Solid electrolyte, preparation method thereof, protected positive electrode comprising same, electrochemical cell and electrochemical device

A solid electrolyte, compound technology, applied in the direction of electrolyte immobilization/gelation, electrolyte, battery electrode, etc., can solve problems such as toxic sulfide gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0177] The solid electrolyte preparation method may further include, after the mechanical grinding, the step of standing. Through this standing step, the temperature of the product from said mechanical grinding can be cooled down. Through this standing step, for example, the temperature of the product from said mechanical grinding can be controlled to 80°C or lower, eg, about 20°C to 80°C.

[0178] For the solid electrolyte according to one or more embodiments, a separate heat treatment process may be omitted, unlike other methods of preparing a solid electrolyte. A separate heat treatment is not performed after the mechanical grinding of the mixture for forming the solid electrolyte according to one or more embodiments. If the heat treatment process is further performed, it may be difficult to obtain the solid electrolyte according to one or more embodiments.

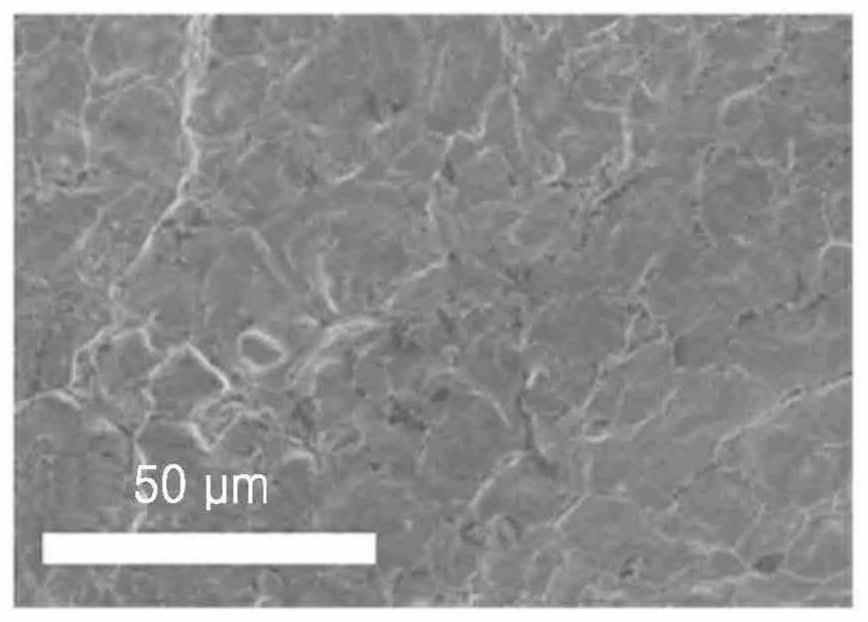

[0179] By mechanical grinding of said mixture as described above, it may be possible to control the particle size ...

Embodiment 1

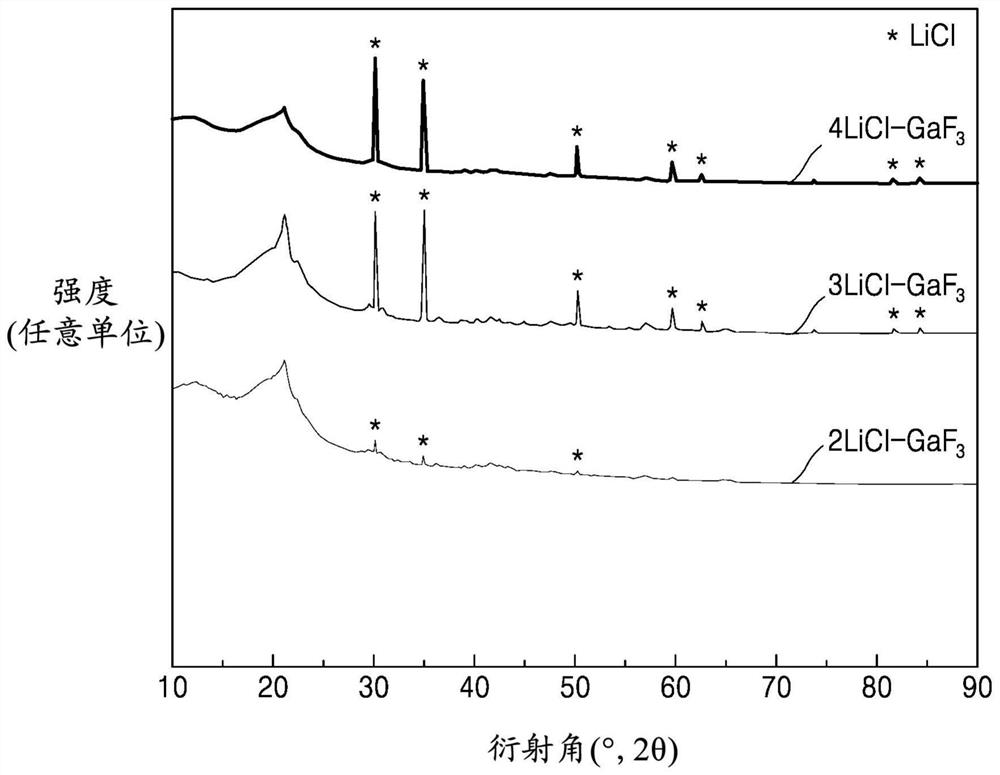

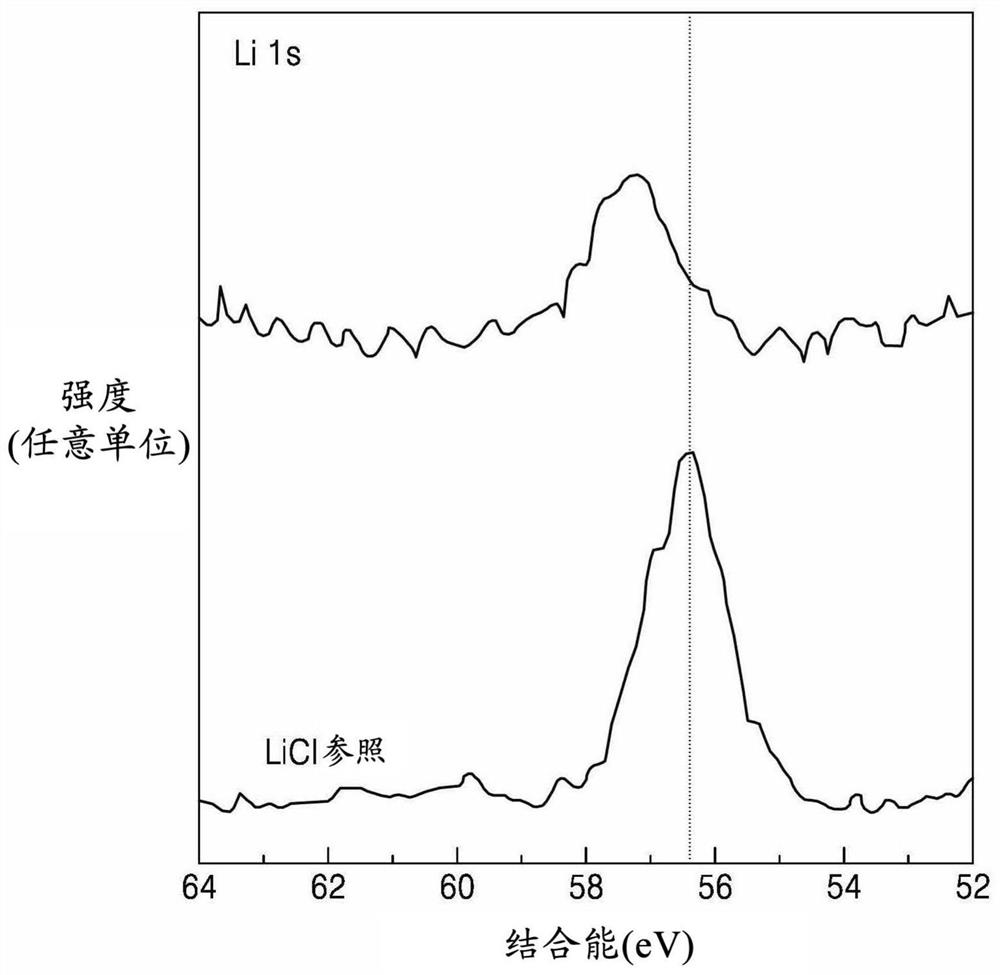

[0251] LiCl (water content: 3.43% by weight) and GaF 3 Mix at 2:1 molar ratio to obtain a mixture, and subject the mixture to high energy milling for 10 minutes by ball milling at 700 rpm using Pulverisette 7 Premium line equipment. After the high energy milling, the resulting product was cooled down by standing for 5 minutes (one cycle). This cycle of high-energy milling and standing steps was repeated for a total of 72 cycles to obtain a compound in clay form having a composition as in Table 1 .

Embodiment 2 and 3

[0253] A compound in the form of clay having a composition as in Table 1 was obtained according to the same method as in Example 1, except as follows: LiCl was added to GaF 3 The mixing molar ratios were changed to 3:1 and 4:1, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com