Corn deep-processing leisure food and making method thereof

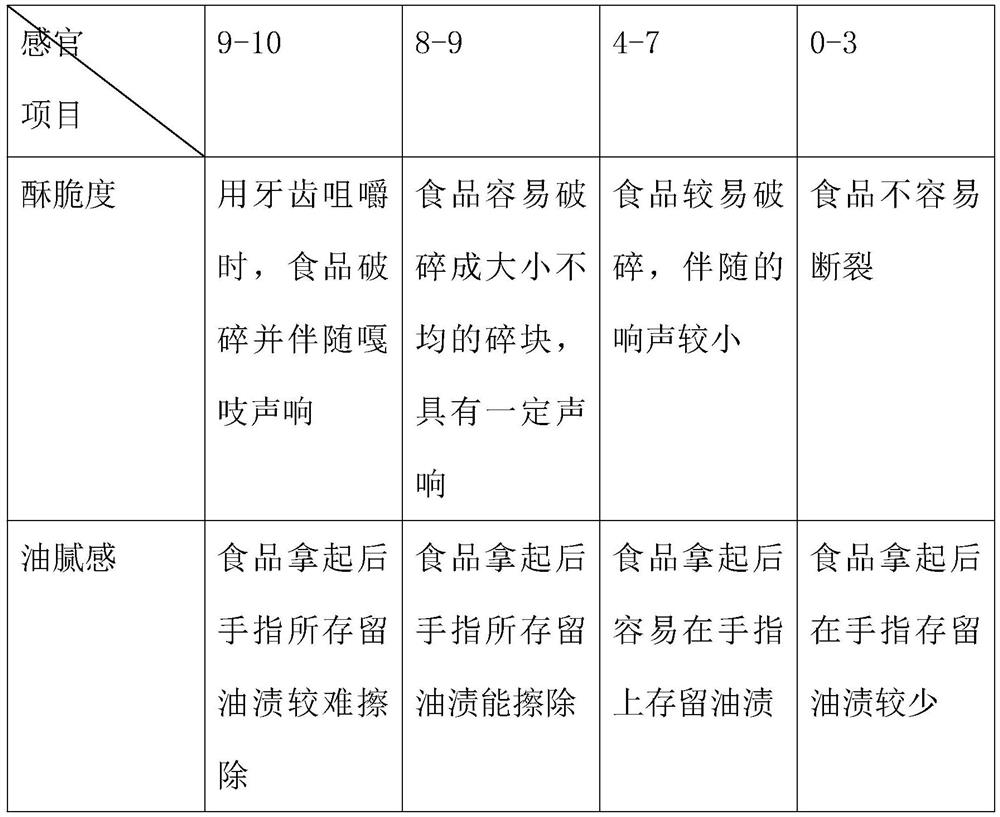

A snack food and deep processing technology, which is applied in baked food, food science, baking, etc., can solve the problems of corn flakes not being crisp enough and affecting the taste, and achieve the effect of improving the degree of crispness and ensuring the oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

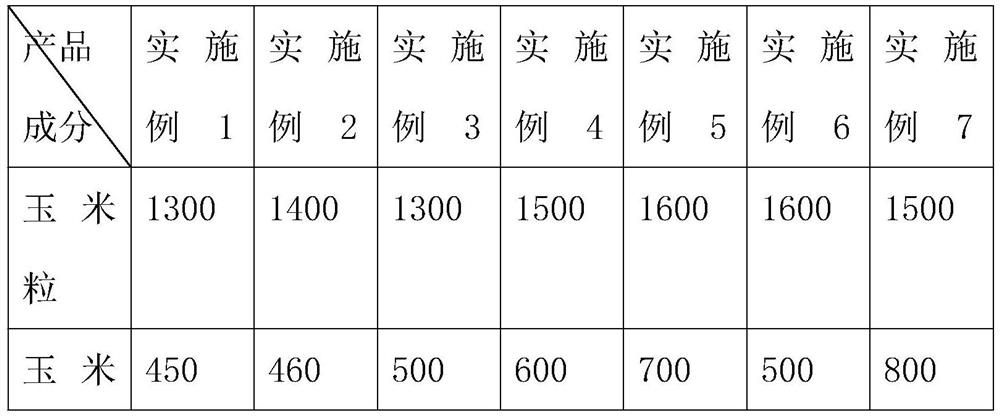

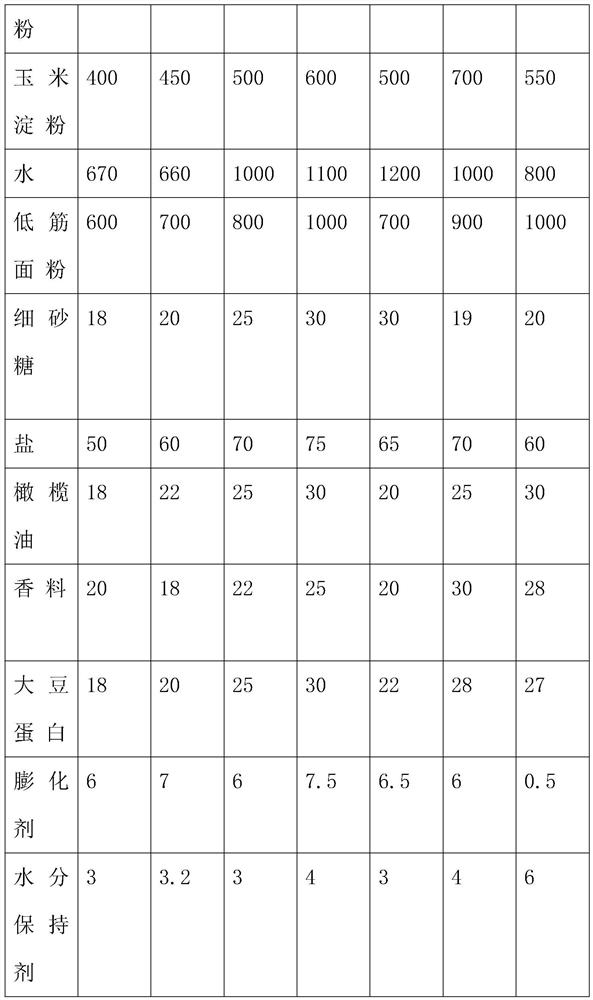

[0023] Each raw material was weighed according to the data of Example 1 corresponding to Table 1.

[0024] Specifically, the bulking agent is composed of potassium lactate.

[0025] Specifically, the moisture retaining agent is composed of glycerin.

[0026] According to the technical scheme of the above corn deep-processing snack food, a method for making the corn deep-processing snack food will also be provided, including the following steps:

[0027] Screening raw materials: take the above-mentioned corn kernels in parts by weight. The corn kernels are made of corn with no pollution, no mildew, no insects, and full grains. Before the acid soaking process, the stones, iron wires and soil clods in the corn should be removed. and other impurities to prevent poor quality corn kernels and impurities contained in corn kernels from affecting the taste;

[0028] Acid and alkali neutralization: Soak the corn kernels with a sulfurous acid solution with a concentration of 0.2% to 0....

Embodiment 2

[0036] Each raw material is taken by weighing the data of Example 2 corresponding to Table 1.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

[0039] Each raw material is taken by weighing the data of Example 3 corresponding to Table 1.

[0040] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com