A Diode Pumped Gas Laser System Based on Electromagnetic Driving Mode

An electromagnetic drive and gas laser technology, applied in the laser field, can solve the problems of low thermal conductivity, single-channel output power of all solid-state lasers, finite mode volume, etc., and achieve high electro-optical efficiency, good heat dissipation effect, and low working fluid consumption small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

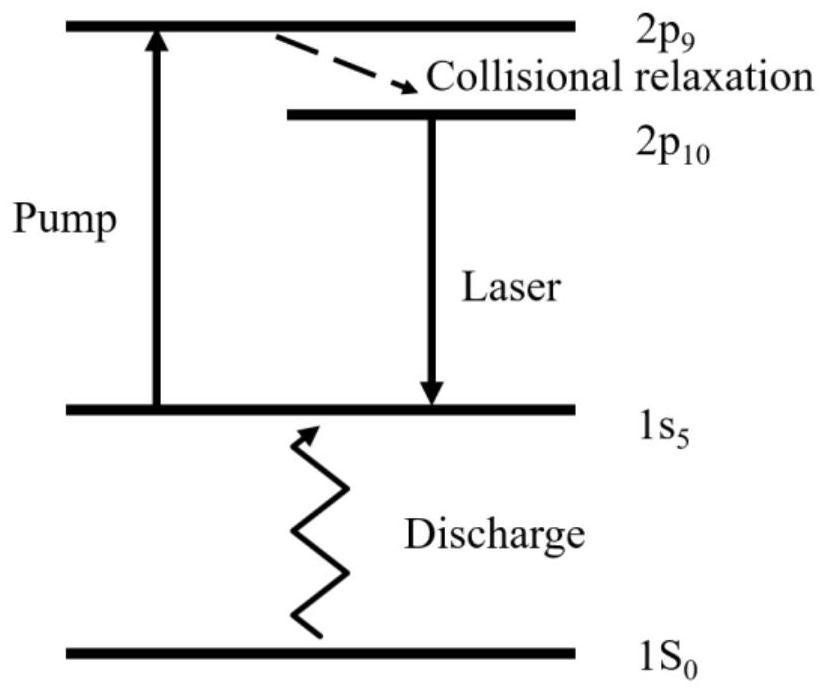

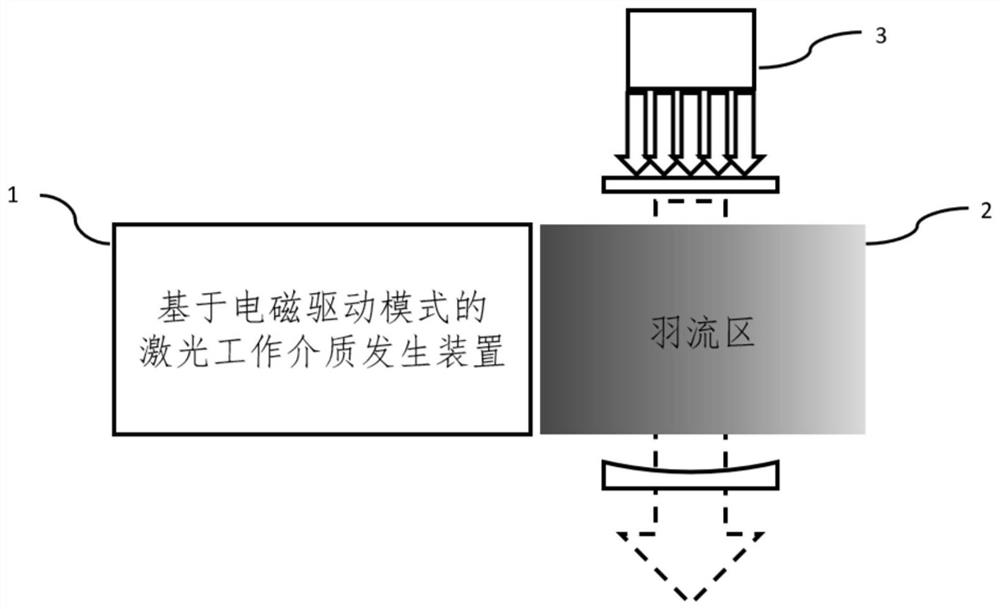

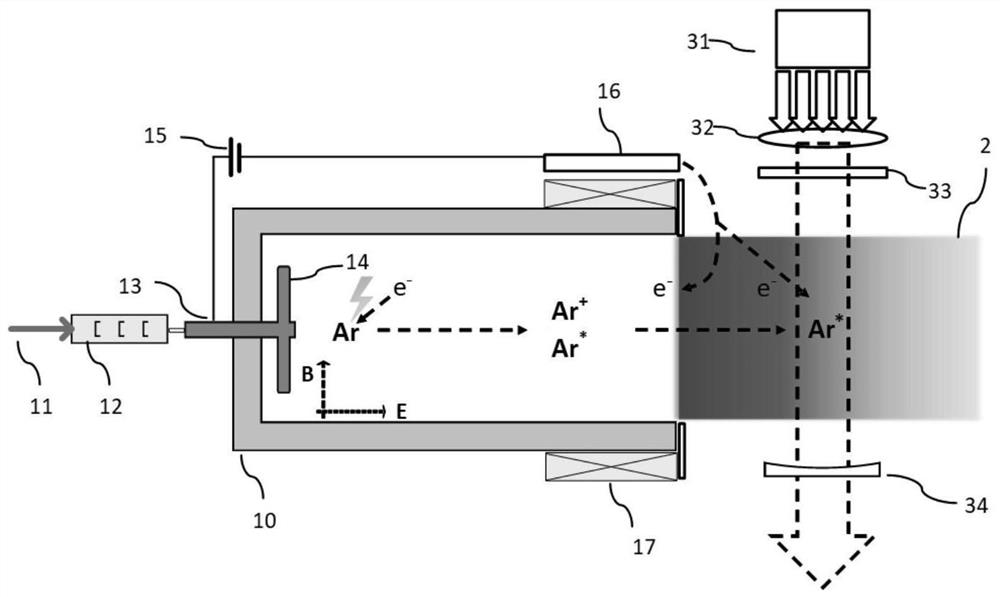

[0031] Embodiment 1: When the laser working medium generating device 1 based on the electromagnetic drive mode is a metastable inert gas atom generating device based on the Hall thruster working mode, the structure of the laser system is as follows image 3 shown. image 3 Among them, the laser working medium generating device 1 is a metastable inert gas atomic generating device based on the Hall thruster working mode, including a gas supply pipeline 11, and the gas flowing in the pipeline is a high-purity argon and helium mixed gas source, Among them, argon is the laser working medium, accounting for 5% by mole, and helium is the buffer gas, accounting for 95% by mole, which is used to promote 2p 9 →2p 10 No radiative transition and atomic absorption line broadening, in order to prevent the impurity gas for 1s 5 Collision quenching of metastable argon atoms, the impurity content of the gas source is controlled within 1ppm, the pneumatic control element 12 includes a mass fl...

Embodiment 2

[0033] Embodiment 2: When the laser working medium generating device 1 based on the electromagnetic drive mode is a nano-gas generating device based on the pulsed plasma propulsion mode, the structure of the laser system is as follows Figure 5 Shown:

[0034] Figure 5 Among them, the laser working medium generating device 1 is a pulsed plasma thruster, including an energy storage capacitor 11, which stores external electric energy and serves as a system discharge source; parallel plate electrodes 12 and 13 are used as an anode and a cathode, respectively; a ground terminal 14, Connected to the cathode 13, the rare earth element target 15, taking ytterbium as an example, has a purity ≥ 99.9%, and is used as a working fluid material for ionization; the spring 16 is used to maintain the front end of the target at a constant level after the target is bombarded by electrons and the mass is reduced. Position, for the system to continuously provide rare earth ion implantation, gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com