B column decorative plate with face recognition function and vehicle

A face recognition and decorative panel technology, applied in vehicle parts, transportation and packaging, etc., can solve the problem that weather resistance and scratch resistance do not meet the daily needs of users, infrared transmittance cannot meet performance requirements, face recognition module The size and shape are cumbersome and other problems, so as to weaken the engineering layout defects and gap level difference problems, realize free replacement and disassembly and maintenance, and avoid the effect of profile mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

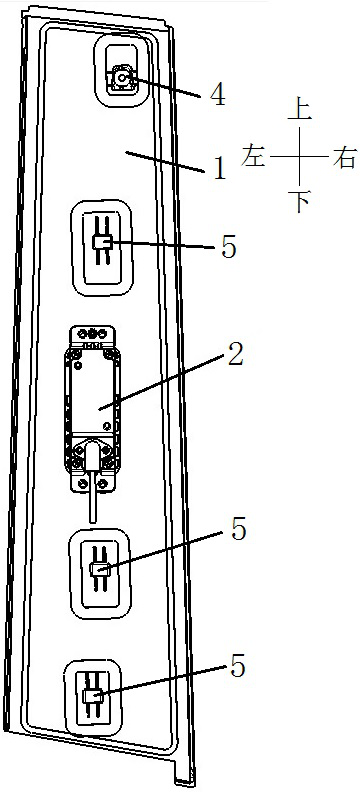

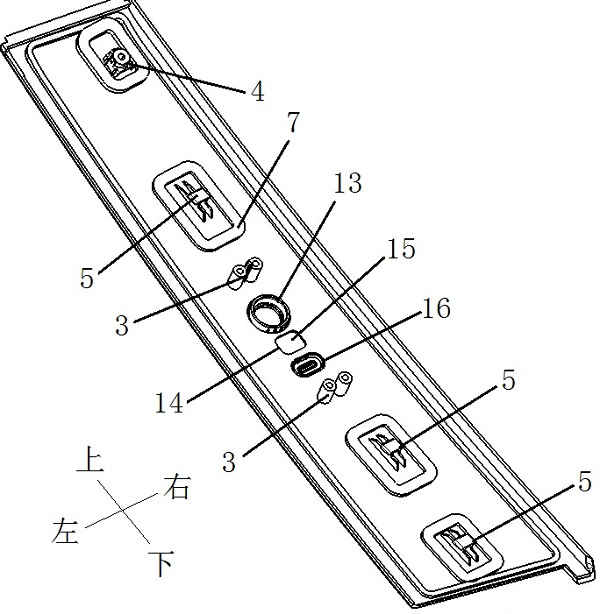

[0027] As a preferred embodiment of the present invention, the material of the inner panel 11 is ABS, which is a terpolymer of three monomers of acrylonitrile, butadiene and styrene, and has high strength, high hardness and low shrinkage. The characteristics ensure that the decorative panel body has sufficient structural strength. The outer plate 12 is made of PMMA, PMMA refers to polymethyl methacrylate, which is high-gloss black and has high infrared transmittance, high weather resistance and scratch resistance. The effective fusion of ABS and PMMA is realized by adopting a two-color injection molding process, that is, the decorative panel body 1 is a two-color injection molded part.

[0028] As a preferred embodiment of the present invention, the decorative panel body 1 is provided with two first screw columns 3 at the upper and lower ends of the assembly position of the face recognition module 2, and the first screw columns 3 are integrated with the inner panel 11. For in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com