Bridge pile hole sediment treatment device

A technology for processing devices and pile holes, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as energy consumption, negative impact on the inner wall of pile holes, and potential safety hazards, so as to reduce labor intensity and impact. Frequency, the effect of reducing the number of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

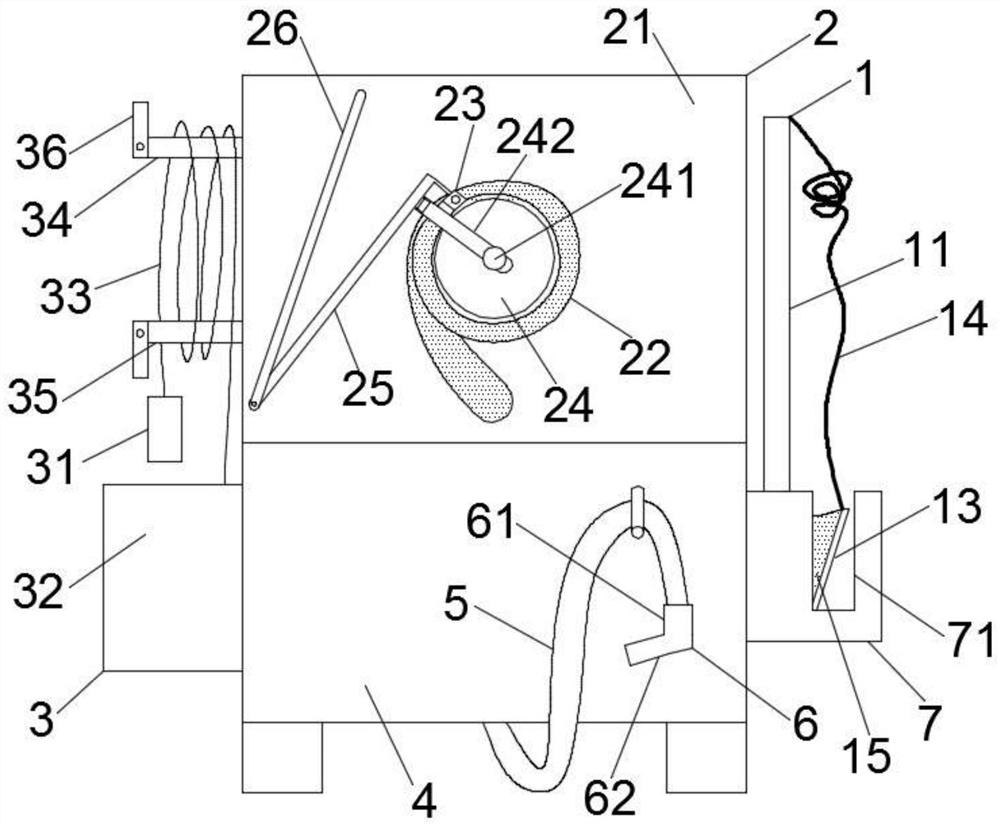

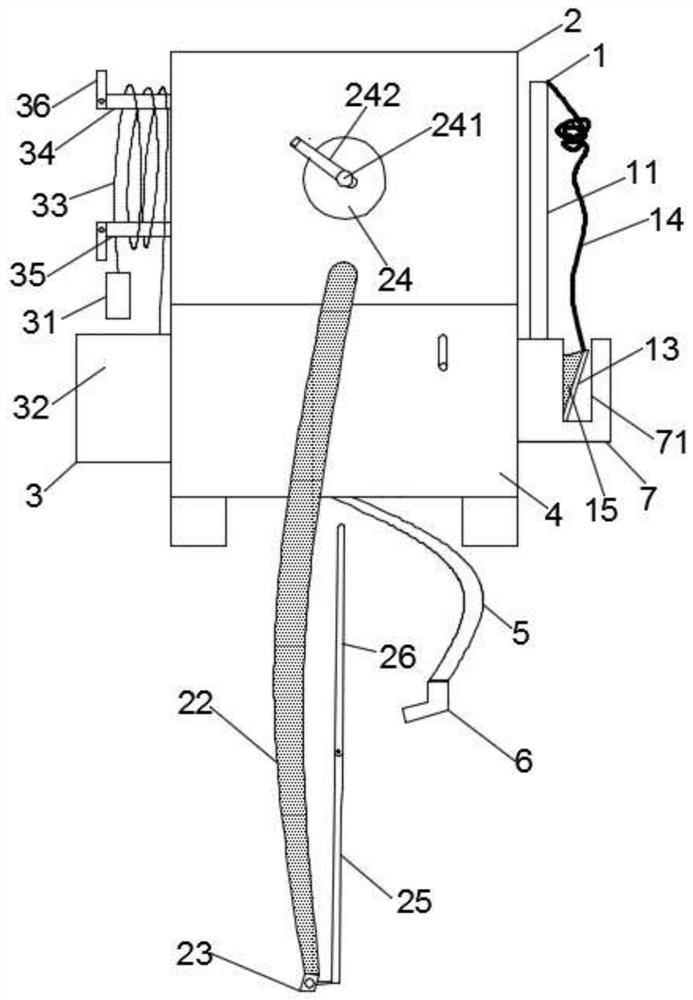

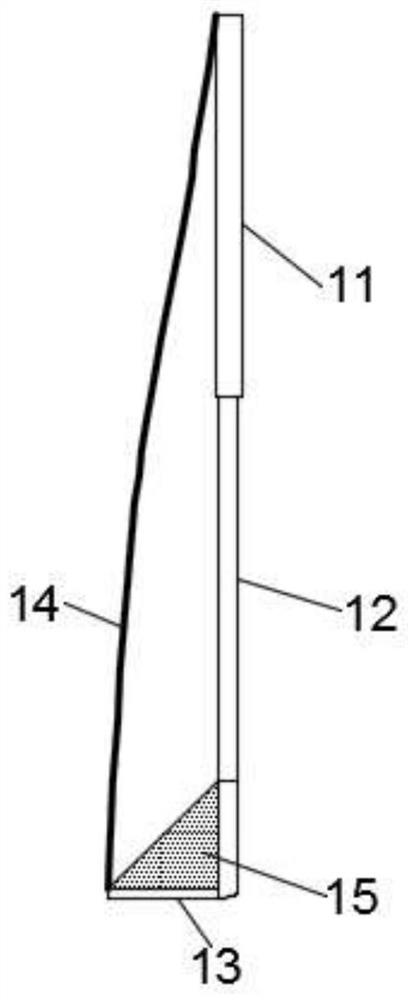

[0028] see Figure 1 to Figure 2 , the present invention provides a technical solution: a bridge pile hole sediment treatment device, including a cleaning treatment box with straps installed, the cleaning treatment box includes a primary cleaning mechanism 1, a secondary cleaning mechanism 2, a suction mechanism and a geological inspection mechanism 3; The primary cleaning mechanism 1 includes an upper connecting rod 11, a lower connecting rod 12, and a hard base plate 13, the upper connecting rod 11 is slidably connected with the lower connecting rod 12, and the hard base plate 13 is rotationally connected with the lower connecting rod 12; the secondary cleaning mechanism 2 includes a blower 21 , the air supply pipe 22 that can stretch into the stake hole, the injection pipe 23 and the support seat 24 that is used to coil the air supply pipe 22, one end of the air supply pipe 22 is fixedly connected with the blower 21, and the other end of the air supply pipe 22 is fixed with ...

Embodiment 2

[0033] see Figure 1 to Figure 5, the present invention provides a technical solution: a bridge pile hole sediment treatment device, including a cleaning treatment box with straps installed, the cleaning treatment box includes a primary cleaning mechanism 1, a secondary cleaning mechanism 2, a suction mechanism and a geological inspection mechanism 3; The primary cleaning mechanism 1 includes an upper connecting rod 11, a lower connecting rod 12, and a hard base plate 13, the upper connecting rod 11 is slidably connected with the lower connecting rod 12, and the hard base plate 13 is rotationally connected with the lower connecting rod 12; the secondary cleaning mechanism 2 includes a blower 21 , the air supply pipe 22 that can stretch into the stake hole, the injection pipe 23 and the support seat 24 that is used to coil the air supply pipe 22, one end of the air supply pipe 22 is fixedly connected with the blower 21, and the other end of the air supply pipe 22 is fixed with t...

Embodiment 3

[0037] see figure 1 , figure 2 and Figure 6 , the present invention provides a technical solution: a bridge pile hole sediment treatment device, including a cleaning treatment box with straps installed, the cleaning treatment box includes a primary cleaning mechanism 1, a secondary cleaning mechanism 2, a suction mechanism and a geological inspection mechanism 3; The primary cleaning mechanism 1 includes an upper connecting rod 11, a lower connecting rod 12, and a hard base plate 13, the upper connecting rod 11 is slidably connected with the lower connecting rod 12, and the hard base plate 13 is rotationally connected with the lower connecting rod 12; the secondary cleaning mechanism 2 includes a blower 21 , the air supply pipe 22 that can stretch into the stake hole, the injection pipe 23 and the support seat 24 that is used to coil the air supply pipe 22, one end of the air supply pipe 22 is fixedly connected with the blower 21, and the other end of the air supply pipe 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com