Bending machine controller mounting mechanism capable of being quickly disassembled and assembled

A technology for installing mechanisms and controllers, applied in the direction of supporting machines, mechanical equipment, etc., can solve problems such as unfavorable high-efficiency production, cumbersome operation of the moving position of the controller, etc., and achieve the effect of convenient device loading and unloading, convenient loading and unloading, and fast loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

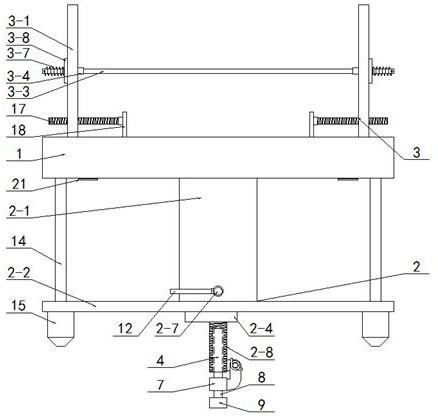

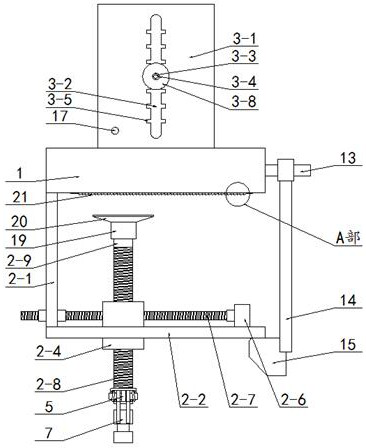

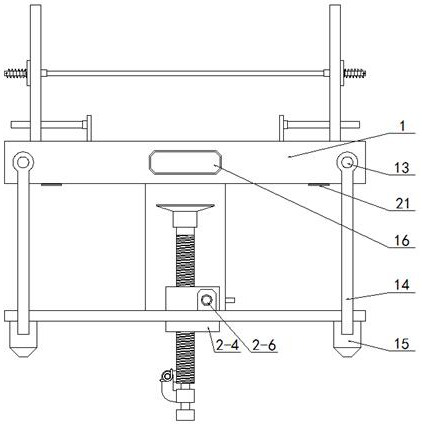

[0029] Such as Figure 1-Figure 7As shown, this specific embodiment adopts the following technical scheme: including a mounting base 1, a fixing component 2, and a connecting component 3, wherein the fixing component 2 is riveted on the lower surface of the mounting base 1, and the mounting base 1 is connected to the external machine through the fixing component 2. The frame is connected and set, the connecting assembly 3 is riveted on the upper surface of the mounting seat 1, and the lower surface of the mounting seat 1 is riveted with a rubber rack 21, and the lower end of the tooth of the rubber rack 21 is inclined forward. When placed on the frame, the mounting seat 1 is pressed against the upper surface of the frame through the rubber rack 21, and then the rubber rack 21 prevents the frame from sliding forward. To increase the frictional force when sliding forward, if a forward force is generated at this time, the rubber rack 21 will deform and further press against the f...

Embodiment 1

[0036] When fixing the mounting seat 1 and the frame, mount the mounting seat 1 on the panel of the frame, rotate the vertical threaded rod 2-8, and mount it up and down on the panel of the frame through the mounting seat 1 and the top block 2-9 On both sides, realize the clamping and fixing of the mounting base 1:

Embodiment 2

[0038] When fixing the mounting base 1 and the frame, mount the mounting base 1 on the rod of the frame, rotate the vertical threaded rod 2-8 so that the stopper 9 is located at the rear of the rod, and rotate the horizontal threaded rod 2-8 7 Move the fixed seat 2-4 forward, and then the connecting plate 2-1 and the top block 2-9 are mounted on the front and rear sides of the bar, so that the top block 2-9 is pressed against the rear side wall of the bar, and the connecting plate 2-9 1 against the front side wall of the rod, and clamp and fix the mounting base 1.

[0039] After adopting the above structure, the beneficial effects of this embodiment are as follows:

[0040] 1. The lower part of the mounting seat 1 is connected with the connecting plate 2-1 and the riveting plate 2-2 is set, and the fixing seat 2-4 is set on the riveting plate 2-2 through the No. 1 waist-shaped hole 2-3, and the fixing seat 2-4 is Set the horizontal threaded rod 2-7, the vertical threaded rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com