Method and system for digesting heavy metal in solid wastes with high organic matter content

A technology for solid waste and heavy metals, applied in the field of heavy metal detection, can solve the problems of failure of digestion and easy occurrence of liquid splash, and achieve the effect of complete digestion, avoiding low detection data and avoiding liquid splash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

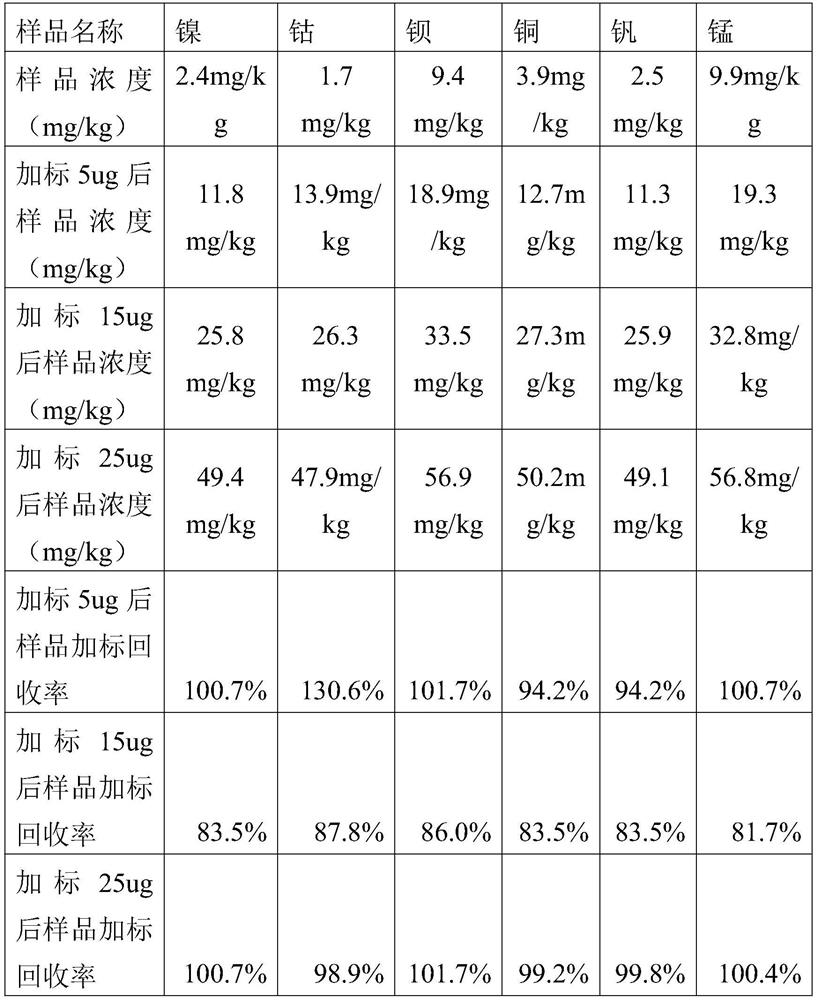

Embodiment 1

[0024] A method for digestion of heavy metals in solid waste with high organic content, comprising the following steps: weighing 0.5 g (accurate to 0.0001 g) of an appropriate amount of sample in a polytetrafluoroethylene digestion tank, adding hydrogen peroxide in small amounts several times, and polytetrafluoroethylene at 180 ° C. Heat the vinyl fluoride digestion tank with an open electric heating plate to remove some organic matter, until no large amount of bubbles are generated after adding hydrogen peroxide, and the adding process takes about 2 hours. Move the sample in the polytetrafluoroethylene digestion tank to the polytetrafluoroethylene microwave digestion instrument, rinse it with water for 3 times, add 10ml of nitric acid, the concentration of nitric acid is 1.42g / mL (the following examples are the same), 5ml of hydrochloric acid, the concentration of hydrochloric acid 1.19g / mL (the same in the following examples) and 10ml of hydrofluoric acid, the concentration o...

Embodiment 2

[0026] A method for digestion of heavy metals in solid waste with high organic content, comprising the following steps: weighing 1 g (accurate to 0.0001 g) of an appropriate amount of sample in a polytetrafluoroethylene digestion tank, adding hydrogen peroxide in small amounts several times, The ethylene digestion tank is heated with an open electric heating plate to remove some organic matter, until no large amount of bubbles are generated after adding hydrogen peroxide, and the addition process takes about 0.5 hours. Move the samples in the polytetrafluoroethylene digestion tank to an oven for high-pressure sealed tanks, rinse with laboratory water for 3 times, add 5ml of nitric acid, 2ml of hydrochloric acid and 2ml of hydrofluoric acid, digest at 120°C for 30min, and then at 150°C Digest at high temperature for 20 minutes, and finally digest at 200 ° C for 20 min. After the high-pressure sealed tank is cooled by oven temperature, remove the polytetrafluoroethylene digestion...

Embodiment 3

[0028] A method for digestion of heavy metals in solid waste with high organic content, comprising the following steps: weighing 1.2 g (accurate to 0.0001 g) of an appropriate amount of sample in a polytetrafluoroethylene digestion tank, adding hydrogen peroxide in small amounts several times, and polytetrafluoroethylene at 160 ° C. Heat the vinyl fluoride digestion tank with an open electric heating plate to remove some organic matter, until there is no large amount of bubbles after adding hydrogen peroxide, and the addition process takes about 1 hour. Move the sample in the polytetrafluoroethylene digestion tank to a polytetrafluoroethylene microwave digestion apparatus, wash it with laboratory water for 3 times, add 7ml of nitric acid, 3ml of hydrochloric acid and 5ml of hydrofluoric acid, digest at 120°C for 30min, and then Digest at 150°C for 20min, and finally at 200°C for 20mim. After the temperature of the PTFE microwave digestion instrument cools down, remove the PTFE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com