Quantitative glue spraying equipment for accurately spraying glue on new energy automobile driving motor iron core

A technology for new energy vehicles and driving motors, which is applied in the fields of motors, electric vehicles, and devices for coating liquid on surfaces, etc. Reduce the frequency of manual maintenance, improve the effect of automation, and accurately control the effect of glue dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

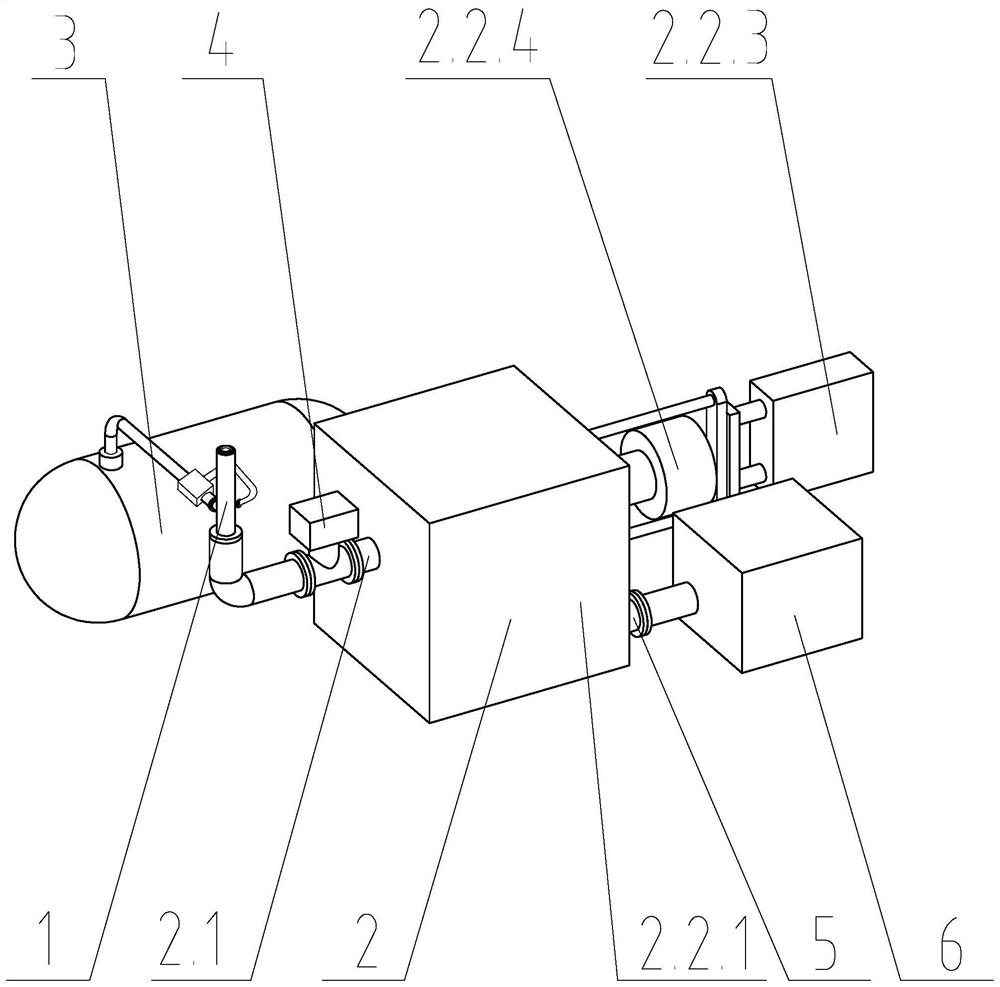

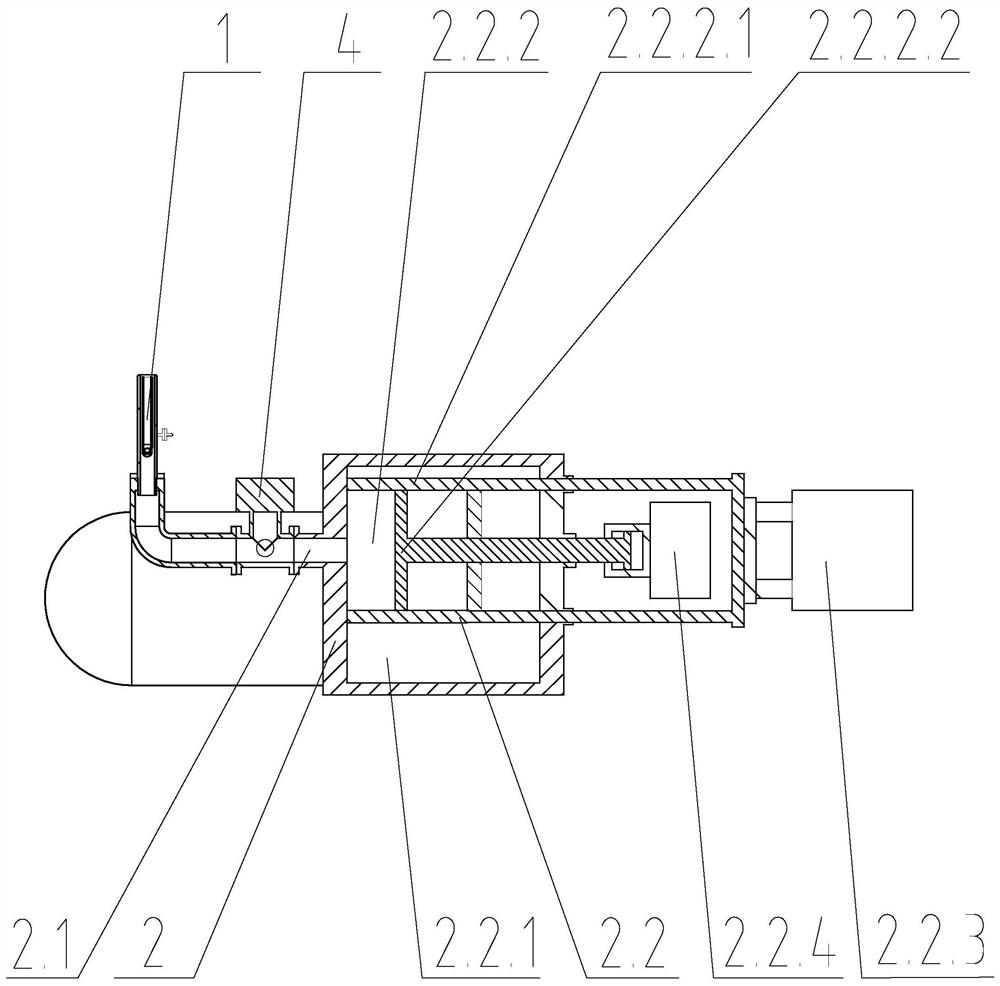

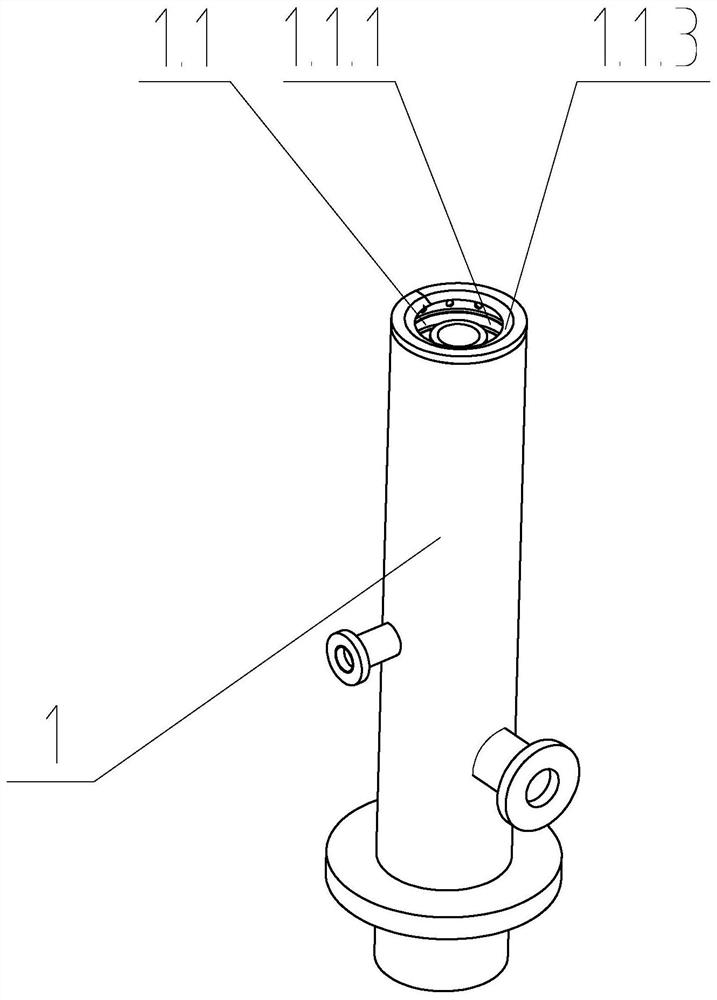

[0029] Such as Figure 1-2 As shown, a quantitative glue spraying equipment for accurately spraying glue on the core of a new energy vehicle drive motor includes a glue spray head 1 for glue spraying and a glue supply machine 2 for supplying glue to the glue spray head 1. The glue machine 2 is provided with a glue outlet pipe 2.1, and the glue spray head 1 is connected on the glue outlet pipe 2.1, and the glue spray head 1 includes a glue spray channel 1.1 for glue spraying and a glue spray channel 1.1 for glue droplets. The cutting air duct 1.2 for separation, the glue spraying channel 1.1 includes a glue outlet 1.1.1, the glue outlet 1.1.1 is set vertically upward, and the inside of the side wall of the glue spraying channel 1.1 is provided with damping 1.1.2, the glue spray channel 1.1 is connected with the rubber outlet pipe 2.1, the cutting air duct 1.2 is connected with the air pump 3, and an electric control switch valve is provided on the connecting pipe between the ai...

Embodiment 2

[0032] Such as figure 2 , Figure 6 As shown, a quantitative glue spraying equipment for accurately spraying glue on the core of a new energy vehicle drive motor includes a glue spray head 1 for glue spraying and a glue supply machine 2 for supplying glue to the glue spray head 1. The glue machine 2 is provided with a glue outlet pipe 2.1, and the glue spray head 1 is connected on the glue outlet pipe 2.1, and the glue spray head 1 includes a glue spray channel 1.1 for glue spraying and a glue spray channel 1.1 for glue droplets. The cutting air duct 1.2 for separation, the glue spraying channel 1.1 includes a glue outlet 1.1.1, the glue outlet 1.1.1 is set vertically upward, and the inside of the side wall of the glue spraying channel 1.1 is provided with damping 1.1.2, the glue spray channel 1.1 is connected with the rubber outlet pipe 2.1, the cutting air duct 1.2 is connected with the air pump 3, and an electric control switch valve is provided on the connecting pipe bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com