Robot with intelligent inspection and early warning functions

An inspection robot and intelligent inspection technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as hidden dangers of equipment safety, harsh environment, and limited space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

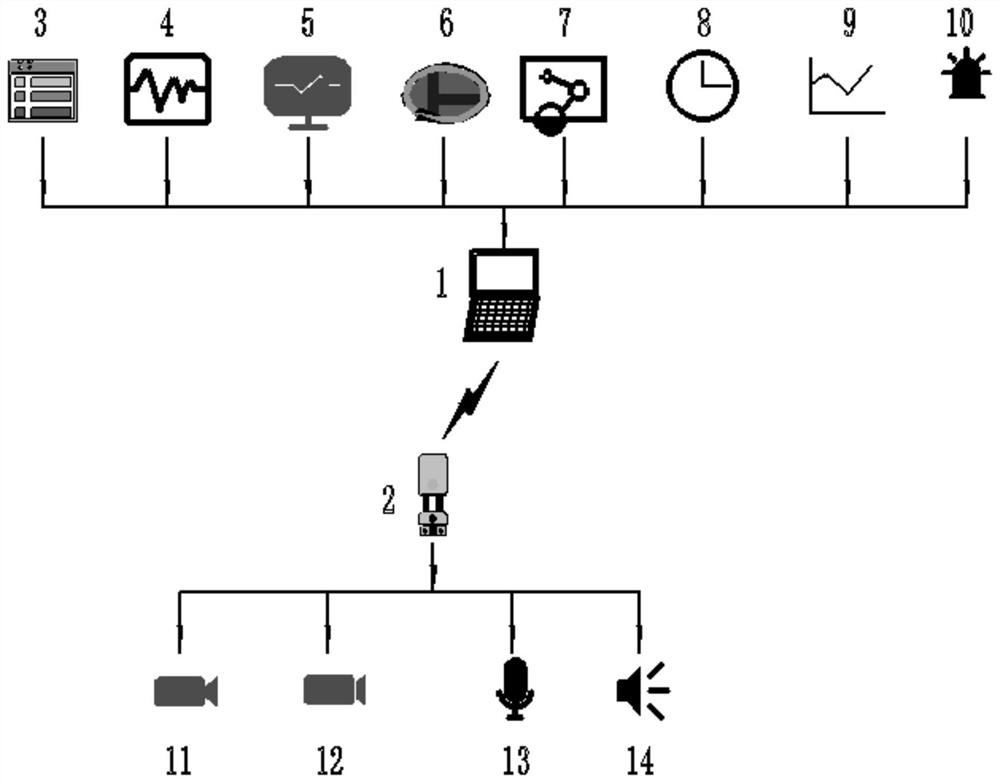

[0017] Embodiment 1: see figure 1 , a robot with an intelligent inspection and early warning function, the robot includes a monitoring background 1 and a robot body 2; The equipment temperature rise detection data of the thermal imager 12; at the same time, the monitoring background 1 checks the robot manual remote control panel 3 of the robot body 2 and the robot's own status panel 4, and the robot body is equipped with a directional MIC13 in real time. In the monitoring background 1, the robot real-time Position 6, the monitoring background 1 generates graphic image analysis and recognition based on the equipment operation screen fed back by the robot body 2 and the data detected by the infrared thermal imager 12 on the temperature rise of the equipment 7, historical data query statistics 8 logs, and the monitoring background 1 performs data The report summarizes the analysis records of 9, and the monitoring background 1 feeds back the real-time alarm 10 status according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com