Patents

Literature

31results about How to "Facilitate replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sealable packaging structures and applications related thereto

InactiveUS20080070047A1Facilitate replacementImproved performance and cost-effectivenessFlexible coversLiquid surface applicatorsFilm structureAdhesive

Heat-sealable, multi-layer composite packaging structures that are suitable for packaging and having improved sealing properties and simplified construction as compared to prior art composite film constructions are disclosed. The inventive film structure includes a first substrate, such as paper, bonded such as by extrusion lamination, to a sealable, high-barrier film. This inventive “paper-adhesive-polymer” lamination may replace prior art “paper-adhesive-foil-adhesive” foil-based tandem laminations. An improved or comparable polymer film substrate may replace the “foil-adhesive” layer components of the popular incumbent prior art structure.

Owner:JINDAL INNOVATION CENT SRL

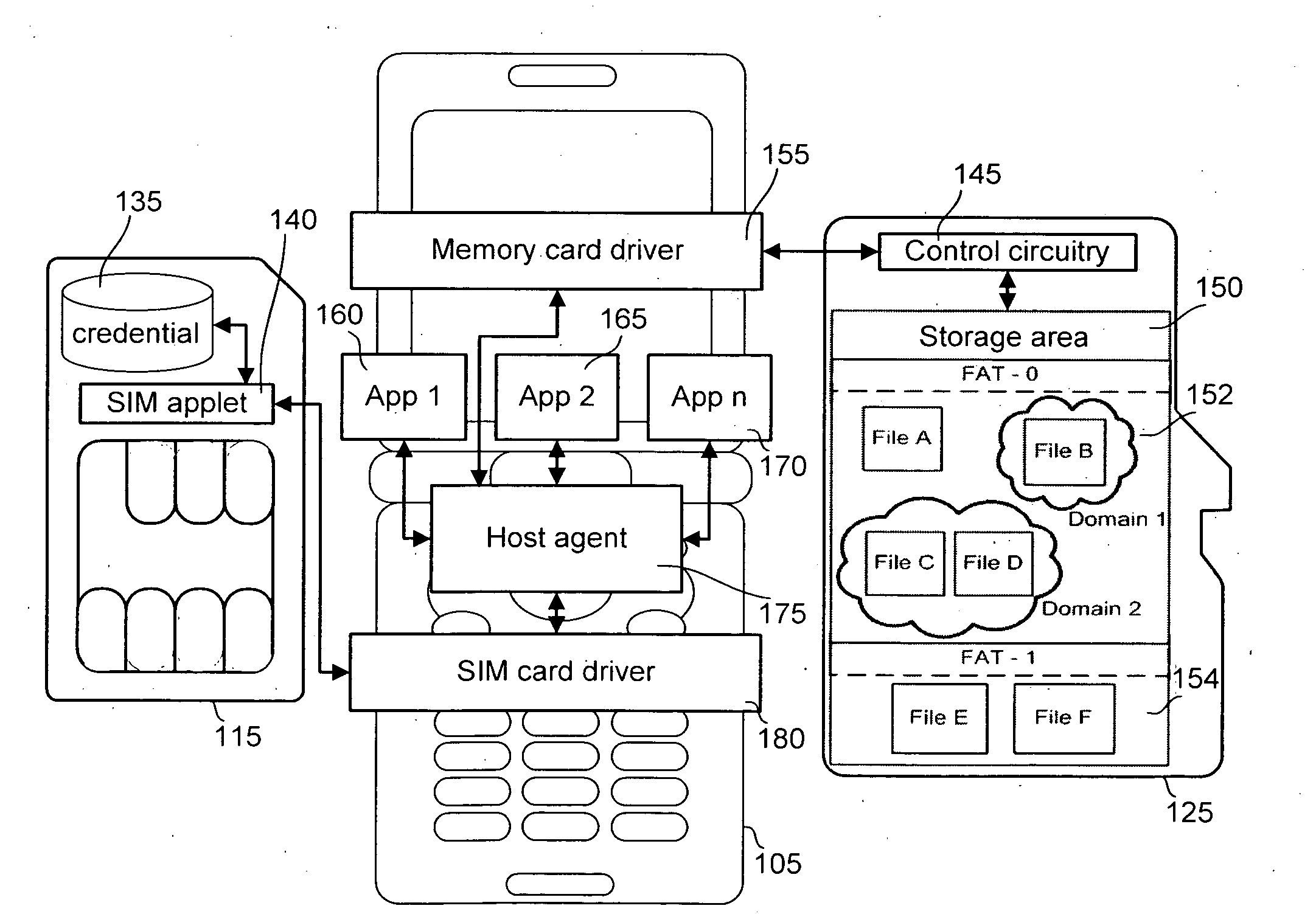

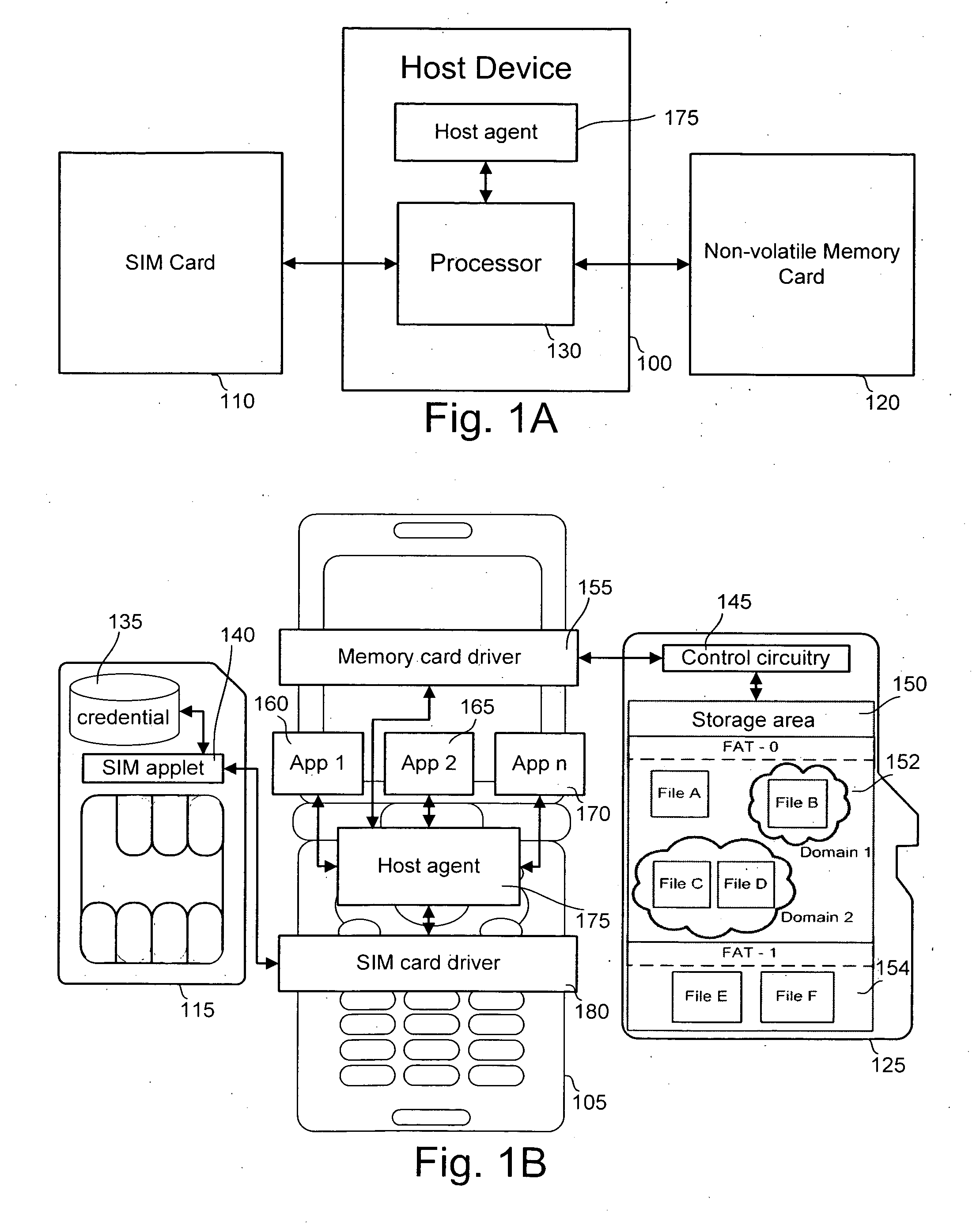

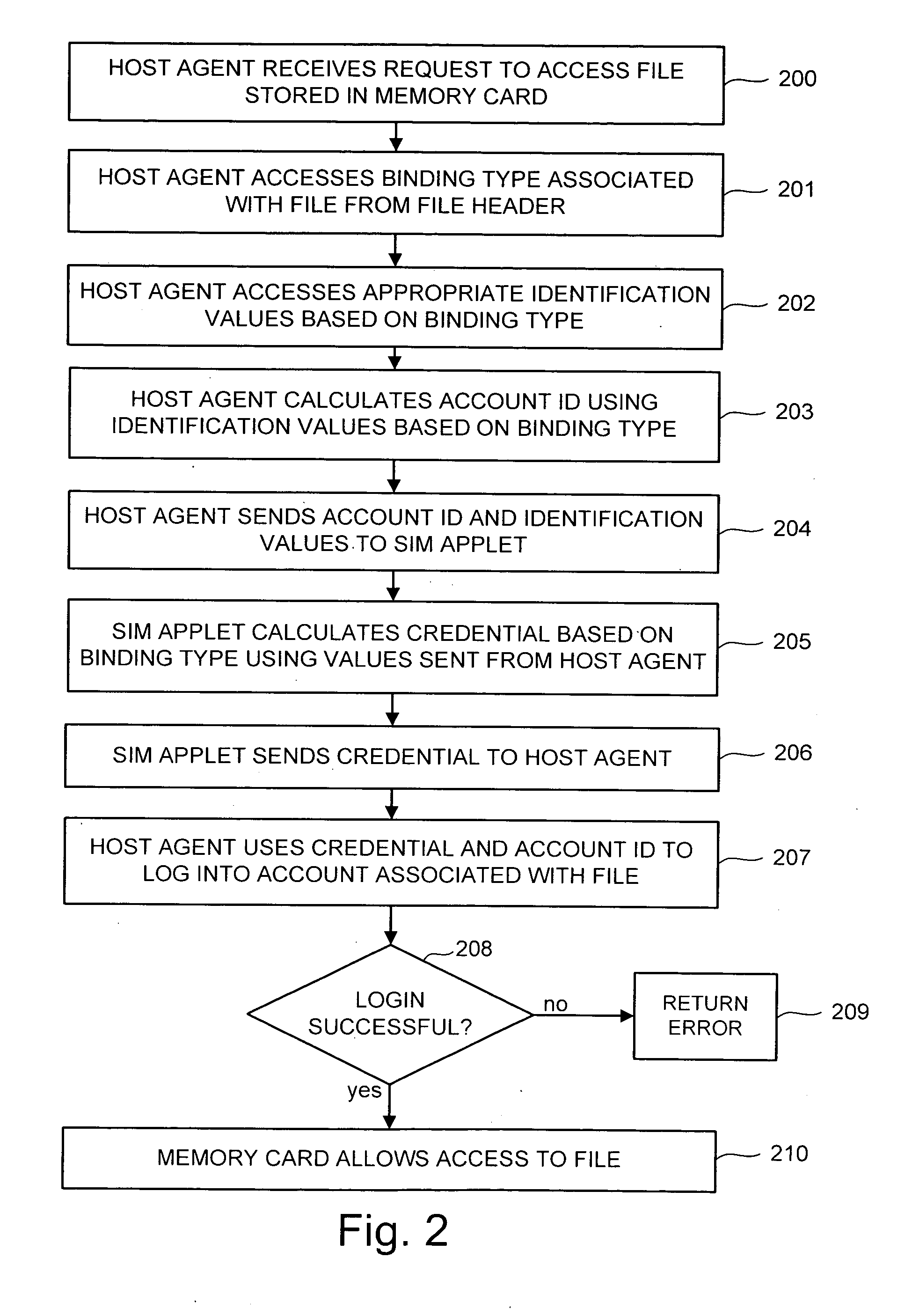

Memory device upgrade

ActiveUS20100048169A1Facilitate replacementEasy to replaceUnauthorised/fraudulent call preventionDigital data processing detailsUpgradeStorage cell

Technology for replacing a first storage unit operatively coupled to a device is provided. Content of the first storage unit is sent to a new storage unit that serves as the replacement of the first storage unit. In one embodiment, the content is first sent to a trusted third-party server and then transferred from the server to the new storage unit. A portion of the content on the new storage unit is adjusted in one embodiment to maintain content security features that were implemented in the first storage unit. The upgrading can be performed under the control of a software entity that is installed on the device. In various embodiments, the first storage unit may be bound to a third storage unit prior to the upgrade process. In such cases, the process can include measures to bind the new storage unit to the third storage unit.

Owner:SANDISK TECH LLC

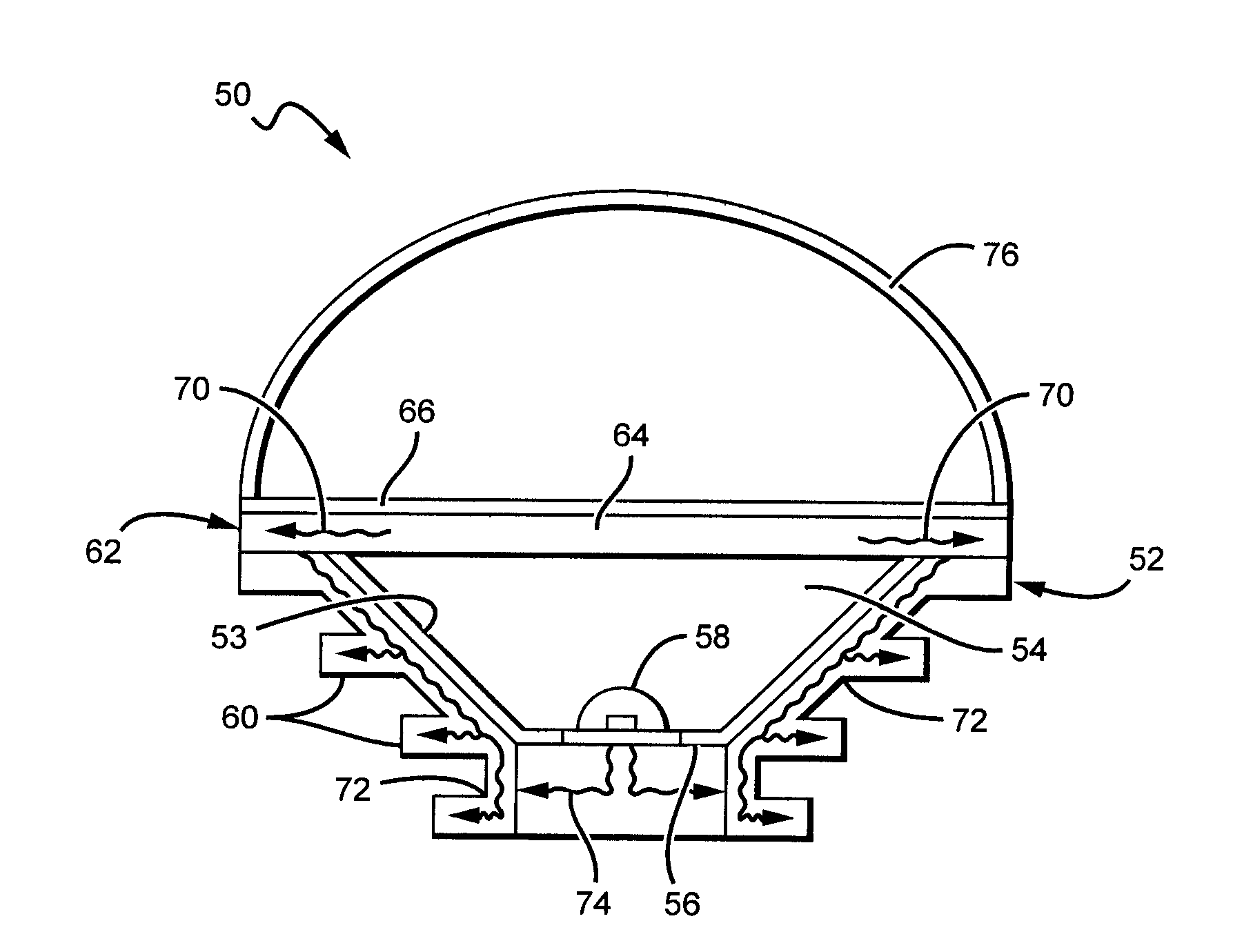

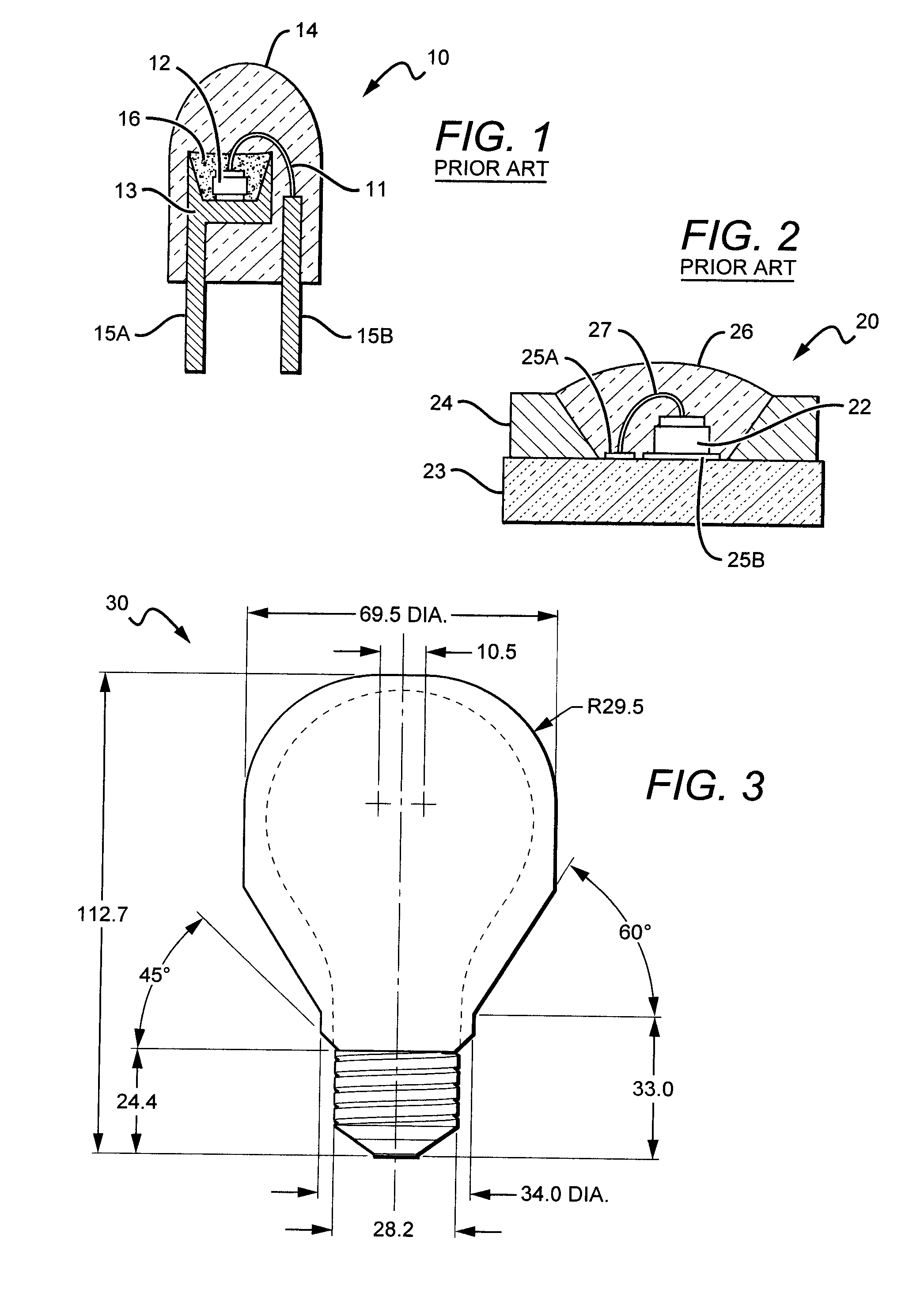

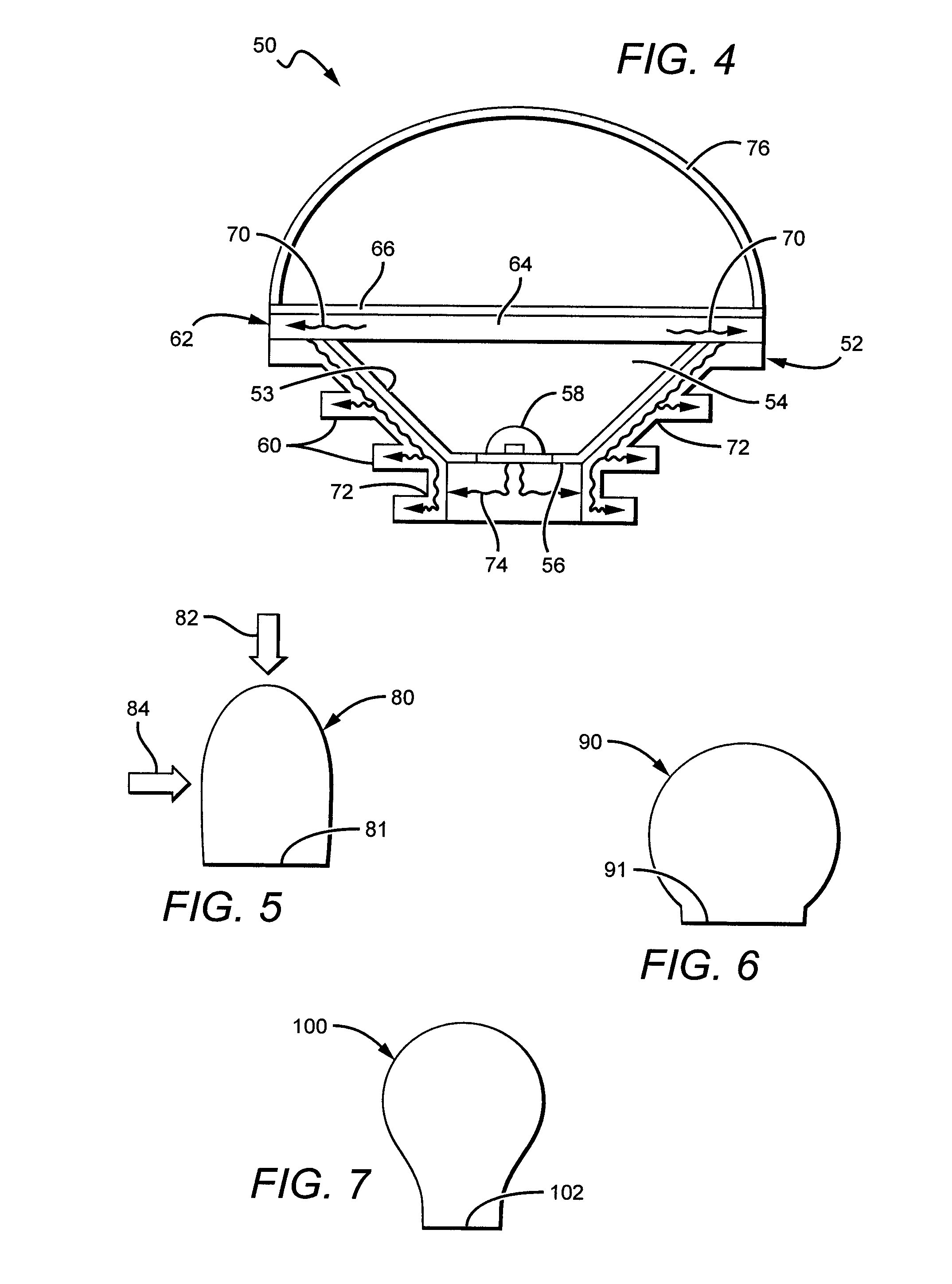

LED lamp or bulb with remote phosphor and diffuser configuration with enhanced scattering properties

ActiveUS20110267801A1Cost efficient and reliableFacilitate replacementPoint-like light sourceLighting heating/cooling arrangementsLight sourceHeat spreader

An LED lamp or bulb is disclosed that comprises a light source, a heat sink structure and an optical cavity. The optical cavity comprises a phosphor carrier having a conversions material and arranged over an opening to the cavity. The phosphor carrier comprises a thermally conductive transparent material and is thermally coupled to the heat sink structure. An LED based light source is mounted in the optical cavity remote to the phosphor carrier with light from the light source passing through the phosphor carrier. A diffuser dome is included that is mounted over the optical cavity, with light from the optical cavity passing through the diffuser dome. The properties of the diffuser, such as geometry, scattering properties of the scattering layer, surface roughness or smoothness, and spatial distribution of the scattering layer properties may be used to control various lamp properties such as color uniformity and light intensity distribution as a function of viewing angle.

Owner:IDEAL IND LIGHTING LLC

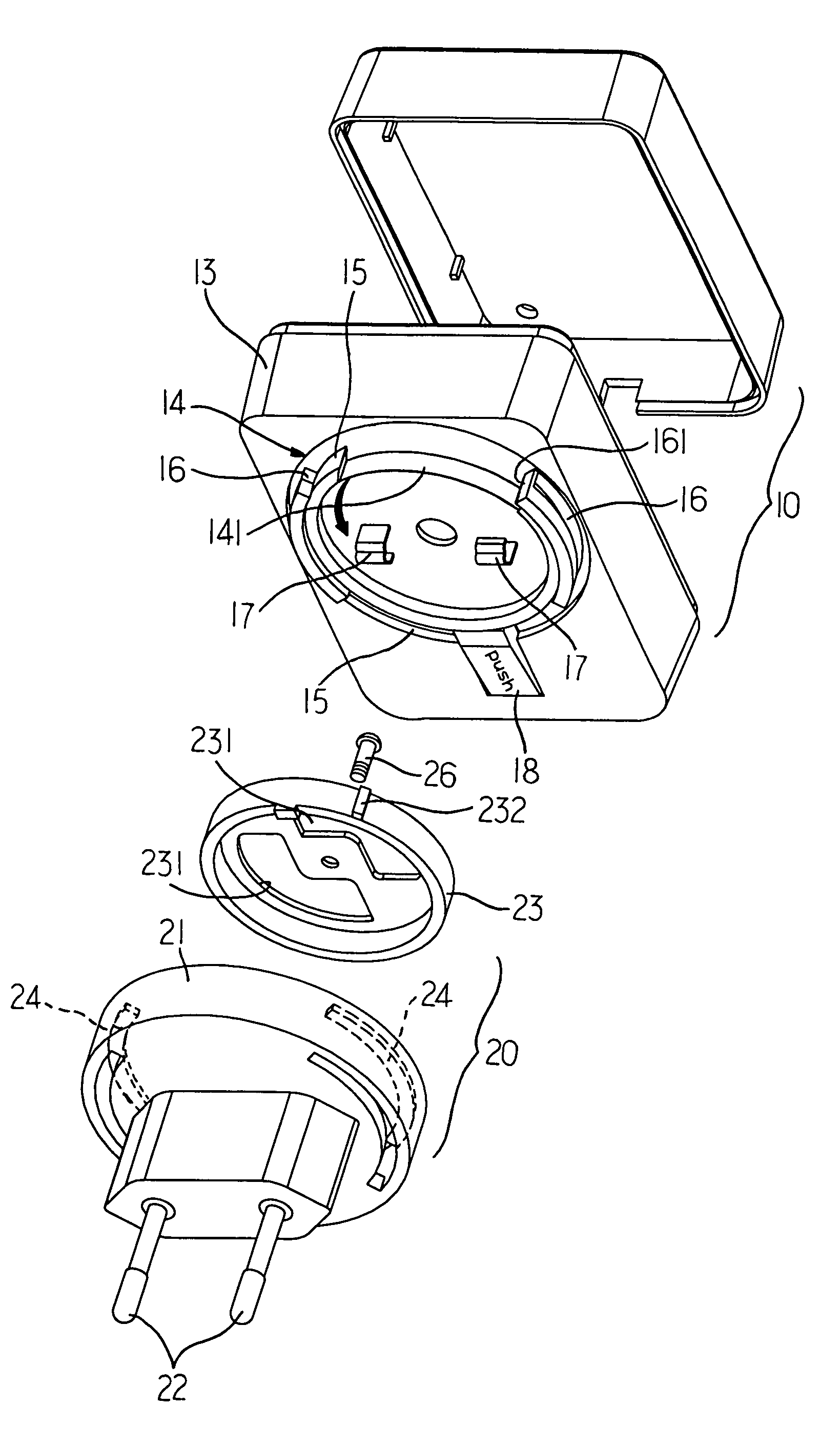

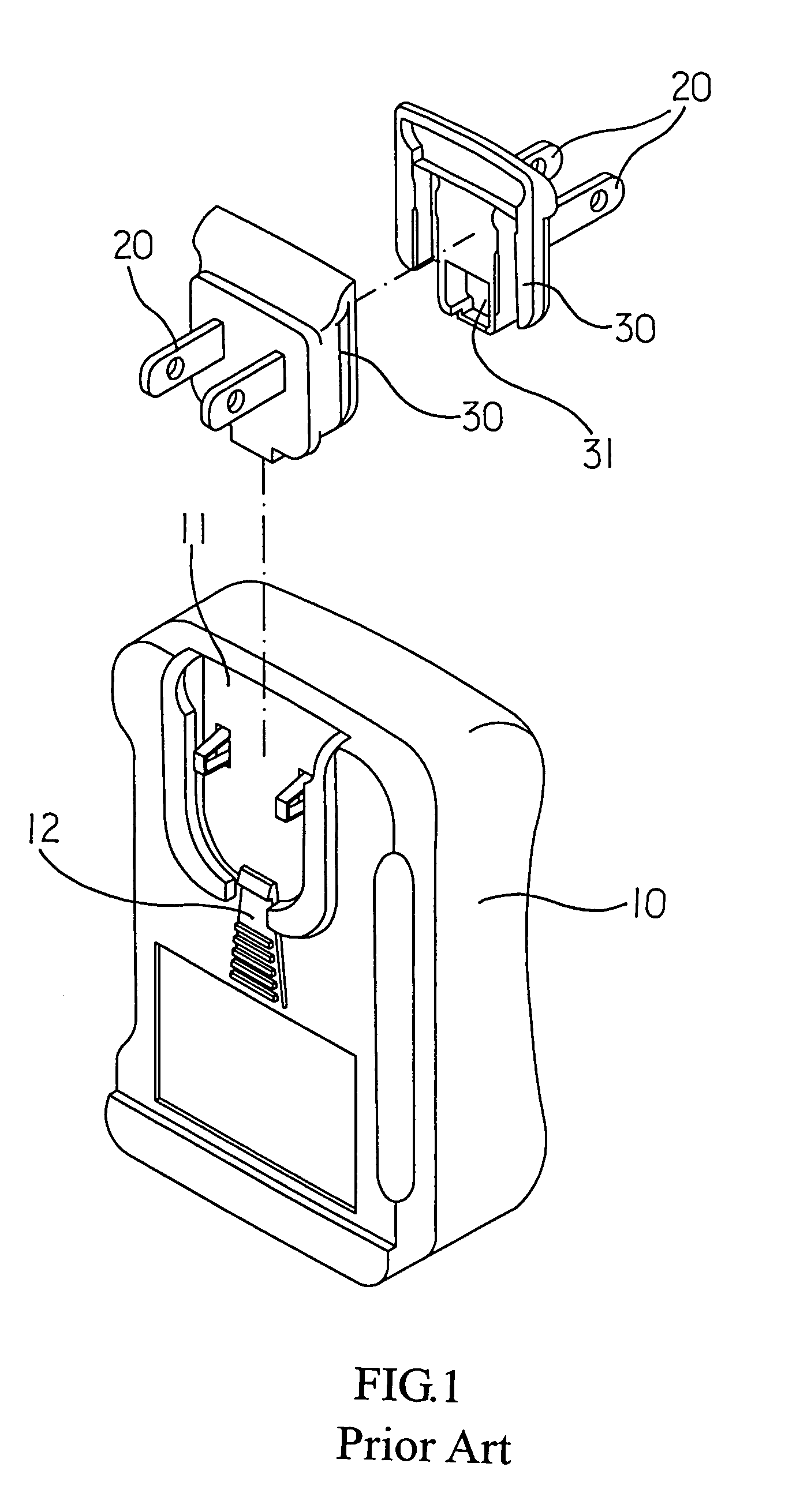

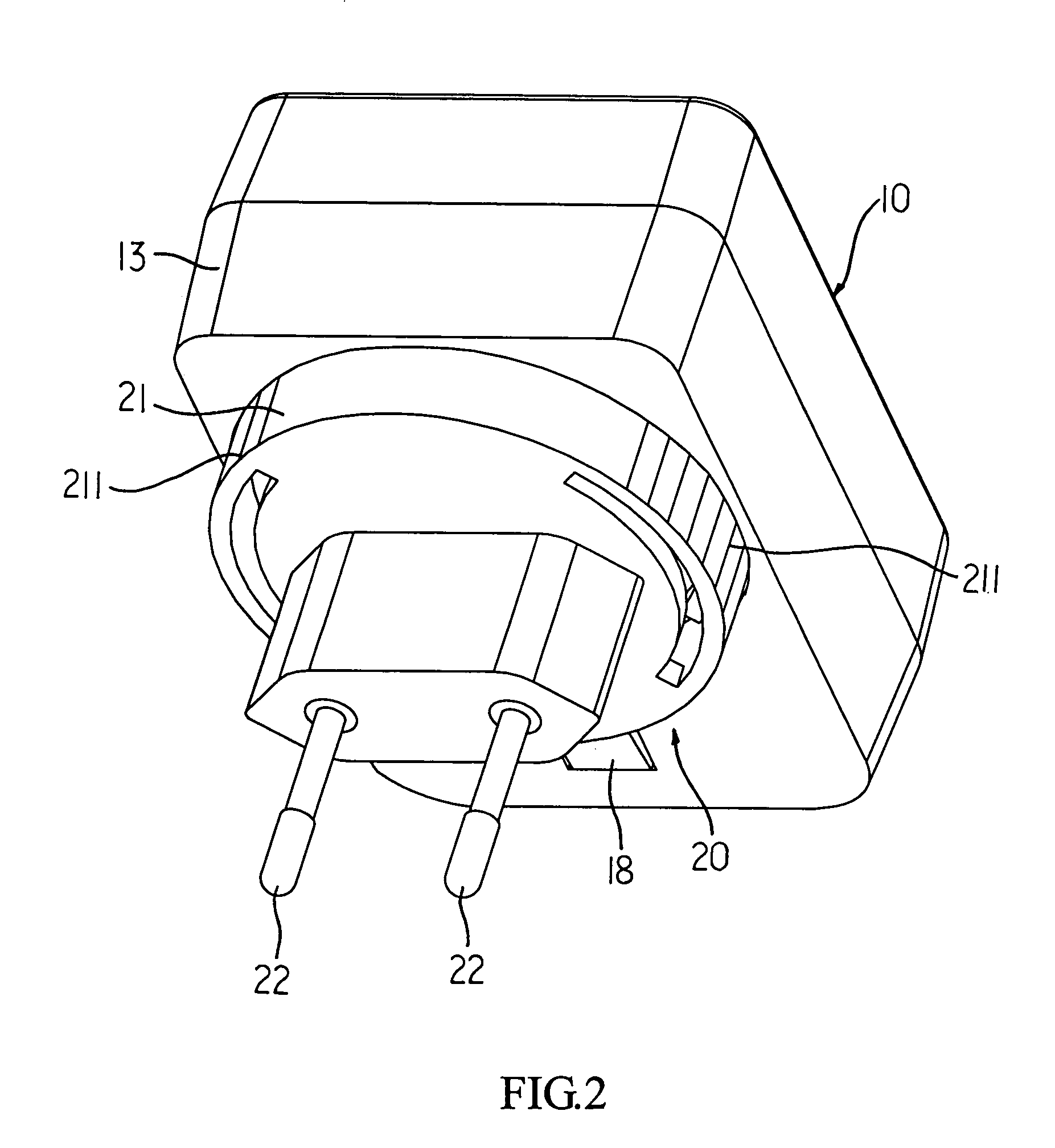

Plug adapter

InactiveUS7168968B1Facilitate replacementTwo pole connectionsCoupling device detailsMechanical engineeringEngineering

A plug adapter includes a holder and a plug. An adaptation ring is provided on the holder; the adaptation ring containing multiple gaps. A mounting plate from the plug is snapped into the adaptation ring and turns in a given direction. The mounting plate is secured in place by pressing a push for the plug to engage with the holder. The push may also be pressed to turn the mounting plate in an opposite direction, causing the plug to disengage from the holder to facilitate replacement of the plug with another plug of differing specification.

Owner:SPI ELECTRNIC

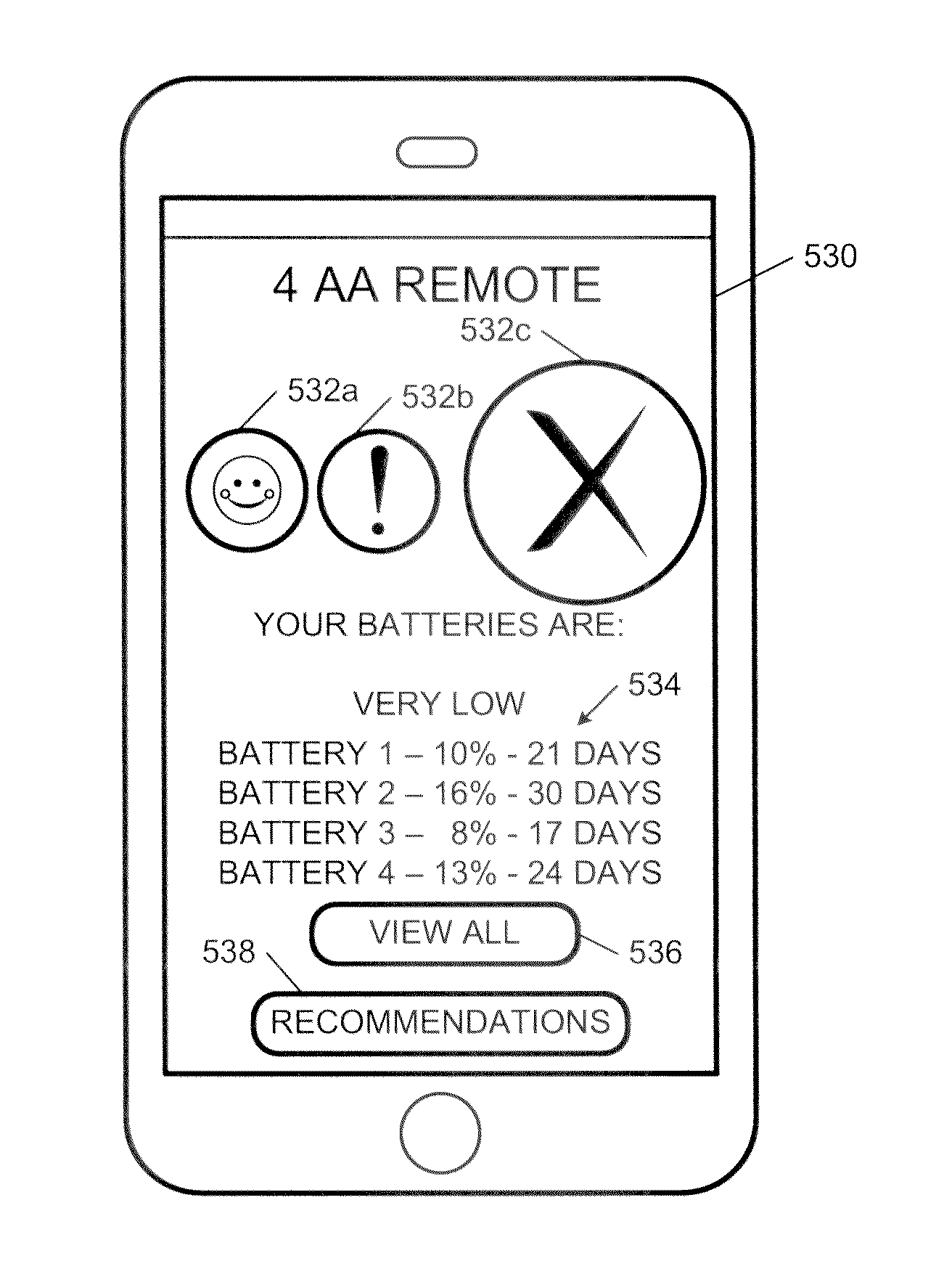

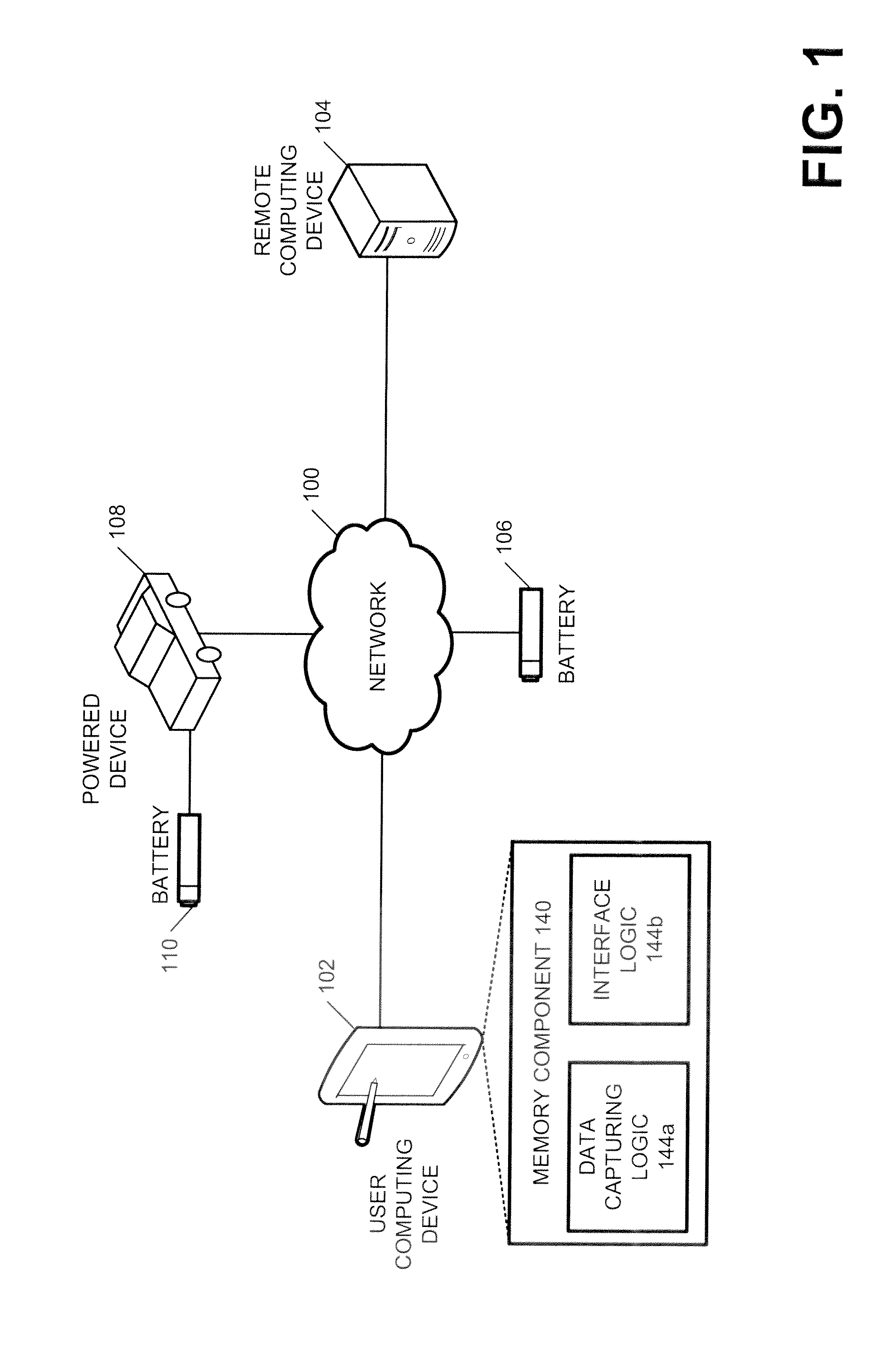

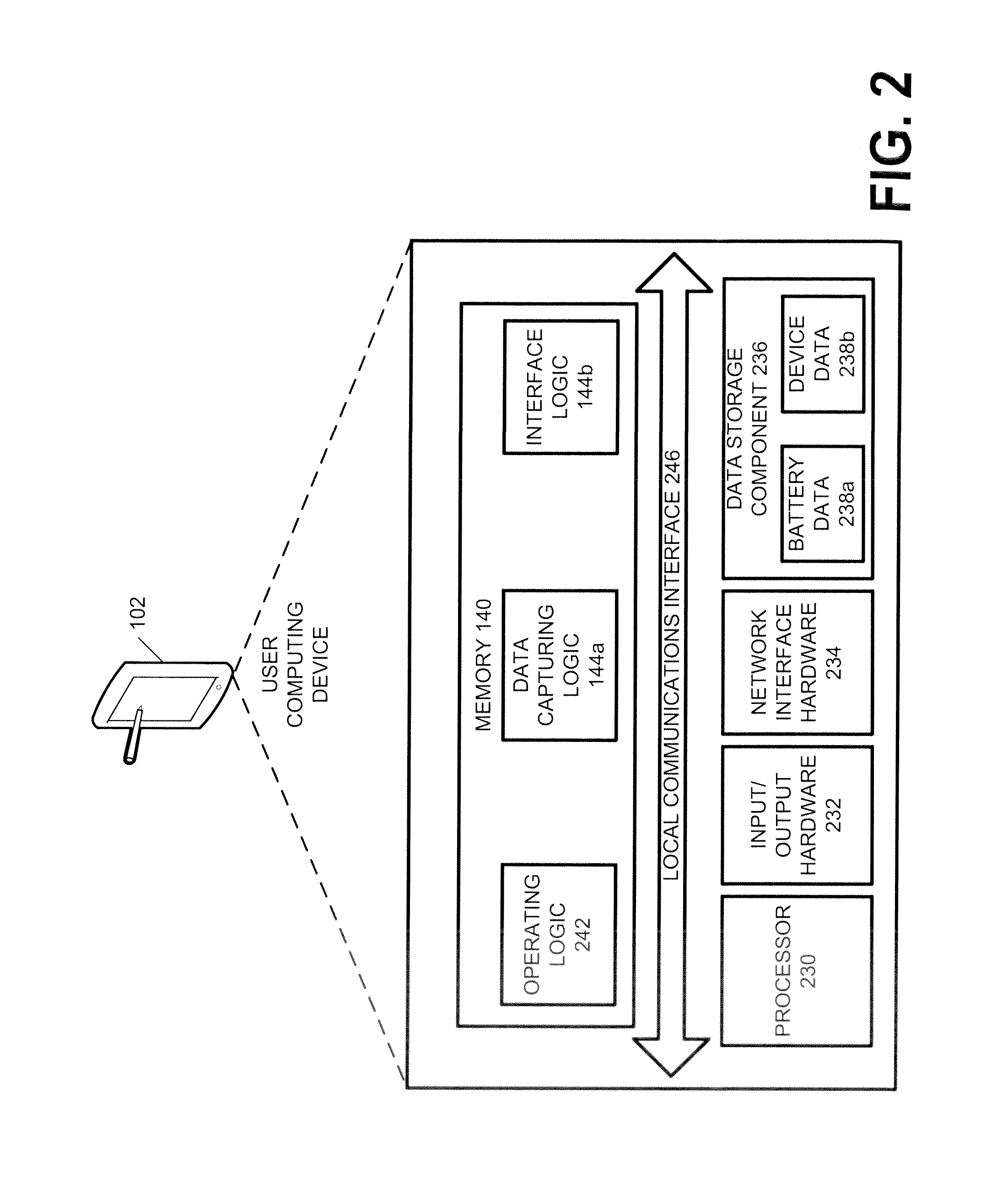

Systems and methods for remotely determining a battery characteristic

ActiveUS20140379285A1Facilitate replacementElectrical testingCells structural combinationEngineeringEnergy storage

Included are embodiments for remotely determining a battery characteristic. Some embodiments include searching for a first wireless signal that identifies the energy storage device and, in response to receiving the first wireless signal, determining a current charge level of the energy storage device. Some embodiments include receiving a second wireless signal from the energy storage device, determining from the second wireless signal, whether the current charge level of the energy storage device reaches a predetermined threshold, and in response to determining that the current charge level of the energy storage device reaches the predetermined threshold, sending, by the computing device, an alert indicating the current charge level.

Owner:DURACELL U S OPERATIONS

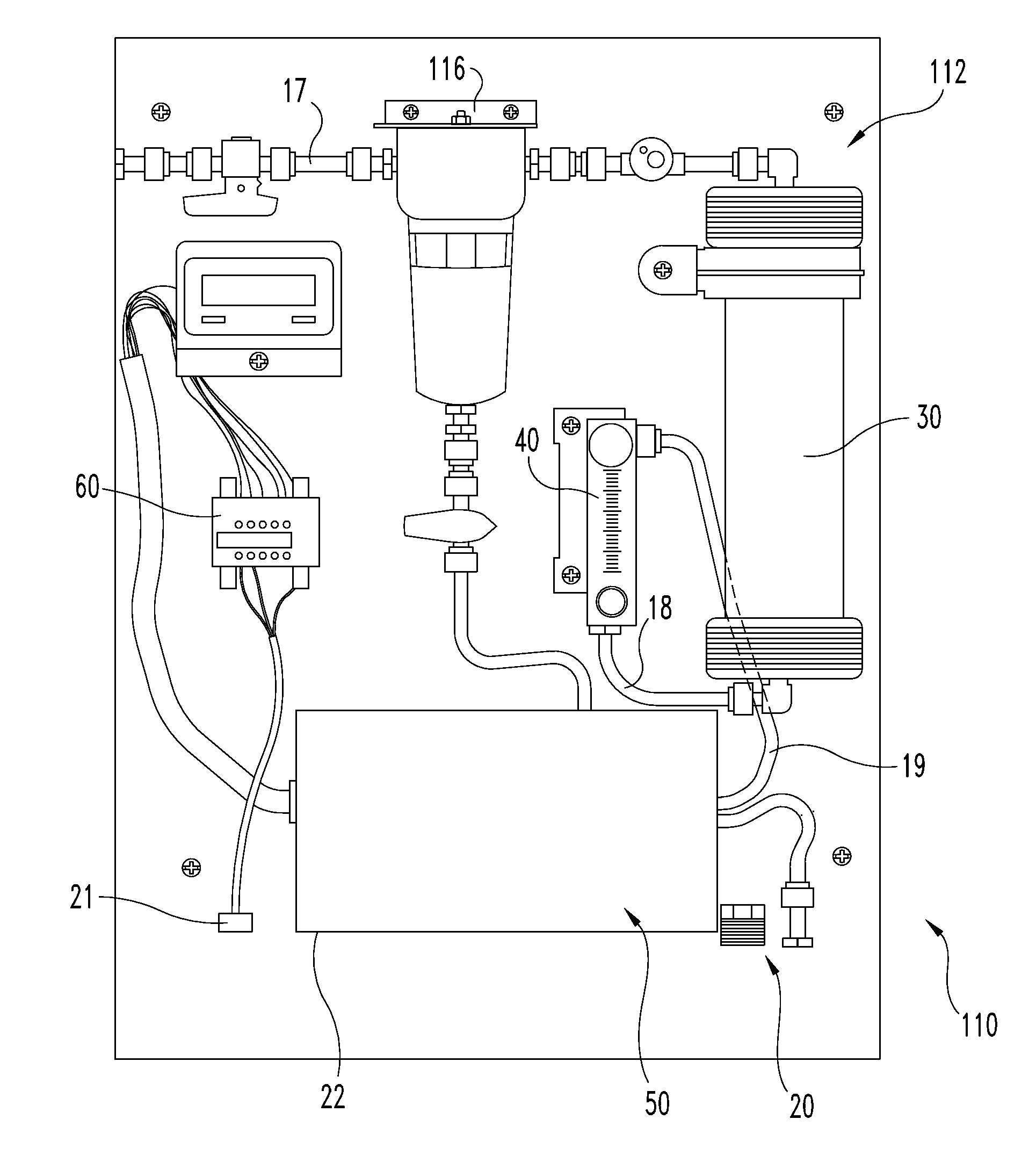

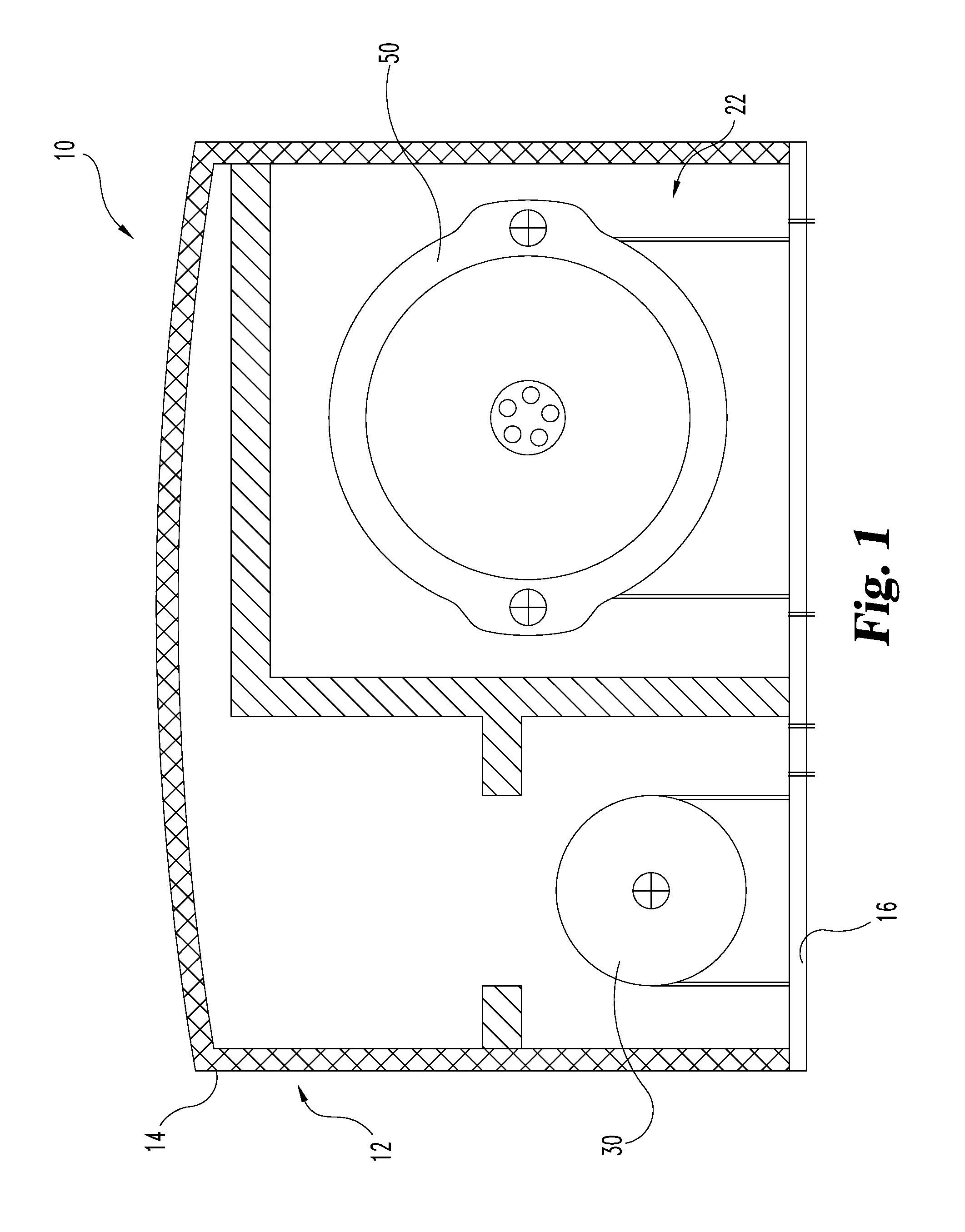

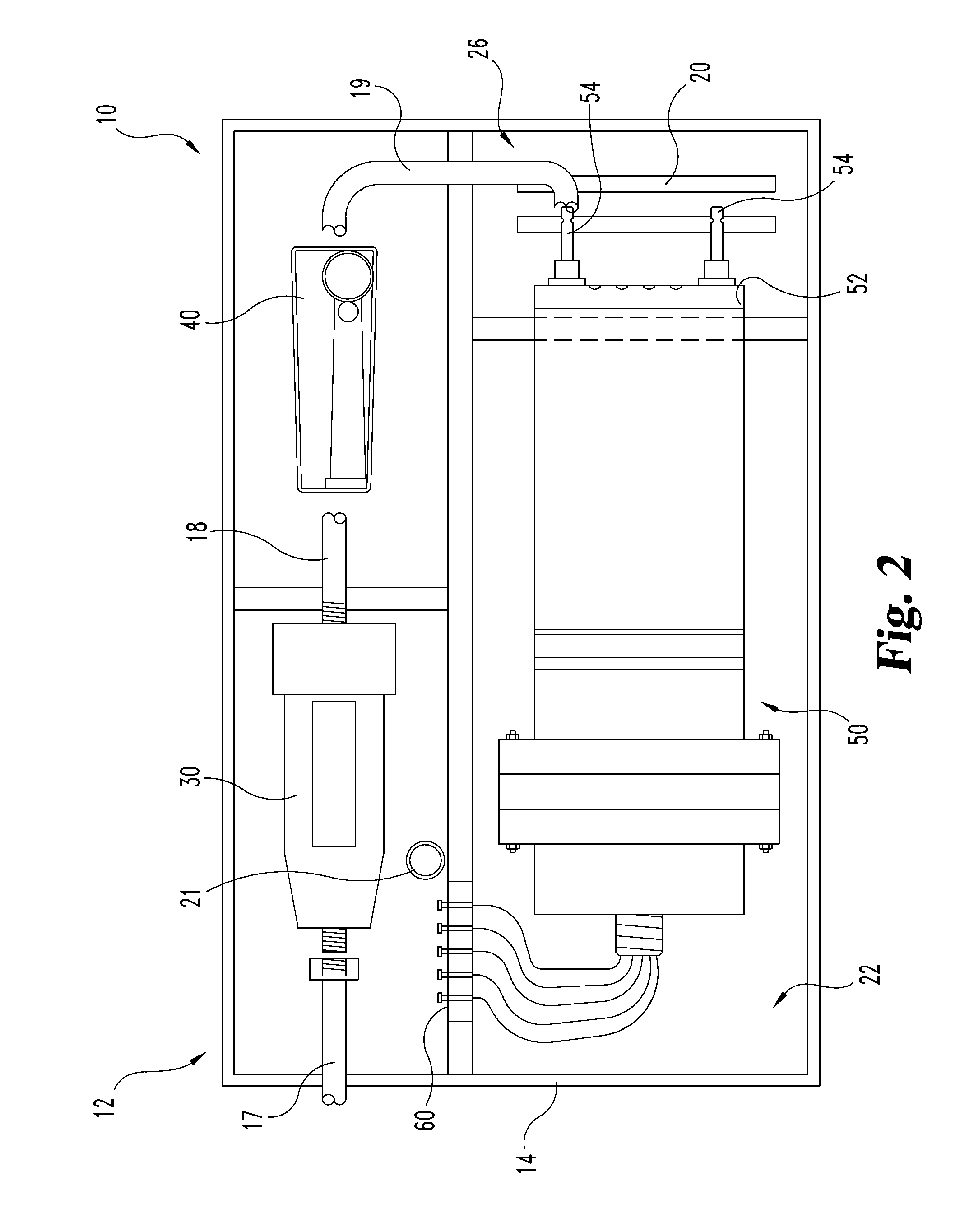

Methane monitoring system

InactiveUS20120206715A1Facilitate replacementFacilitate placementRadiation pyrometryMaterial analysis by electric/magnetic meansPipingSatellite

A methane monitoring system including a filter, a flow restrictor and a methane level detector is disclosed. The sensor system draws gas from a piping system through a sample line into the filter. The filter removes moisture vapor from the gas, with the remaining gas passing into a flow meter. The flow meter regulates the gas pressure for the gas output to a sensing chamber containing the methane meter. The methane meter operates to sample the methane level in the gas and provides an electrical signal which can be output to a recording device such as a flash memory card or to real time remote reporting via direct connection or a wireless signal such as a cell phone, radio or satellite telecom system. Landfill gas which is introduced into the sensing chamber is then exhausted through vent slots in the housing.

Owner:LANDMARC ENVIRONMENTAL SYST

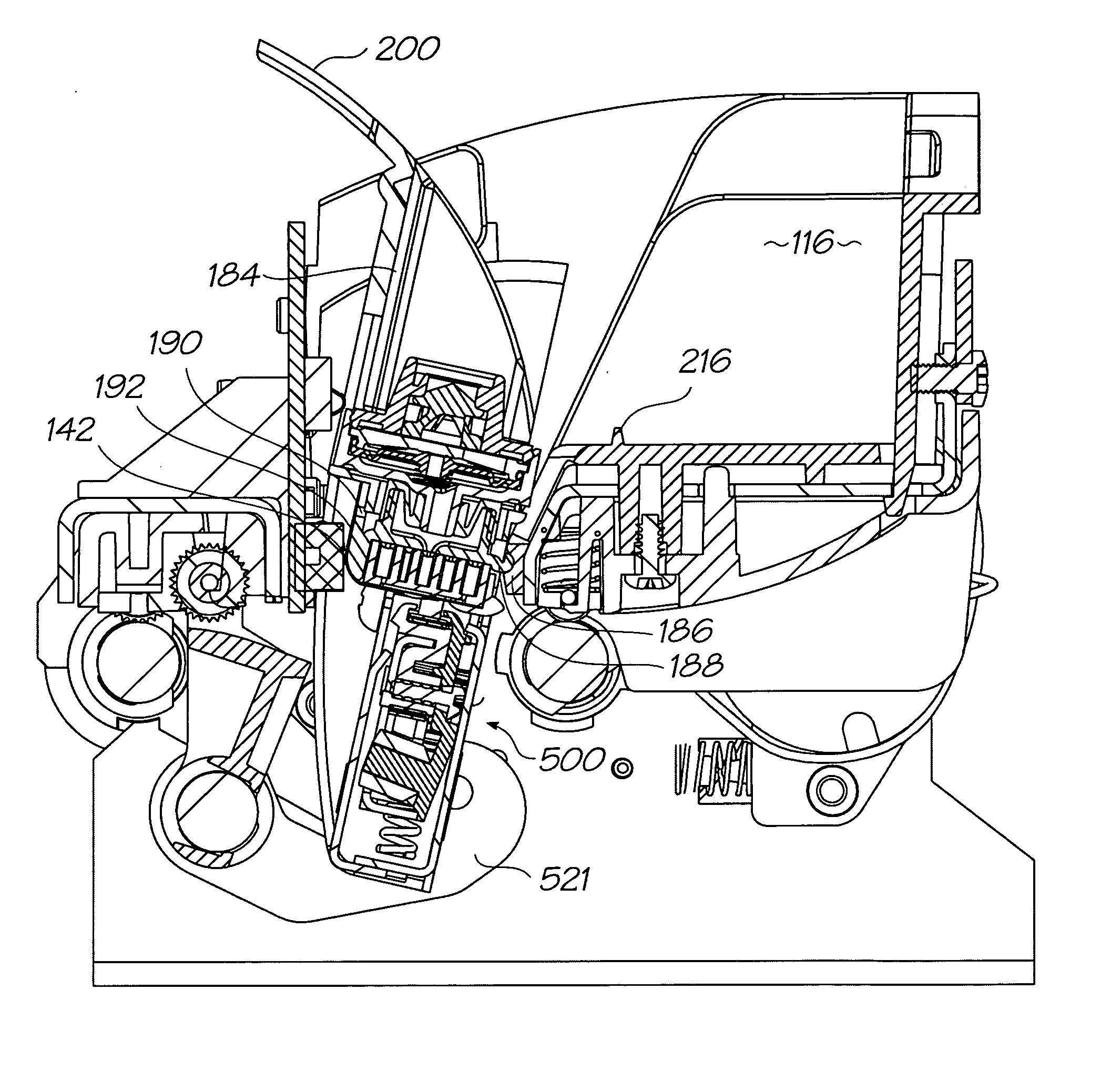

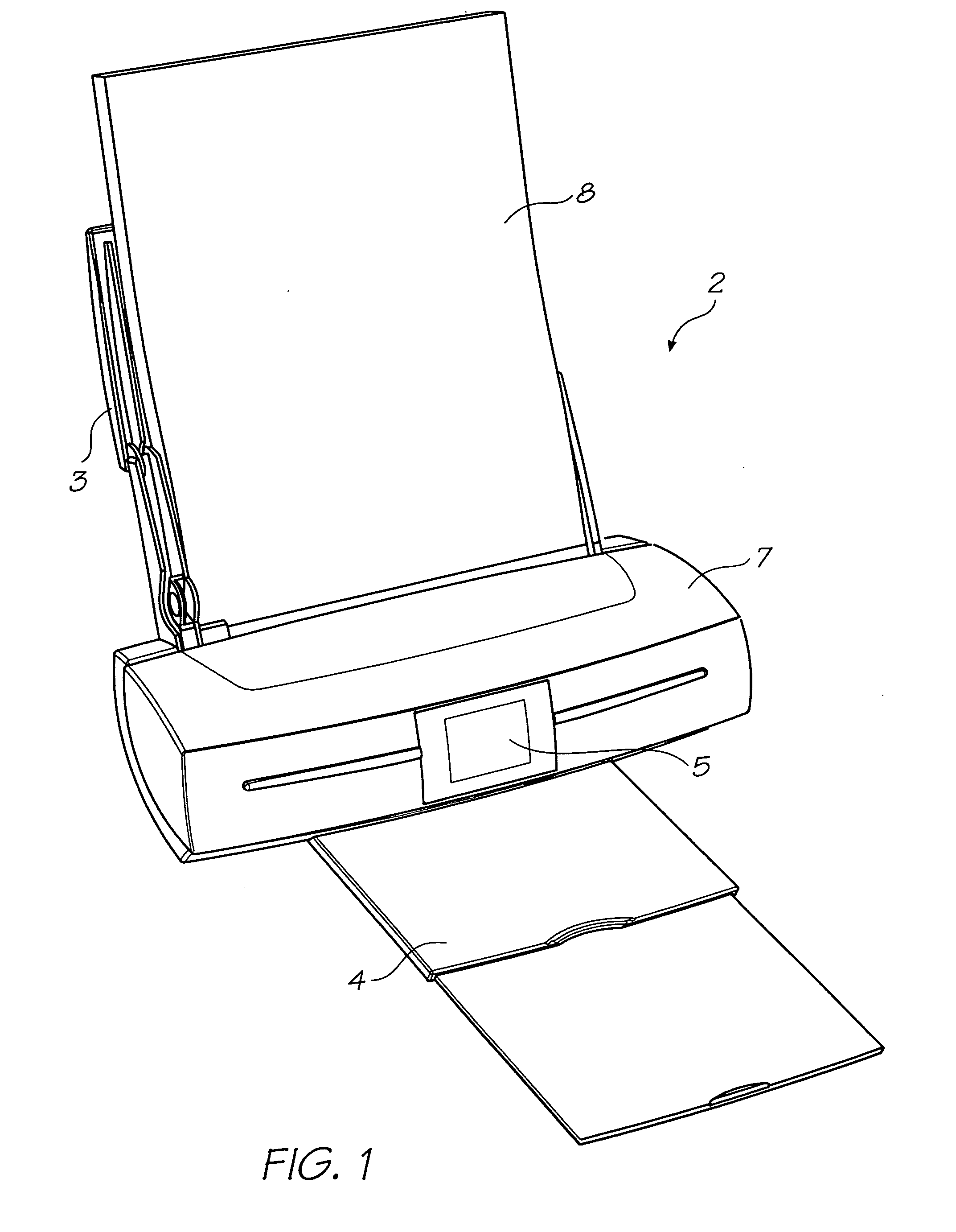

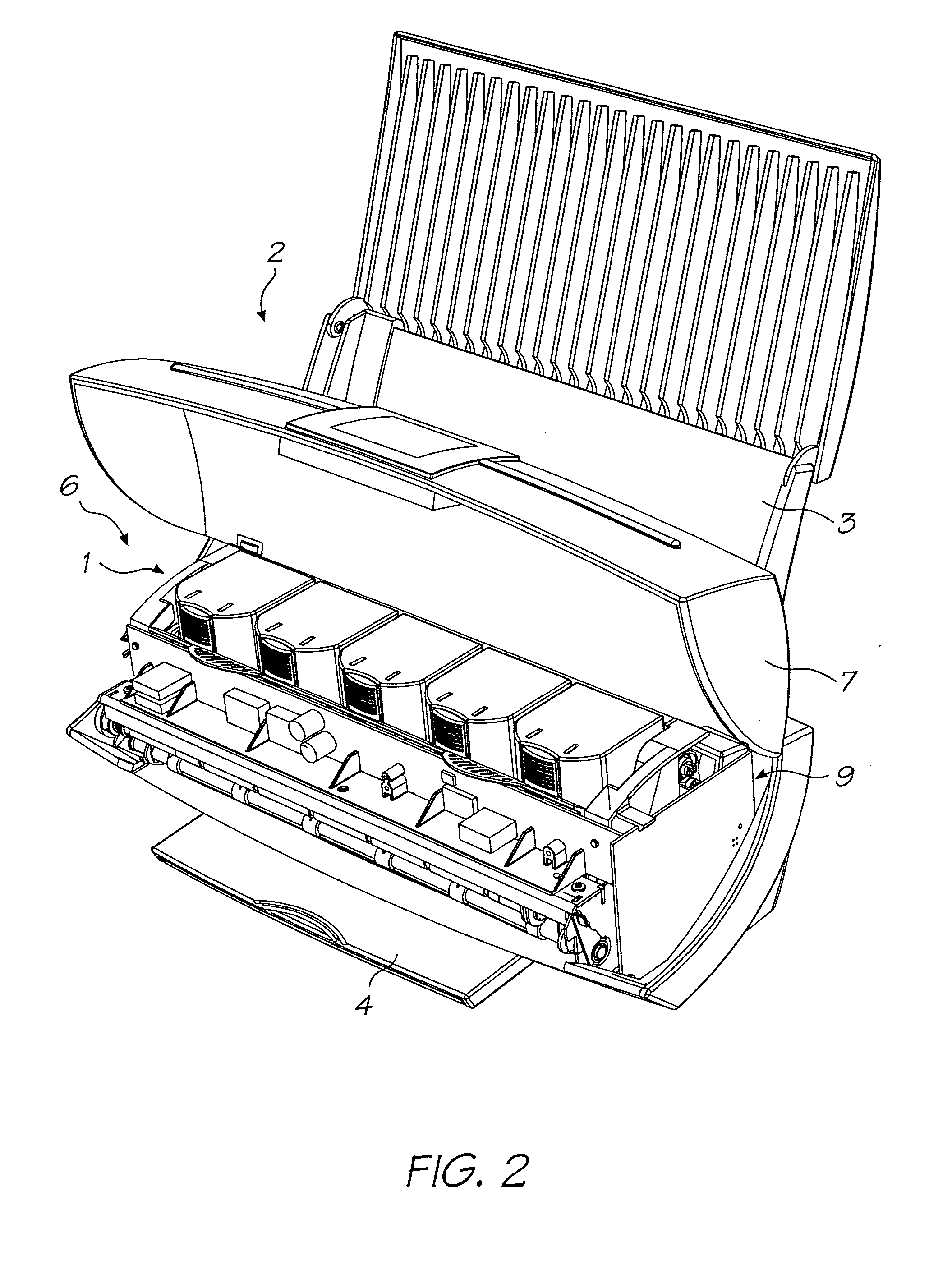

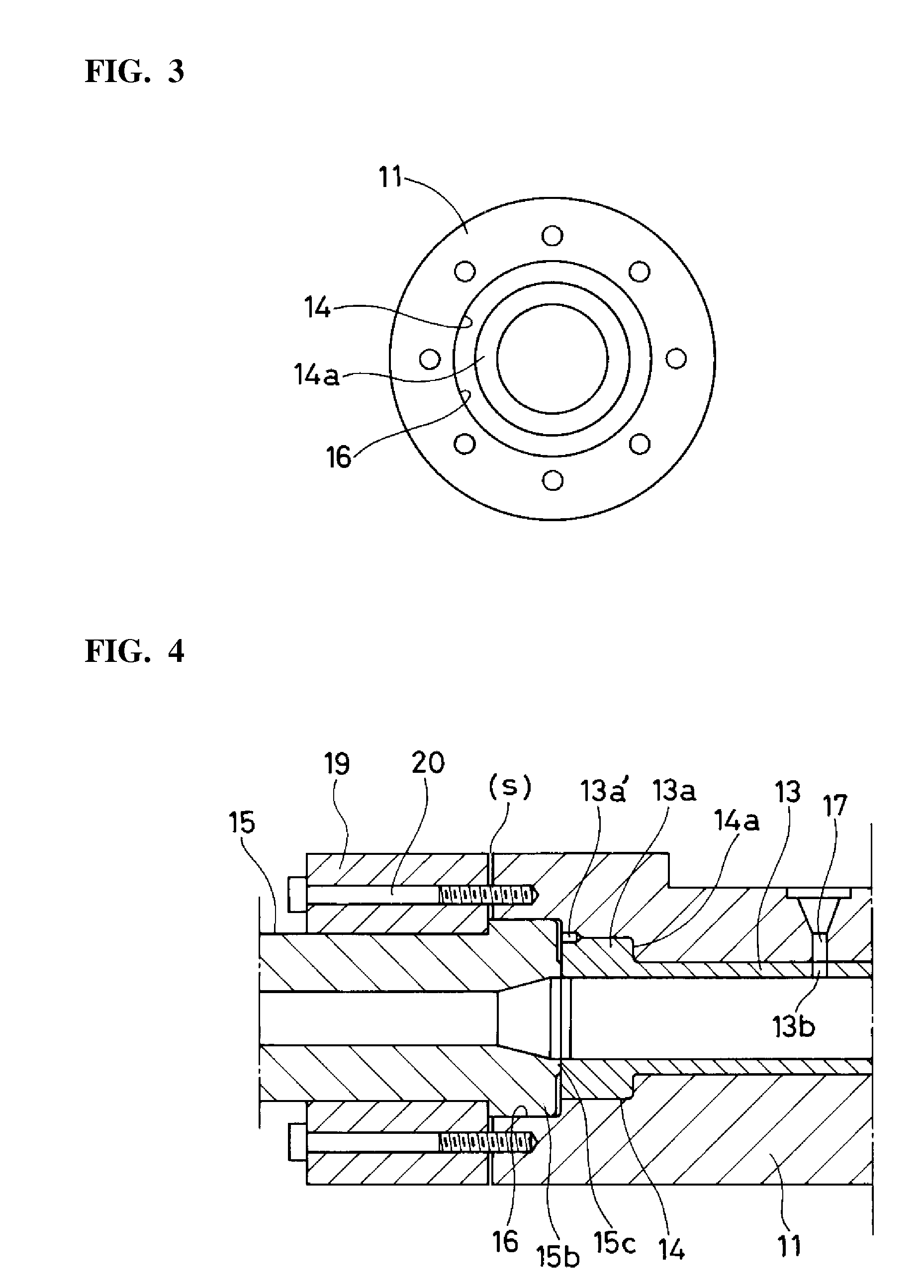

Inkjet printer with printhead cartridge and cradle that interengage via an overcentre mechanism

ActiveUS20070126844A1Facilitate replacementSimple procedureOther printing apparatusEngineeringMechanical engineering

An inkjet printer comprising: a printer body and a replaceable printhead cartridge, the printhead cartridge having a casing that supports a pagewidth printhead; the printer body having a cradle for holding the printhead cartridge in an operative position such that the pagewidth printhead is adjacent a paper path defined by the printer body; wherein, during insertion, the cradle and the casing interact to form an over centre mechanism whereby, the printhead cartridge rotates against a bias prior until reaching a balance point, after which it is biased to rotate into the operative position.

Owner:SILVERBROOK RES PTY LTD +1

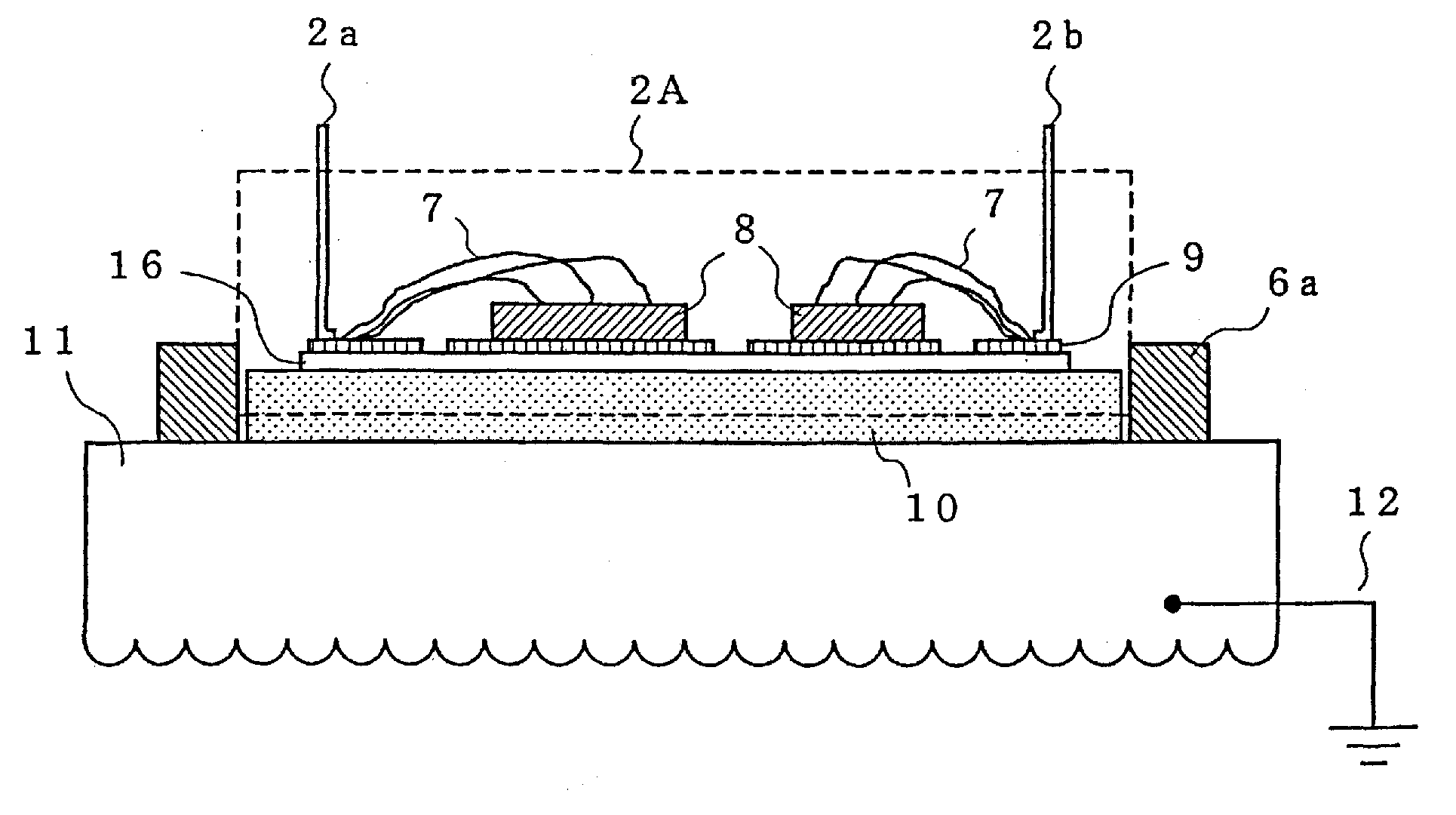

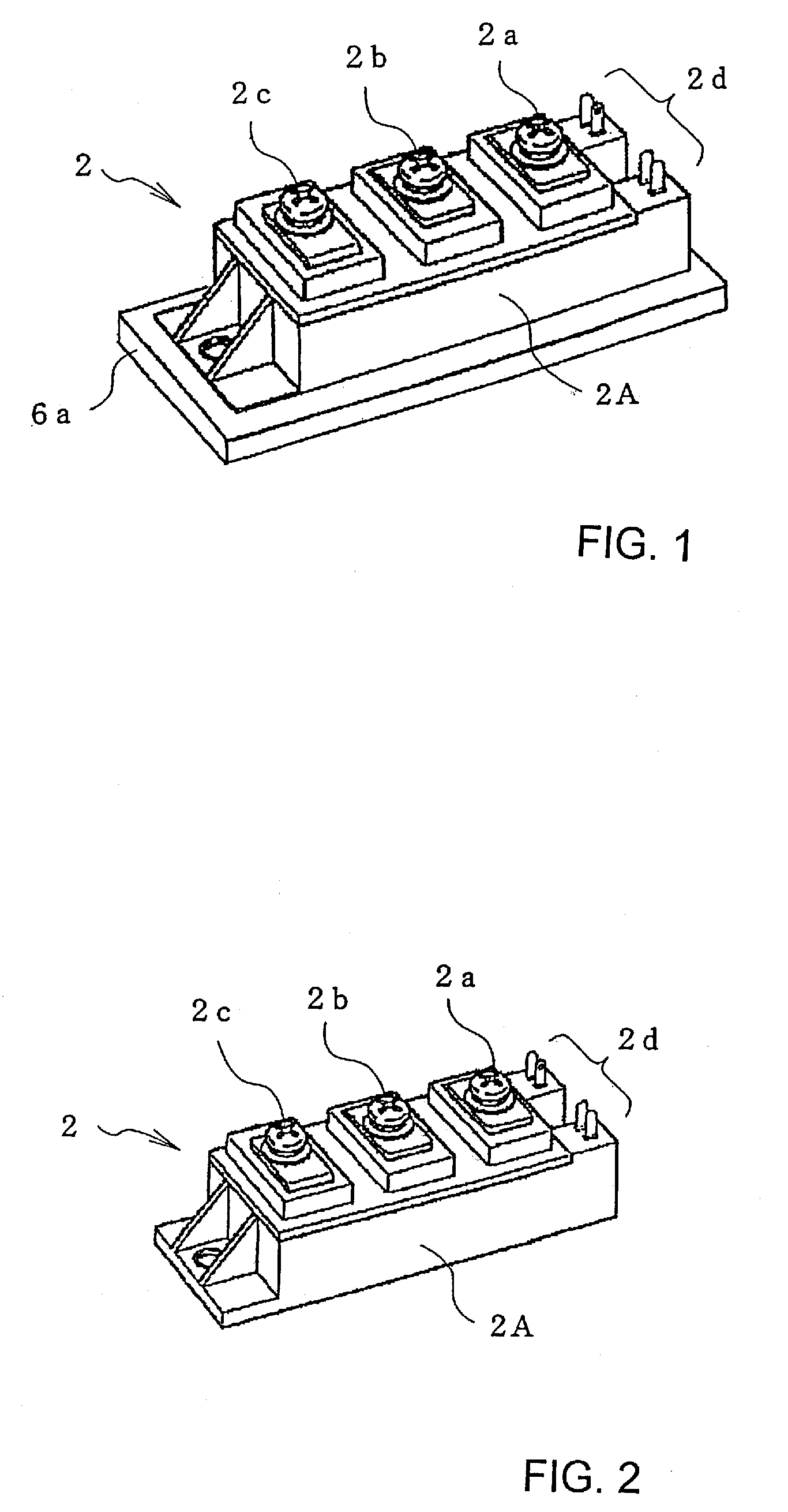

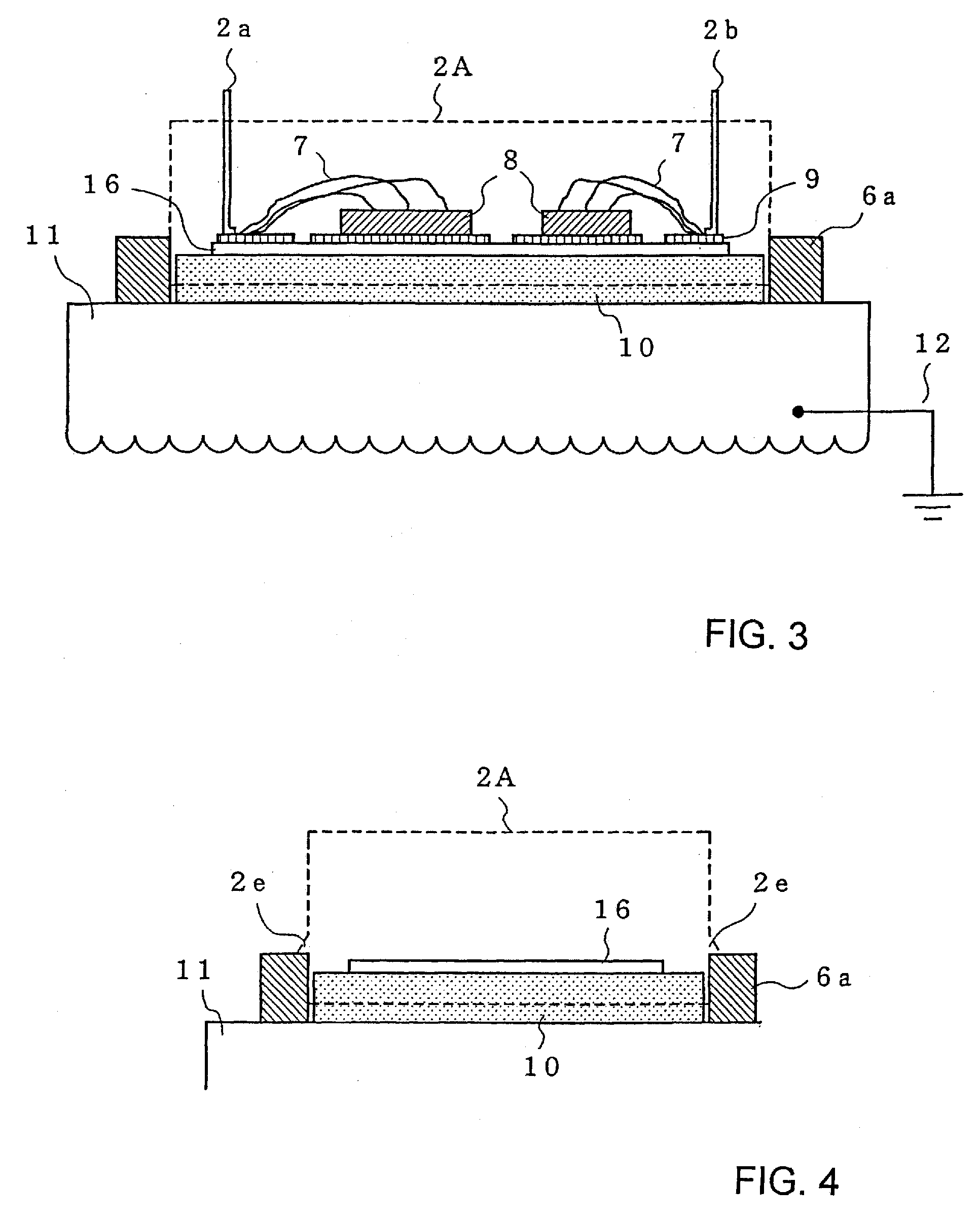

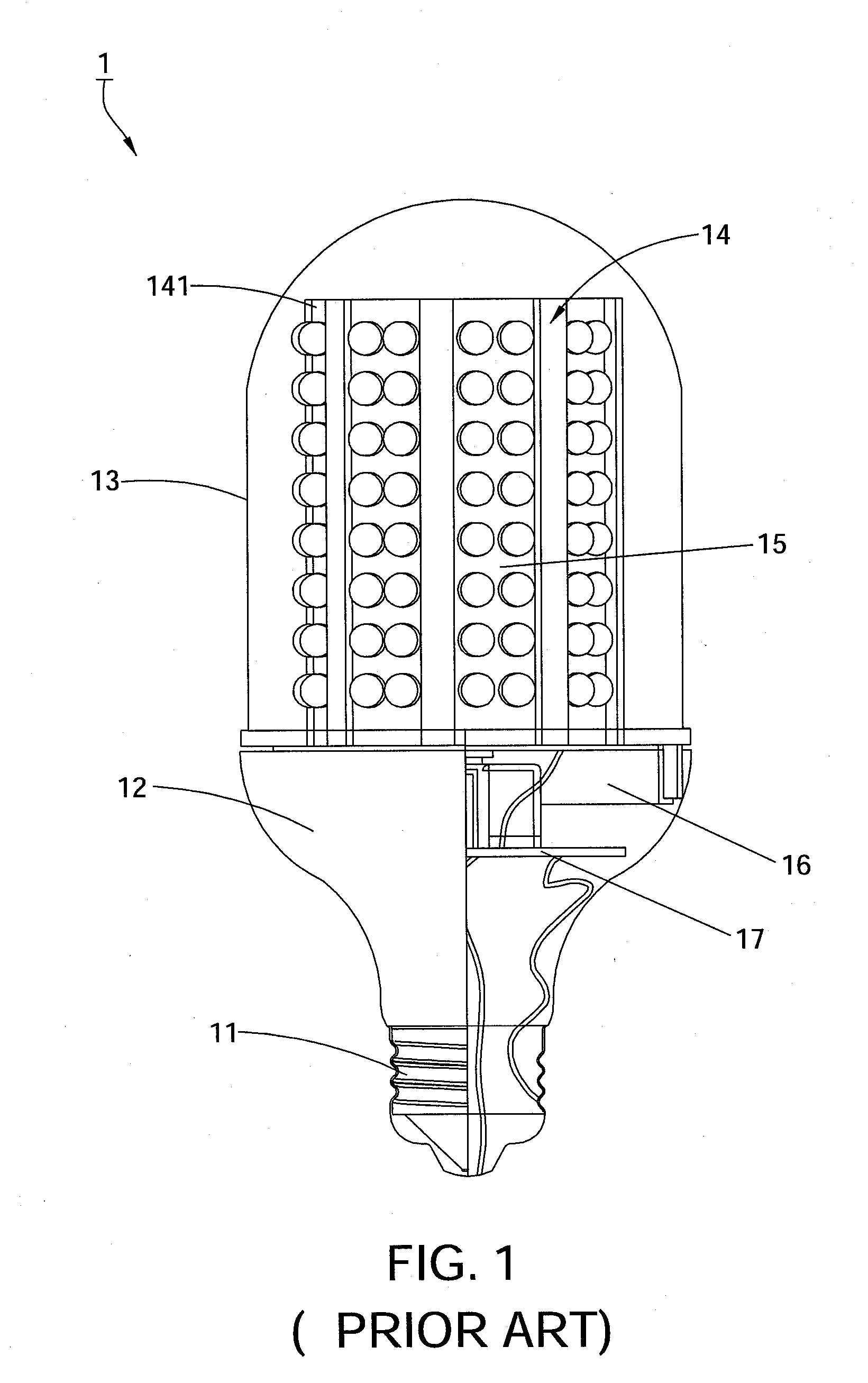

Power semiconductor module

InactiveUS20060284211A1Facilitate replacementSimple structureSemiconductor/solid-state device detailsConversion constructional detailsMagnetic corePower semiconductor device

The power semiconductor module includes a module package housing power semiconductor devices therein and a magnetic core set around the module package, such that magnetic core surrounds the power semiconductor devices such as IGBTs. Alternatively, the magnetic core is built in the module package such that the outer circumference faces of magnetic core and the side faces of module package form side faces of the power semiconductor module. The power semiconductor module according to the invention facilitates replacing the magnetic core, setting the magnetic core around the module package thereof, reducing the size thereof, simplifying the structure thereof, and easy manufacture thereof.

Owner:FUJI ELECTRIC CO LTD

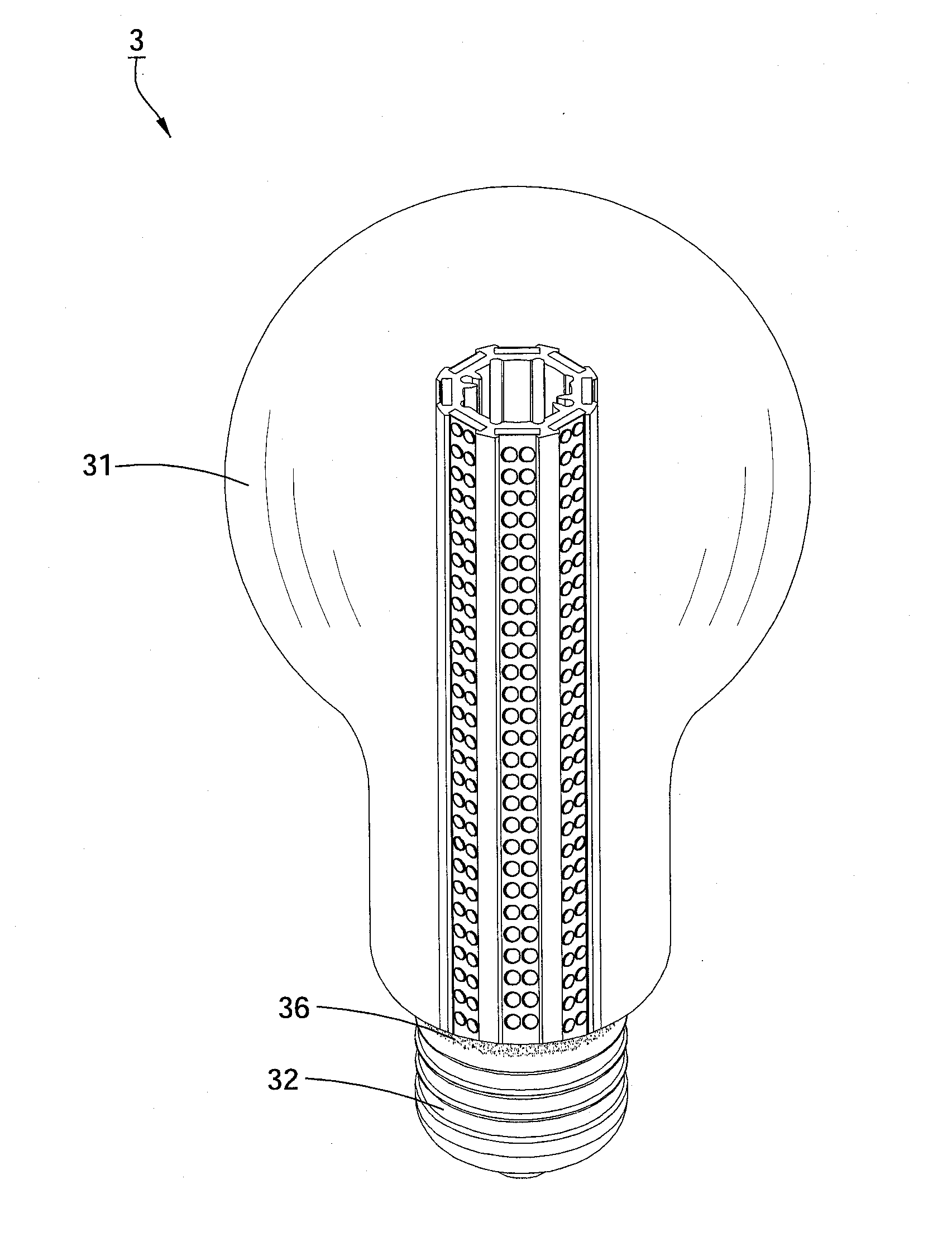

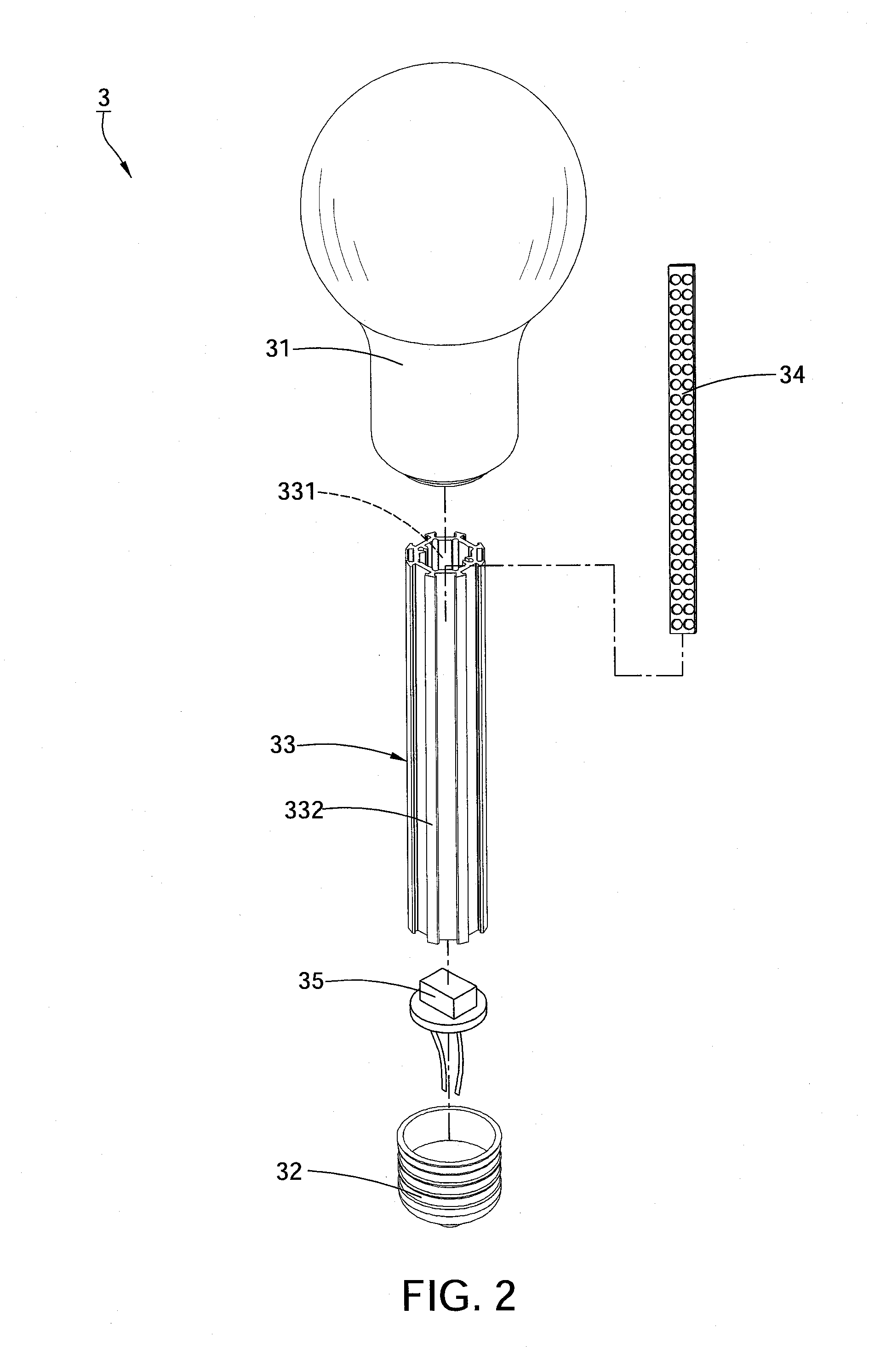

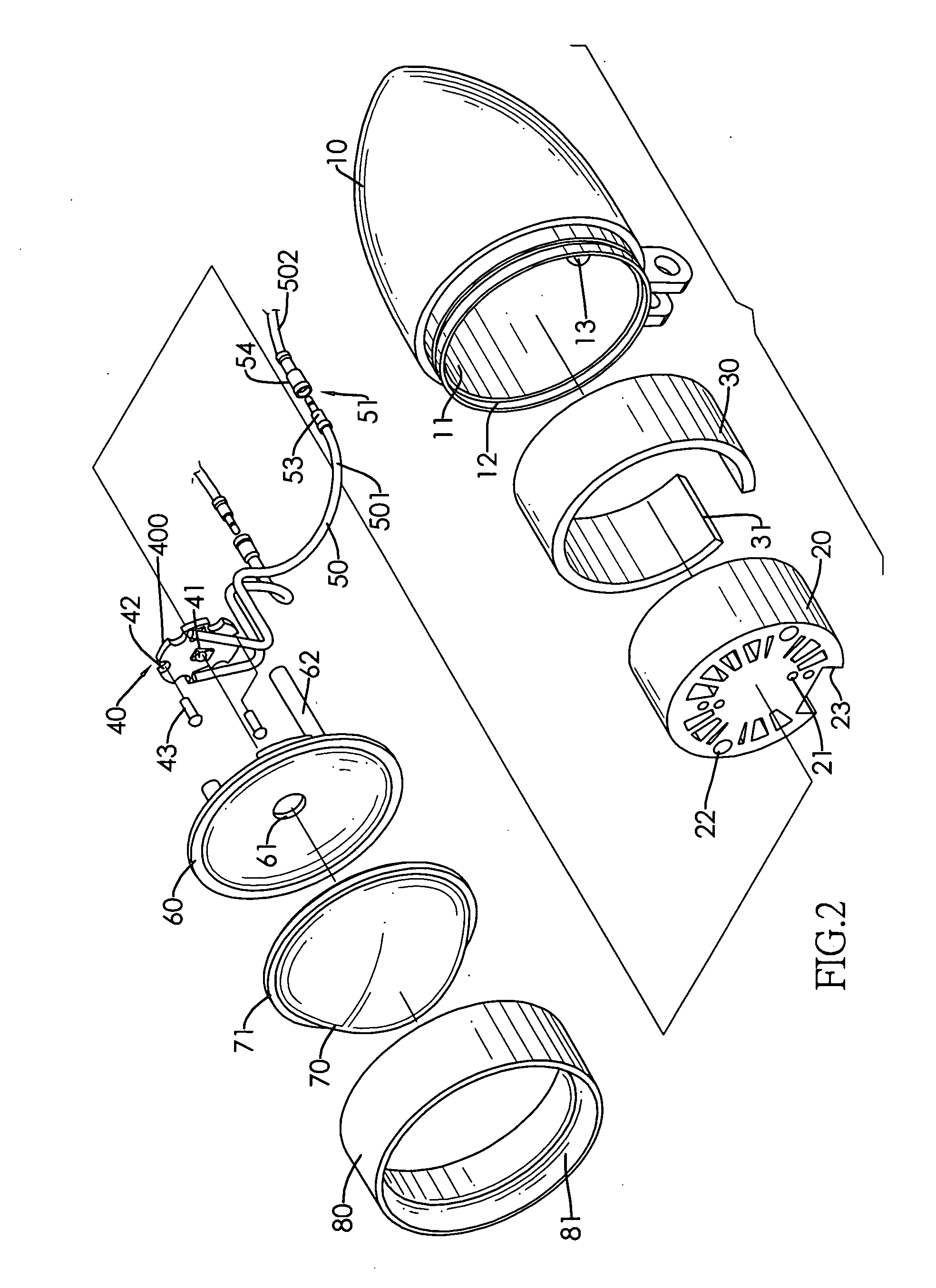

LED bulb

InactiveUS20110254423A1Facilitate replacementSwift dissipationPoint-like light sourceElectric discharge tubesLead plateEngineering

An LED bulb comprises a lamp housing, a lamp cap, a core tube disposed inside the lamp housing, a plurality of LED plates mounted on the core tube, and a controller serving to manipulate an on-off operation of the LED plates. Wherein, the controller is substantially disposed inside a room of the core tube, and the core tube has one end thereof connected to the lamp cap, so as to facilitate a free substitution of the controller and promote the using convenience. The connection of the core tube and the lamp cap serves to radiate the thermal created by the LED plates from the core tube toward the lamp cap and the lamp housing for a speedy dissipation and preventing from burning the LED bulb under a high temperature.

Owner:LEE CHUN HSIEN

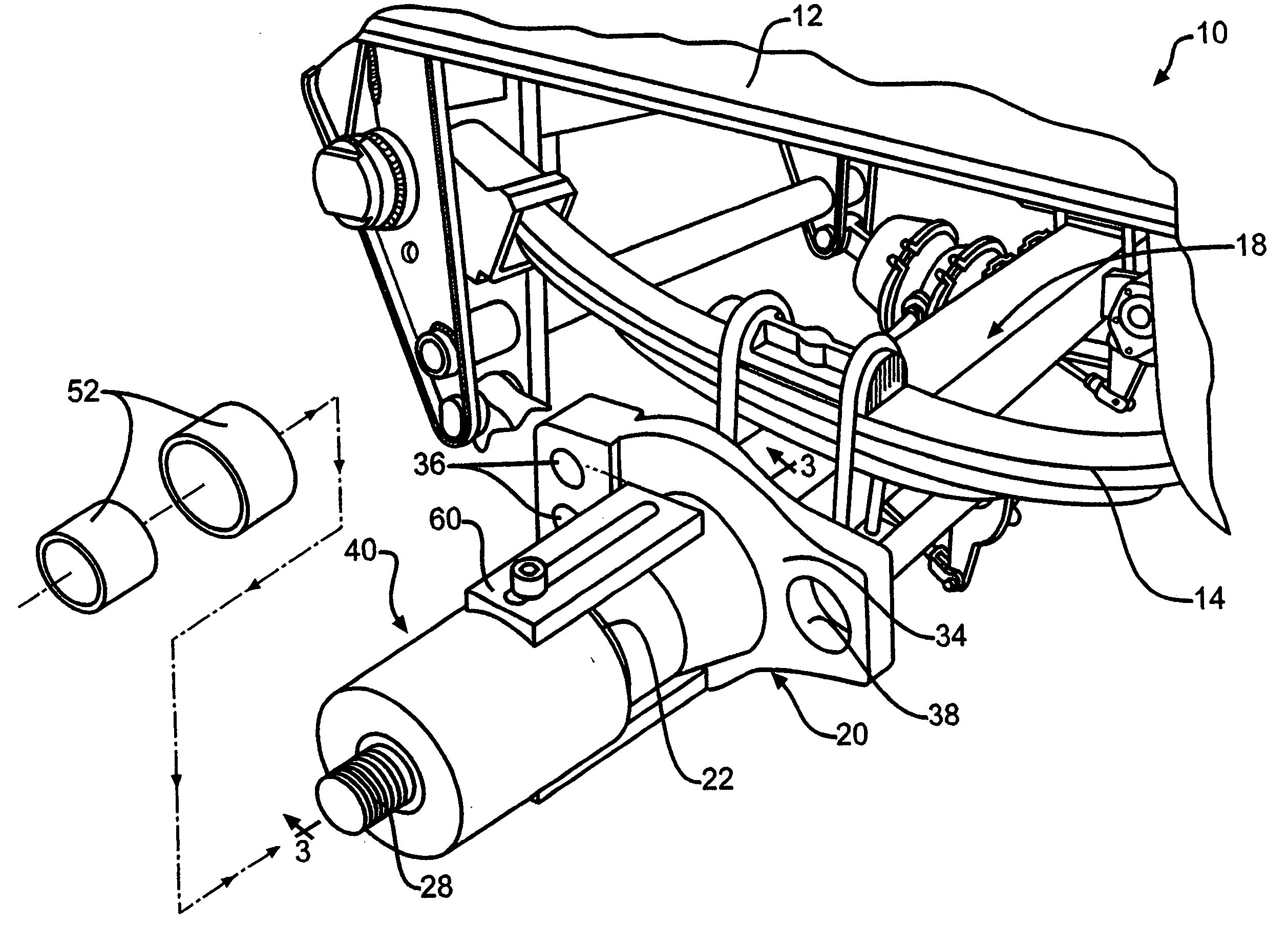

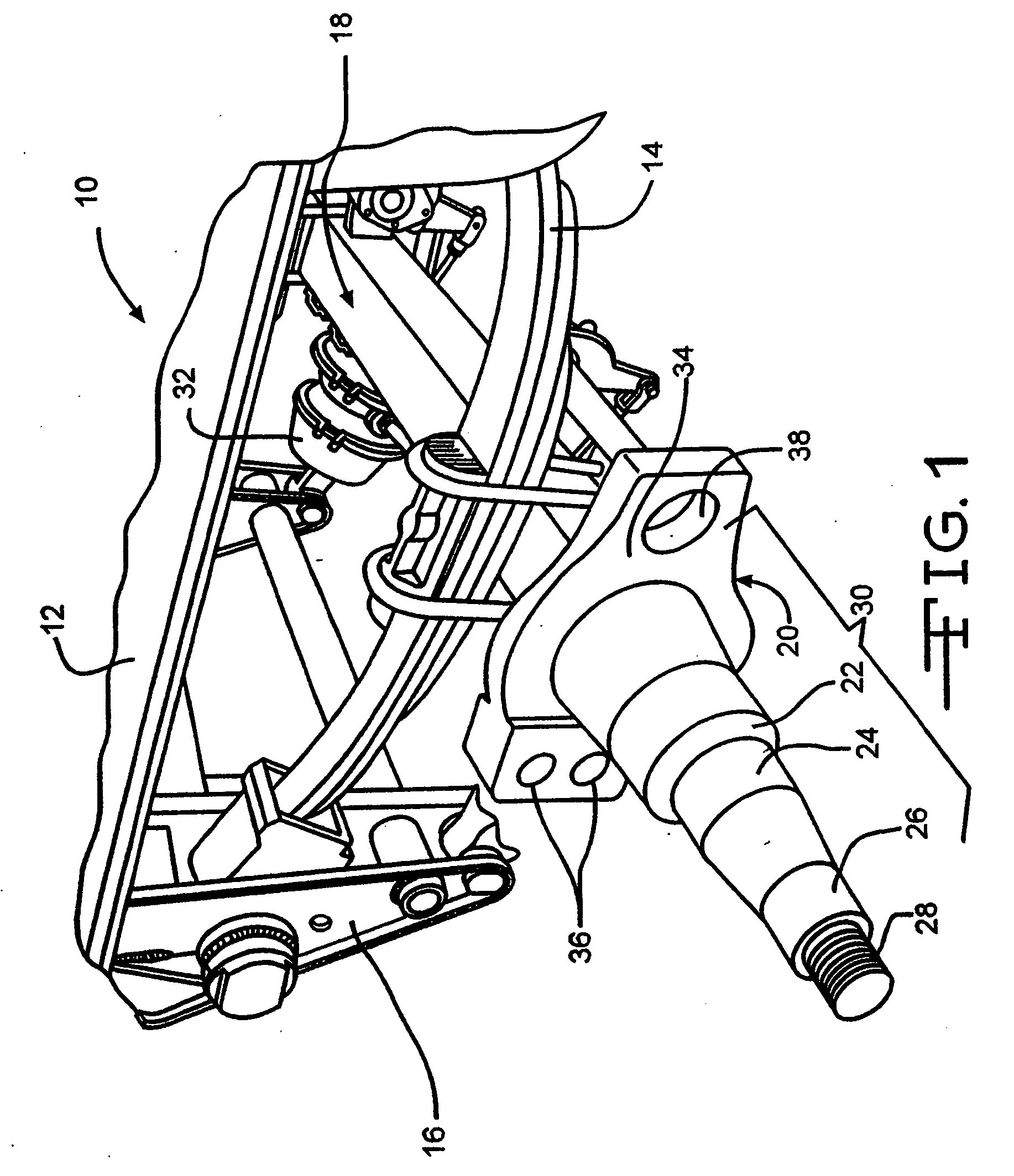

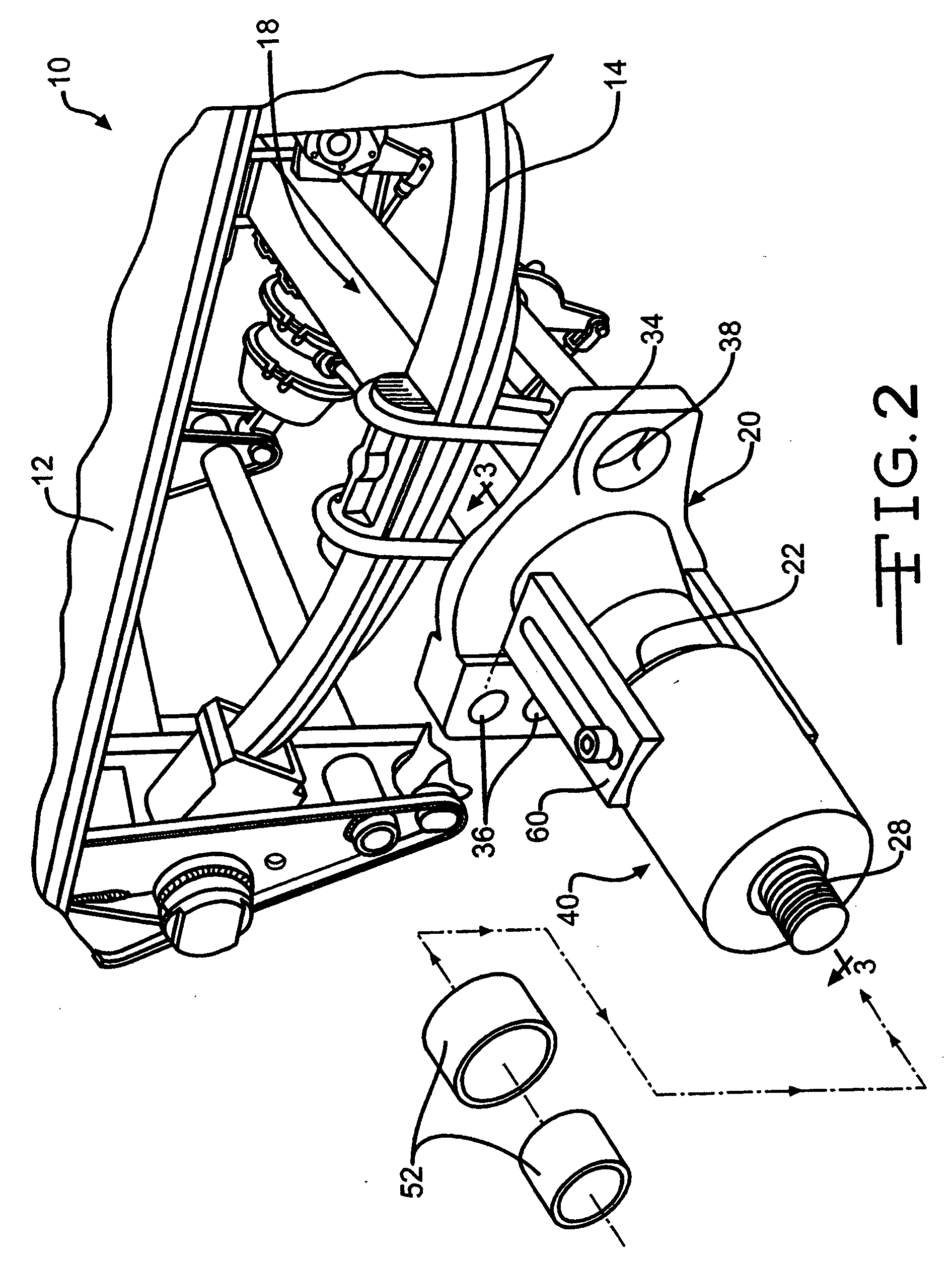

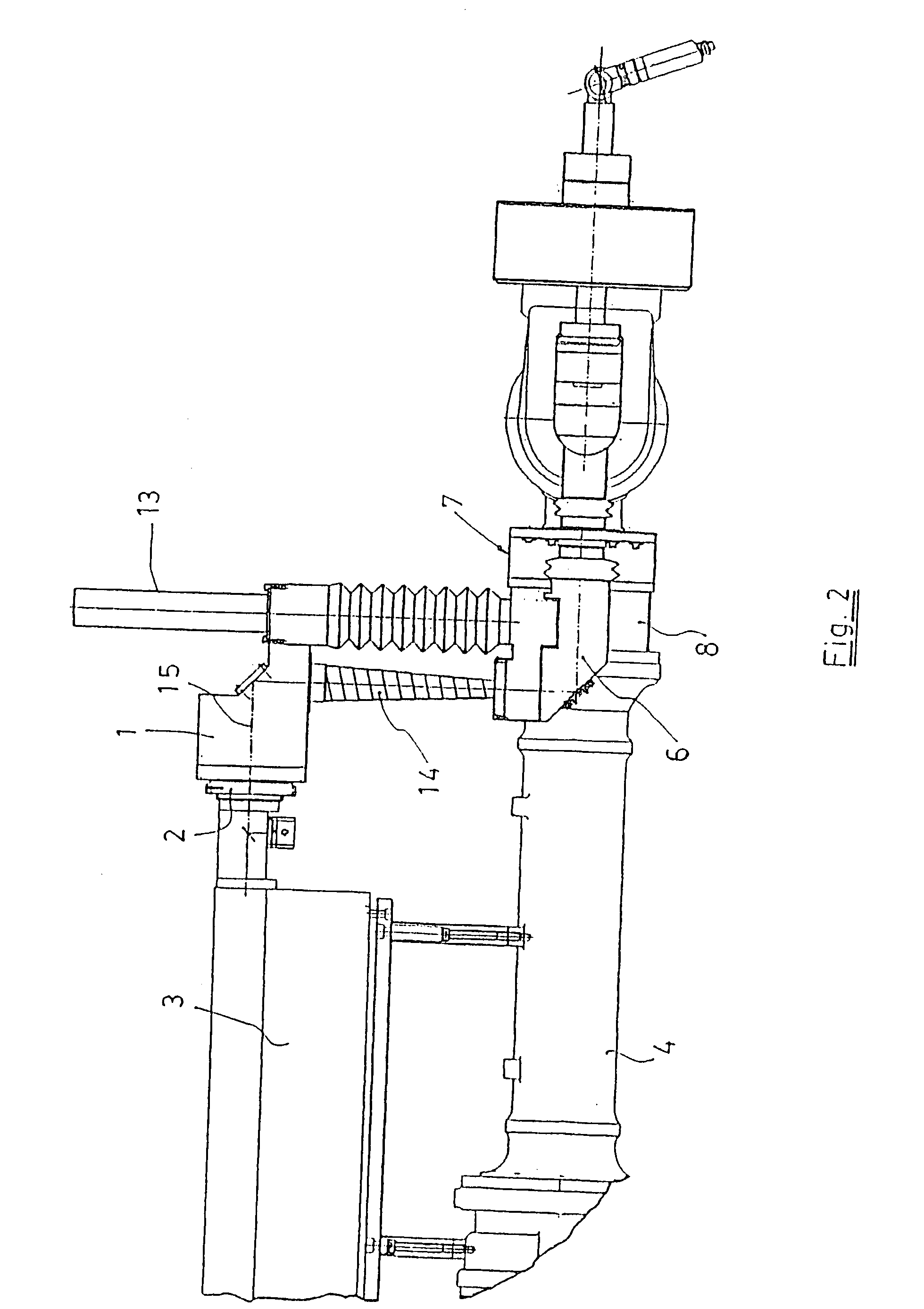

Fixture and method for replacing vehicle axle brake spiders

ActiveUS20060170279A1Facilitate replacementEasy to replaceBraking elementsDrum brakesTruckBearing surface

A fixture and method for replacing brake spiders on heavy duty vehicle and truck axles includes fixture having an assembly with a flat reference surface and two internal bores just slightly larger than the respective inner and outer bearing surfaces on the axle having a damaged brake spider. The fixture also includes longitudinally adjustable rods or fingers. The method comprises the steps of determining a reference distance between a feature of the axle and the brake. The damaged spider is removed from the axle with, for example, an oxy-acetylene torch. Next, a replacement spider is temporarily attached to the rods or fingers which are adjusted to locate the replacement spider at the previously determined reference distance. The fixture and the spider are then placed on the axle. The spider is then tack welded to the axle, the fixture is removed and the spider is securely welded to the axle.

Owner:EBERT JAMES L

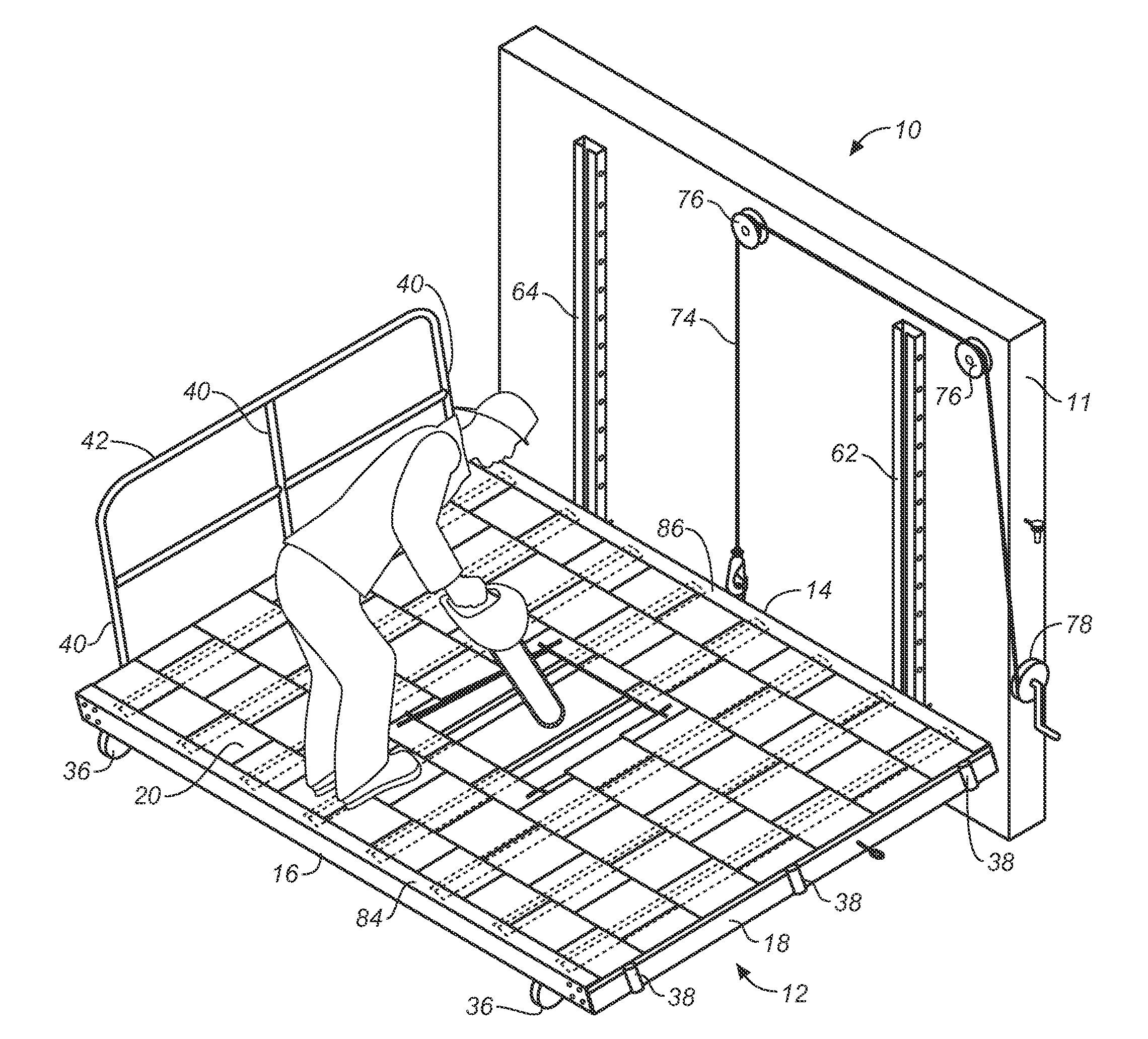

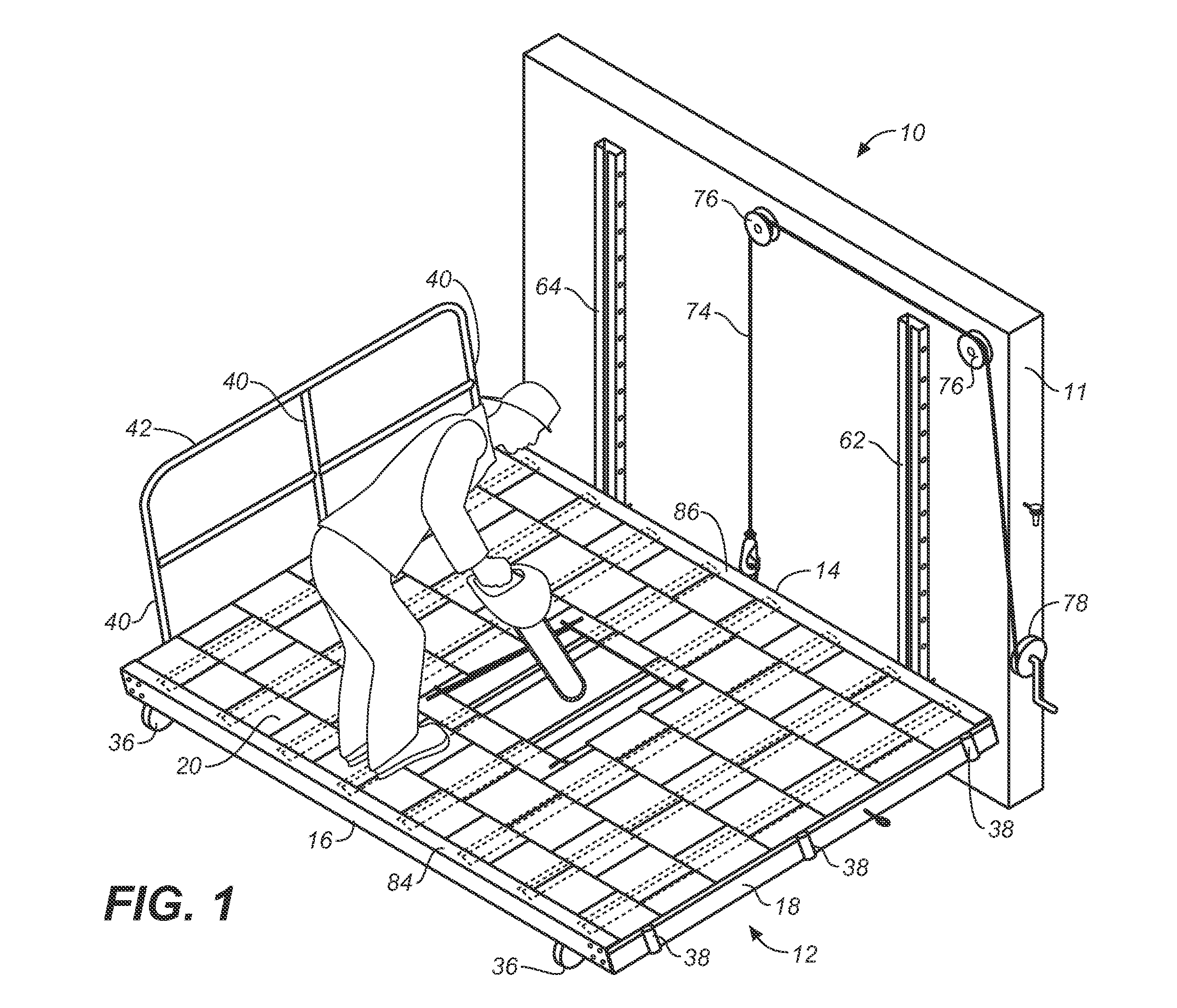

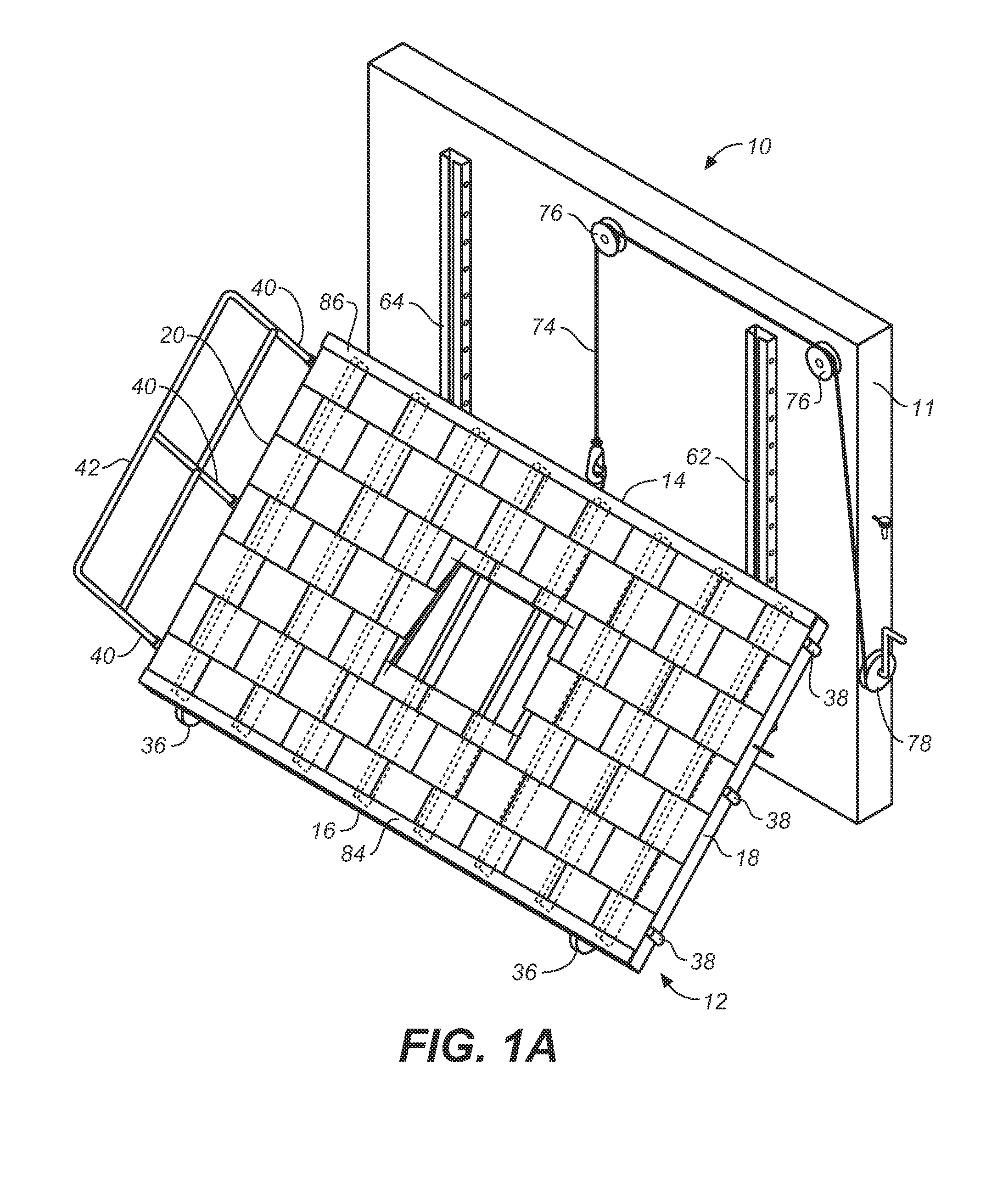

Adjustable pitch simulated roof for training firefighters in roof ventilation procedures

An adjustable pitch simulated roof for training firefighters in roof ventilation procedures. The apparatus includes a vertical support structure and a pitched roof portion adjustably connected to the vertical support structure. The pitched roof portion includes an outer frame defining an interior region, a plurality of rafter brackets disposed on the outer frame, a plurality of rafters placed the interior region, and a plurality of roofing sheets covering the rafters so as to form a roof field. A mechanical winch or other adjustment means are provided for rapidly and easily changing the roof pitch, and a locking mechanism locks the roof portion in the selected position. A stationary and a trailer-mounted mobile embodiment are each shown and described.

Owner:PAGANINI JEFFREY

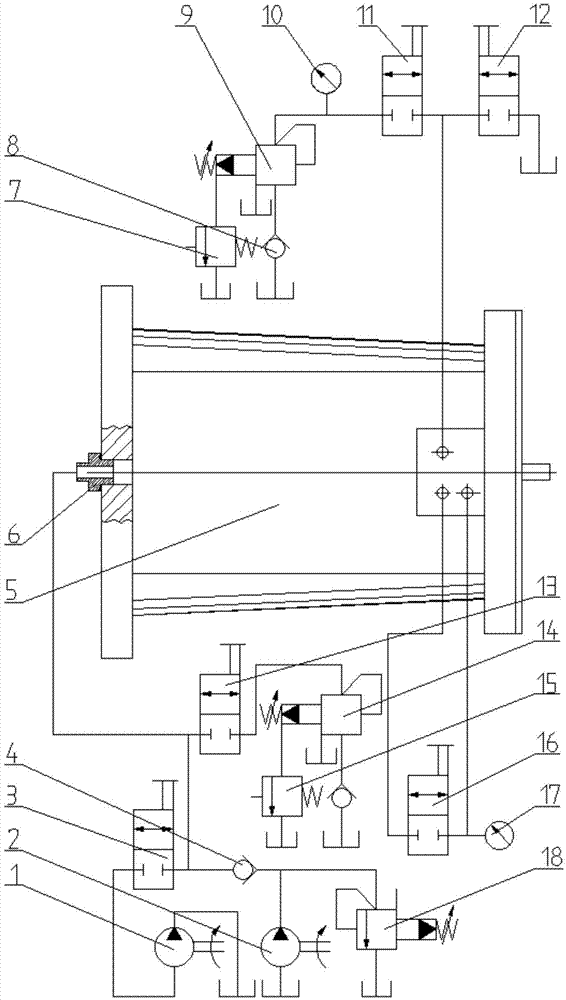

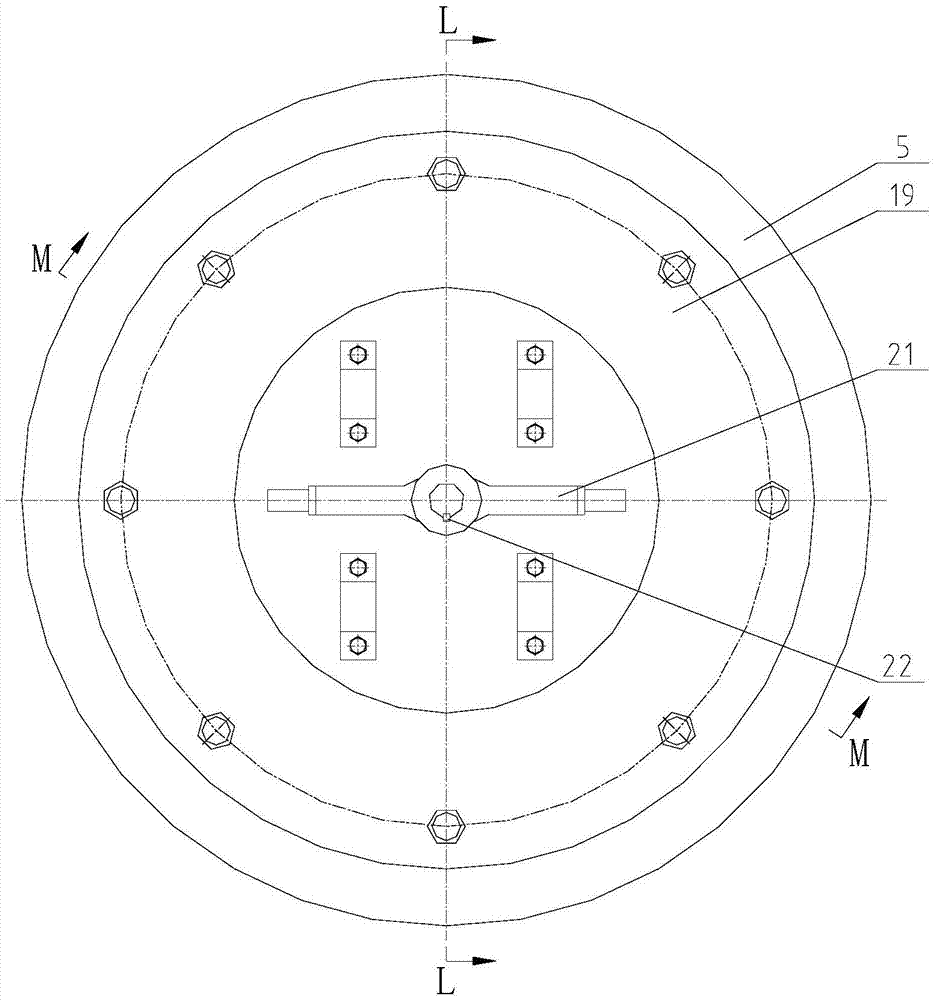

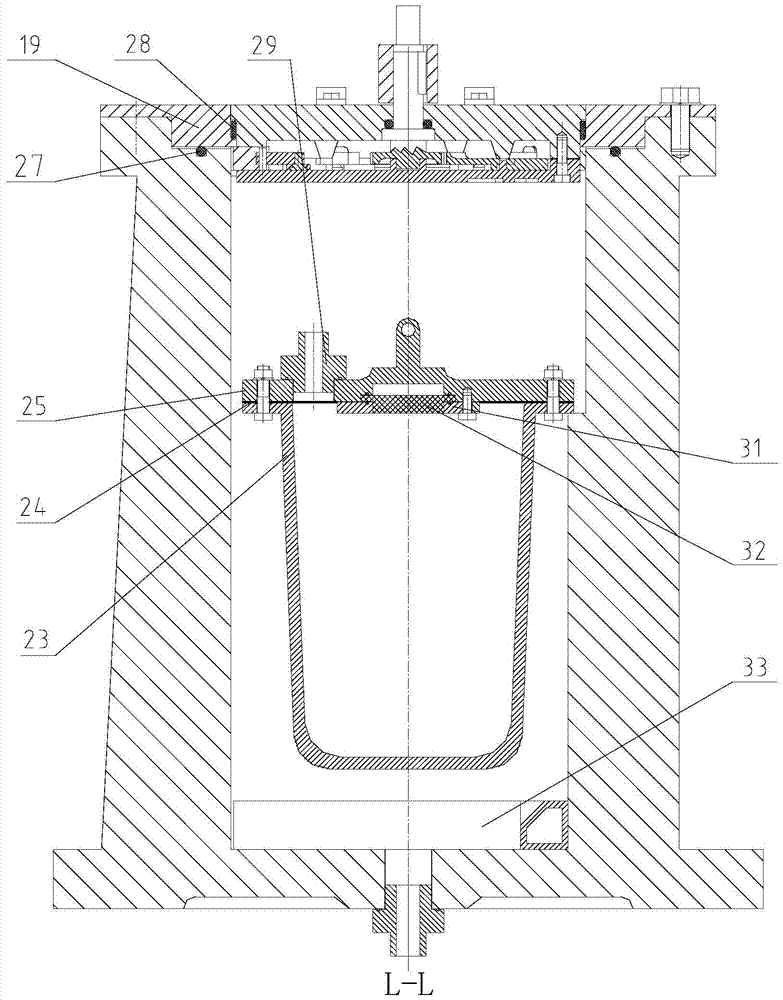

Testing device for hydrostatic pressure

ActiveCN105445108AEasy to disassembleFacilitate replacementMaterial strength using tensile/compressive forcesEngineeringHigh pressure

The invention discloses a testing device for hydrostatic pressure. The testing device comprises a high pressure vessel shell and a high pressure vessel cover, wherein a high pressure vessel cover frame is arranged at the top of the high pressure vessel shell; the high pressure vessel cover is arranged in the high pressure vessel cover frame; a cover base plate is mounted under the high pressure vessel cover; a locking sealing device is arranged on the high pressure vessel cover and is used for sealing the cover base plate; a sample device is arranged in the high pressure vessel shell; a camera module is arranged under the sample device; a water supply system is connected with the bottom of the high pressure vessel shell; the sample device comprises a sample and a sample cover; quick couplers are mounted on the sample cover; a camera position external frame for fixing the camera is fixedly mounted under the sample cover; a transparent block is mounted at the center of the camera position external frame; two quick couplers are mounted on the sample cover. The testing device for hydrostatic pressure provided by the invention is characterized in that the port of a tested sample is connected with an end cover bolt and is embedded in the chamber of the high pressure vessel, the disassembling is convenient and quick, the replacement is benefited and the true environment of the hydrostatic pressure can be accurately simulated.

Owner:CETC NINGBO MARINE ELECTRONICS RES INST

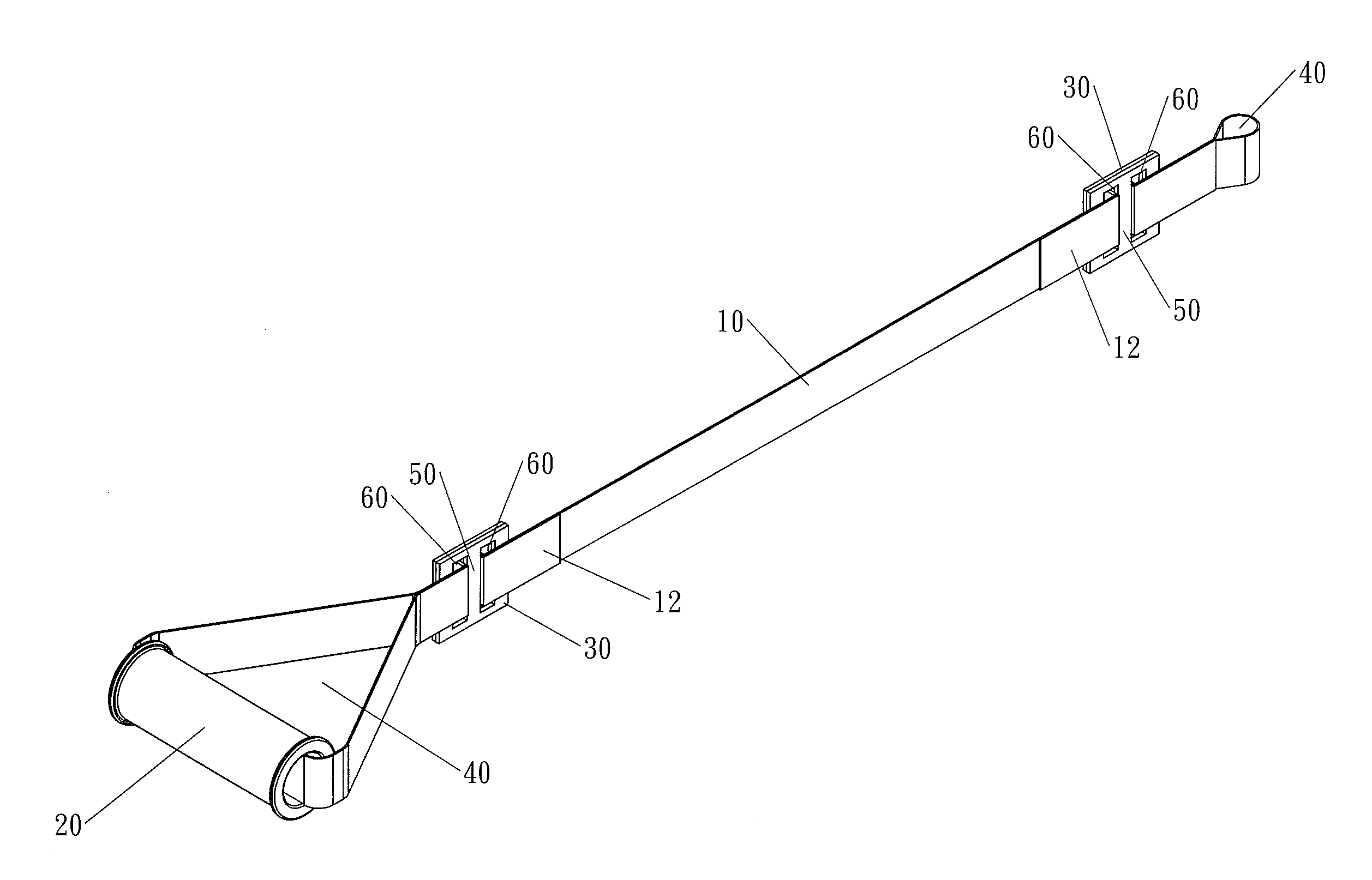

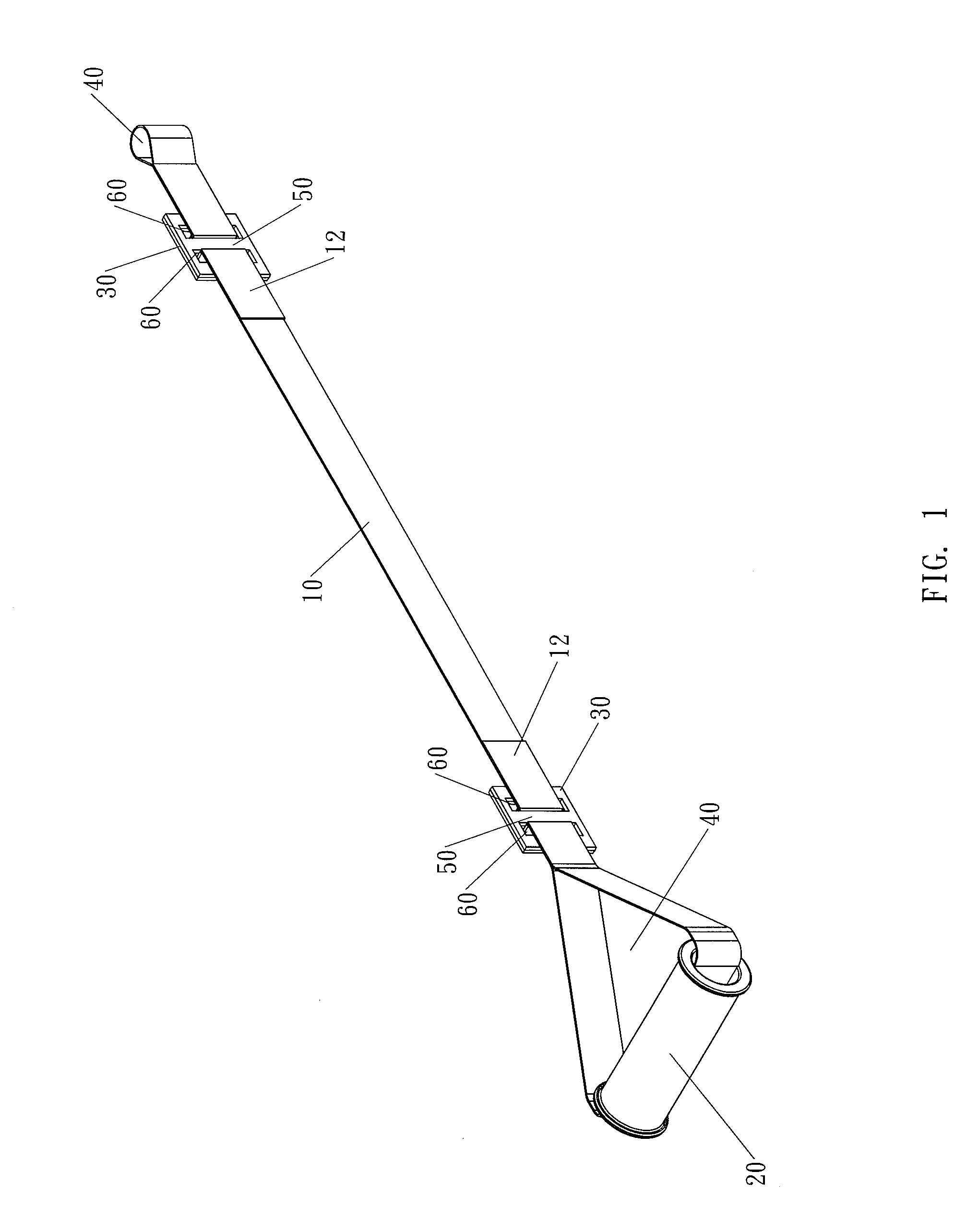

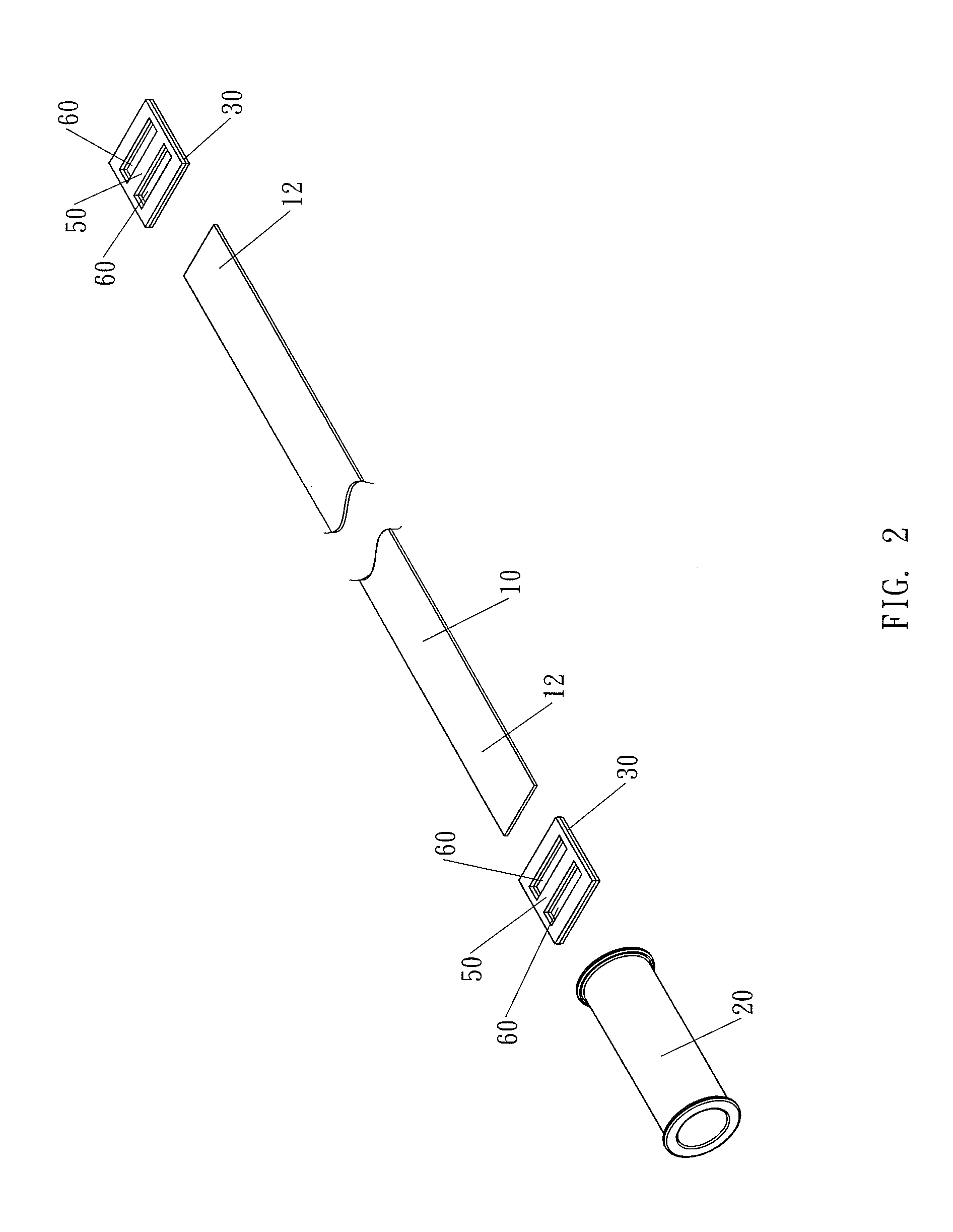

Suspension Exercising Device Having Adjustable Length

InactiveUS20120190510A1Facilitate operationFacilitate replacementMuscle exercising devicesEngineering

Owner:WANG SHIH JUNG

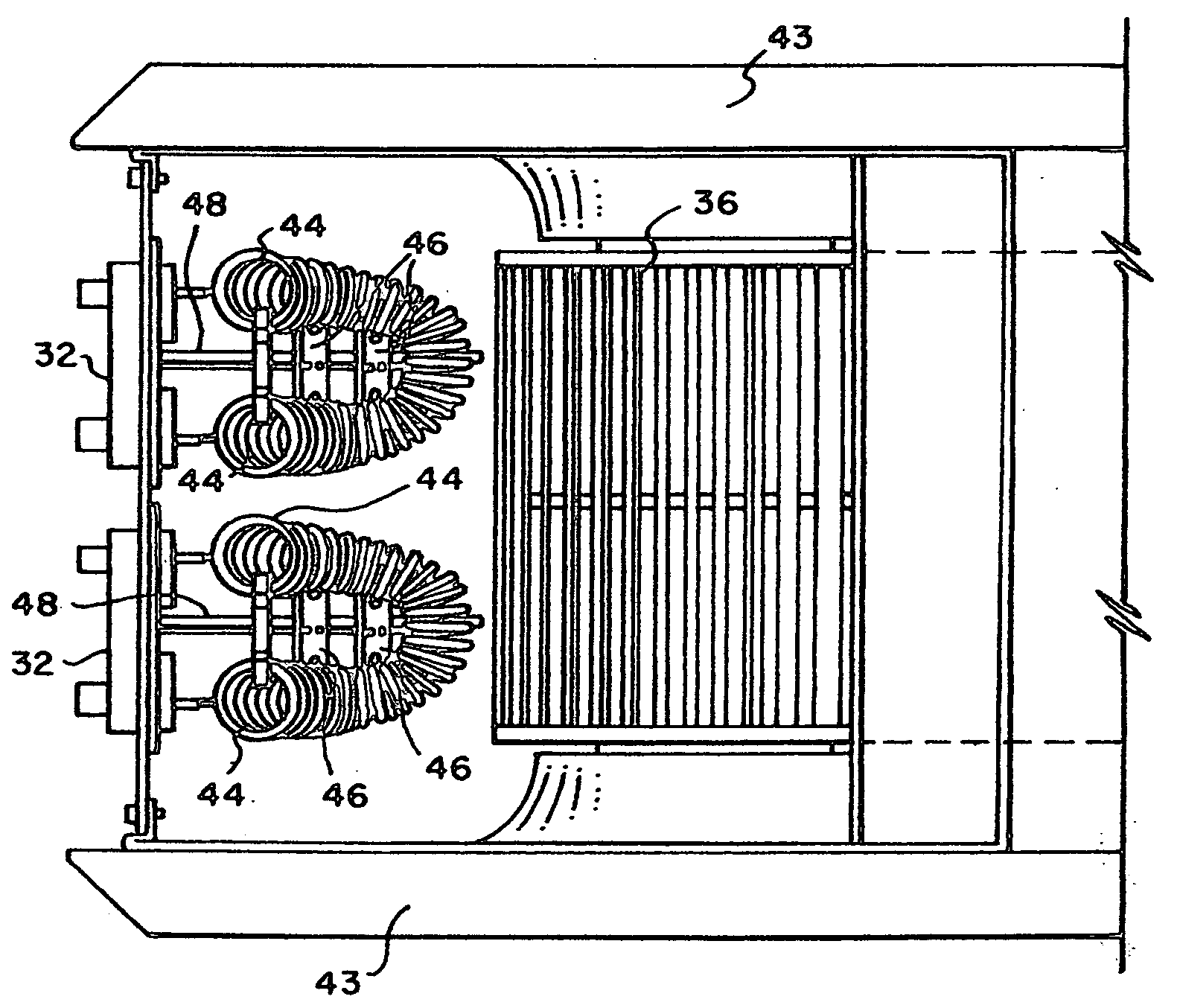

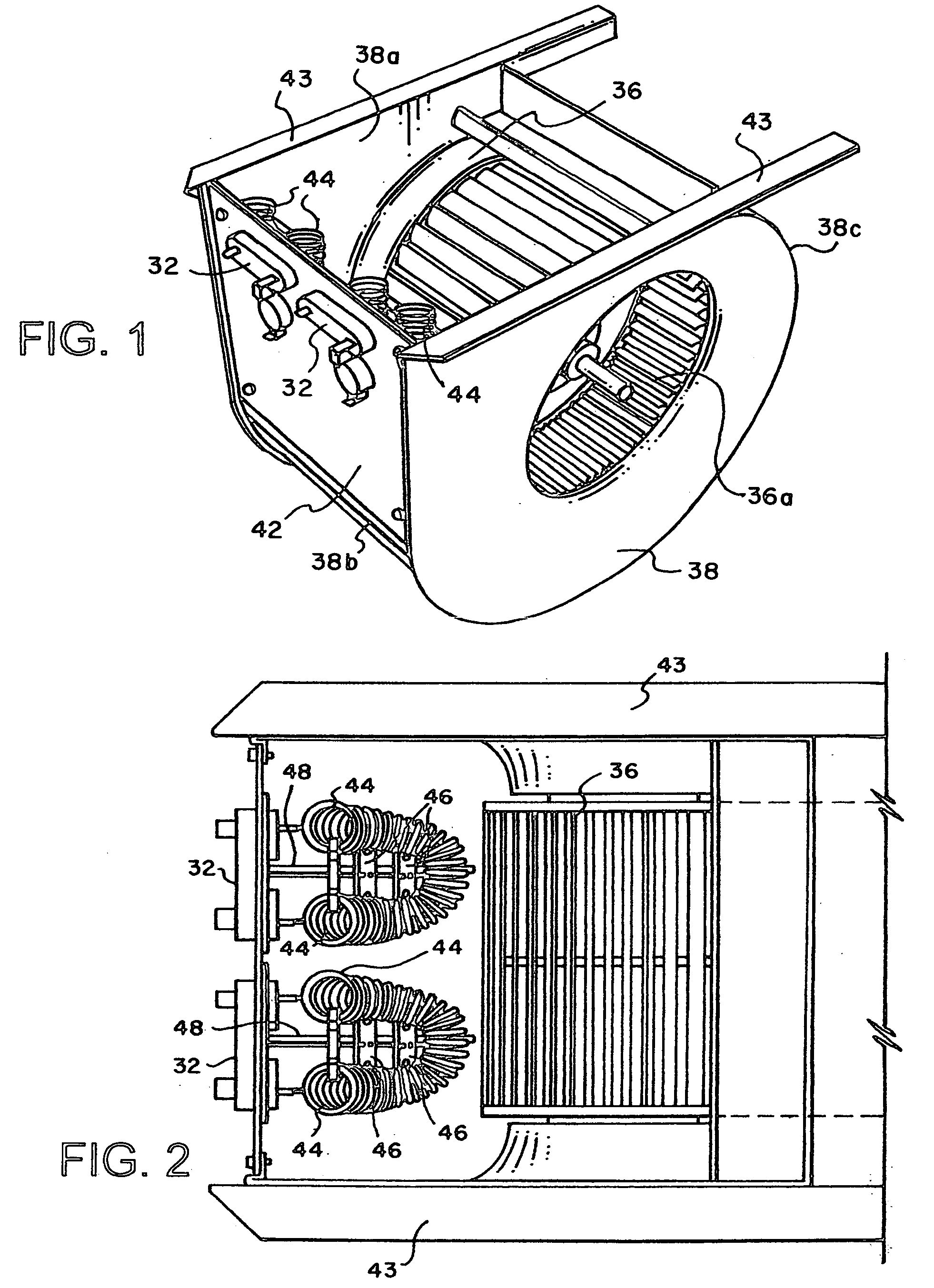

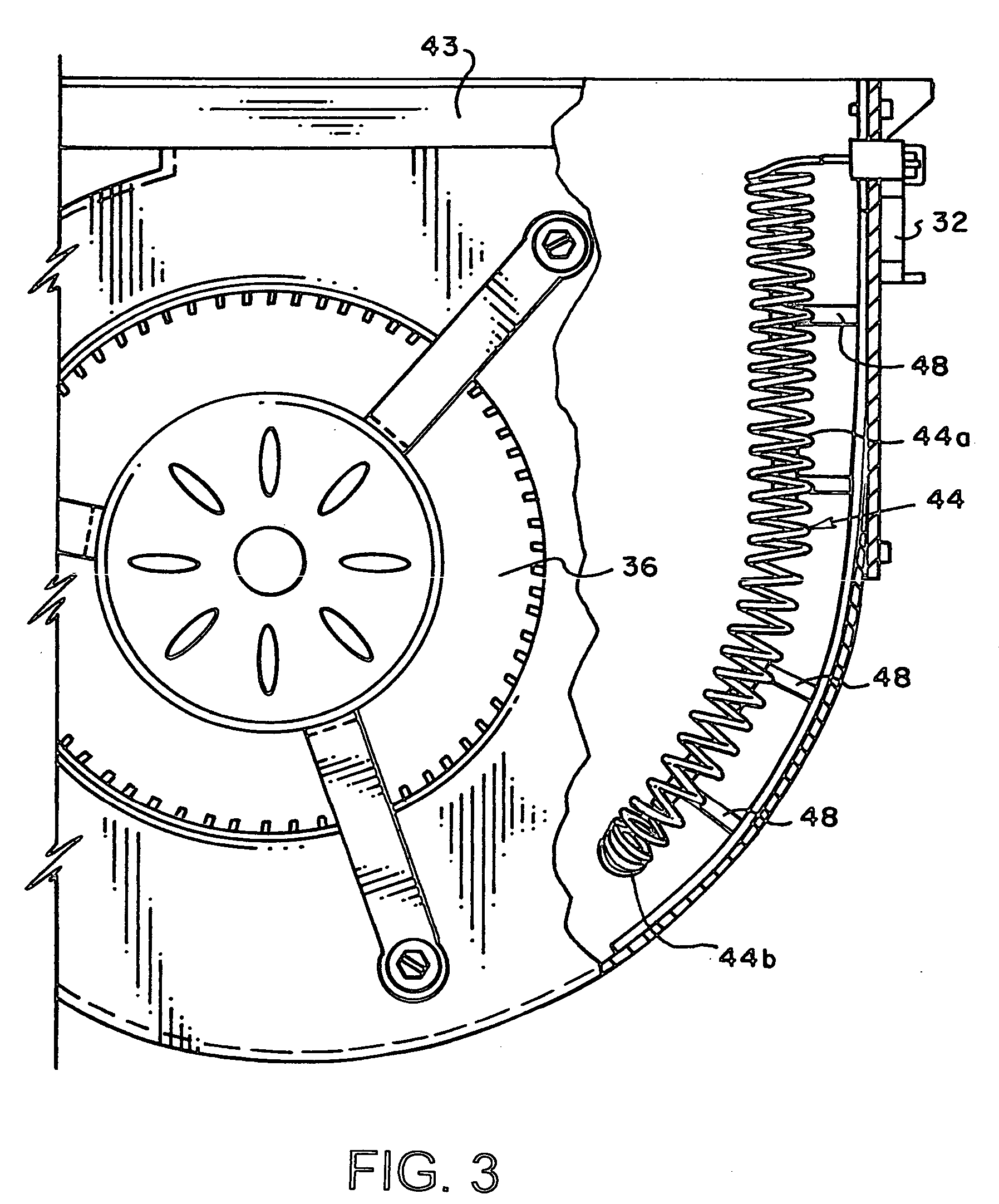

Air conditioning apparatus with blower and electric heater in common housing

ActiveUS20050147400A1Reduce in sizeFacilitate replacementDrying solid materials with heatDrying gas arrangementsAirflowElectrical and Electronics engineering

Air conditioning apparatus is provided in which an air blower and an electric heater assembly are located in a common housing with the heater assembly projecting into the housing from a wall thereof in transverse relationship to the blower. This configuration eliminates the need for a dedicated space for the electric heater downstream of the blower housing, which reduces the size of the apparatus. The wall of the housing includes an opening through which the heater assembly is insertable into the housing. The heater assembly includes a mounting plate to close off the wall opening and to removably mount the heater assembly with the housing. The heater assembly preferably further includes an open coil electric heater, with a major dimension of the heater being oriented generally parallel to the direction of air flow in the blower housing.

Owner:ADVANCED DISTRIBUTOR PRODS

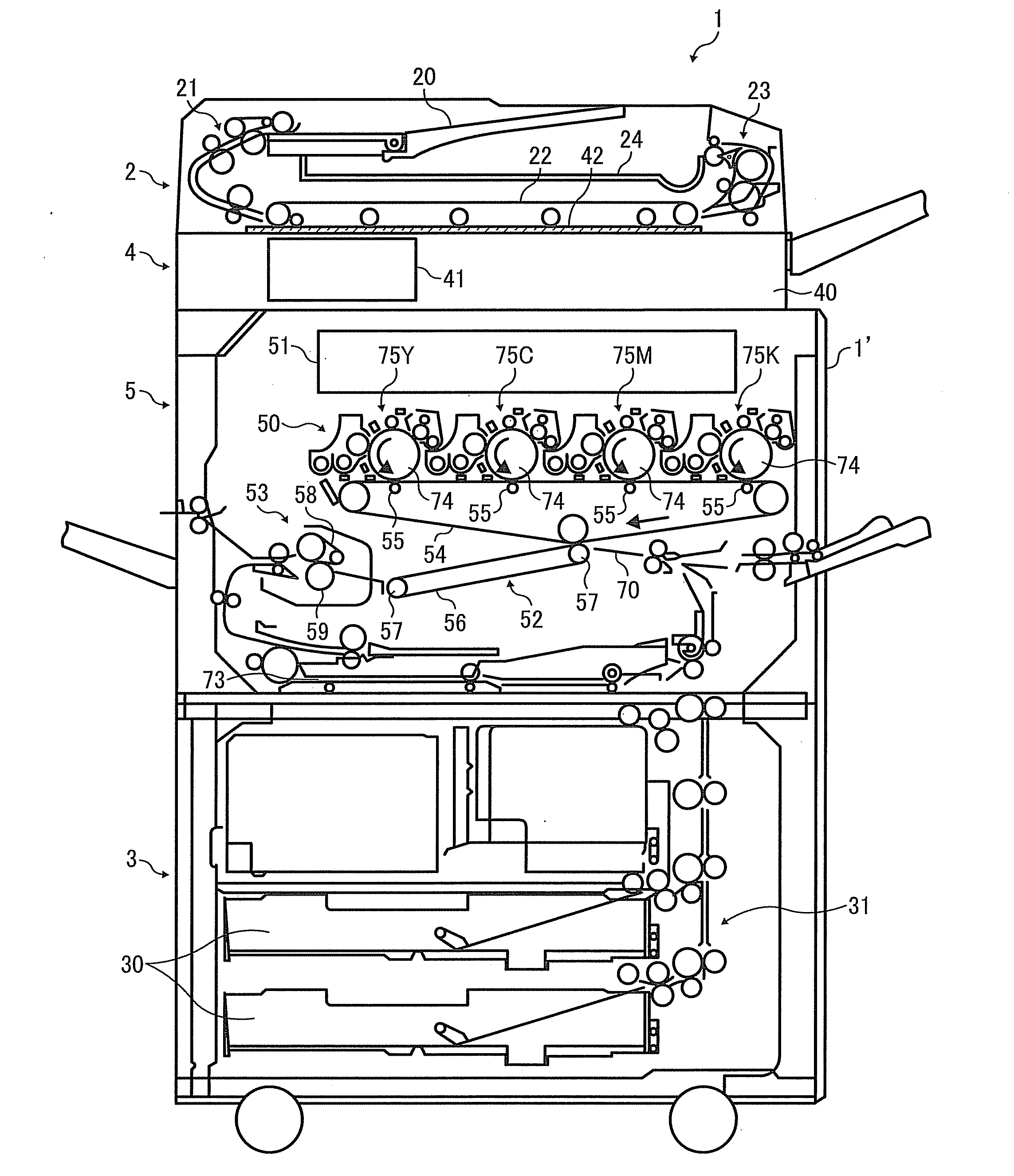

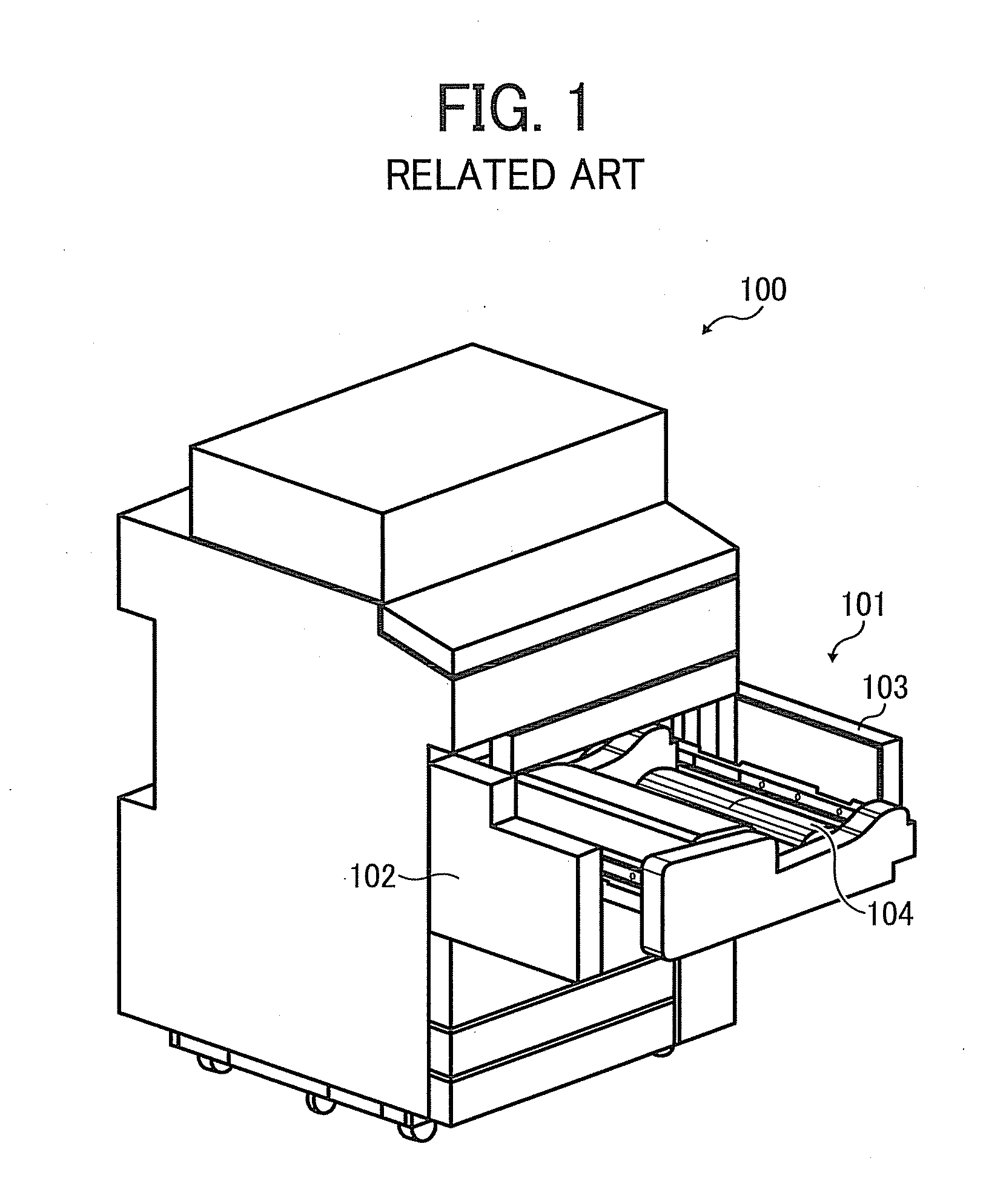

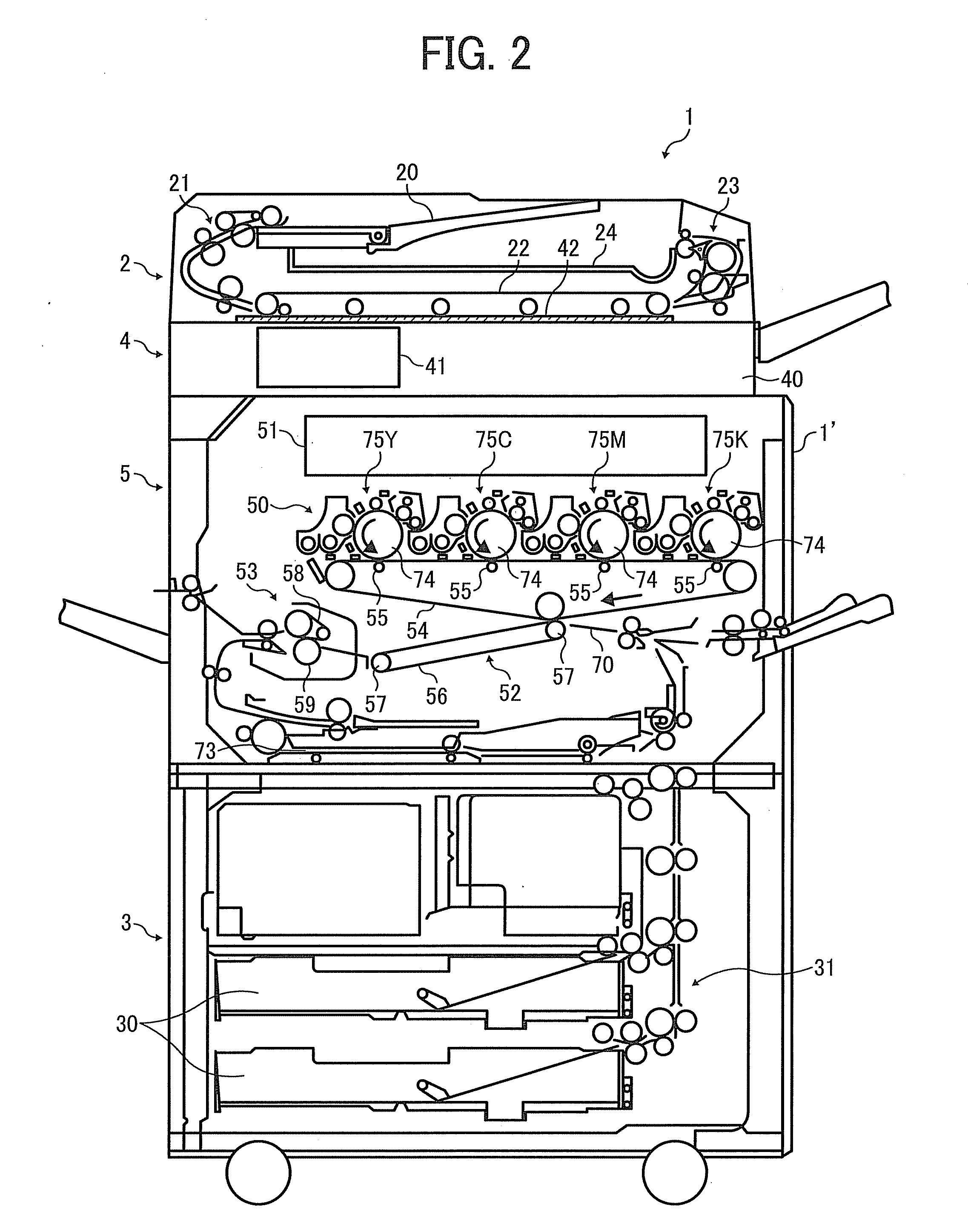

Image forming apparatus

InactiveUS20120294645A1Cost reductionFacilitate replacementElectrographic process apparatusFront coverImage formation

An image forming apparatus including an image forming part to form an image on a recording medium, a sheet feeder to feed the recording medium to the image forming part, a drawer unit withdrawably installable in the image forming apparatus disposed within the image forming pat, and a front cover mounted on the drawer unit. The front cover is closably openable relative to the image forming apparatus with movement of the drawer unit.

Owner:RICOH KK

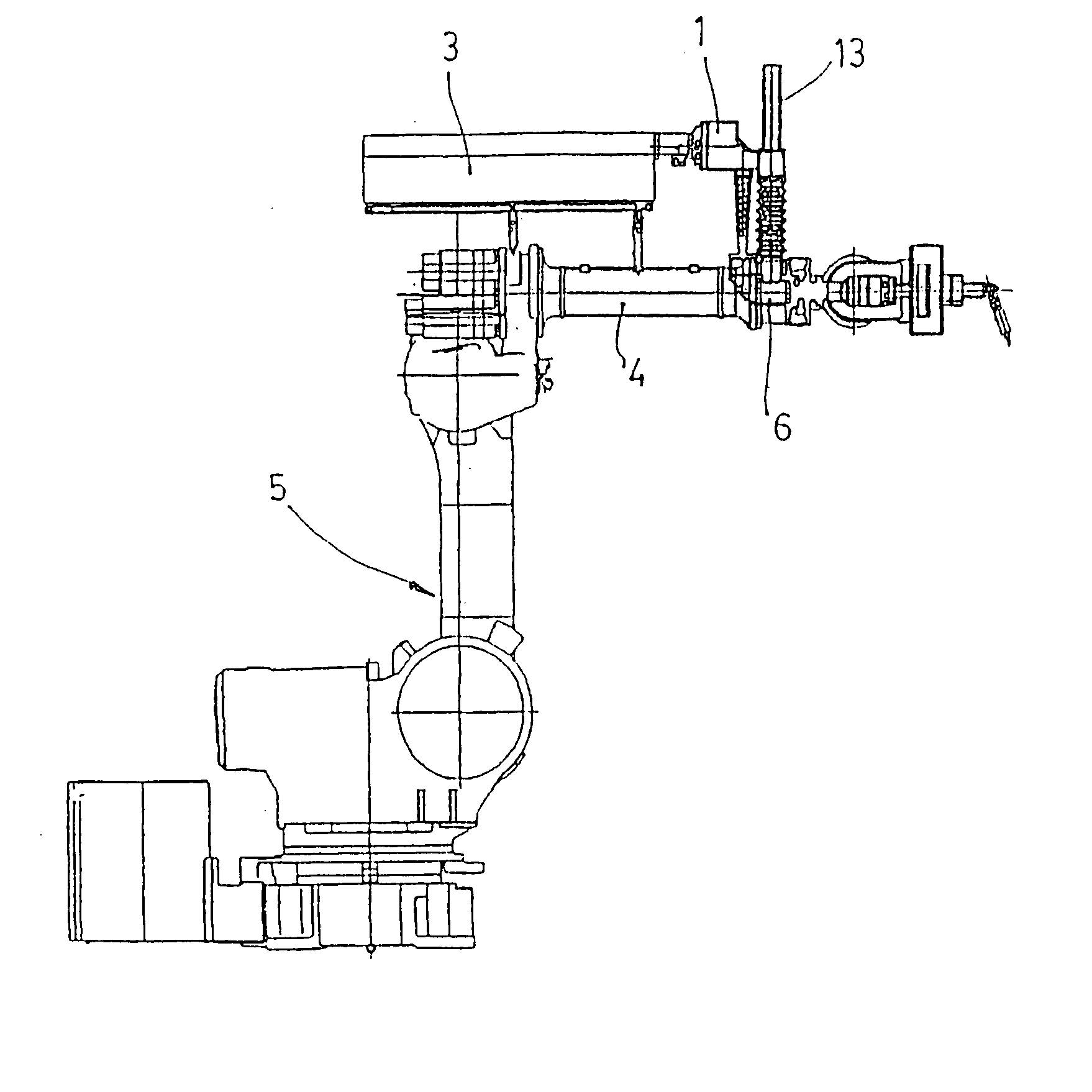

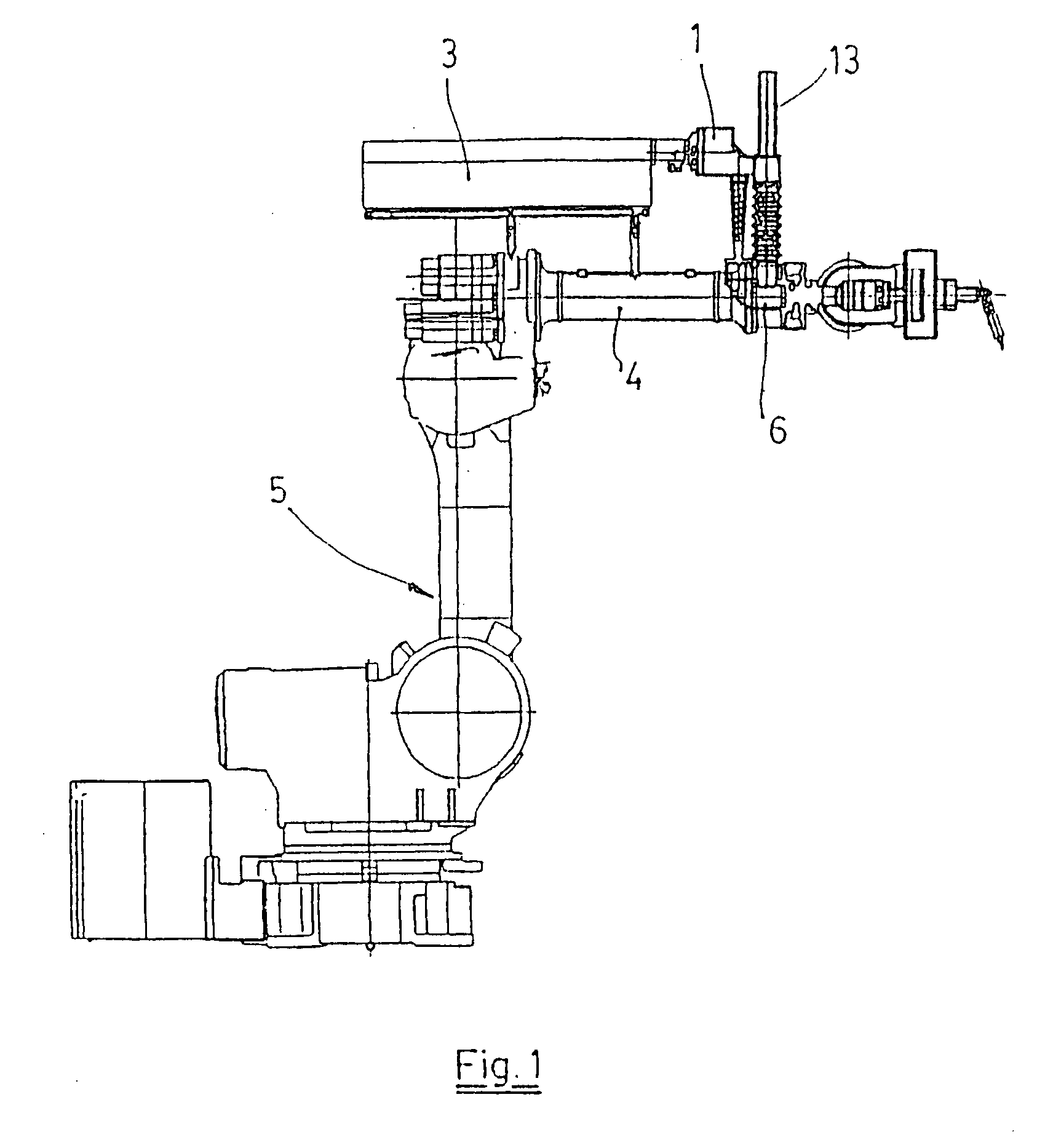

Optical arm for guiding a laser beam on a robot arm

InactiveUS20040078115A1Facilitate replacementProgramme-controlled manipulatorComputer controlEngineeringLaser beams

Owner:ESTUDIOS DE ING ADAPTADA

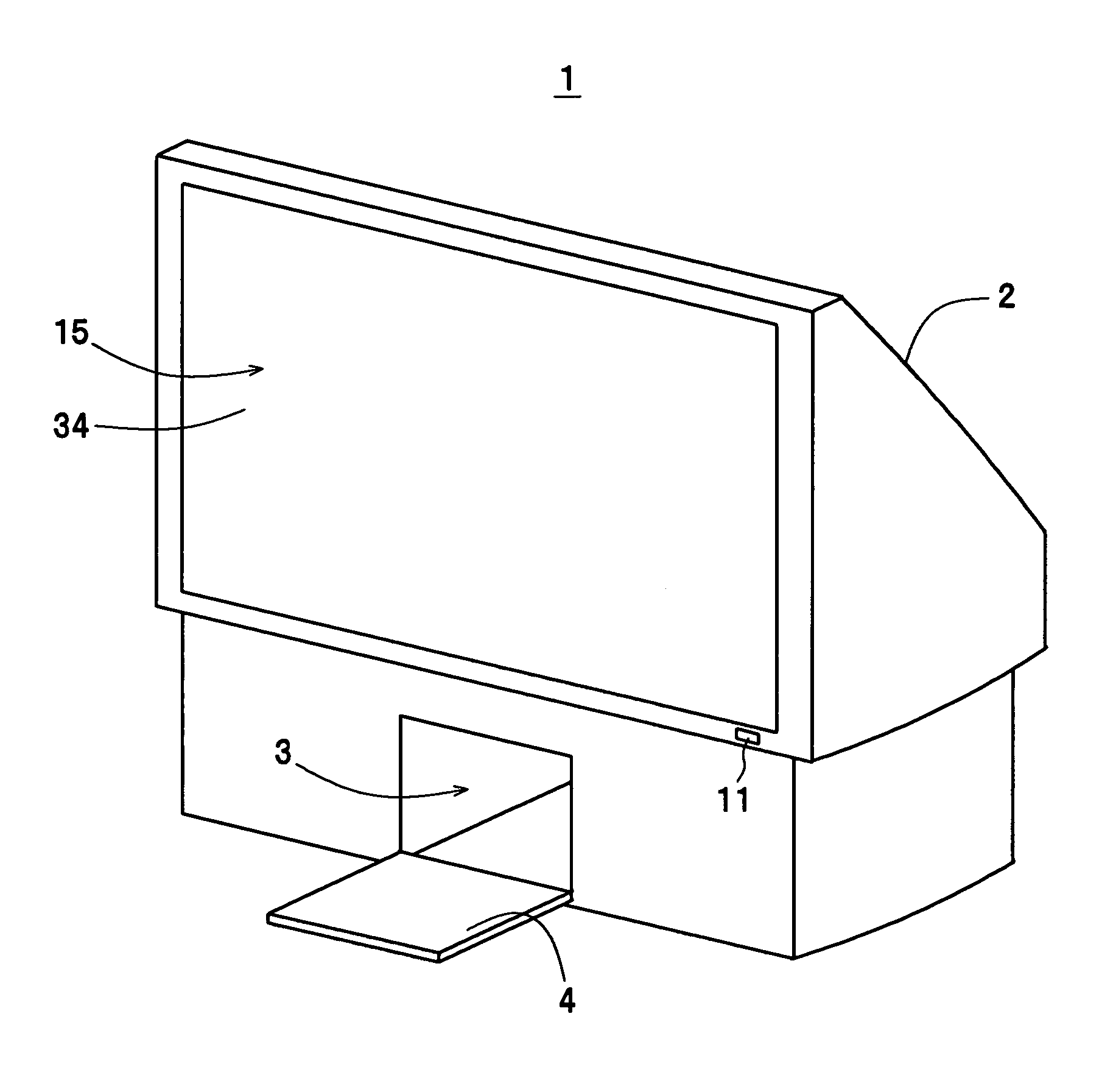

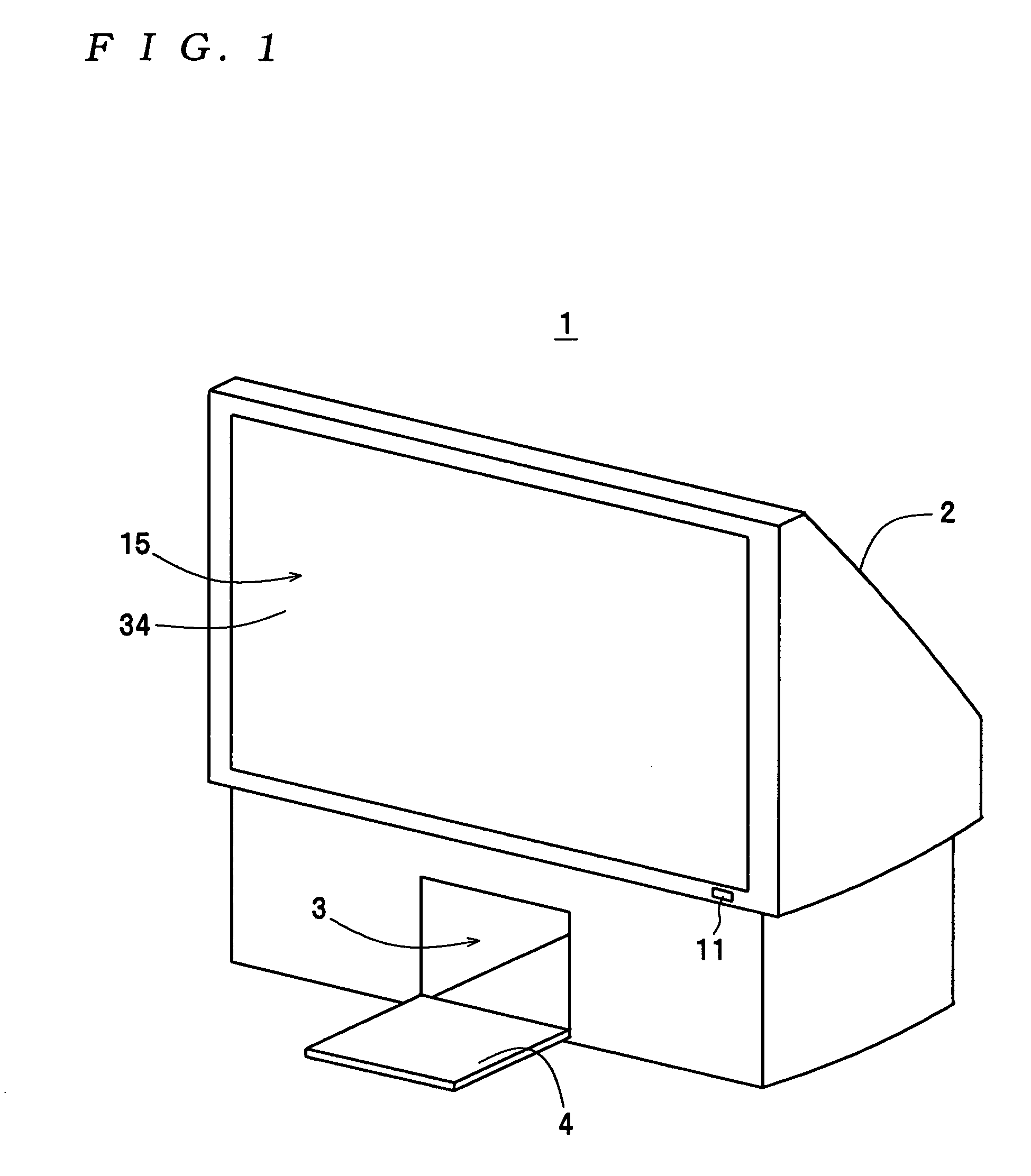

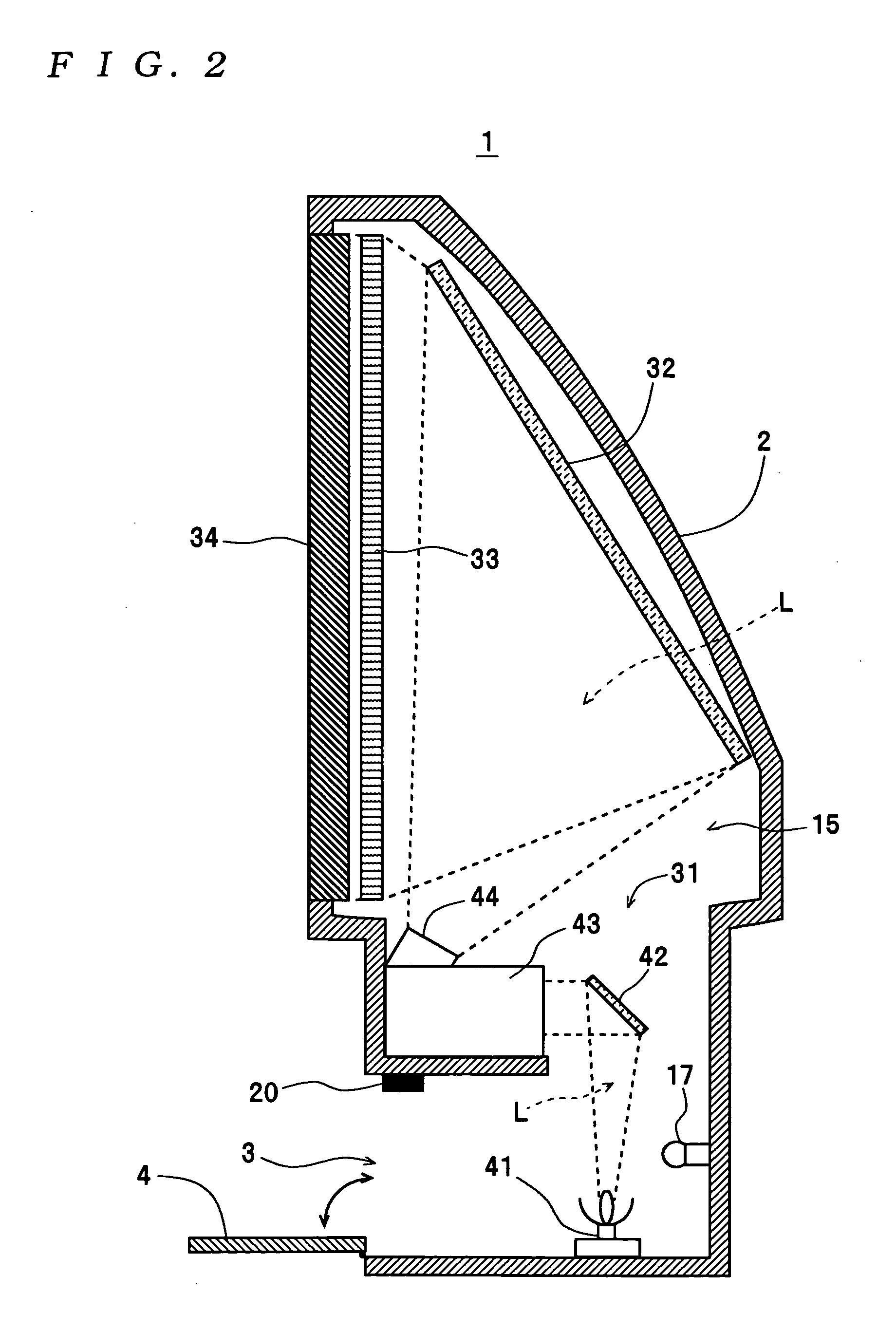

Rear projection television with screen panel for receiving projection light

InactiveUS7025463B2Facilitate replacementEasy to replaceTelevision system detailsBuilt-on/built-in screen projectorsEngineeringLight source

There is provided a rear projection television having a construction which facilitates replacement of a light source lamp and repair work within the body. The rear projection television includes a screen panel disposed at the front of a cabinet thereof, for receiving projection light projected from behind for image display, to thereby display an image thereon, a light source lamp removably disposed within the cabinet, for projecting the projection light, and a working door provided in the front face of the cabinet. An opening-detecting sensor detects opening of the working door and outputs an opening-detecting signal. An illumination section for replacement work disposed within the cabinet illuminates the inside of the body. The control section causes the illumination section to light when the opening-detecting signal is outputted by the opening-detecting sensor.

Owner:SEIKO EPSON CORP

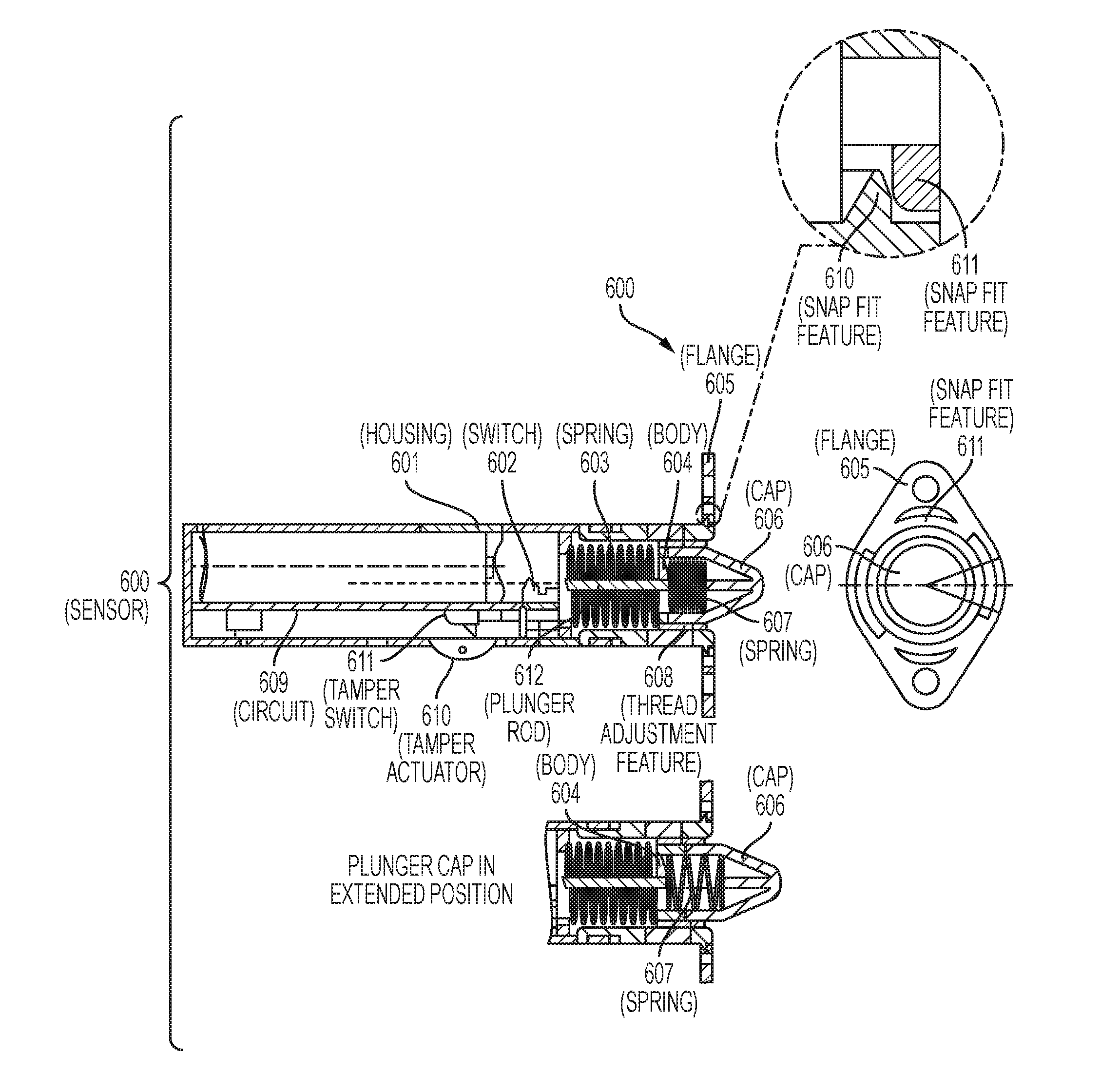

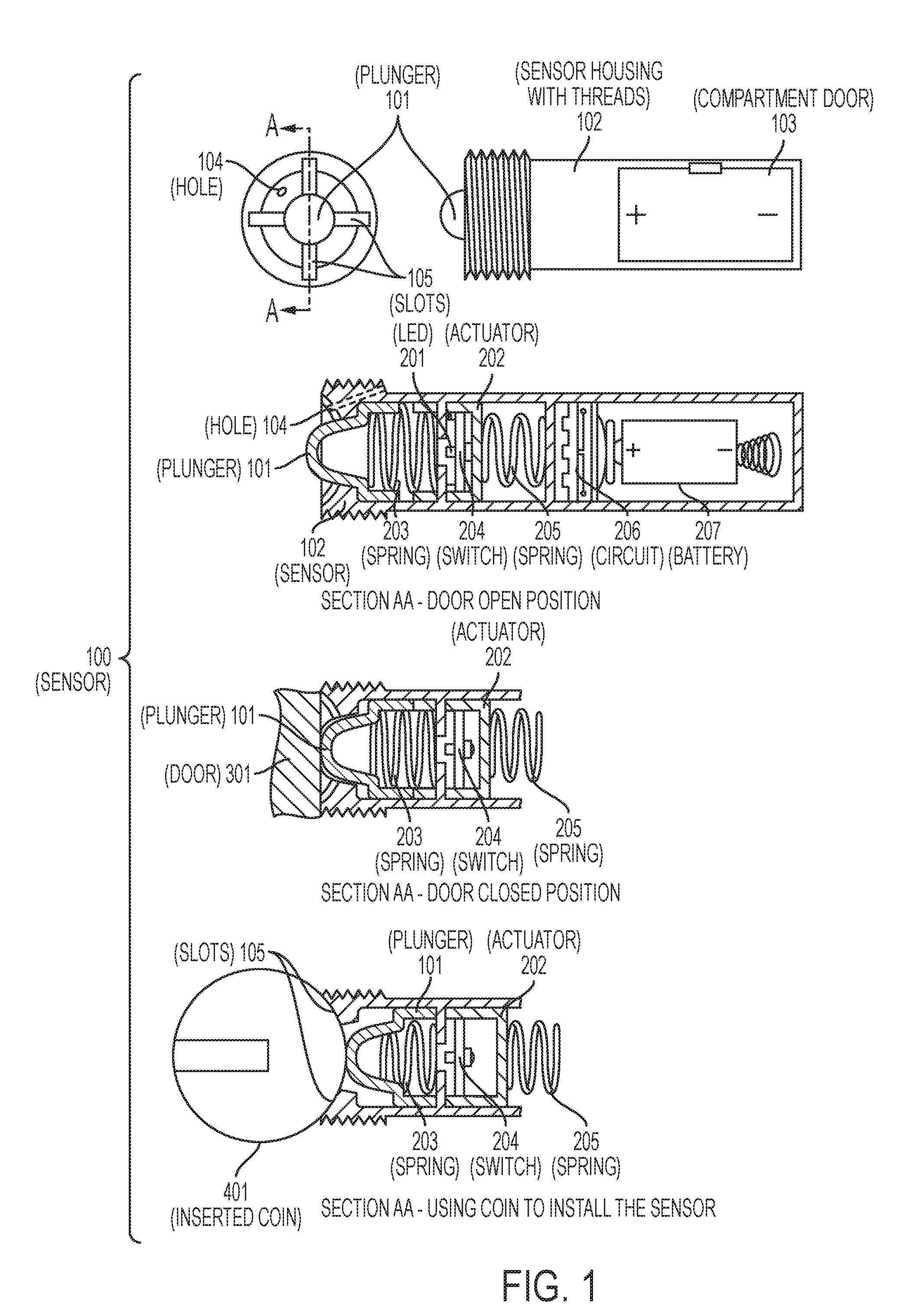

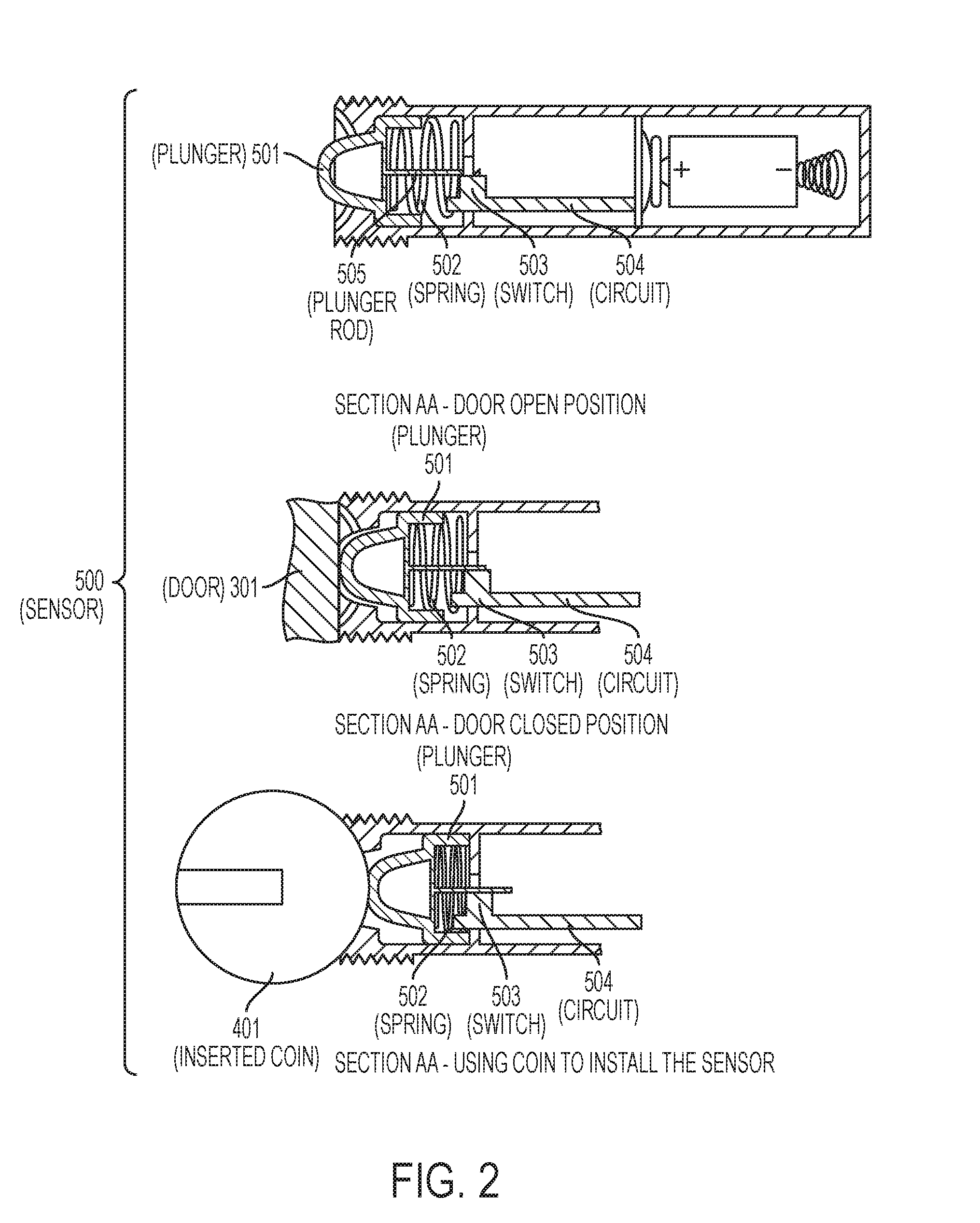

Adjustable building entry sensor

ActiveUS20160196729A1Facilitate replacementFacilitate installationBurglar alarm by openingElectric switchesEmbedded systemPoint of entry

An entry sensor, which supports either wireless or wired operation, facilitates installation and is adjustable for gaps between a building entry barrier such as a door or window and the surrounding frame. The sensor, which may be implemented as a single piece design, includes an adjustment mechanism that enables an installer to vary the extension of the sensor to match the actual gap so that the sensor properly secures the building entry when closed. The sensor includes a detector that determines the state of a switch that is responsive to the movement of a plunger mechanism, where the state is indicative whether the building entry barrier is opened or closed, and that may determine whether the sensor is tampered with. The sensor also may facilitate battery replacement that protects the associated circuitry during the replacement.

Owner:SALUS NORTH AMERICA INC

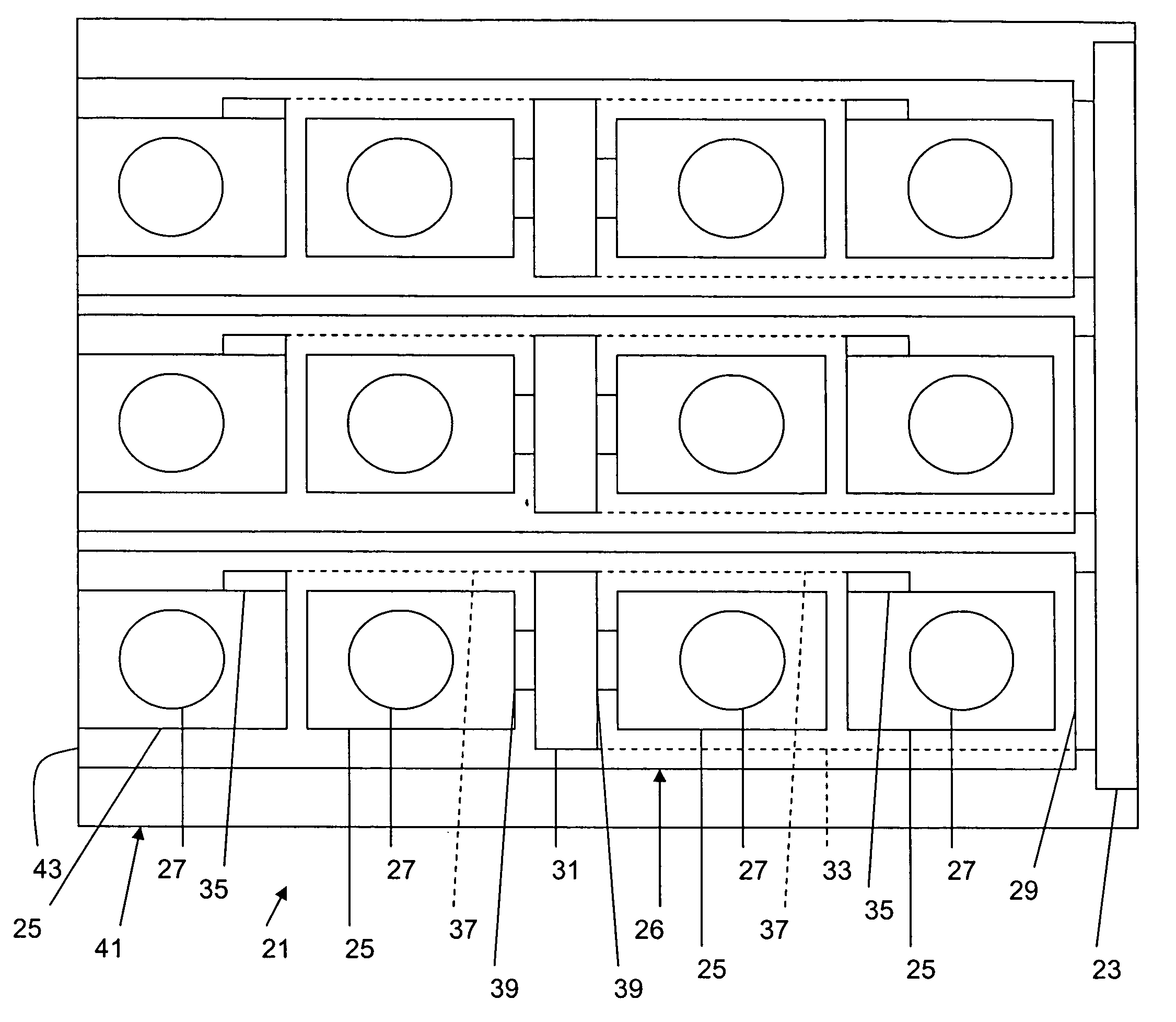

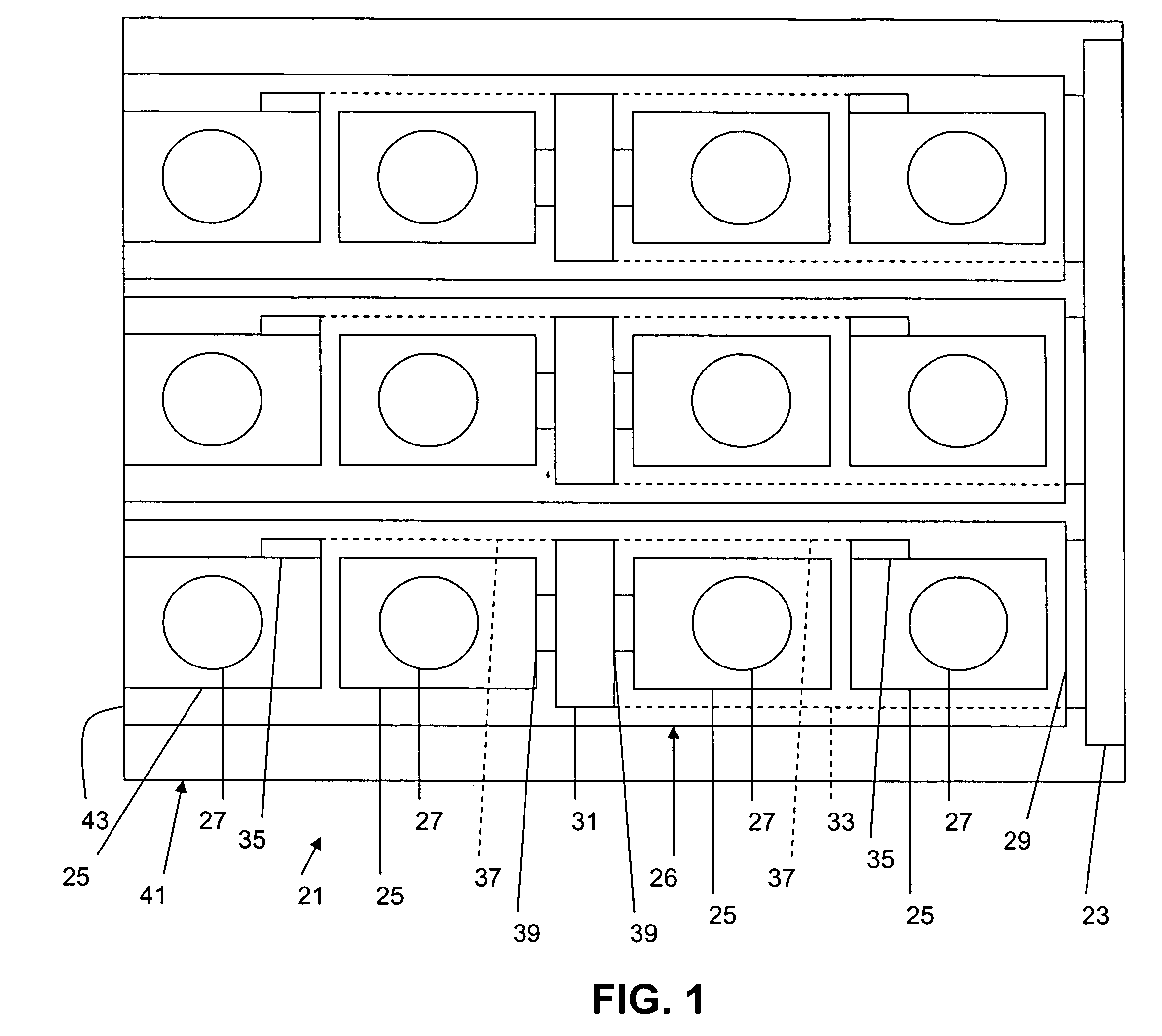

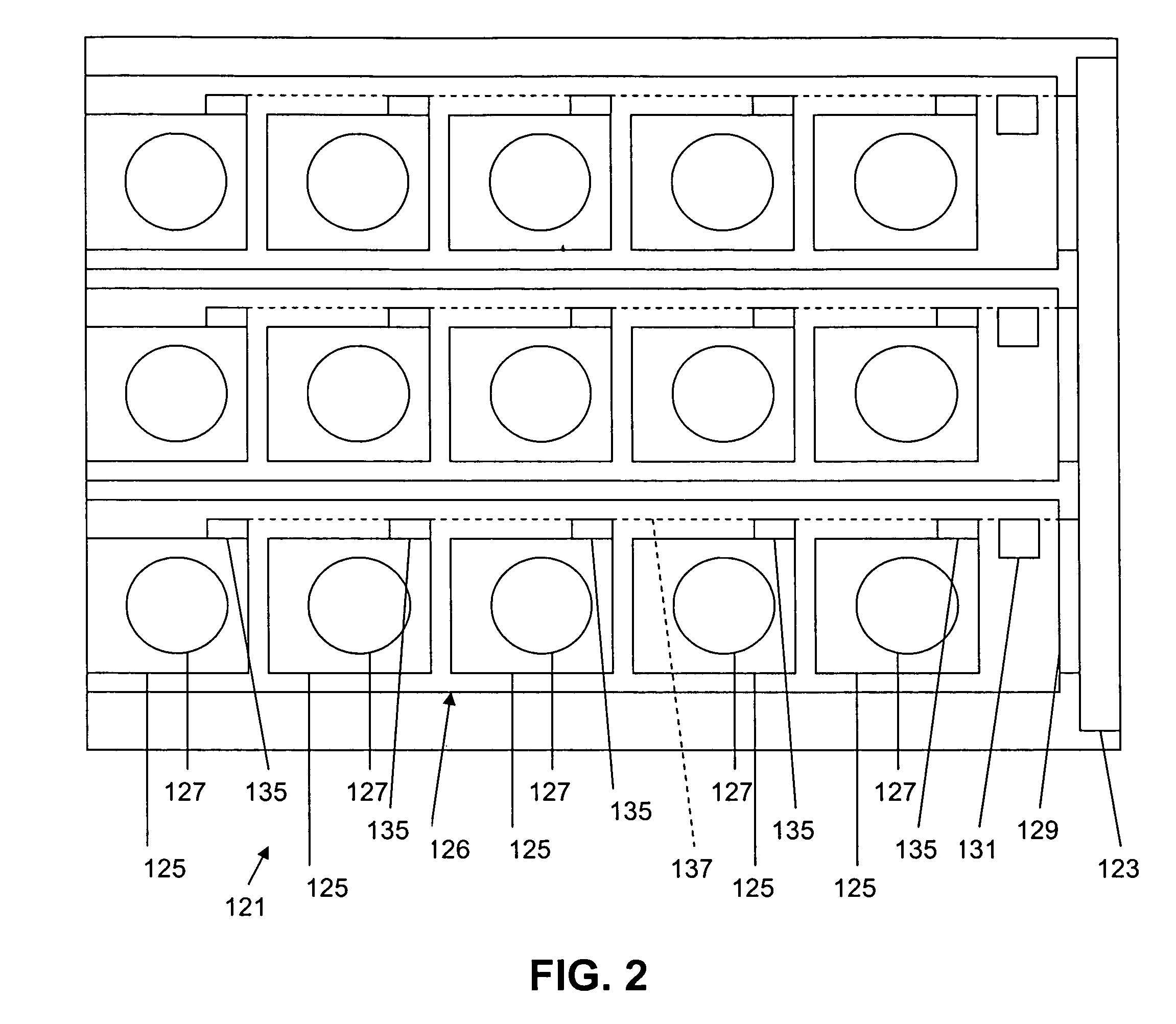

Storage component of a server arrangement with a plurality of hard disk drives

ActiveUS20090179535A1Facilitate replacementEasy to replaceDigital data processing detailsRecord information storageHard disc driveBackplane

A storage component of a server arrangement includes a backplane and a plurality of trays, each of the plurality of trays including at least one frame, at least one frame having at least one hard disk drive mounted thereto, and all of the plurality of trays being configured to receive at least one hard disk drive. Each of the plurality of trays includes a connector adapted to connect the at least one hard disk drive to the backplane.

Owner:GATEWAY

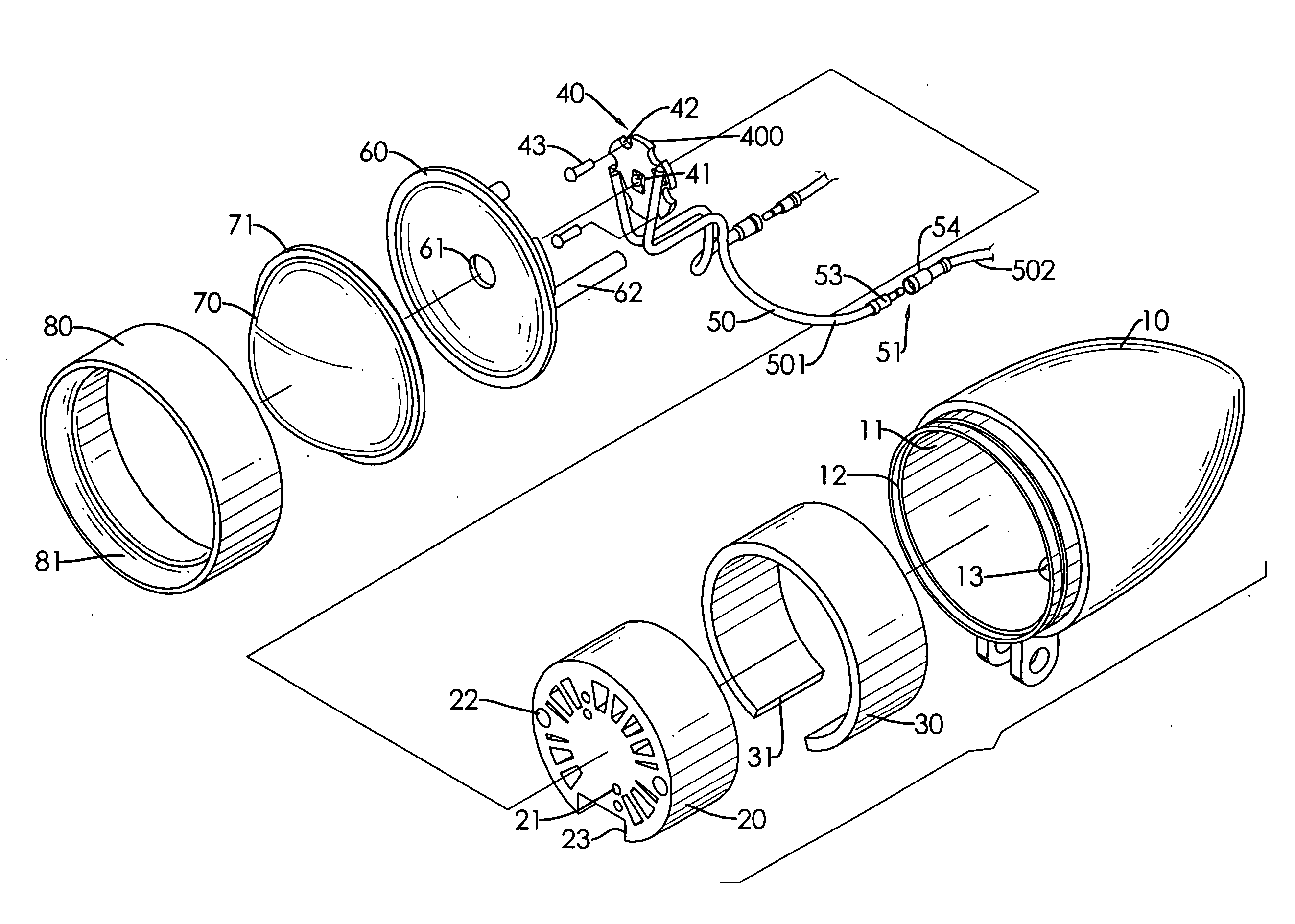

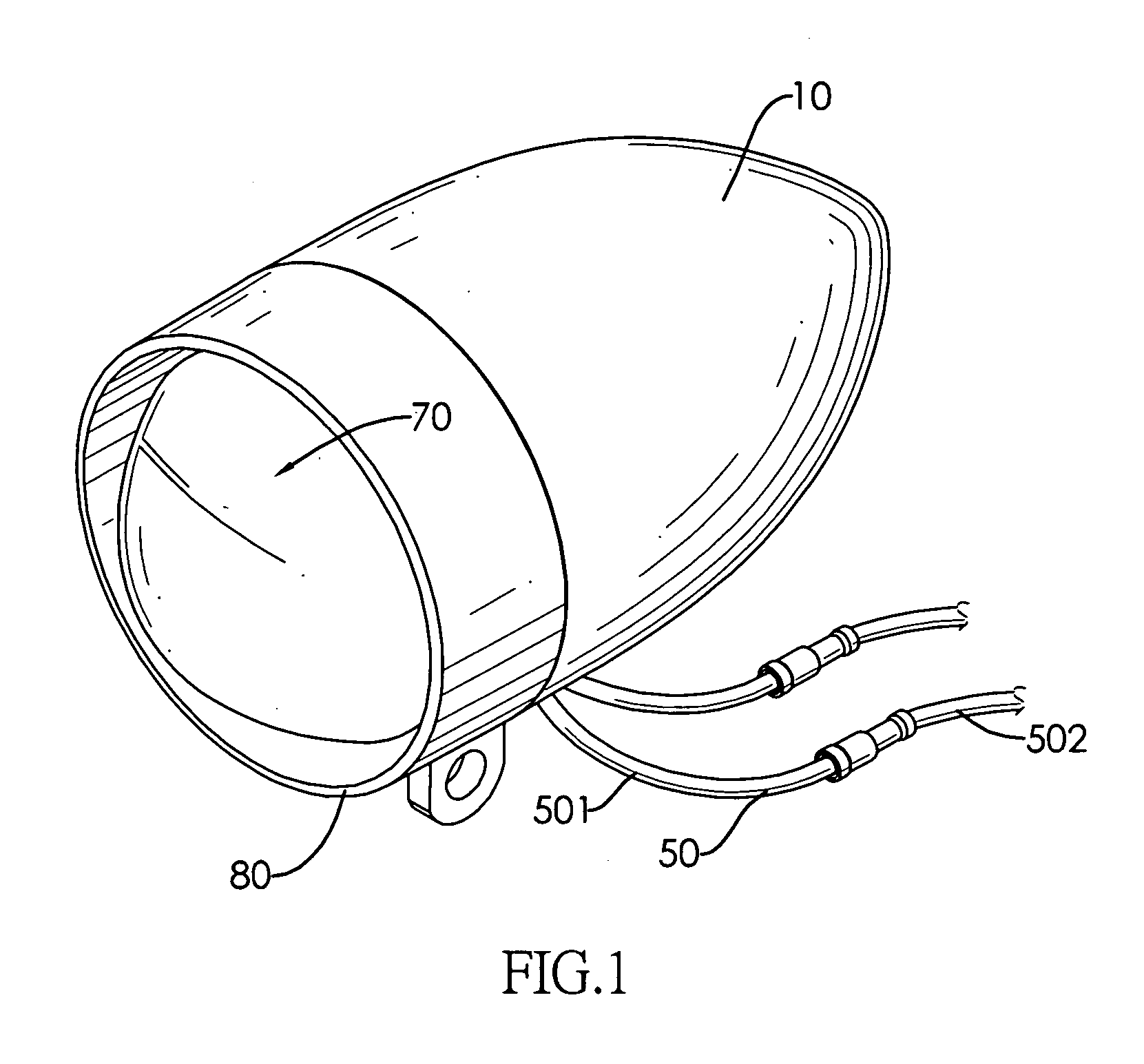

Lamp with cable connector assemblies

InactiveUS20110188252A1Facilitate replacementLower costLighting heating/cooling arrangementsLight fasteningsHeat sink

A lamp has a casing, a heat sink, a thermal tape, an LED module, two cables, a convex lens and a mounting collar. The heat sink, thermal tape and LED module are mounted in the casing. The cables are connected to the LED module and each cable has a stationary cable section, a detachable cable section and a cable connector assembly. The cable connector assembly is mounted between the stationary and detachable cable sections and selectively detaches the detachable cable section from the stationary cable section. The convex lens and mounted collar are mounted in the casing. The cable connector assembly facilitates the replacement of the LED module.

Owner:LIN BENNY

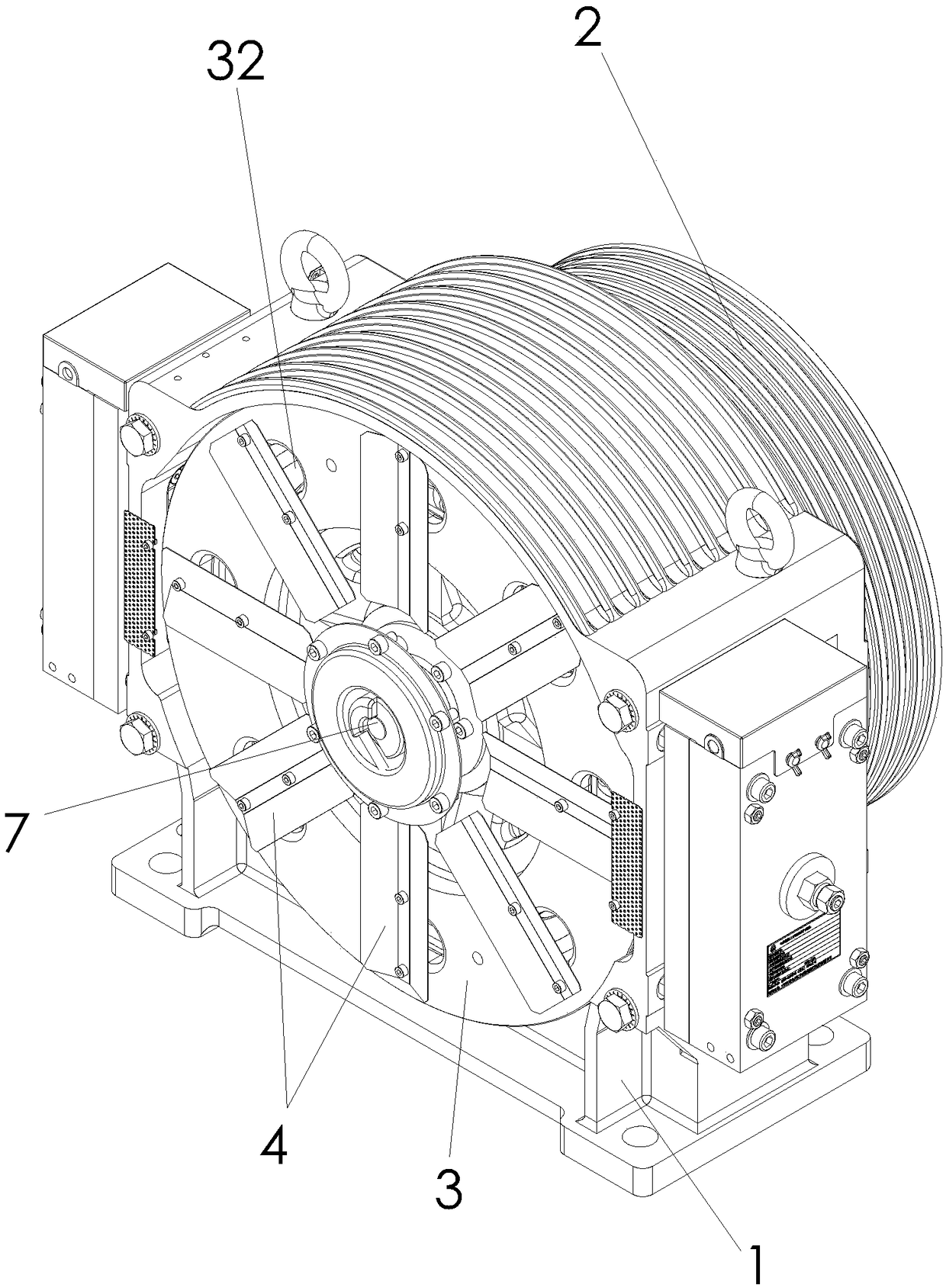

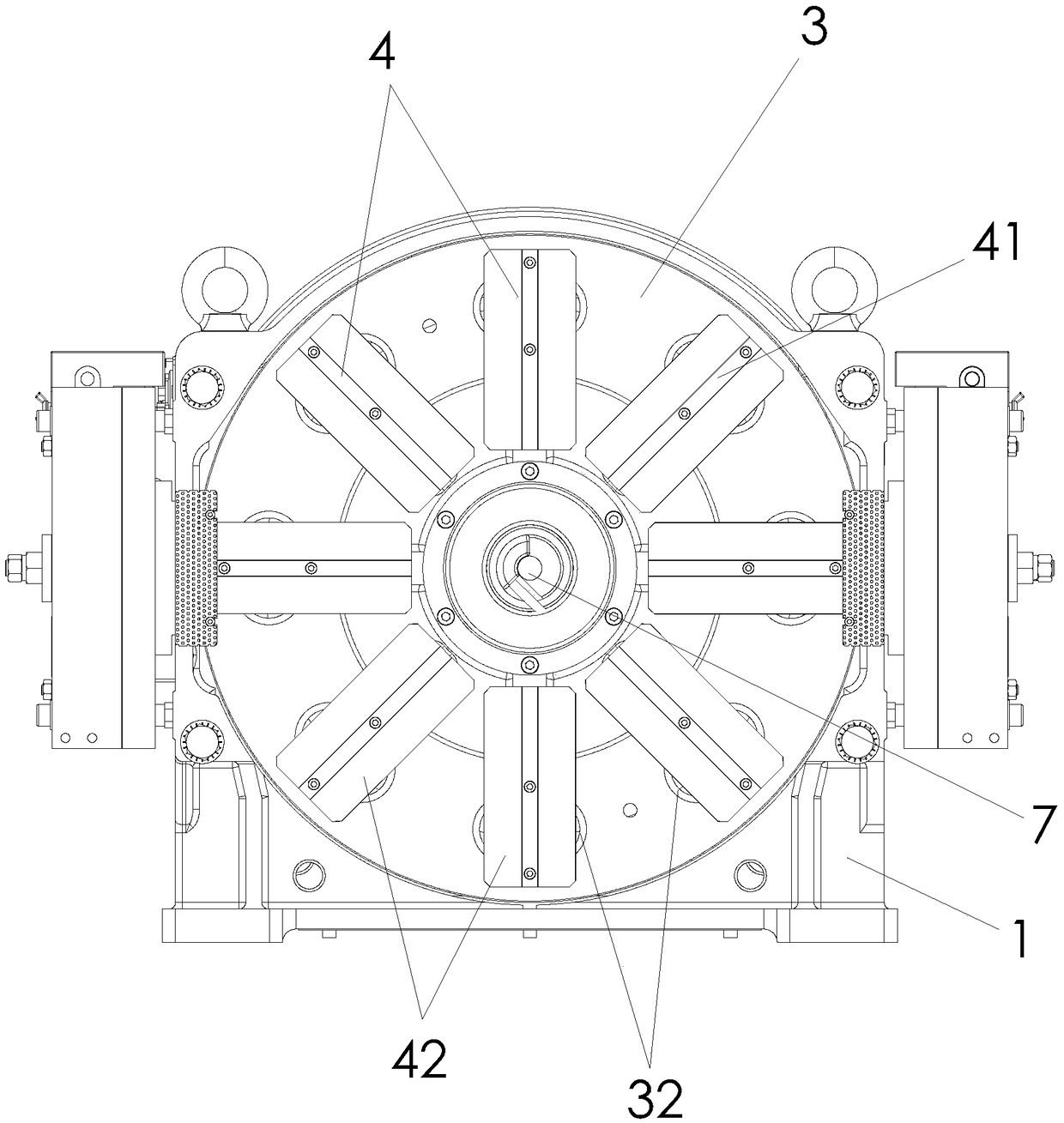

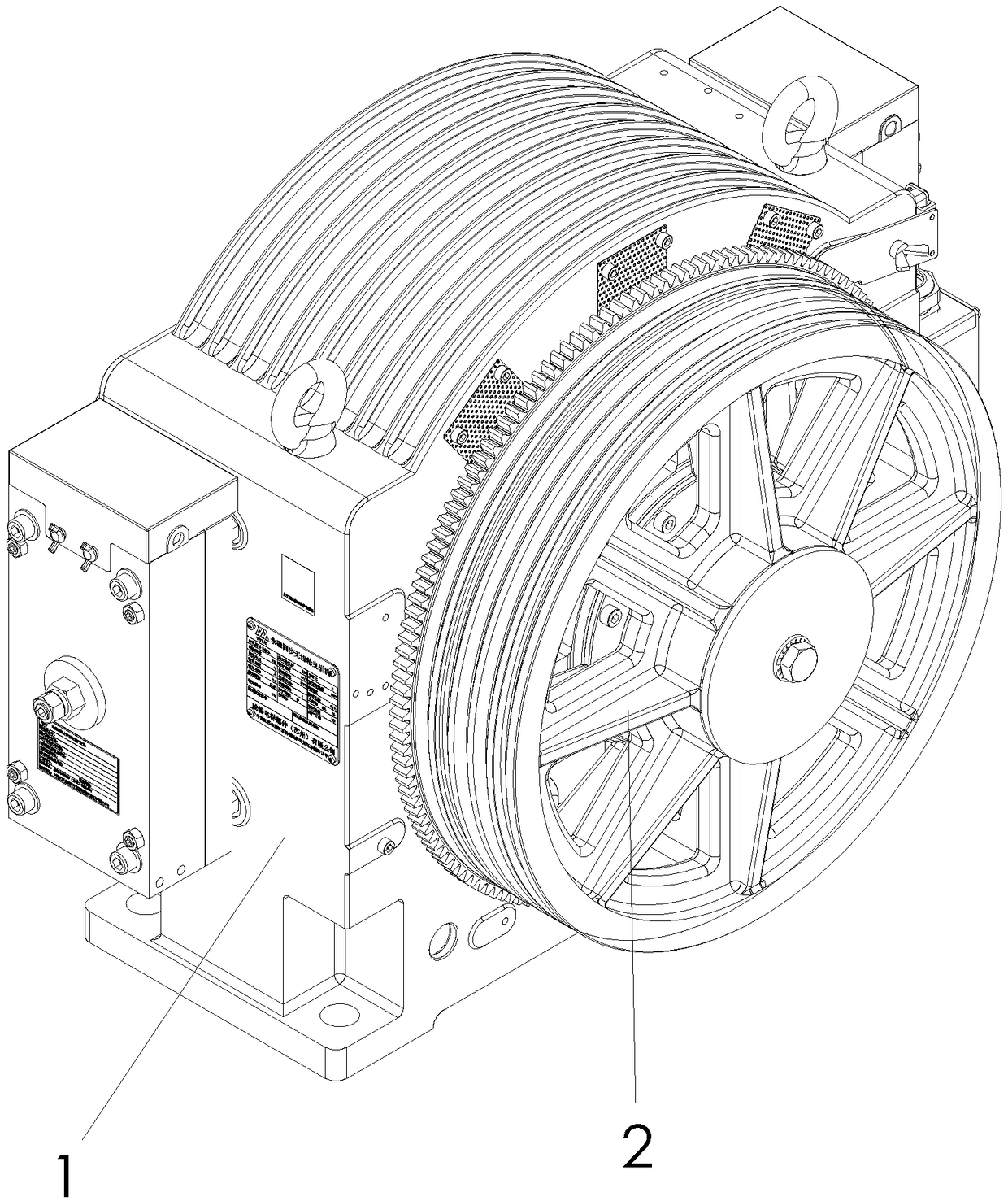

Elevator traction machine

PendingCN109292596AReasonable structural designFacilitate replacementMagnetic circuit rotating partsCooling/ventillation arrangementStatorAirflow

The invention discloses an elevator traction machine. The elevator traction machine comprises a machine base, a stator arranged in the machine base, a rotor cooperating with the stator, a traction wheel and a rotating shaft, wherein one end of the rotating shaft is connected with the rotor, the other end of the rotating shaft is connected with the traction wheel, the end face, far away from the traction wheel, of the rotor is provided with fan blades, one side, far away from the traction wheel, of the machine base is provided with a connecting plate, and the connecting plate is provided with aventilation opening used for allowing air flow to be in and out. According to the elevator traction machine, the structural design is reasonable, the fan blades are arranged on the rotor, so that when the rotor rotates, the fan blades rotate together to stir air inside the traction machine, the air replacement of between the inner part and the outer part of the traction machine is increased, coldair from the outer side is continuously introduced, hot air inside the traction machine is discharged, then heat in the traction machine is taken away, the temperature in the traction machine is reduced, the purposes of dissipating the heat and reducing the winding temperature rise are achieved, and the efficiency of a motor is improved.

Owner:WITTUR ELEVATOR COMPONENTS SUZHOU

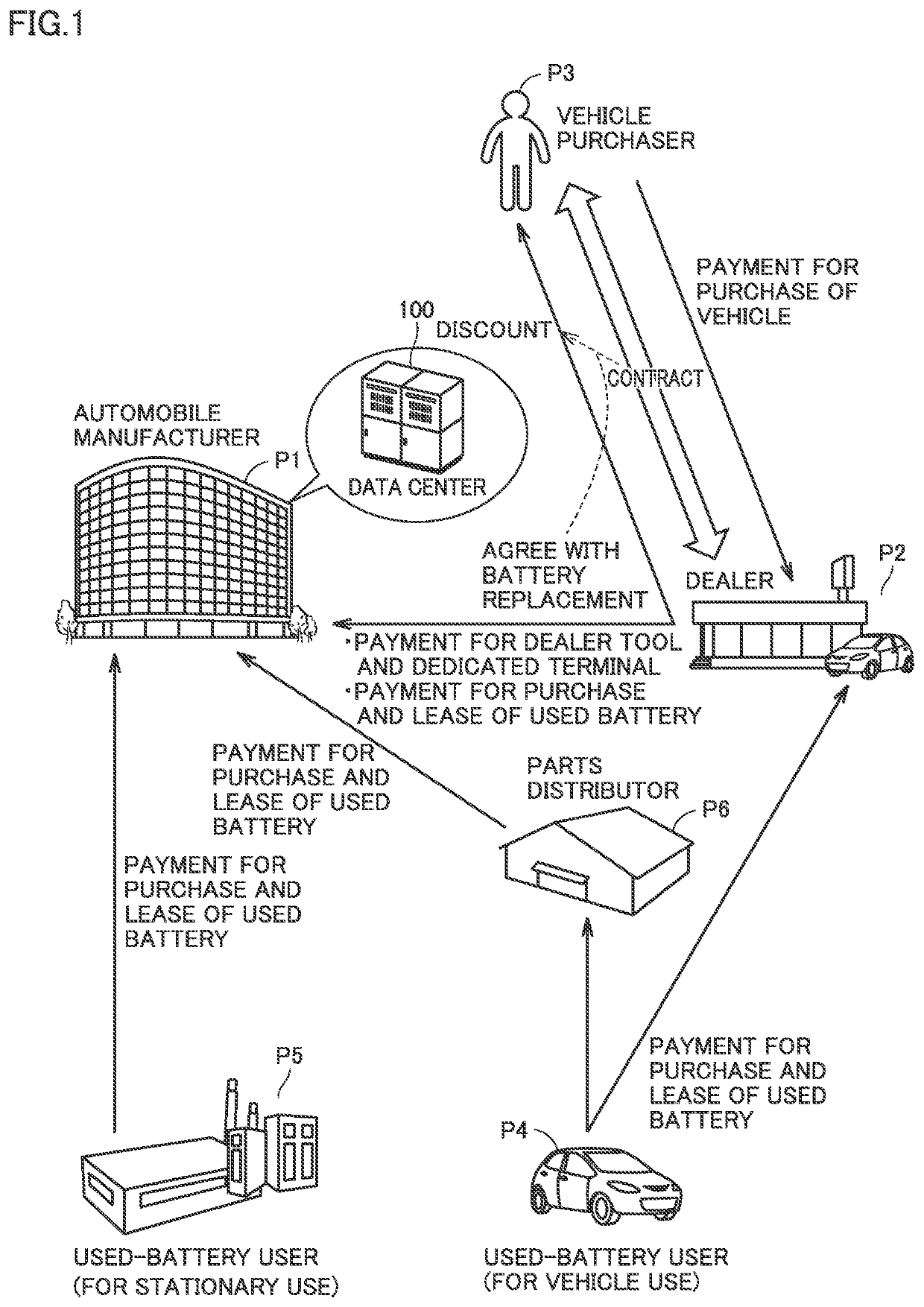

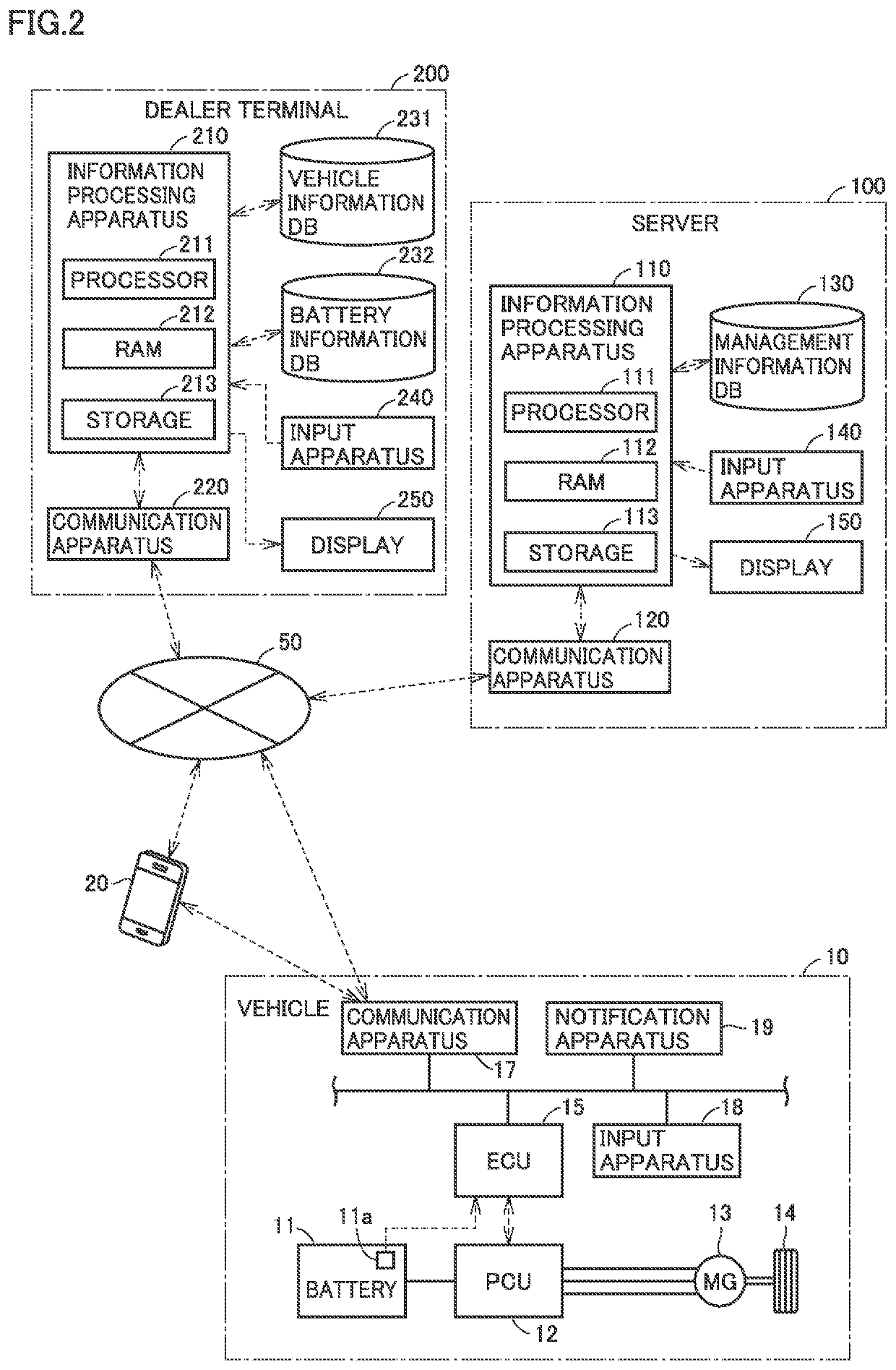

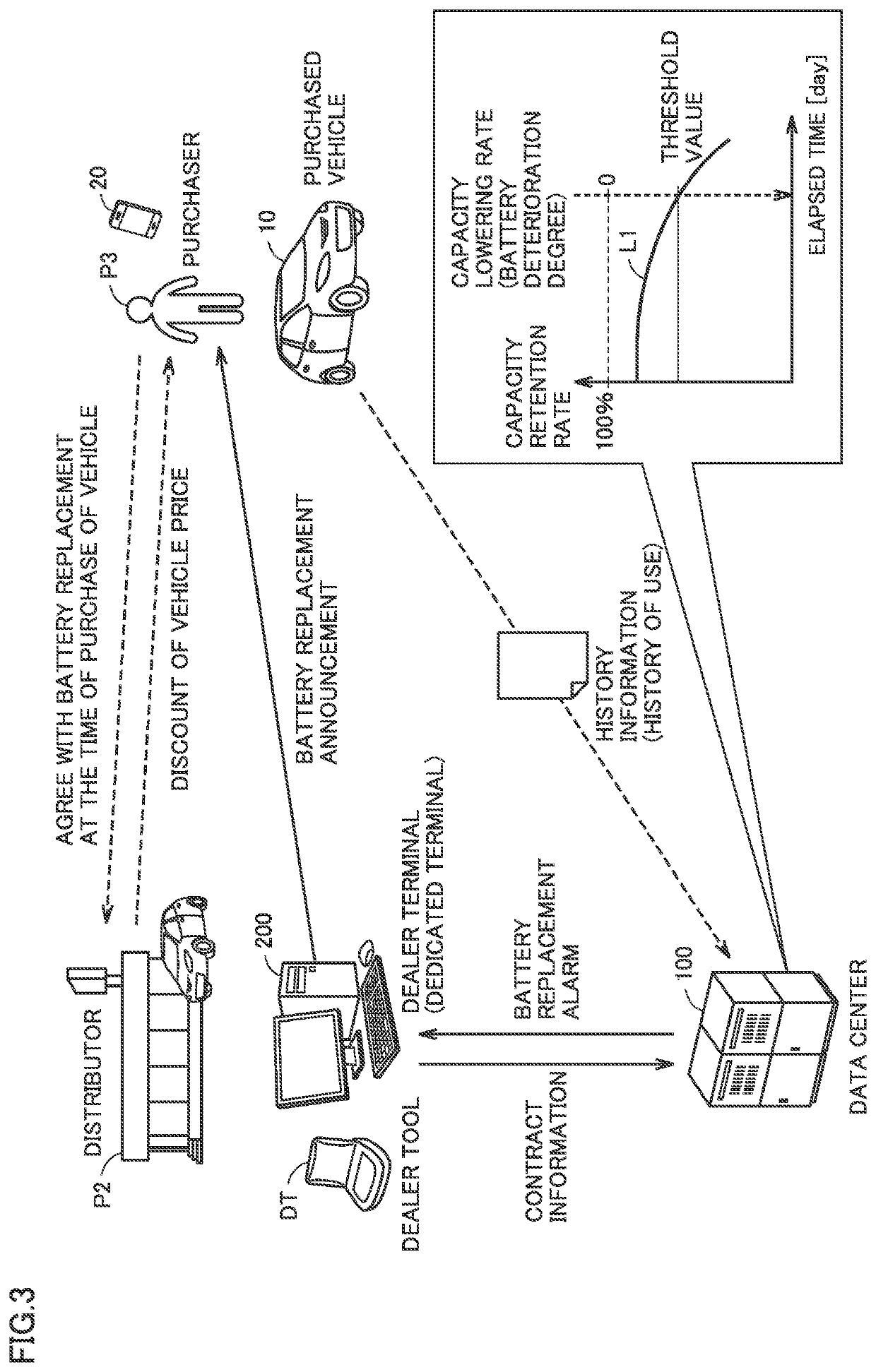

Management apparatus and vehicle sales system

PendingUS20210374816A1Facilitate replacementIncrease in numberDiscounts/incentivesCharging stationsReal-time computingInformation storage

A server includes a management information DB that stores management information indicating whether or not each of a plurality of vehicles falls under a subject vehicle for which battery replacement timing is managed. An information processing apparatus of the server includes an estimator that estimates a degree of deterioration of a secondary battery mounted on the subject vehicle based on history information showing history of use of the secondary battery mounted on the subject vehicle and a notification unit that transmits a battery replacement alarm (a notification signal that gives a notification about battery replacement timing of the subject vehicle) when the estimated degree of deterioration of the secondary battery reaches a prescribed threshold value.

Owner:TOYOTA JIDOSHA KK

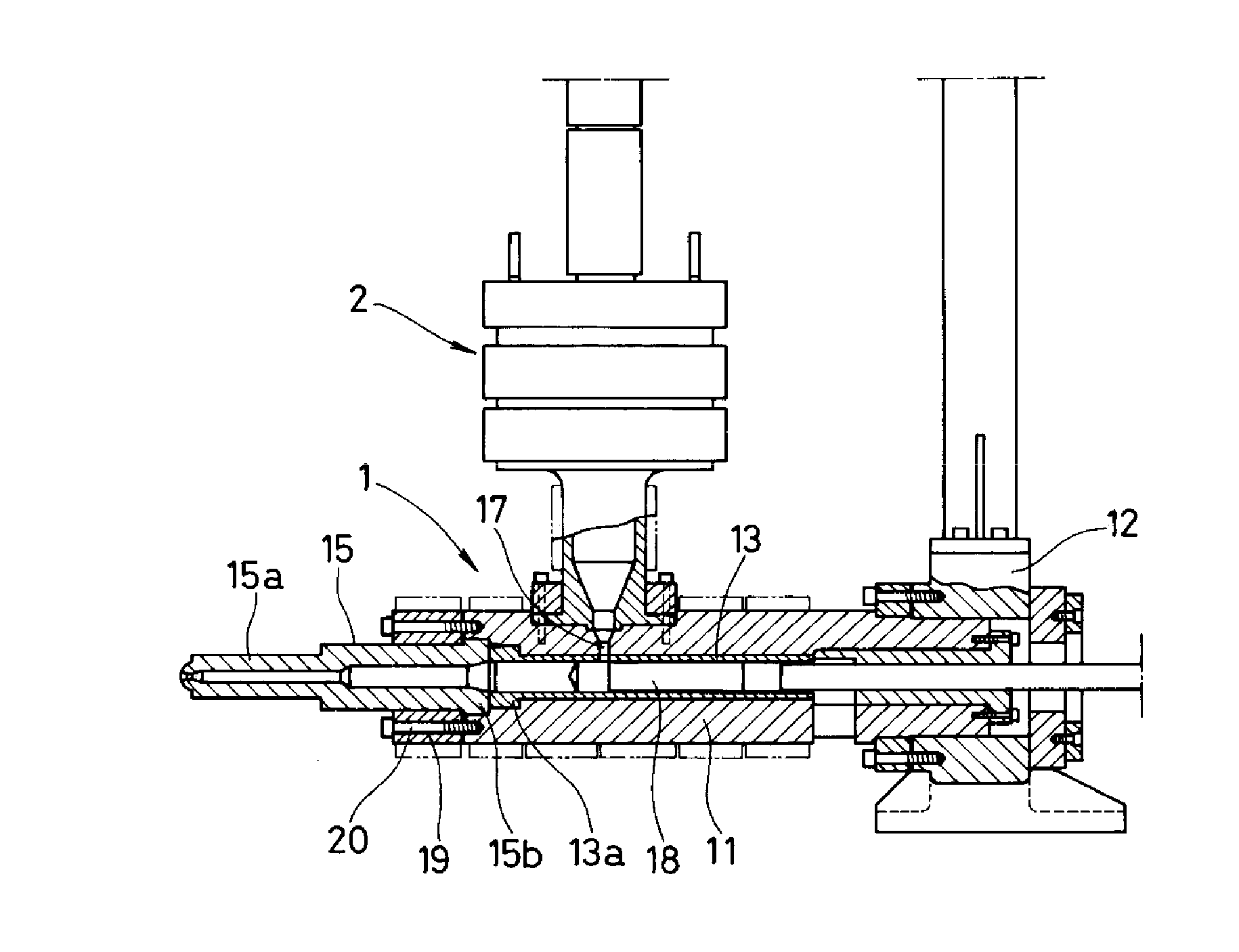

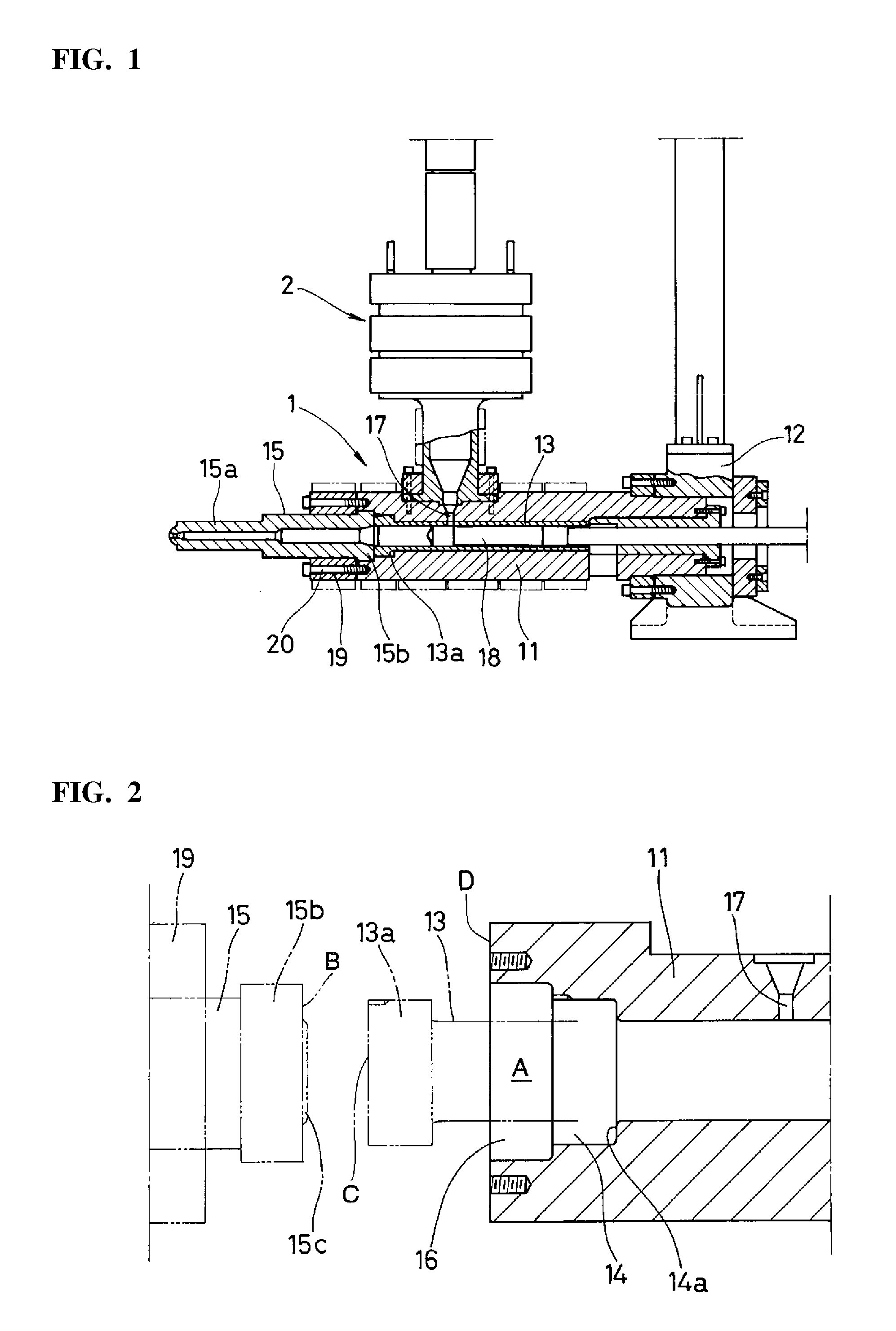

Injection cylinder in injection apparatus for molding metal material

InactiveUS20090165984A1Prevent leakageFacilitate replacementMelt-holding vesselsMetallic materialsMolten metal

Leakage of molten metal material from between a cylinder body having a tight-fitting liner and a nozzle member of an injection apparatus is prevented through the interaction of the nozzle member and a coupling ring with the liner.

Owner:NISSEI PLASTIC IND CO LTD

Intelligent extruding device for supplying cleaning and caring articles

InactiveUS20220183510A1Expand scopeFacilitate replacementHolders and dispensersProcess engineeringHuman body

An intelligent extruding device for supplying cleaning and caring articles relating to the field of automation equipment is provided, comprising: a casing; a fixing device assembled on the casing for detachably installing the casing on the packaging bottle; a human body sensing device mounted on the casing for real-time detection of a human body and sending a control signal to the pressing device based on the detection result; and the pressing device mounted on the casing corresponding to the packaging bottle and used to receive the control signal sent by the human body sensing device to press or stop pressing the indenter of the packaging bottle. A pressing cavity for accommodating the packaging bottle is provided between the casing and the fixing device, and adopting the above technical solution has the advantages of wide application range, portability, convenient disassembly and assembly of cleaning and caring articles, and simple structure.

Owner:SUN TECH ELECTRONICS (SHENZHEN) CO LTD

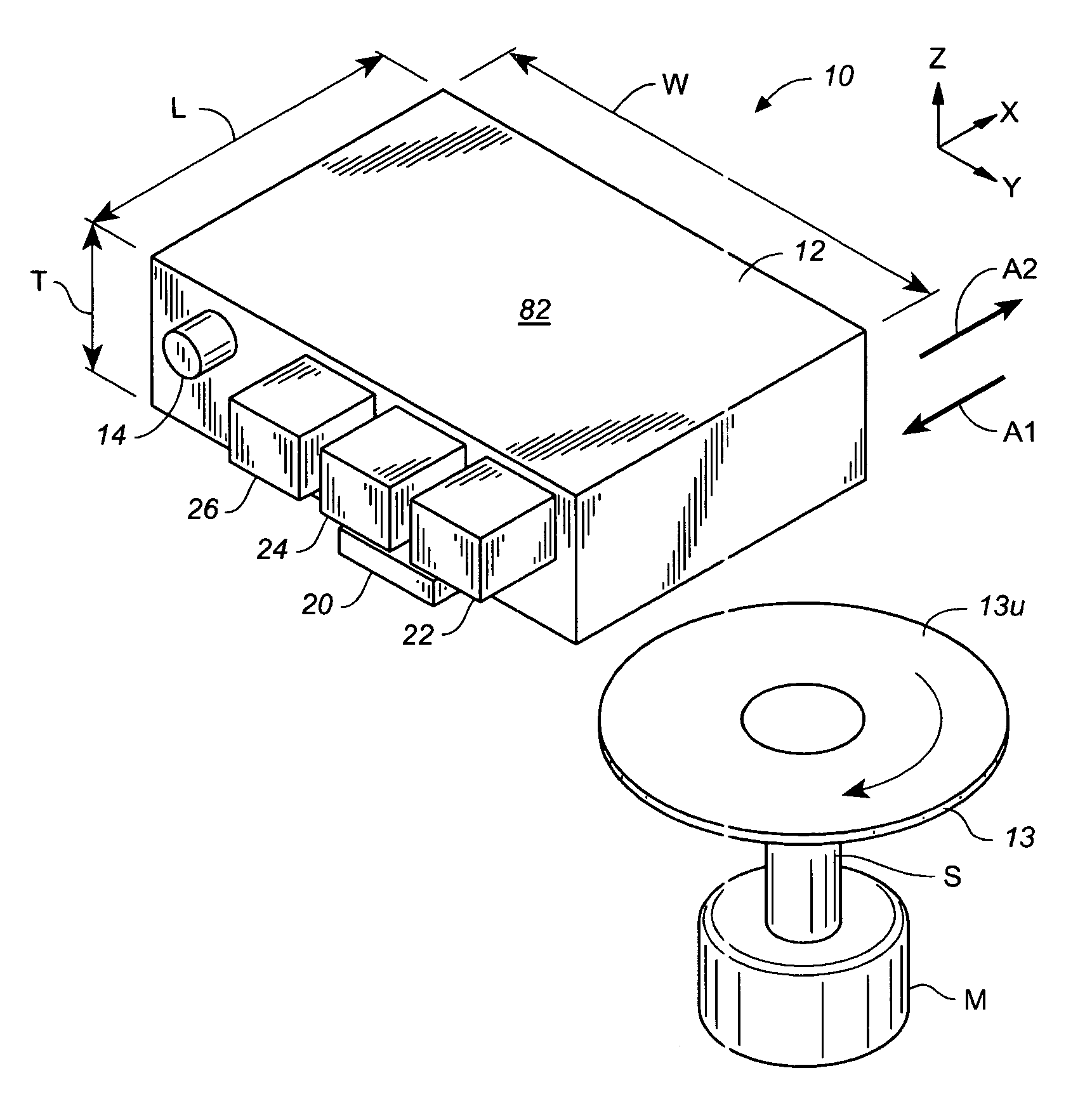

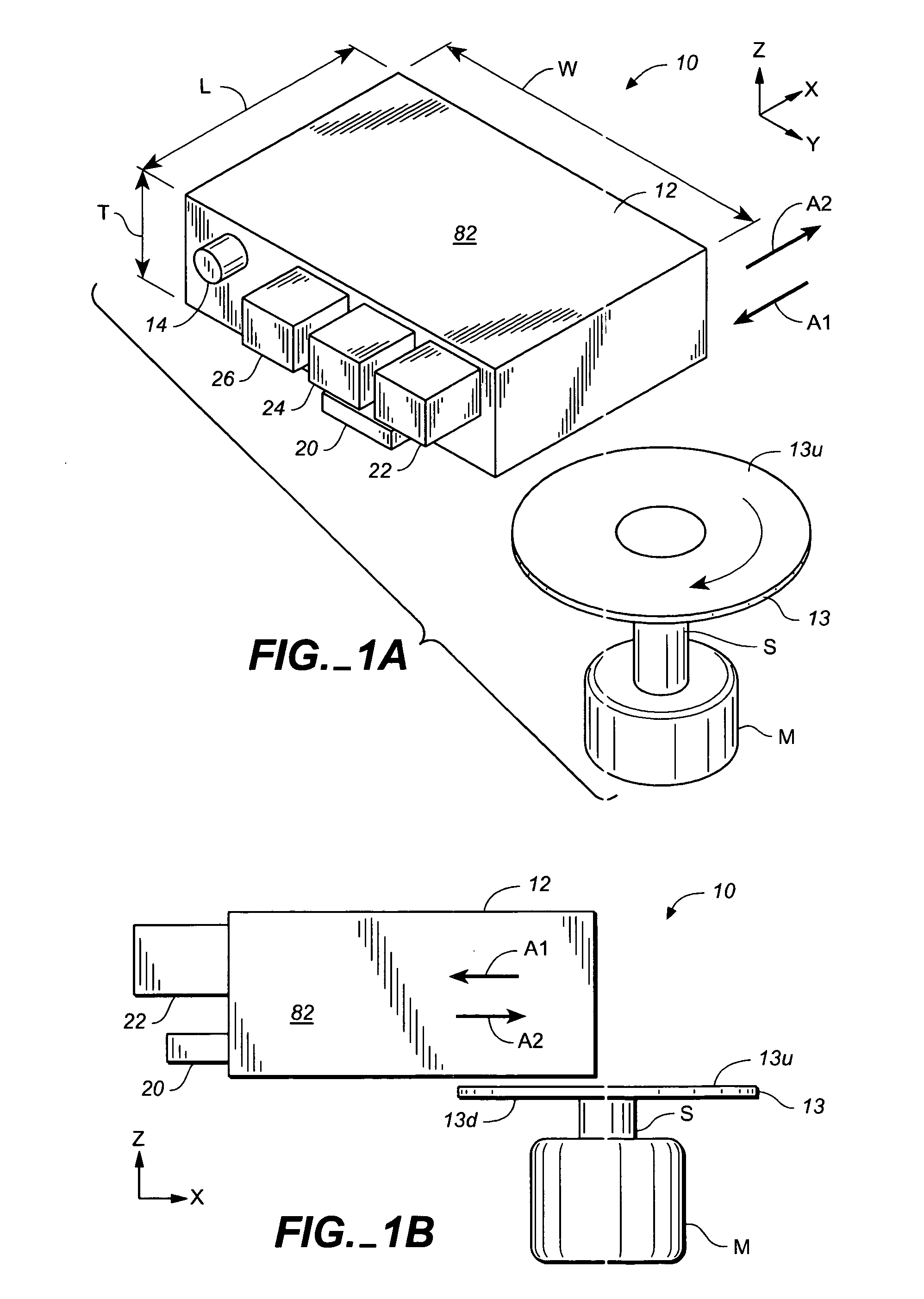

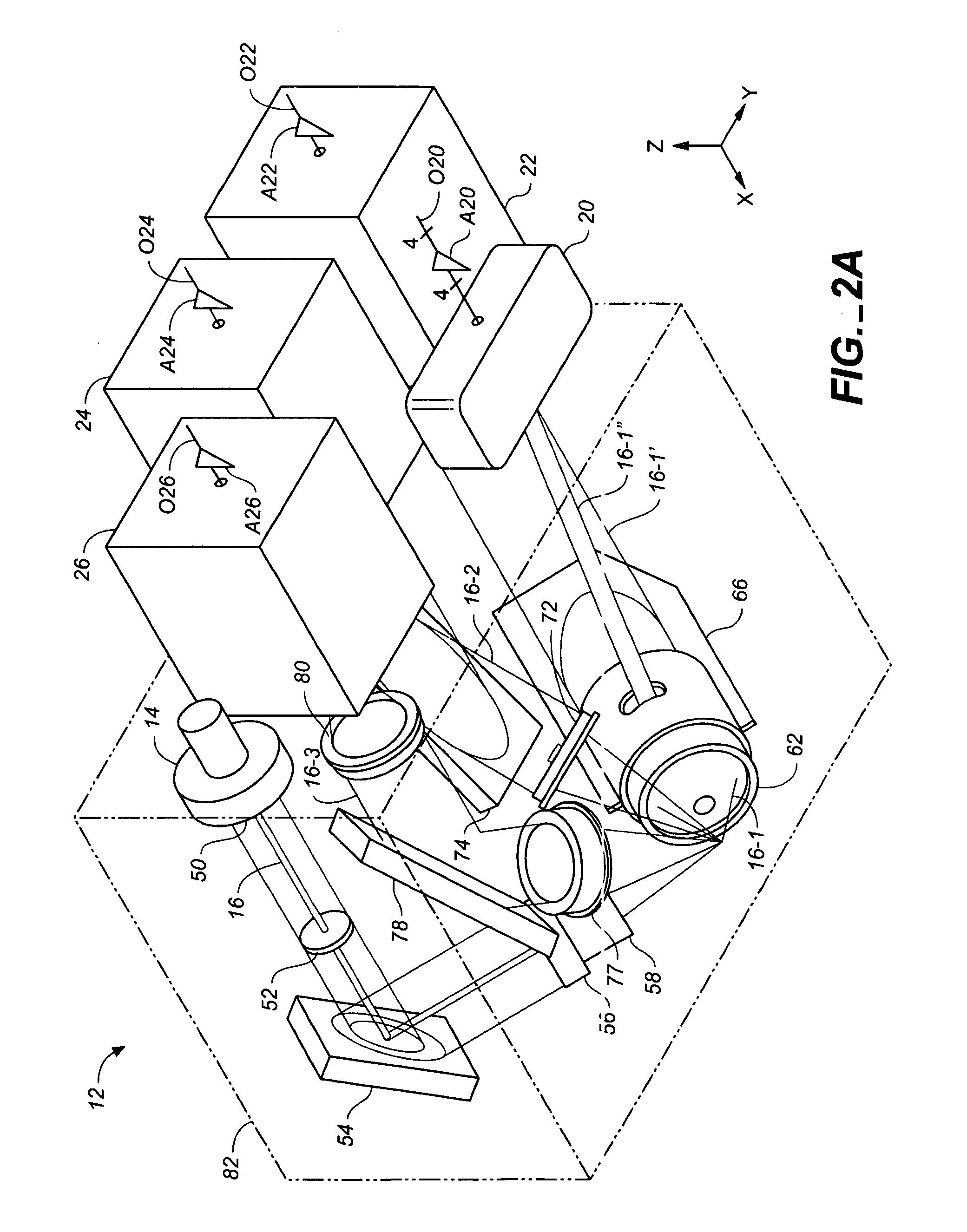

Robotic system for optically inspecting workpieces

InactiveUS20060153525A1Facilitate replacementEasy to replaceProgramme controlTelevision system detailsMagnetic disksRobotic systems

A manufacturing cell for inspecting workpieces such as magnetic disk substrates comprises an input conveyor for providing workpieces to be tested, one or more testers for inspecting the workpieces, and three or more output receptacles for receiving tested workpieces. One or more robotic arms move the workpieces from the input conveyor to the tester and from the tester to one of the output receptacles depending upon the results of the test performed by the tester. The output receptacles include a pass receptacle, a reject receptacle, and at least an additional receptacle for workpieces that are to be re-worked or studied further. If the additional receptacle is full, workpieces that would otherwise be provided to the additional bin are placed in the reject receptacle. The reject receptacle is very large, so that it is rarely filled to capacity, and it is rarely necessary to shut down the manufacturing cell to replace the reject receptacle.

Owner:WD MEDIA

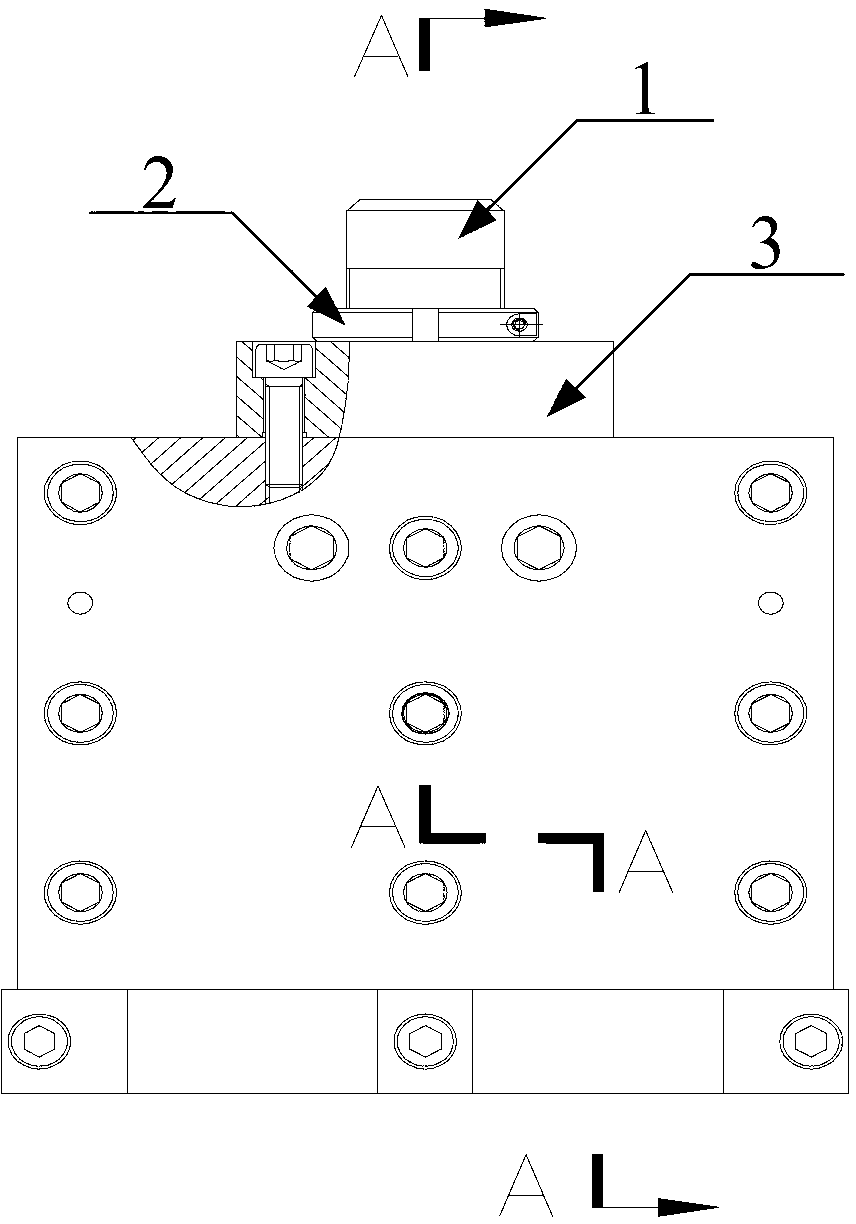

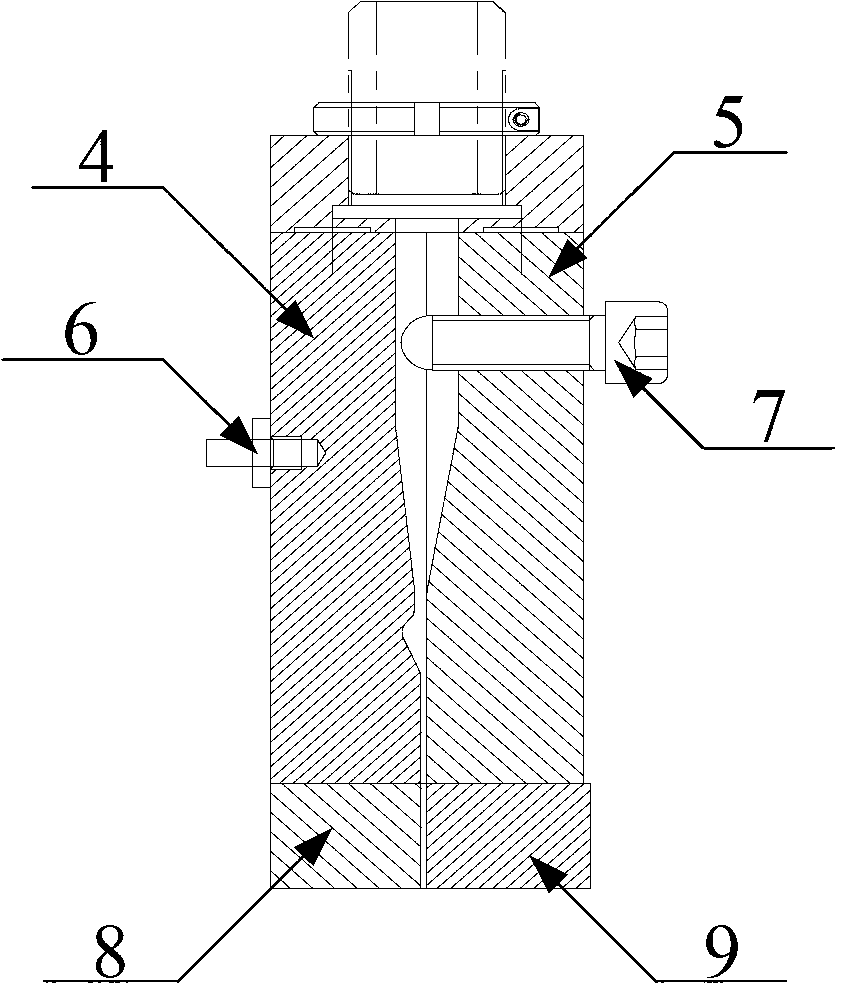

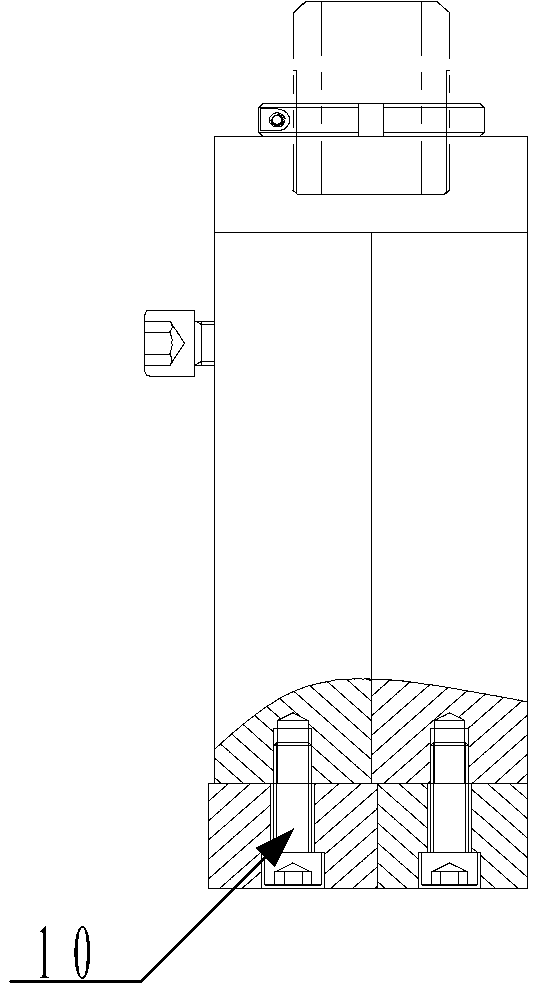

Embedded double-purpose die lip based on hole die for packing belt

The invention discloses an embedded double-purpose die lip based on a hole die for a packing belt. The die lip comprises a hole die main body, wherein a die connecting plate is arranged at the upper end of the hole die main body; a screw short joint is also arranged above the die connecting plate; a round nut is also arranged between the screw short joint and the die connecting plate; a die lip structure is also connected to the lower end of the hole die main body; the hole die main body comprises a first hole die body and a second hole die body; the first hole die body and the second hole die body are integrally fixed through a bolt; and the die lip structure comprises a die lip fixing block and a die lip moving embedded block matched with the die lip fixing block. According to the embedded double-purpose die lip based on the hole die for the packing belt, the die lip is diversified and modularized, so that the shortcoming that the simplification of the die lip cannot meet the production demand is overcome, the adjustment difficulty of the die lip is avoided at the same time, the manpower consumption is reduced, the size adjustment difficulty is lowered, the adjustment error is avoided, and the production cost is reduced.

Owner:四川百联盛世科技有限公司

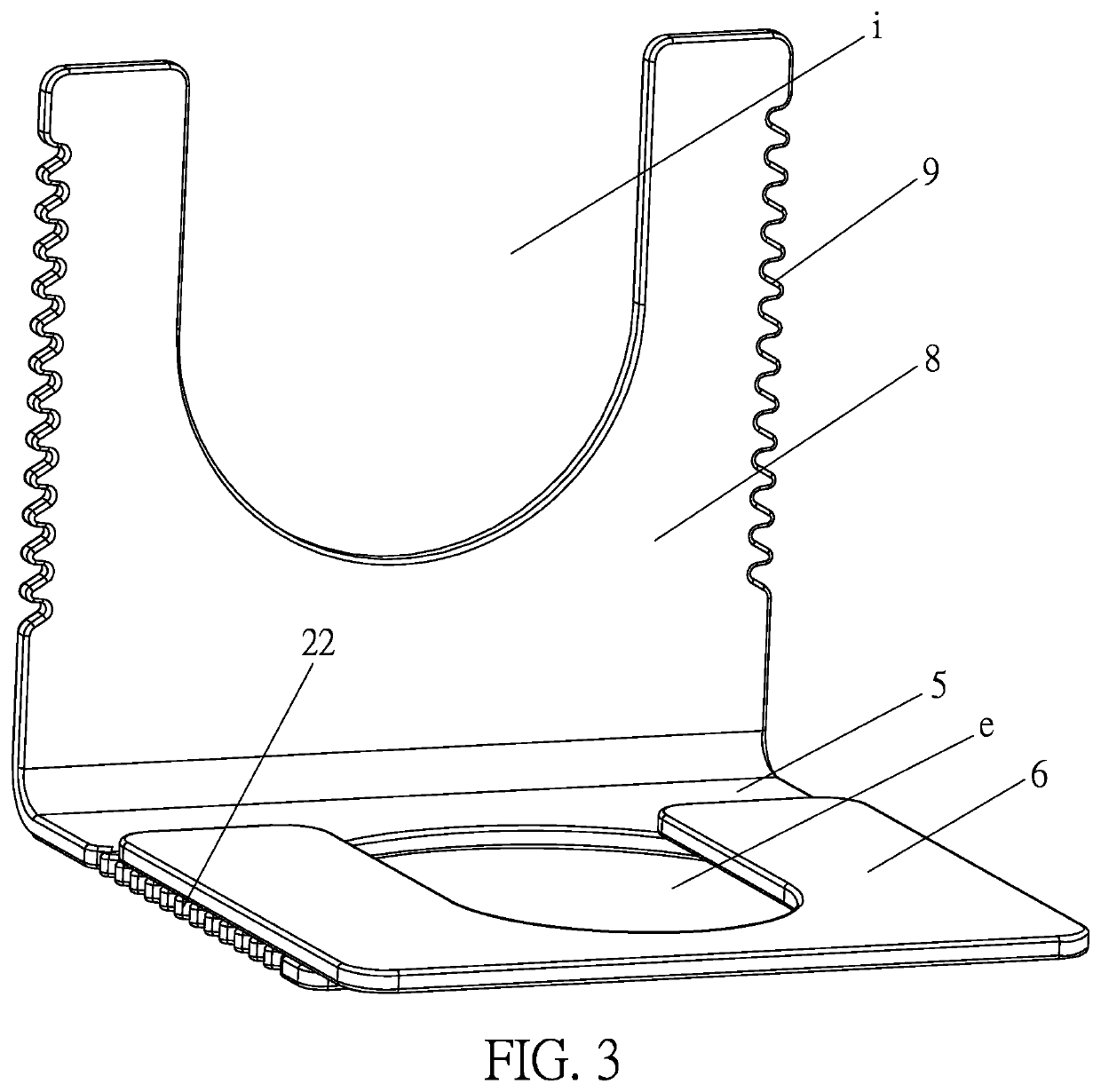

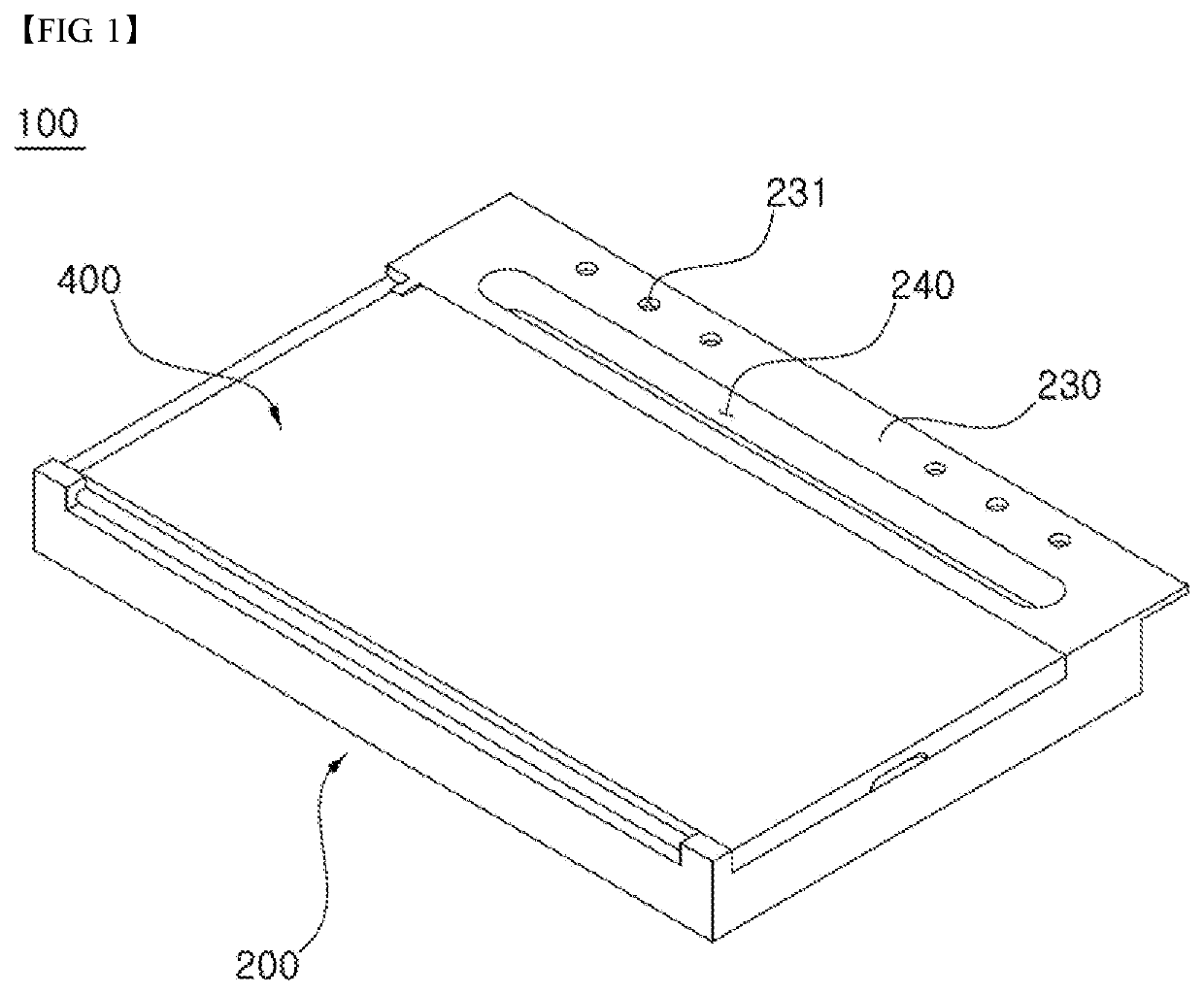

Binder adapted palette

ActiveUS20220266623A1Increase portability and user convenienceFacilitate replacementFiling appliancesBooksEngineeringStructural engineering

Disclosed is a binder adapted palette that is easily attached or detached to or from a diary or notebook binder and thus is easily stored and carried together with the binder. The binder adapted palette includes a body having a palette accommodation groove defined in a top surface thereof and a plurality of through-holes defined and arranged along one edge thereof, wherein the plurality of through-holes receive a binder ring of the binder; a palette detachably inserted into the palette accommodation groove; and a cover coupled to a top of the body to open and close the palette.

Owner:PLUSPRESS CO LTD

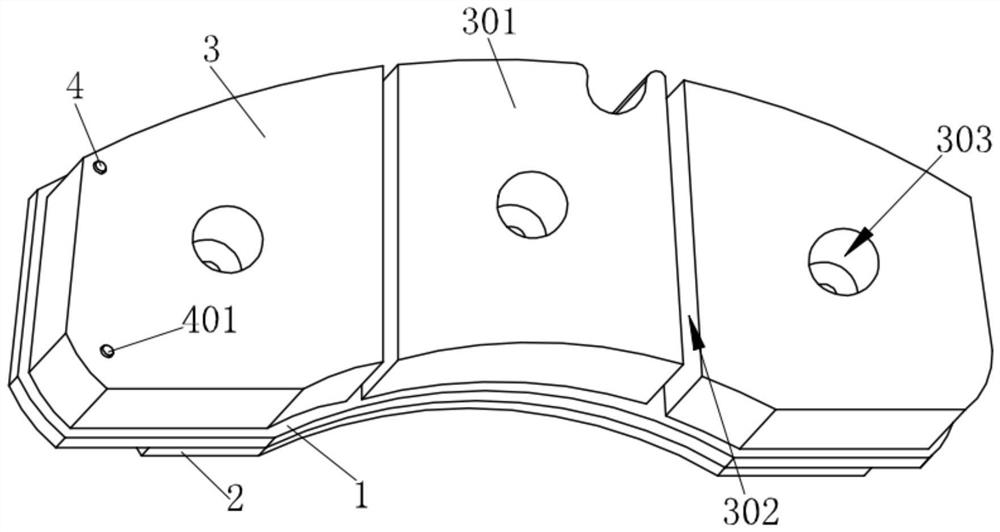

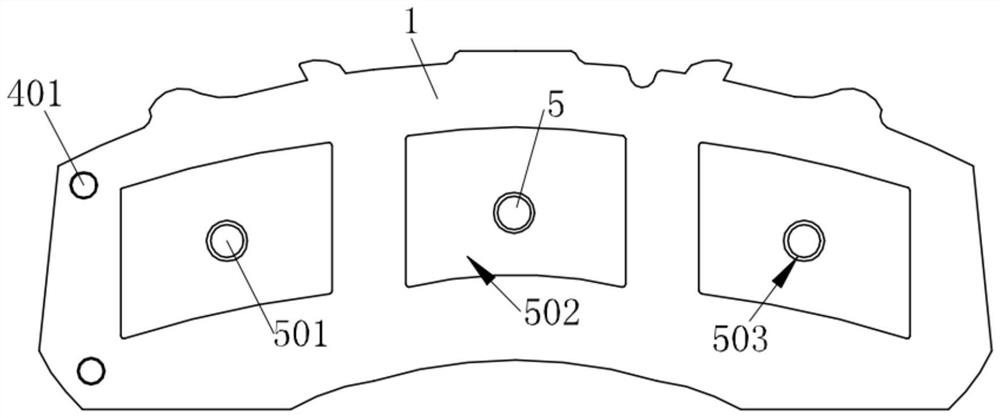

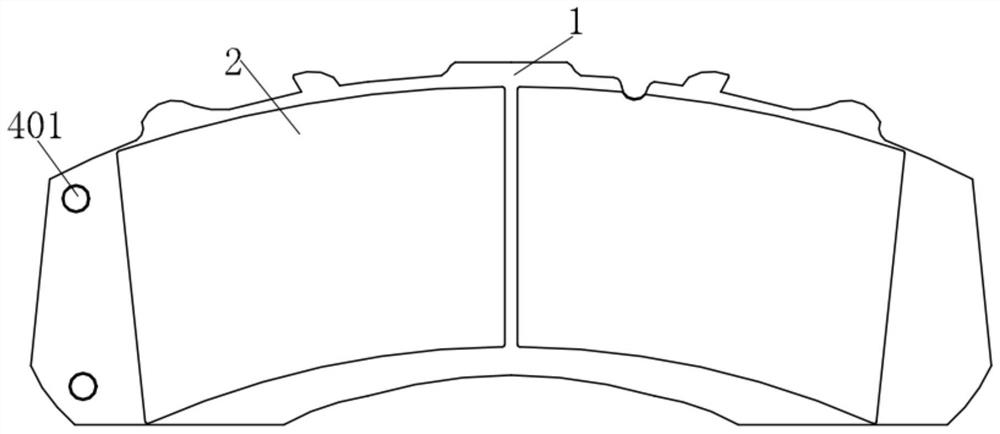

Long-service-life and wear-resistant wheel disc type brake device of truck, formula and manufacturing process of wheel disc type brake device

PendingCN114508555ASave resourcesFacilitate replacementNoise/vibration controlBraking discsTruckCircular disc

The invention relates to the technical field of truck braking, in particular to a truck wheel disc type braking device long in service life and resistant to abrasion and a manufacturing process thereof.The truck wheel disc type braking device comprises a back plate and is characterized in that a silencing plate used for silencing in the braking process is installed on one side of the back plate, and a plurality of braking mechanisms are arranged on the back plate; the brake mechanisms are fixedly connected with the back plate through fixing mechanisms, cooling mechanisms are arranged on the back plate, the silencing plate and the brake mechanisms, a control mechanism is installed on one brake mechanism, and the cooling mechanisms are connected with the control mechanism. Wherein one braking mechanism is provided with the buffering mechanism, when a driver steps on the brake pedal, the braking mechanisms abut against the discs at the positions of the wheels, braking is achieved, the control mechanism abuts against the discs while braking is conducted, water leakage of the control mechanism is controlled, heat dissipation of the braking mechanisms is achieved, and loss of a brake assembly is reduced.

Owner:山东倍瑞恳新材料有限公司

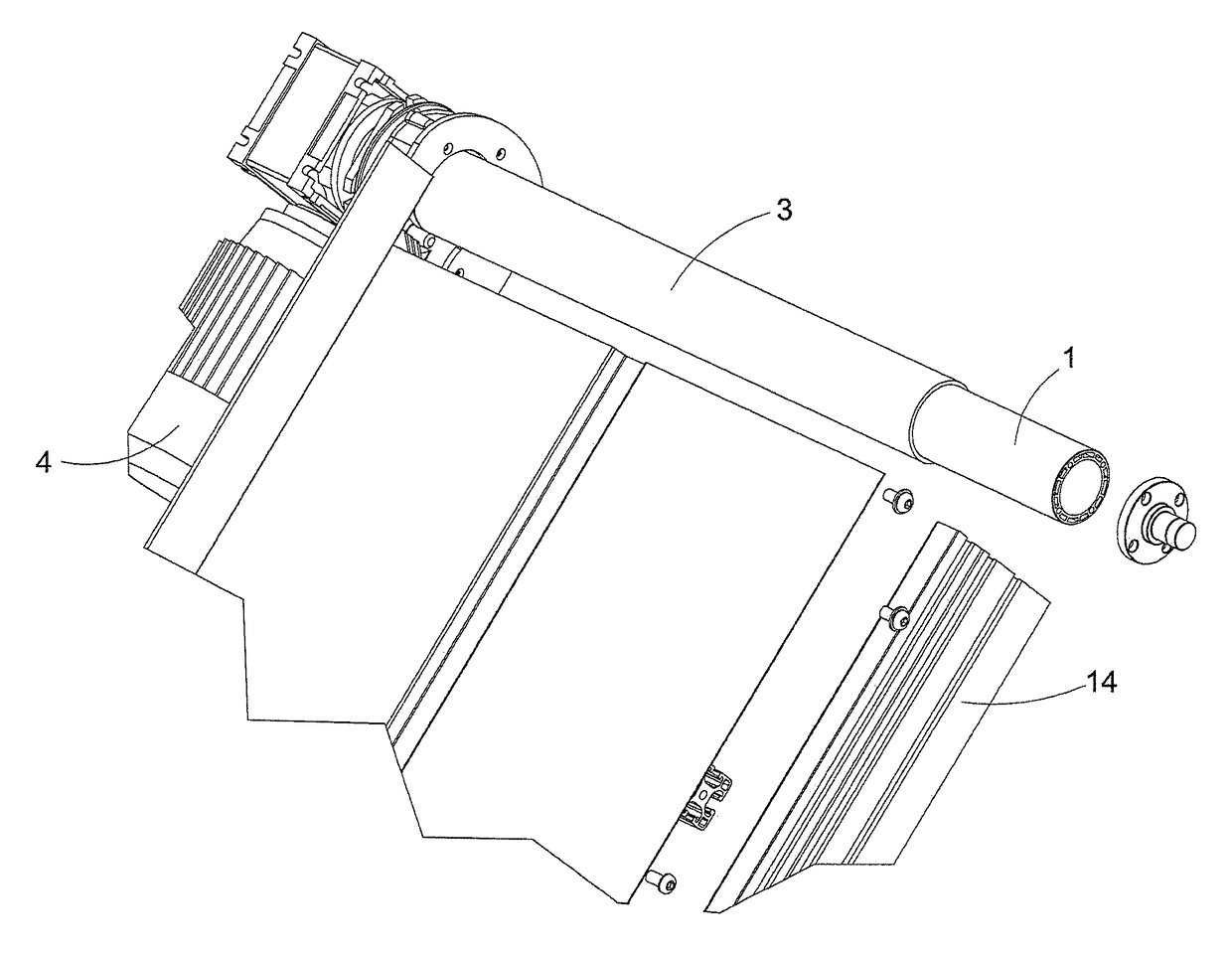

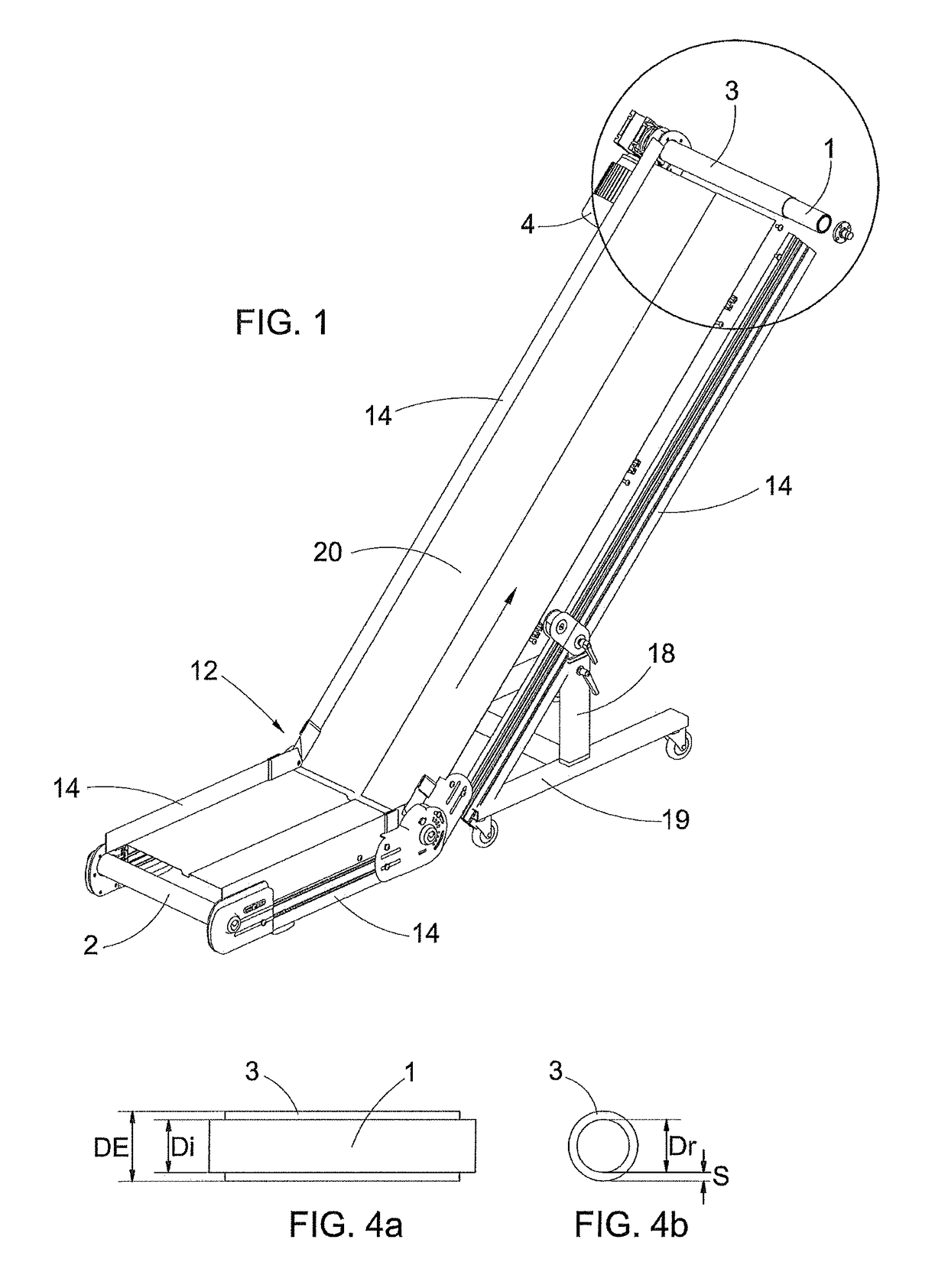

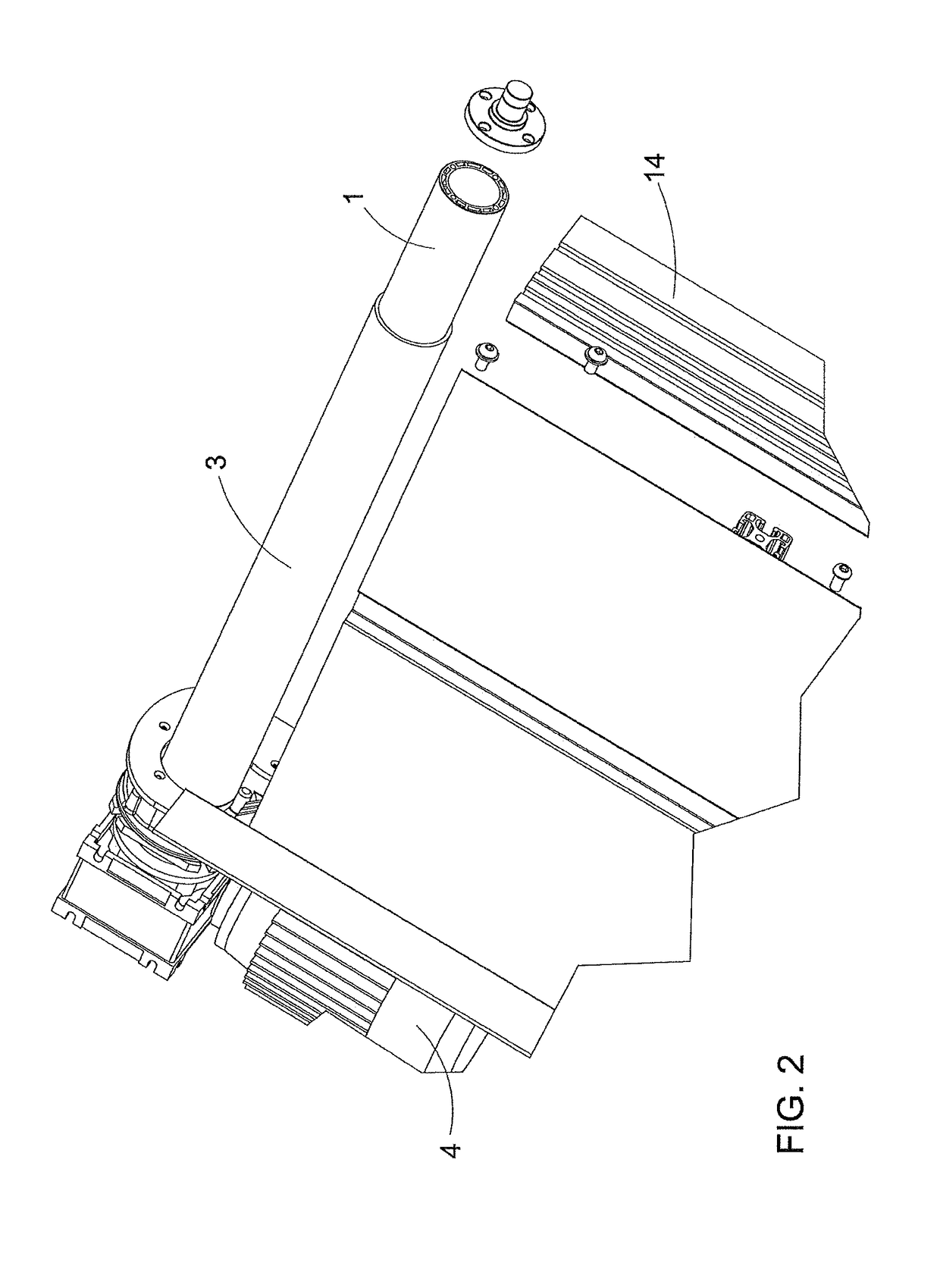

Motorised roller for belt conveyor having high friction in respect of the belt

ActiveUS9975704B2Production cost be saveFacilitate replacementConveyorsPackagingEngineeringAntiwear additive

A motorized or drive roller (1) of a belt conveyor (100) provides, mounted forcedly thereon, an antiwear tube (3) made of PVC additioned with antiwear additives, so that the belt (2) of the belt conveyor (100) rotates around, and in contact with, the antiwear tube (3).

Owner:COSTR MECCANICHE CRIZAF

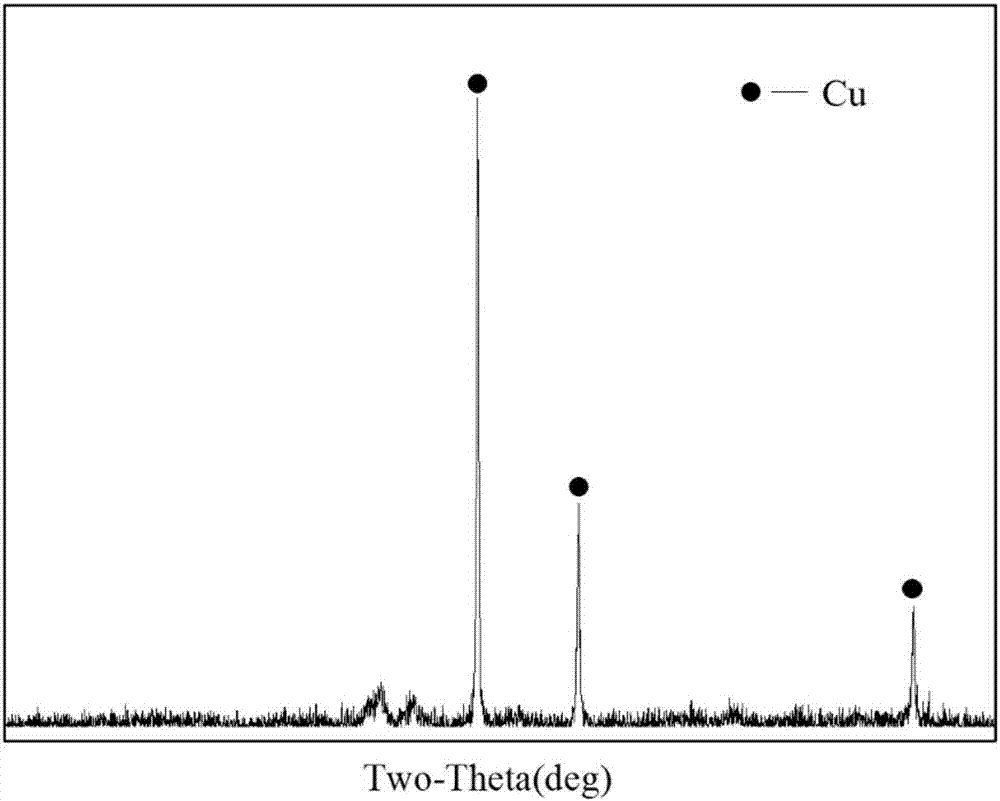

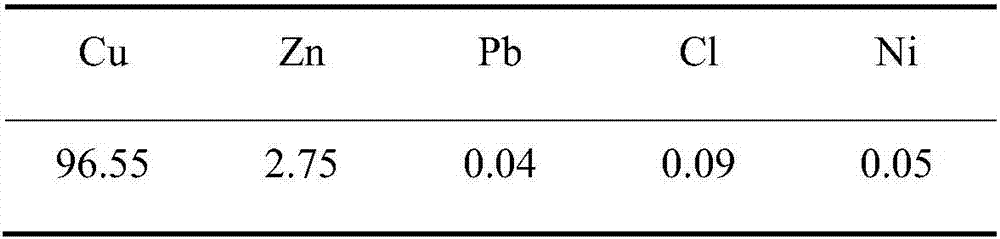

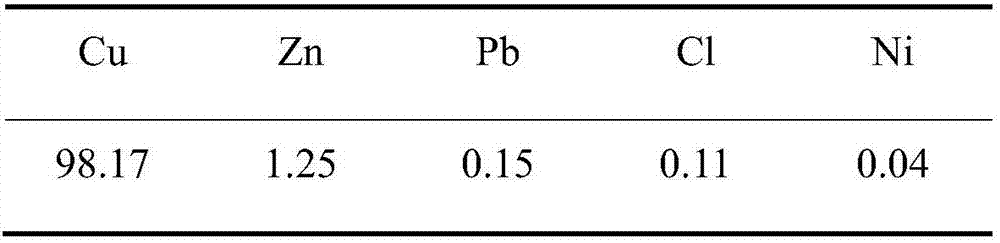

Method for precipitating sponge copper powder through zinc-ammonia-ammonium salt solution system displacement

InactiveCN106917112AFacilitate the replacement processFacilitate replacementRotary drum furnacesCrucible furnacesIonAmmonia ammonium

The invention discloses a method for precipitating sponge copper powder through zinc-ammonia-ammonium salt solution system displacement. The method comprises the following steps: immersing a zinc anode and a cathode in a copper ion-containing zinc-ammonia-ammonium salt solution, powering the anode and the cathode by a direct current to carry out a displacement reaction, and carrying out solid-liquid separation to obtain the sponge copper powder. Compared with a method simply using the zinc powder to displace copper, the method disclosed in the invention has the advantages of promotion and acceleration of the displacement process by the direct current, great increase of the replacement efficiency, great reduction of the use amount of zinc, and reduction of the cost. Compared with copper resides obtained through traditional zinc powder displacement, the sponge copper powder obtained in the invention has the advantages of no zinc wrapping, high purity and few impurities. A solution obtained after the displacement can be used in the electrodeposition of a metal zinc plate after being deeply purified. The method is simple, and the obtained sponge copper powder has high purity, and can be used for producing brass; and the method can be combined with a zinc metallurgical process to facilitate the industrial production.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com