Fiber bragg grating sensor applied to underground stress monitoring

A fiber grating and stress monitoring technology, which is applied in the measurement of force, force/torque/power measuring instrument, instrument, etc. by measuring the change of optical properties of the material when it is stressed, can solve damage, economic loss, long transmission line length, etc. problems, to avoid excessive bending, ensure normal use, and protect the transmission line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

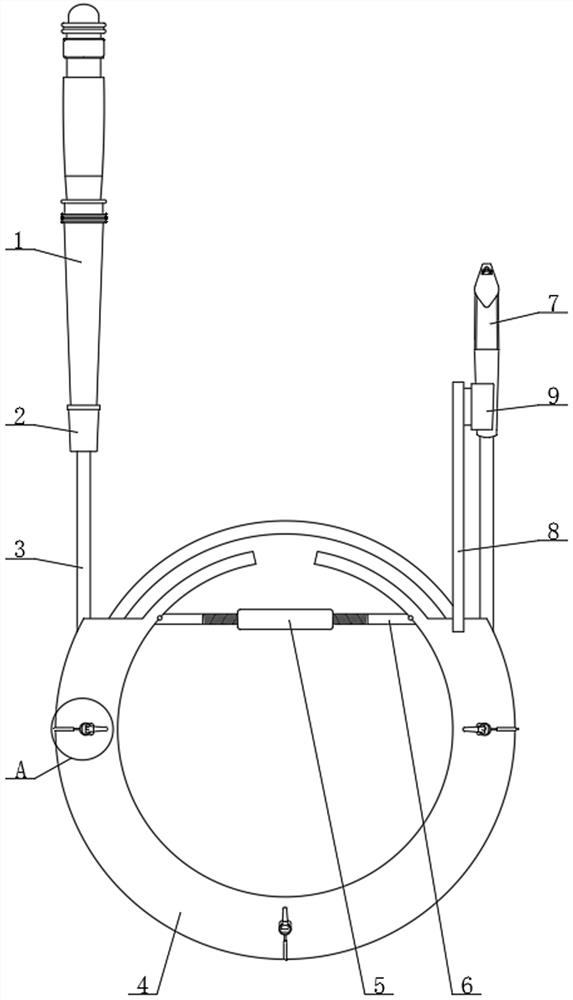

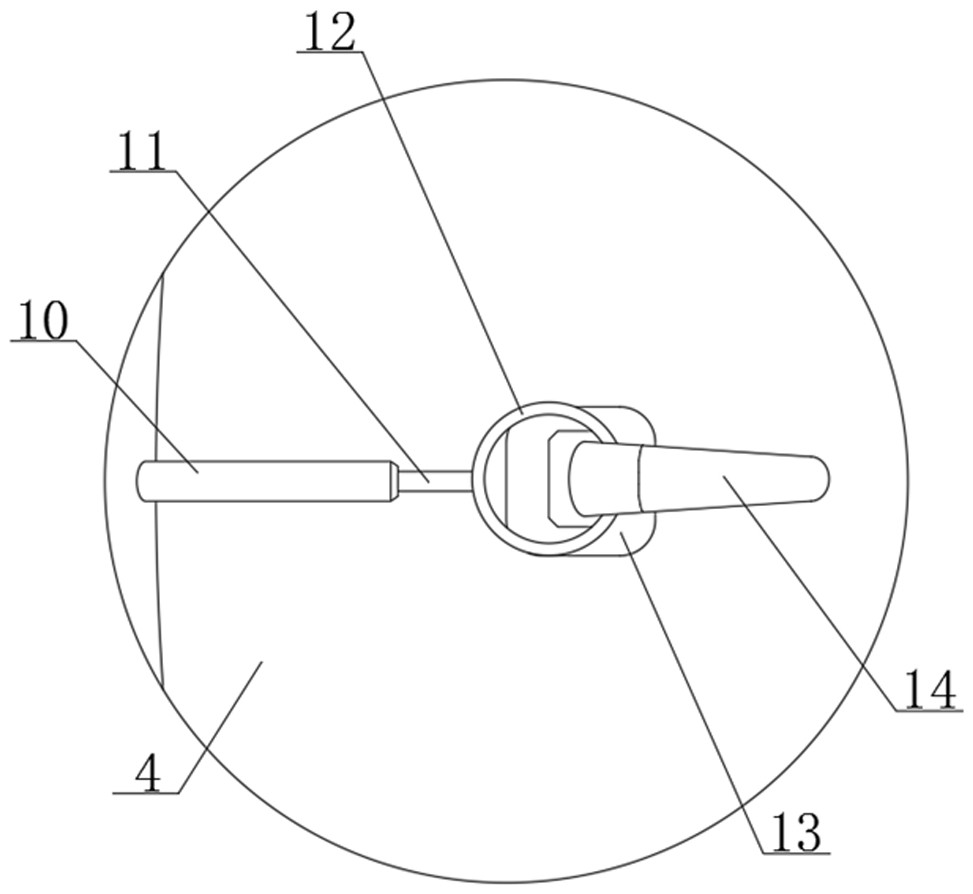

[0022] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution:

[0023] A fiber grating sensor applied to underground stress monitoring, including a sensor body 1 and a detection contact 7, the lower end of the sensor body 1 is fixedly connected with a connection assembly that facilitates the connection between the sensor body 1 and the transmission line 3, and the sensor body 1 is connected to the transmission line 3 through the connection assembly Fixed connection, the other end of the transmission line 3 is fixedly connected to the detection contact 7, the outer side of the transmission line 3 is provided with a protective component with a supporting structure, one end of the outer side of the protective component is fixedly connected to the limit rod 8, and the top of the limit rod 8 is fixedly connected to the limit snap ring 9 .

[0024] The limit snap ring 9 has elasticity, and the detection contact 7 is arranged inside the limit ...

Embodiment 2

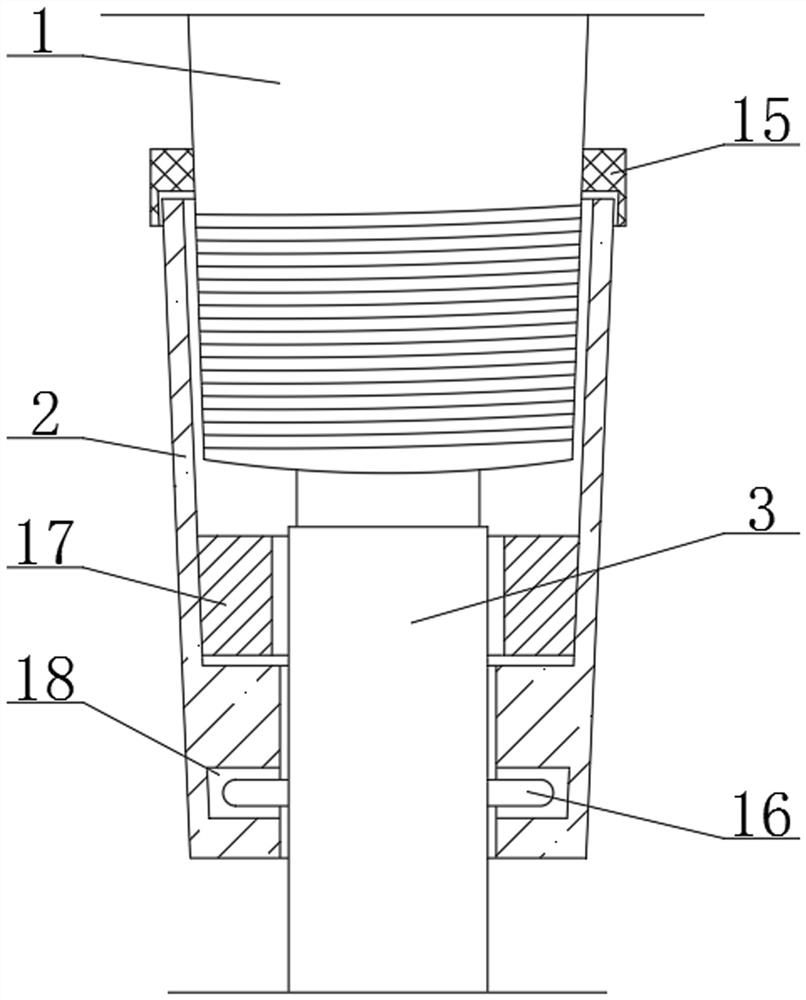

[0033] In embodiment 2, the same part as embodiment 1 will not be repeated, the difference is that when the fiber grating sensor is used, when the sensor body 1 is connected to the transmission line 3, it is inserted into the sensor body 1 through one end of the transmission line 3 , by rotating the protective cover 2, the protective cover 2 is screwed to the thread on the outside of the sensor body 1, and the protective cover ring 15 on the outer side of the sensor body 1 is covered on the outer side of the protective cover 2, and at the same time, the rotating snap ring 16 passes through the groove 18 and The protective cover 2 is rotatably connected, and the two sealing methods cooperate to ensure that the connection part has good sealing performance to avoid the external environment from affecting it. At the same time, when the outer side of the transmission line 3 is damaged in this setting, the spare transmission line 3 can be used. The transmission line 3 can be replaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com