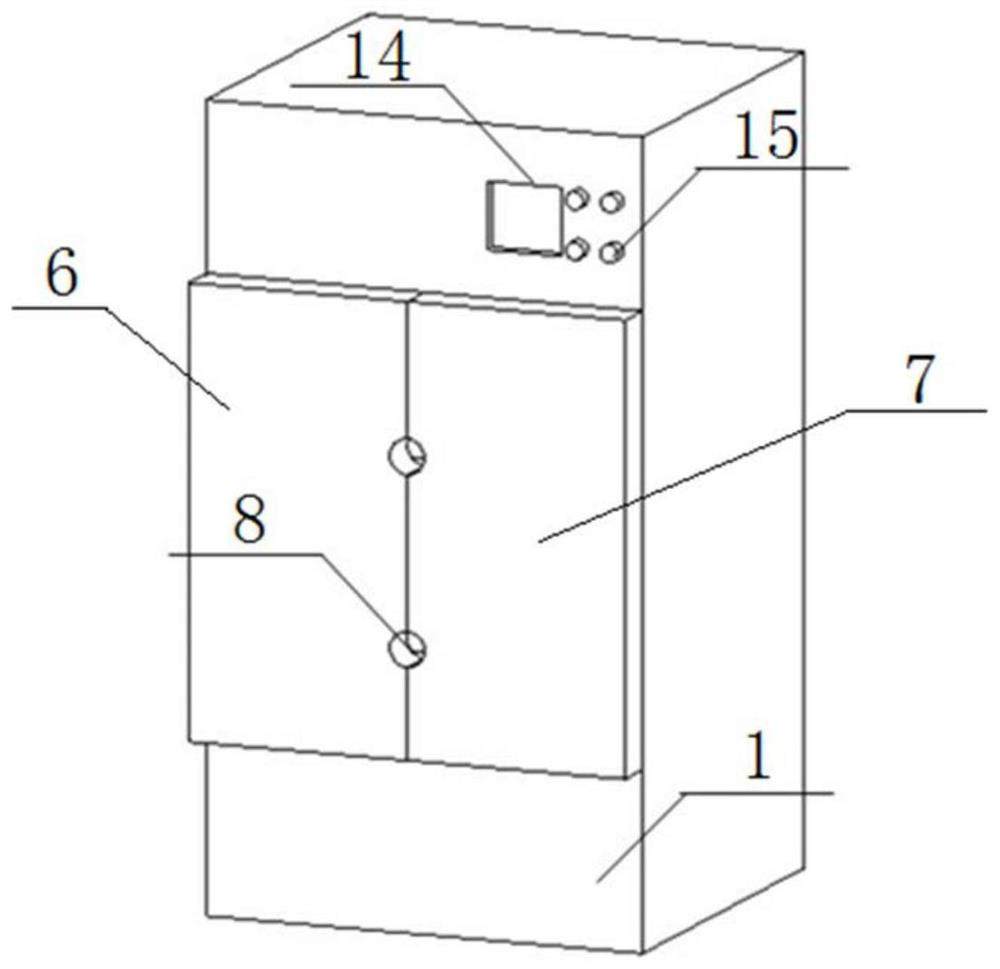

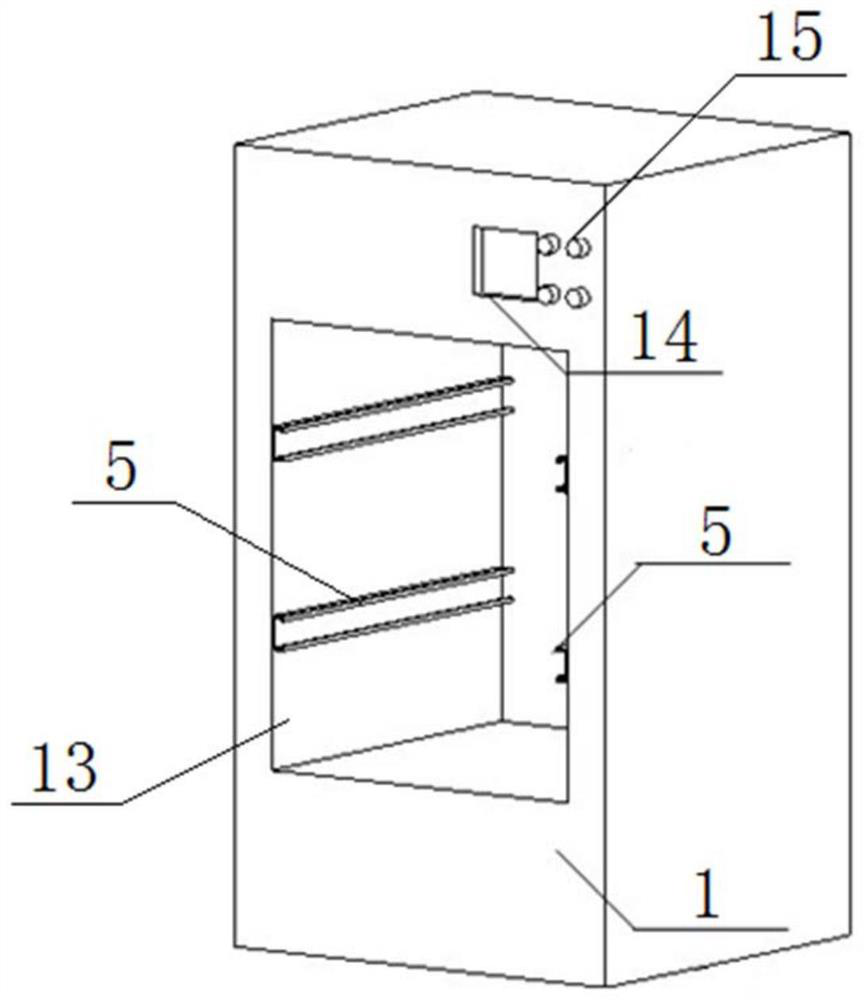

[0030] Such as figure 1 , figure 2 The shown intelligent freeze-thaw cycle test device includes a freeze-thaw cycle test chamber 1, at least two telescopic sample tray mechanisms arranged side by side in the freeze-thaw cycle test chamber 1 from top to bottom, and a telescopic sample tray mechanism A matching telescopic control system and a combined automatic door arranged on one side of the freeze-thaw cycle test chamber 1 and adapted to the telescopic sample tray mechanism.

[0031] Wherein, in the freeze-thaw cycle test chamber 1, two retractable sample tray mechanisms are arranged side by side one above the other.

[0032] The retractable sample tray mechanism includes a sample tray 2 horizontally arranged in the freeze-thaw cycle test chamber 1 and a telescopic rod 3 arranged at the end of the sample tray 2 , and the telescopic control system is adapted to the telescopic rod 3 . Both sides of the sample tray 2 are provided with rollers 4, such as image 3 As shown, th...

Embodiment 2

[0037] Adopt the device among the embodiment 1 to carry out the freeze-thaw cycle test of concrete, process is as follows:

[0038] First mix the formed concrete. Concrete is the mortar used in construction engineering. It is mainly composed of cementitious materials, coarse aggregate, fine aggregate and water in a certain proportion. The performance of building concrete materials can be adjusted according to building requirements and relevant specifications. The formulation and properties of the concrete are not limited.

[0039] After the concrete is molded and maintained, put it into two sample trays 2 respectively, and set the temperature, cycle time, and cycle times required for the freeze-thaw cycle through the control panel 14 . In this example, the low temperature of sample A is set to -20°C, the high temperature is set to 50°C, the cycle time is set to 6h, and the number of cycles is 500 times; the low temperature of sample B is set to -20°C, and the high temperature...

Embodiment 3

[0044] Adopt the device among the embodiment 1 to carry out the freeze-thaw cycle test of concrete, process is as follows:

[0045] After the concrete is molded and maintained, put it into two sample trays 2 respectively, and set the temperature, cycle time, and cycle times required for the freeze-thaw cycle through the control panel 14 . In this embodiment, samples C and D are set as follows: the low temperature is -20°C, the high temperature is room temperature, the cycle time is 5 hours, and the number of cycles is 500 times.

[0046] In this embodiment, the freeze-thaw cycle test chamber 1 only uses the low-temperature freezing function, and the thawing step is realized at room temperature outside the device.

[0047] (a) After freezing for 5 hours, the time controller 10 controls the upper contact of the electromagnetic relay 11 to contact the upper contact plate 12, the upper telescopic rod 3 starts to stretch out, and the combined automatic door opens automatically, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com