Crop planting irrigation equipment

A crop and equipment technology, applied in the field of crop planting irrigation equipment, can solve the problems of cumbersome operation, affecting installation efficiency, increasing the limitations of crop planting irrigation equipment, etc., and achieve the effect of improving the use effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

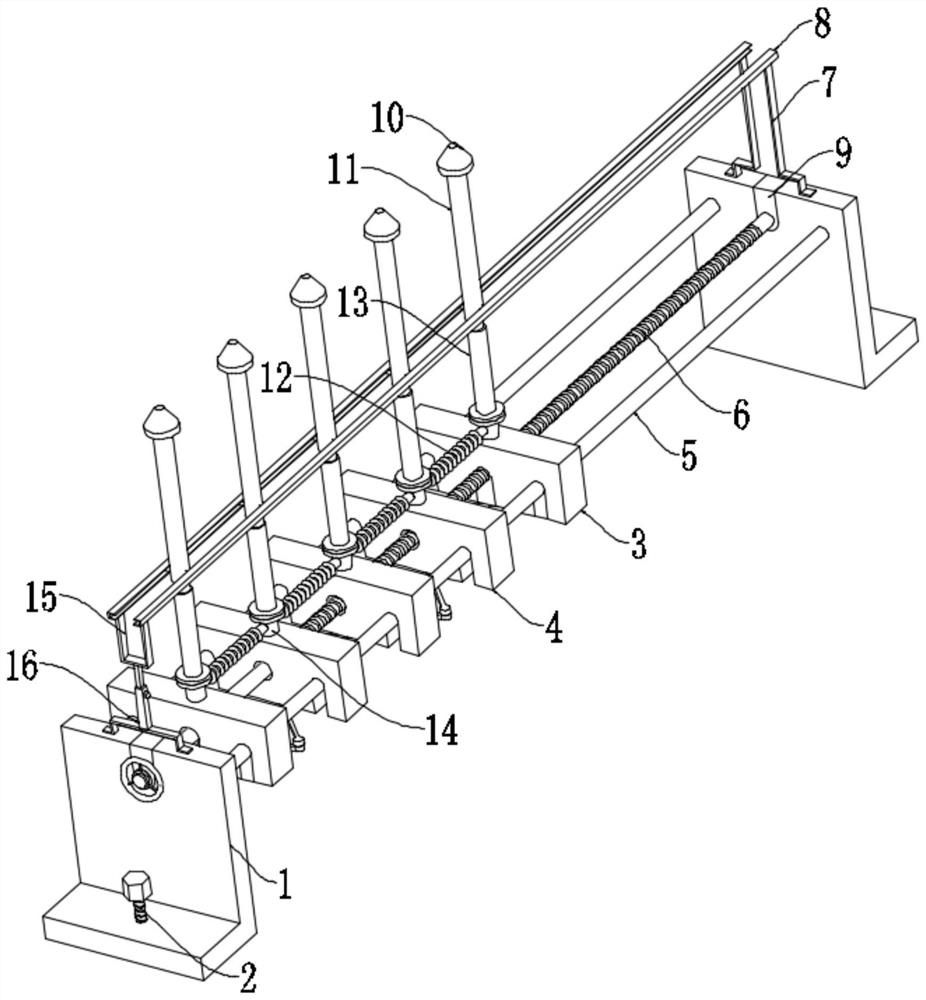

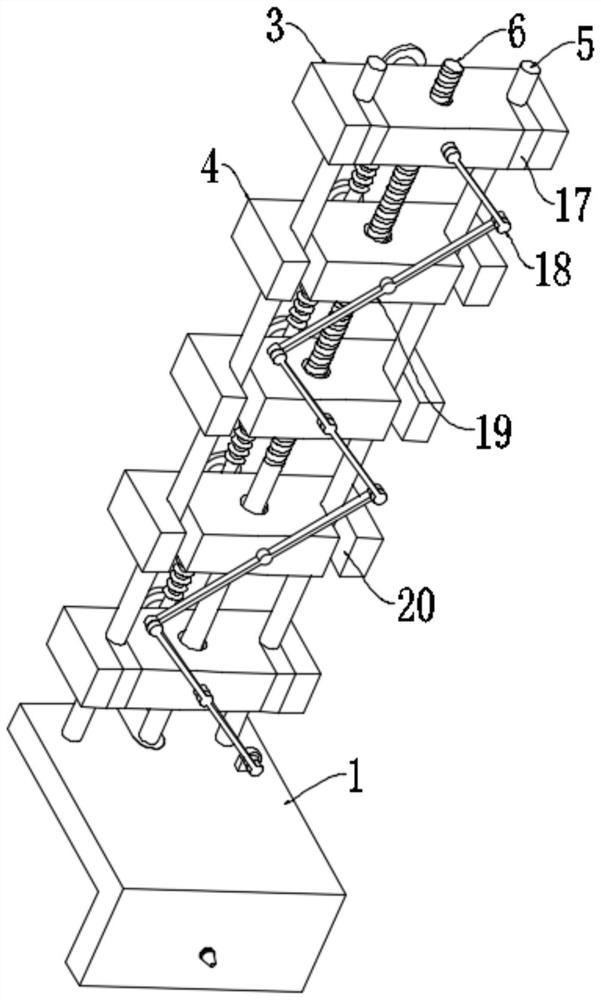

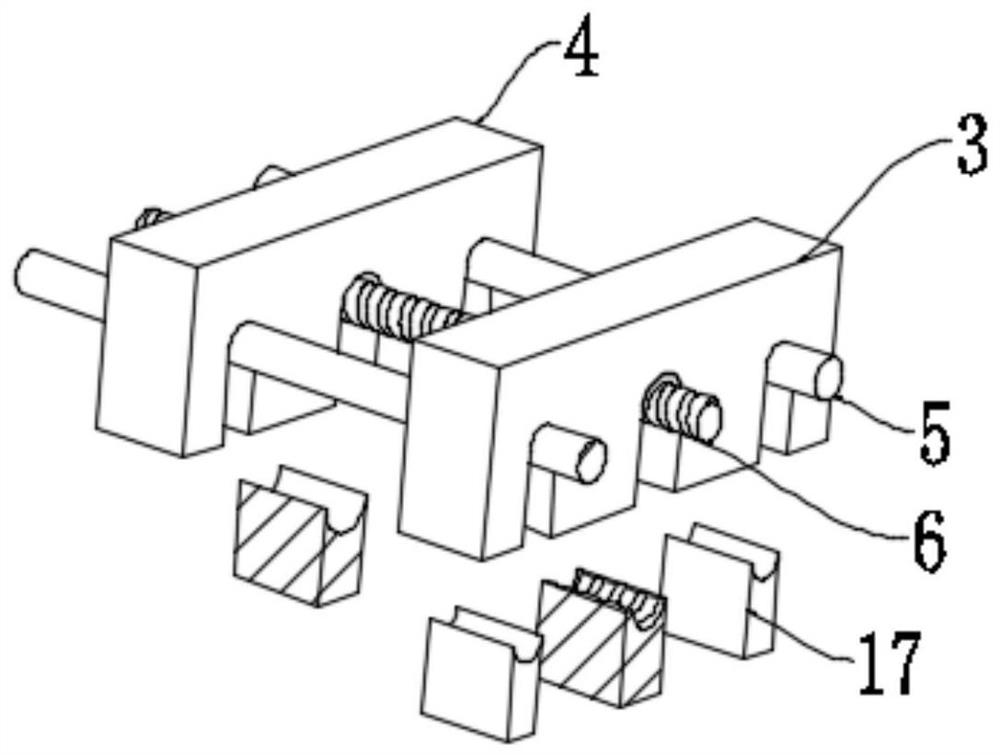

[0034] see Figure 1-5 , including two sets of support bases 1, a sliding rod 5 is fixedly installed between the two sets of support bases 1, and the horizontal ends of the two sets of support bases 1 are screwed and connected with buried rods 2, and the two sets of support bases 1 are movably installed with screw rods 6. The outer wall of the slider 5 is slidably connected with a horizontally distributed moving seat 3 and multiple groups of moving seats 2 4, the interior of the moving seat 3 is screwed and connected with the outer wall of the screw rod 6, and the moving seat 1 3 is connected with multiple groups of moving seats 2 4. The top is fixedly equipped with connecting pipes 14, and the two adjacent groups of connecting pipes 14 are connected by telescopic pipes 12. Any one of the multiple groups of connecting pipes 14 is provided with joints for connecting with external transmission pipes. Group connecting pipe 14 tops are all fixedly installed with the injection mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com